-

Posts

2,596 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

Our local library prints for free but limits the file size to 8Mb as it takes them 5 hours to print that size.

I submitted my file two weeks ago this Tuesday and am still waiting.

- rshousha, mtaylor and thibaultron

-

3

3

-

You are very welcome.

Happy I finally could help someone.

Use the windows snipping tool and capture the screen image so others can see.

Sometimes I just take a pic with my phone and use it after resizing with MS Paint.

- mtaylor, druxey and thibaultron

-

3

3

-

Mark, try increasing the deviation.

Druxey, adding a radius (softening the edges) of such a complex shape would be, IMHO, nightmarish for the 3D. It needs to calculate the whole mess and if you haven't a NASA computer the humble home computer will likely crash.

-

I sometimes find the program suggests you have joined one line to another... but it did not. It stopped short and left a gap or it went beyond and overlapped the line.

To get away from this I purposefully draw the line beyond so I can see it and then trim it back. Extra work but it keeps me from banging my head against the wall and throwing the monitor out the window! 😠

- mtaylor and thibaultron

-

2

2

-

Have you selected SHELL as opposed to SOLID?

- mtaylor and thibaultron

-

2

2

-

- paulsutcliffe, ronald305, mtaylor and 1 other

-

4

4

-

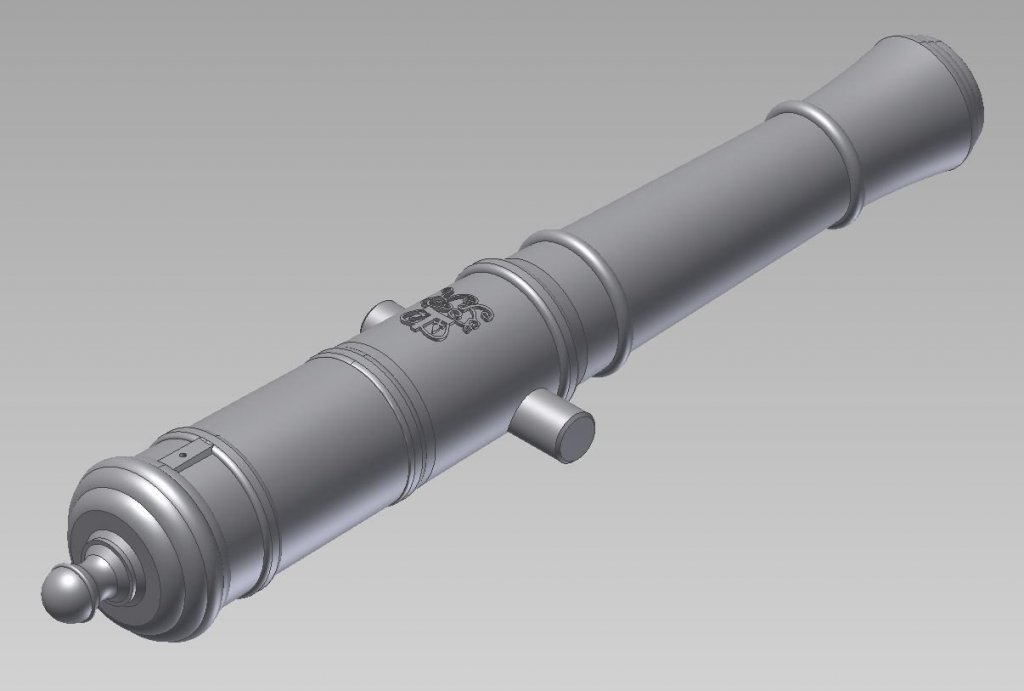

I attempted to draw a segment of a tube above the trunnion at both ends of the insignia at locations of known diameters.

I then attempted to loft and cut using the two sketches and a 3D line connecting the two as a rail.

My program (Inventor) does not seem to want to cut away with the loft command.

With my second attempt... If I cut away a Rotated (tube) segment drawn on the XZ plane above the trunnion that is successful.

As the trunnion is below the horizontal plane it is below the cutaway and is not touched.

- mtaylor, Captain Poison, tkay11 and 2 others

-

5

5

-

-

the other option might be to apply the insignia flat, protruding from the surface and then manually file or sand it round after printing.

I was told that 3D printing is an open honeycomb cell structure below the thin solid surface so you might have to use some type of filler afterwards.

- mtaylor, claybaker and thibaultron

-

3

3

-

- Jorge Diaz O, Bob Legge, mtaylor and 5 others

-

8

8

-

- thibaultron and mtaylor

-

2

2

-

-

-

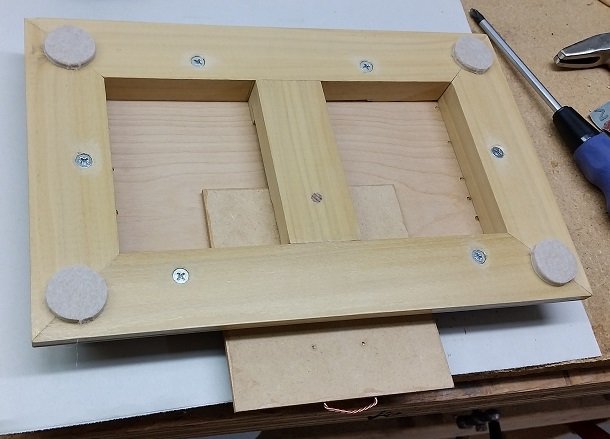

I have a Mastercraft table saw bought from Canadian Tire a few years ago.

It needed a zero clearance insert plate as the one supplied accommodated angle cuts and it also sat below the deck surface which caused me some grief.

I made my new plate out of oak... good and hard and flush with the table top, and it has made a world of difference.

I then made a Cross Cut Sled and added an adjustable stop block. To improve on this I mounted my old (never used again) vernier caliper instead of a measuring tape. The pin that locks the fixed end of the vernier is an old worn out drill bit. So a drilled the hole with a new one and I knew it would be a perfect fit. The moving side is locked to the stop block by a profile plate on one side and a rotating locking cam on the other. As an after thought I drilled another hole to keep the cam Allen Key in as I am sure I would spend 20 minutes or more looking for it otherwise.

This vernier reads to only two decimal places and has an accuracy of only +/- 0.01 inches. This is fine enough for quite a few of my cuts.

The saw can only be raised 1-1/2 inches for this sled so it will be used on small stuff.

I did not invent this sled... I found a version on YouTube and made some small improvement.

-

At 1:64 won't they all look very similar?

- paulsutcliffe, Siggi52, Jorge Diaz O and 1 other

-

4

4

-

-

-

Been there.

Done that. 😉

Actually, I've done considerably worse.

- paulsutcliffe and mtaylor

-

2

2

-

Why might the 9 pdr 7.5ft be longer than the 9 pdr 6.5ft image???

-

-

-

-

Found some stainless steel screws that were 3/8" (9.5mm) too long which worked out well after I cut the extra length off the pointy tip. This meant the amount that engaged (3/8") was all full form threads.

Drilled the pieces and countersunk for the screw head. Assembled it all and the drawer would not pull out. I had to sand the thickness of the varnish off the frame under the sliding tray.

Now everything works well. The new aluminium plates were installed, along with the felt foot pads... and a couple photos were taken.

Next week (Tuesday) I take the 3D printing seminar and then I'll get my cannon printed up.

You will hear from me after that.

PS: Yesterday was our 43rd wedding anniversary.... today I turned a year older.

- paulsutcliffe, mtaylor, Tigersteve and 2 others

-

5

5

-

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

in - Build logs for subjects built 1751 - 1800

Posted

Mark

If you are interested, I might possibly get you one of each size printed for you for free at our local library. This would be for your collection. It is a shame to do all that work for nothing.

PM me and we can discuss.

Alan