-

Posts

6,142 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

That is looking real good, Martin. On the homeward leg now. What's up after this one? Amati Victory?

- 122 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

HMS FLY by cafmodel - 1/48

James H replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

Do you just need to square the corners of the CNC-cut rebates? I assume they will leave a small round corner. Looking great so far. 🤩- 59 replies

-

HMS FLY by cafmodel - 1/48

James H replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

Lovely, clean CNC work there Tom. That will certainly save the modeller time when it comes to building.- 59 replies

-

Great story and intro! And you served on the Bering Sea, so kudos for that too! 💪 Lovely modelling too, and I can't wait to see your build logs!

-

HMS FLY by cafmodel - 1/48

James H replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

I can't wait to see this progress, Tom. How accurate to the real thing will frame construction be, and will it have a full interior?- 59 replies

-

CNC wood carving

James H replied to cafmodel's topic in Painting, finishing and weathering products and techniques

Beautiful work. Are all these shown in boxwood? -

It will be featured here soon,

-

I have no words for this apart from that I'm stunned. 😲

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Can't wait for the photos. Those internals you added sound interesting.

- 60 replies

-

- enterprize

- caf

-

(and 1 more)

Tagged with:

-

I'm absolutely stunned by this work. I really wish I could do this sort of thing. At least I can dream.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Hi all, Model Ship World would very much like to announce CAFModel as a site sponsor and supporter, and also of the NRG. This has taken some real work, but it's great to see CAFModel here amongst our other sponsors, and it will be wonderful to see their creations built as logs here at MSW. We have added the CAF banner to the website, complete with a link to their own site, and included it in this post also. I will also start to bring you a series of in-box reviews of CAF kits here too, starting very soon. Dont forget to check out the CAF website for kits of all kinds, along with fittings and carvings. Note from Admin: CAF now meets all criteria as a legitimate MFG of ship model kits. They have stopped producing all kits based on source material they did not have the rights to use, mainly from Ancre. There current kits available on their website including the Enterprise, are perfectly fine and original works not taken without consent from other authors, designers and mfg's. We are currently helping Tom at CAF to acquire the proper rights through an agreement with Ancre to make any Ancre kits legally allowable. Until such time all CAF Ancre inspired kits are not allowed on MSW. But we are hopeful they soon will be. CAF has stopped mfg them and selling these Ancre related kits voluntarily after admitting he copied the material from Ancre without consent. Negotiations are currently underway to rectify that situation.

-

We will certainly be doing that.

-

Recommended toolkit for beginner

James H replied to Niall's topic in Modeling tools and Workshop Equipment

That's the one I have. -

Recommended toolkit for beginner

James H replied to Niall's topic in Modeling tools and Workshop Equipment

Depends where you are. If UK, then try https://www.cornwallmodelboats.co.uk/acatalog/hammers_pin_pushers.html Outside of UK, not sure. Maybe Ages of Sail do them? -

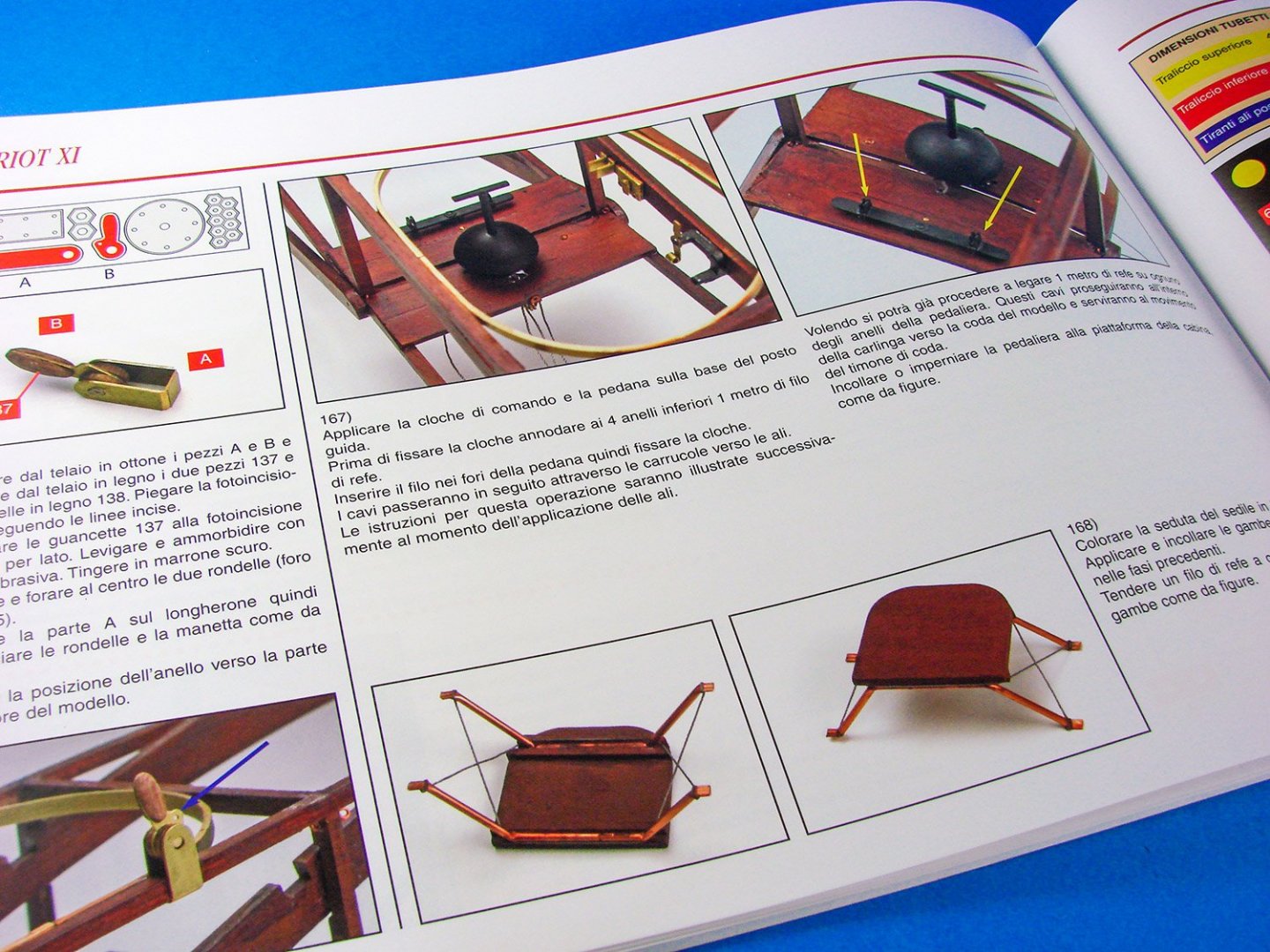

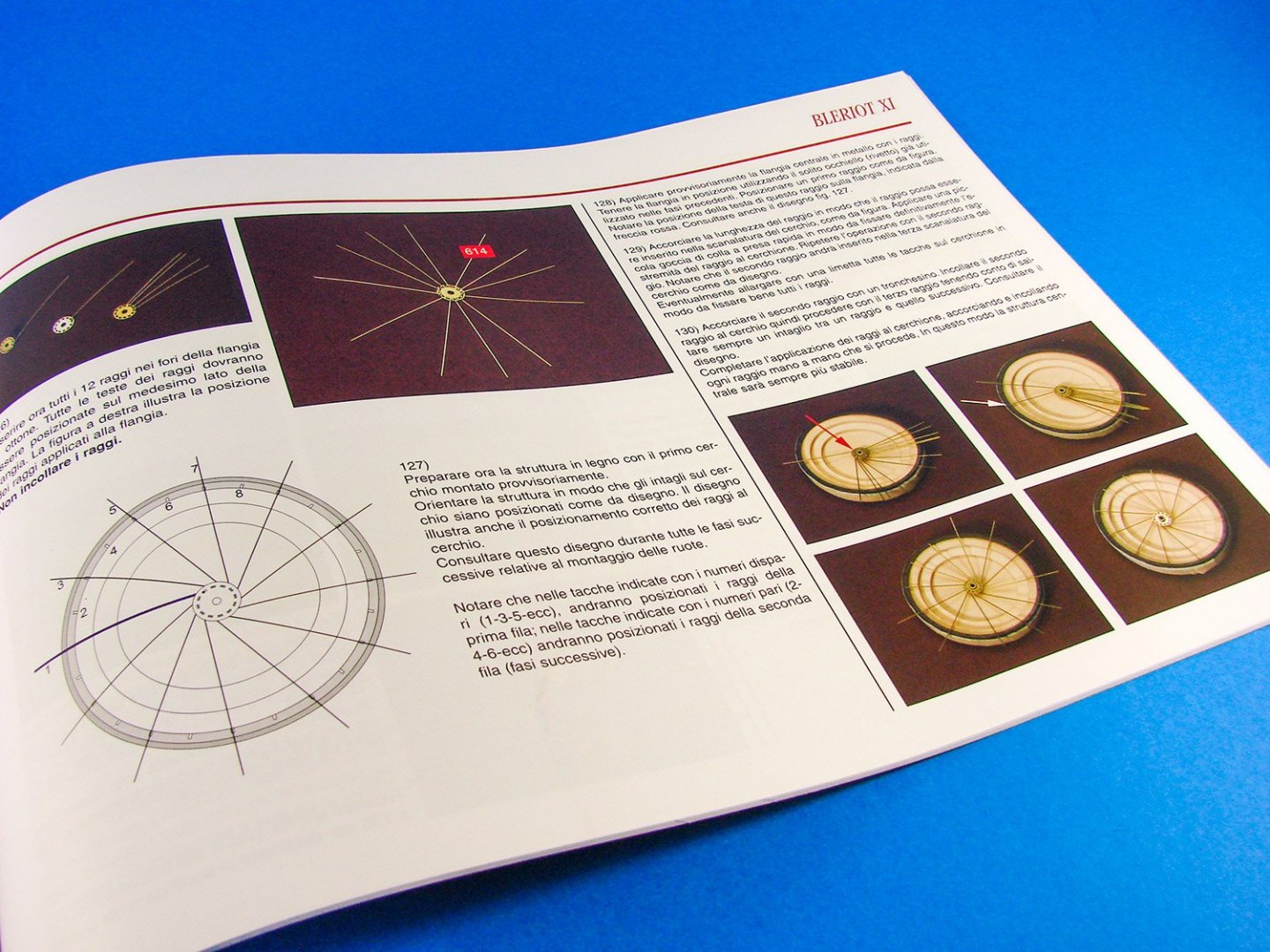

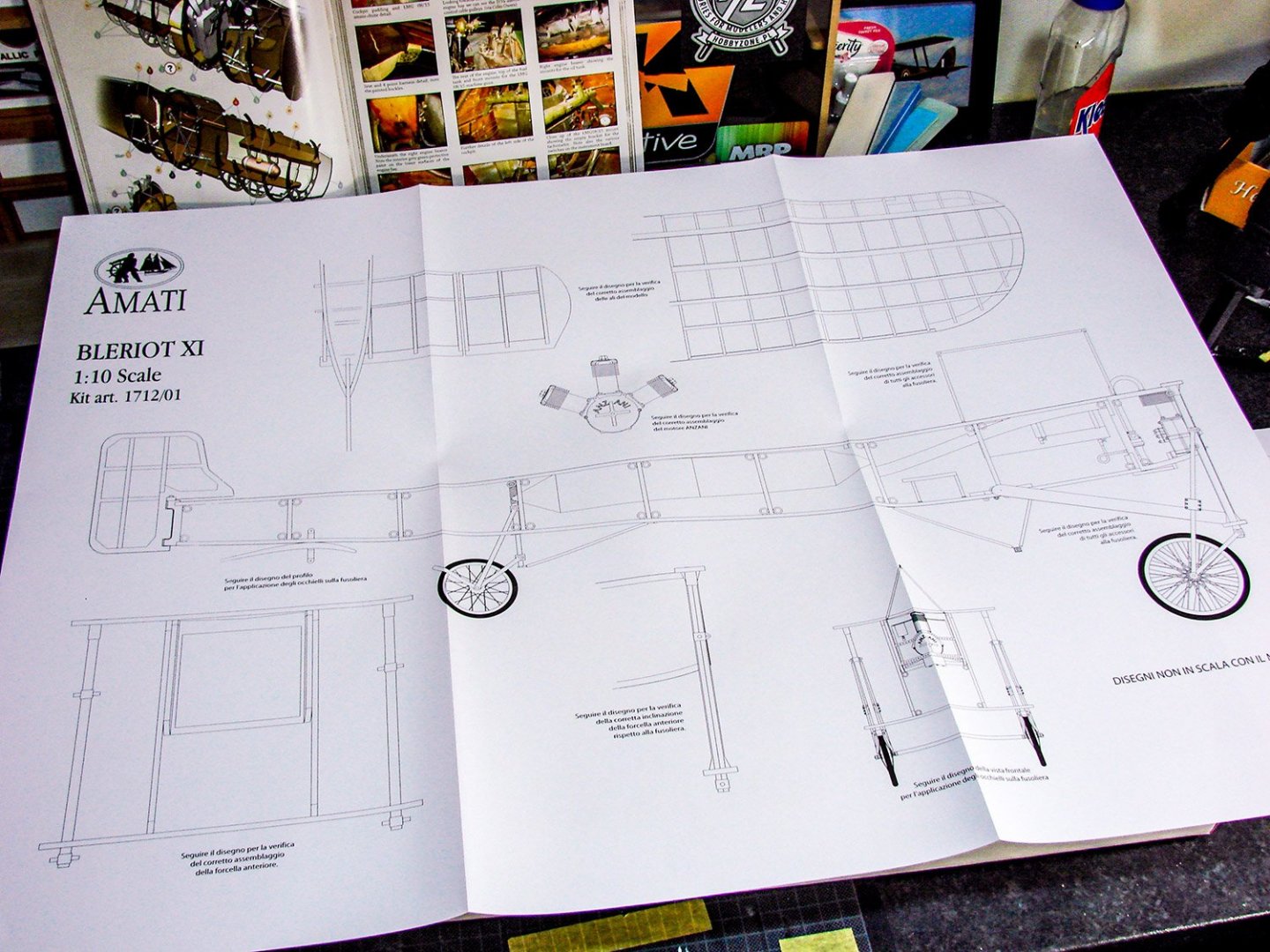

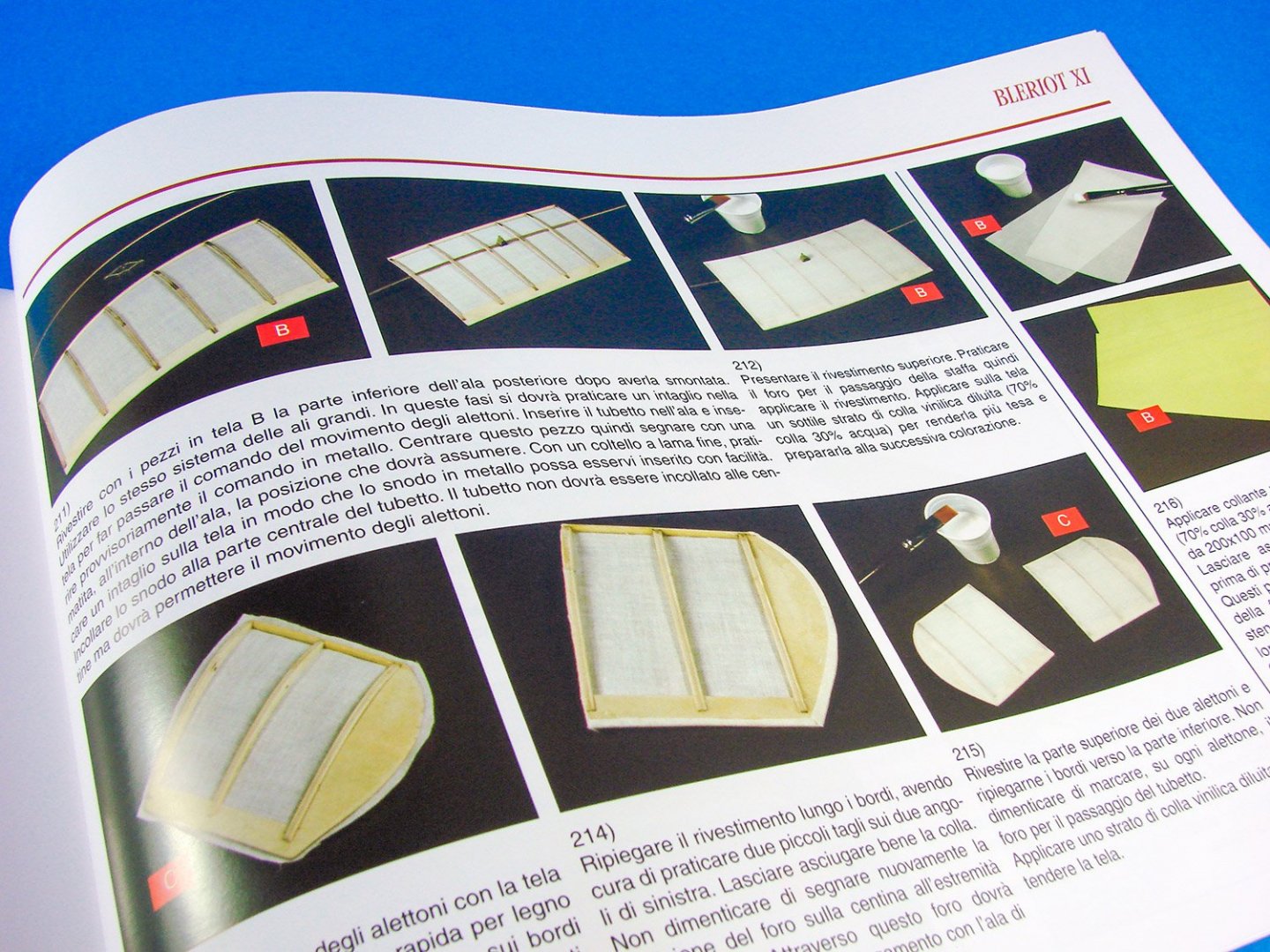

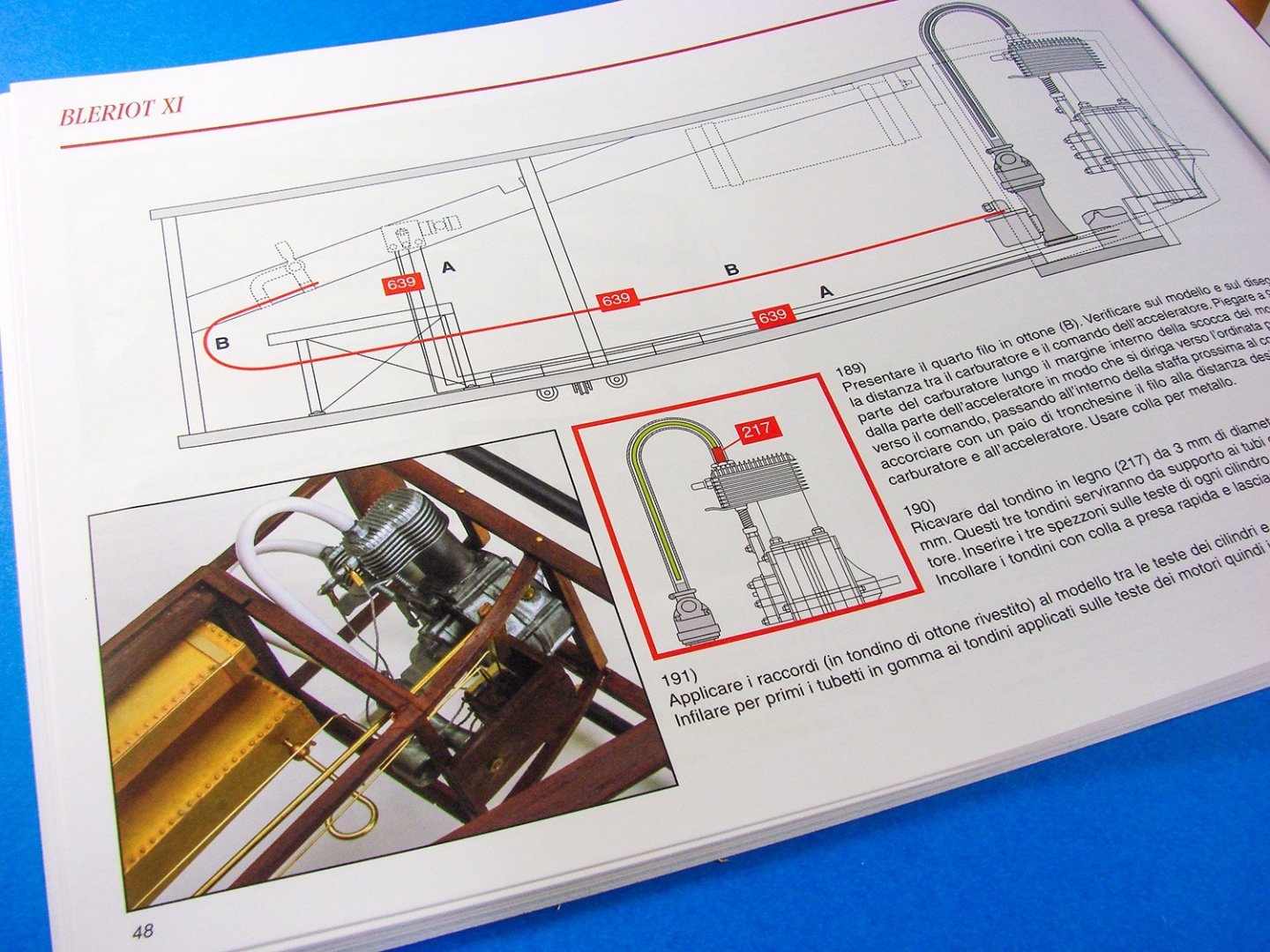

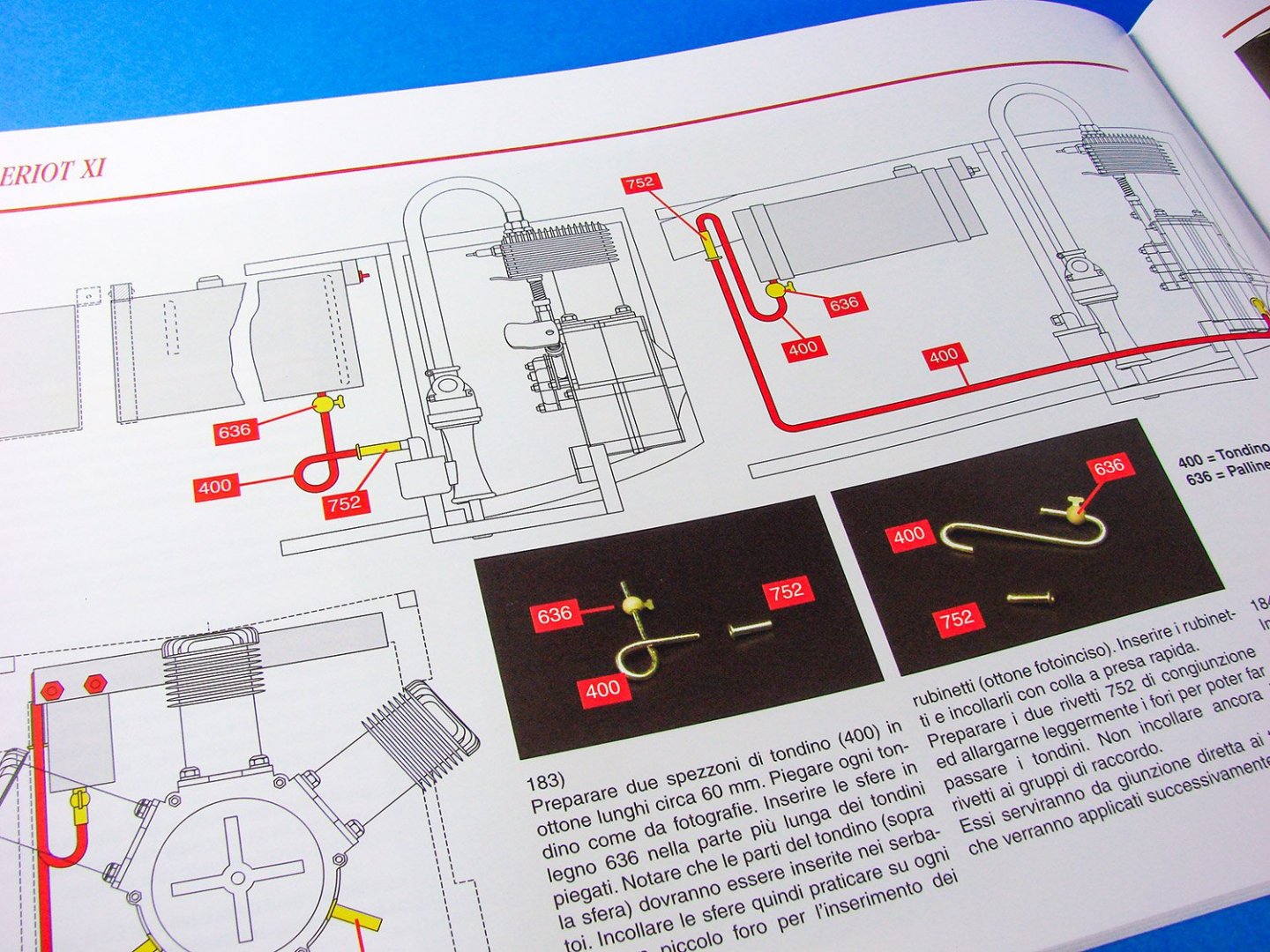

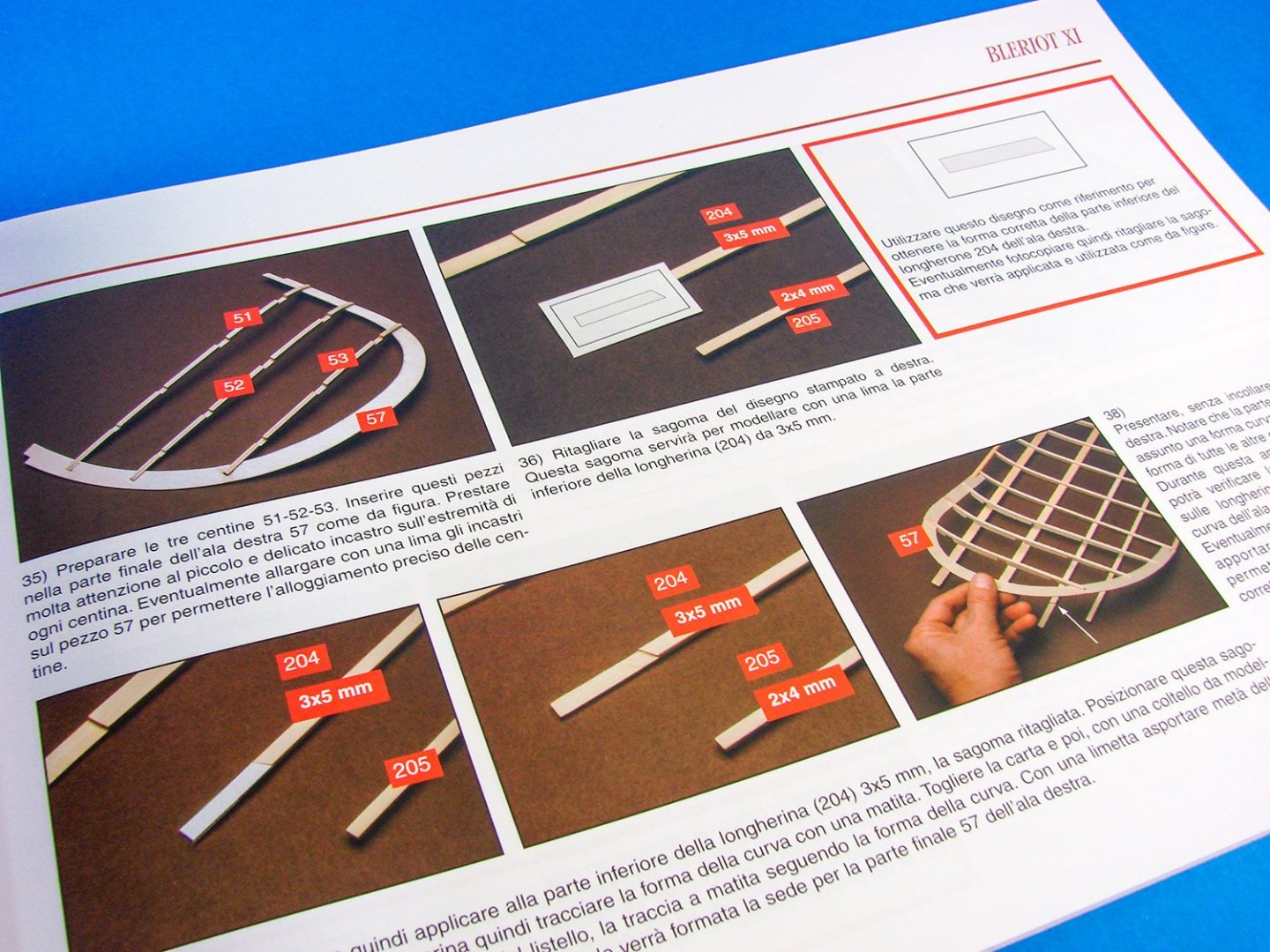

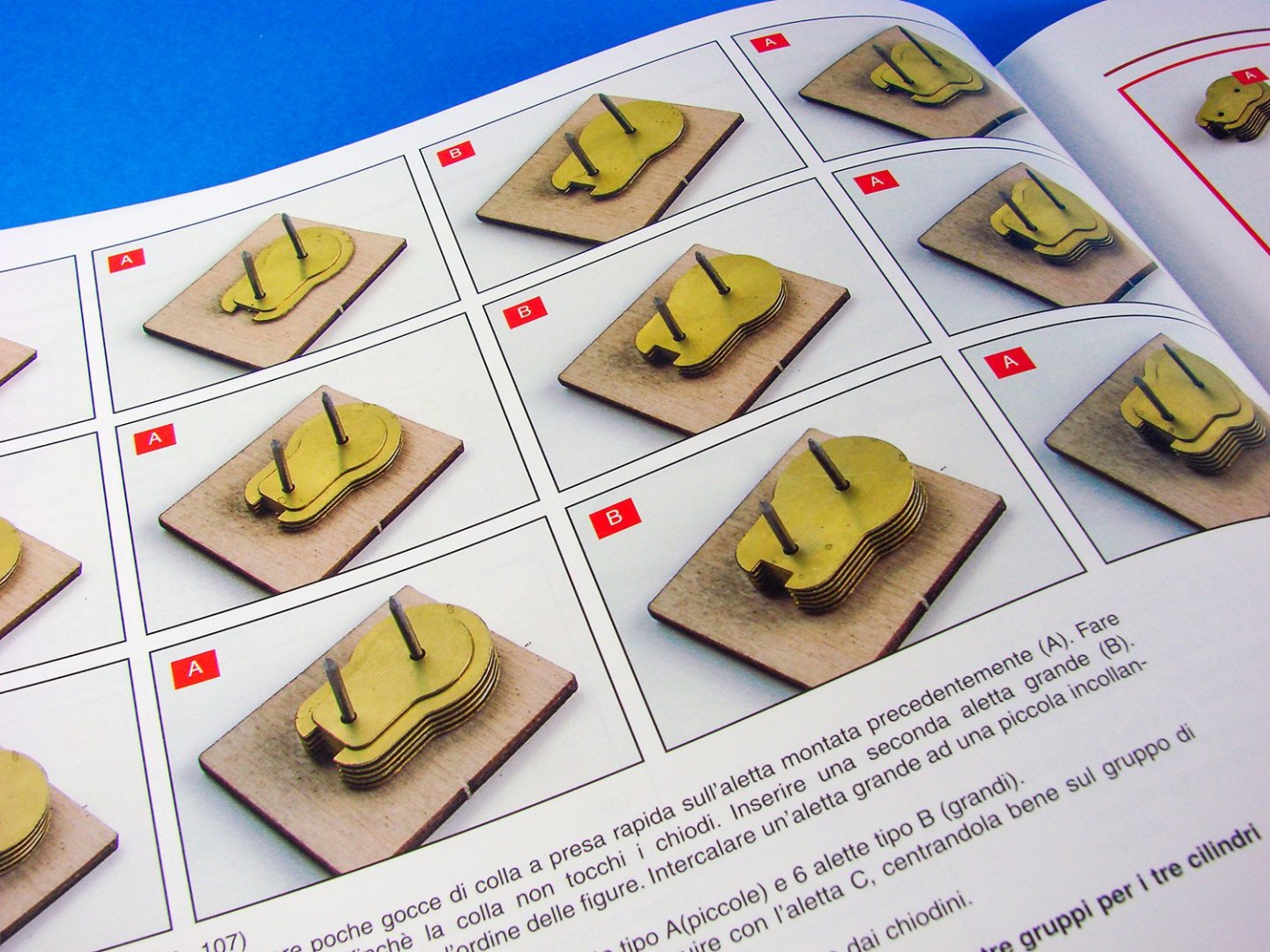

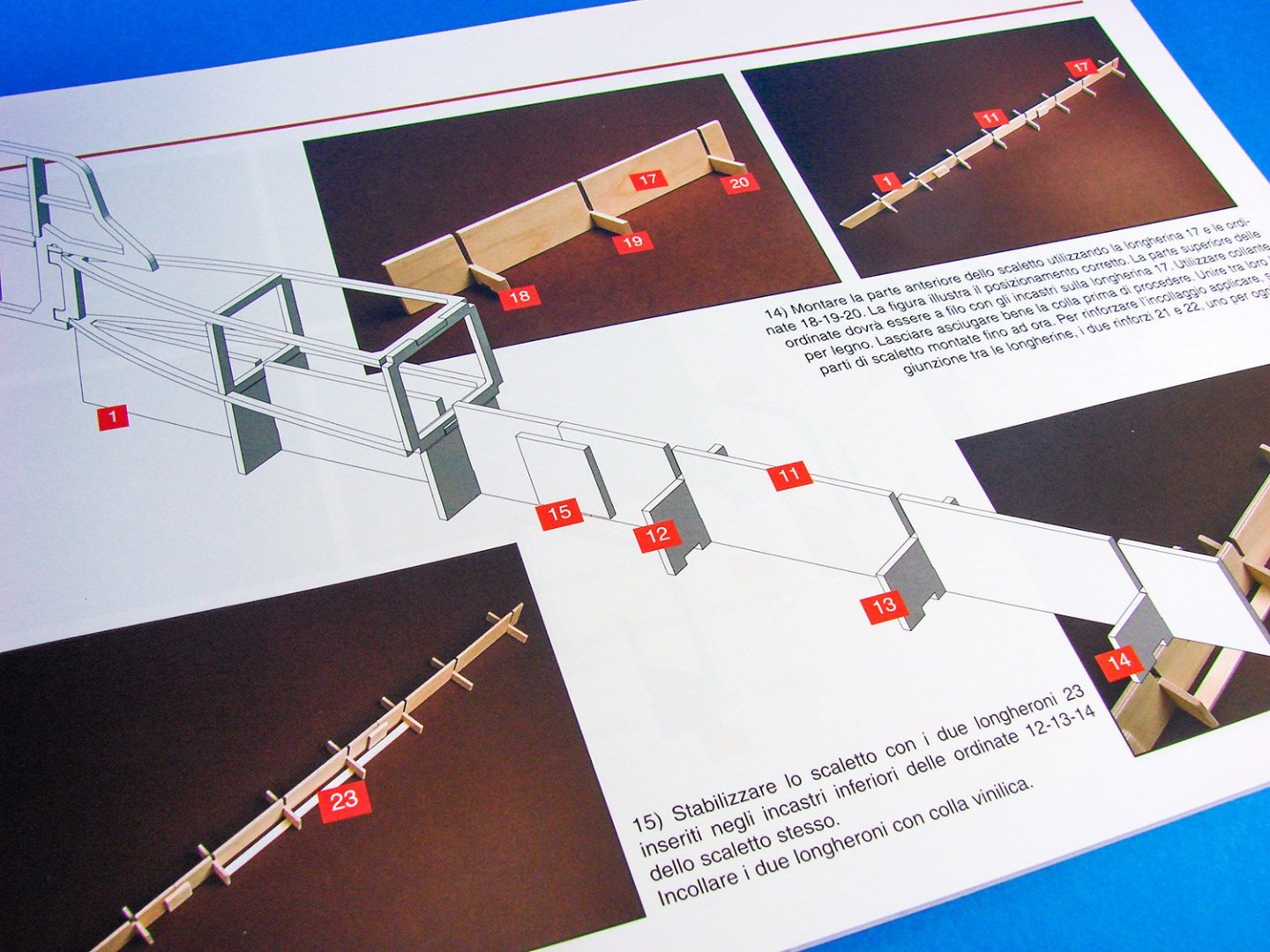

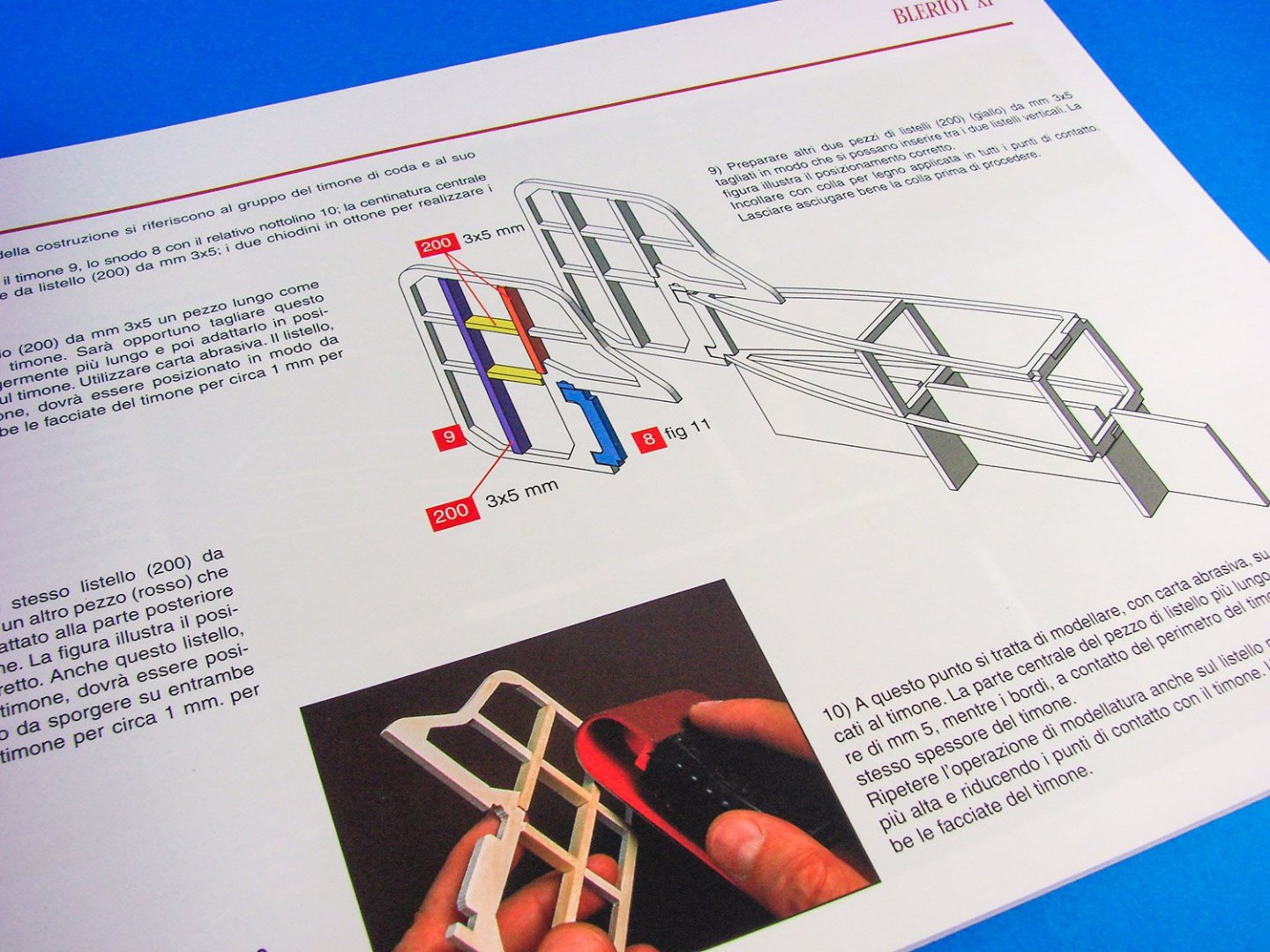

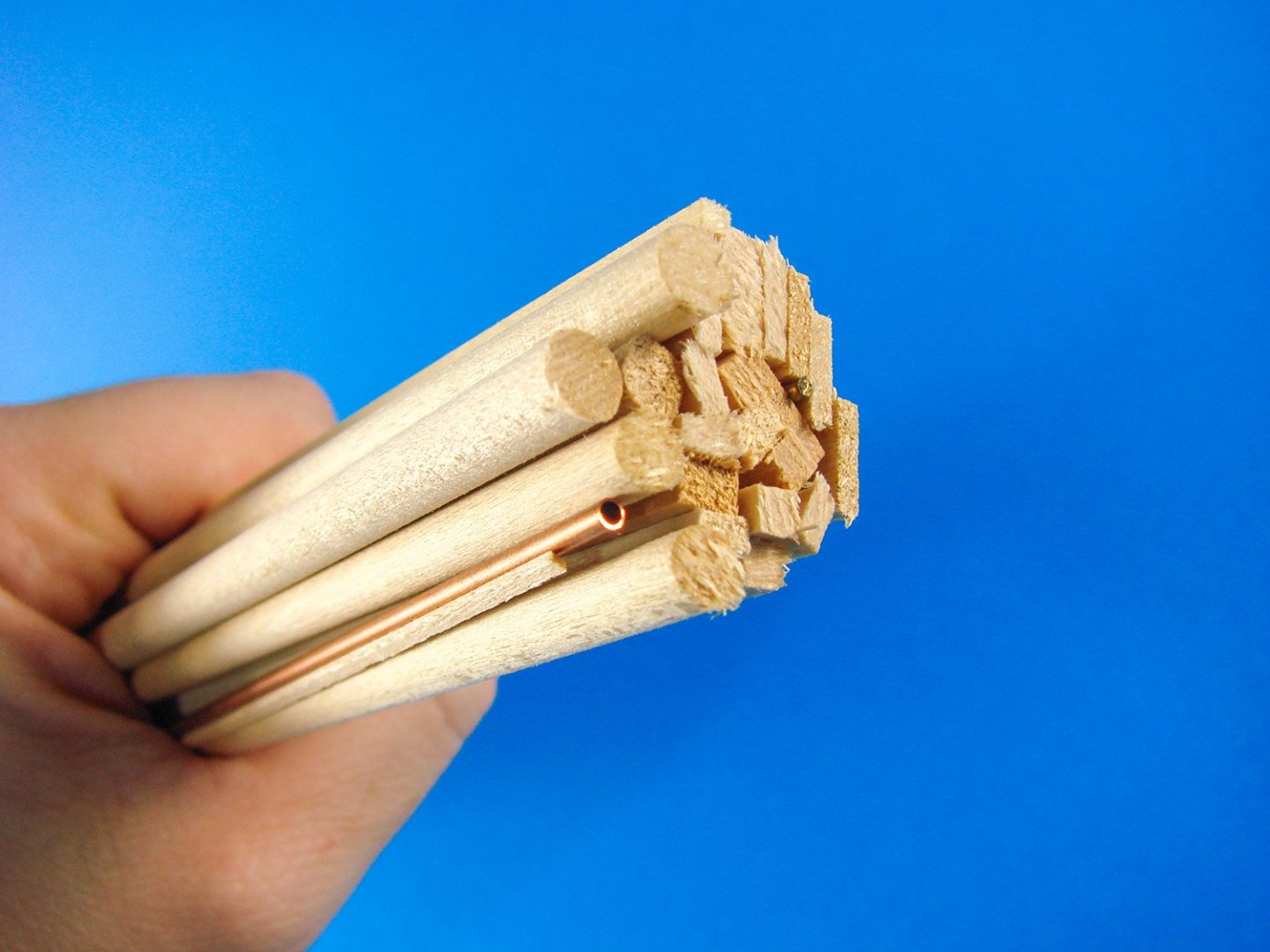

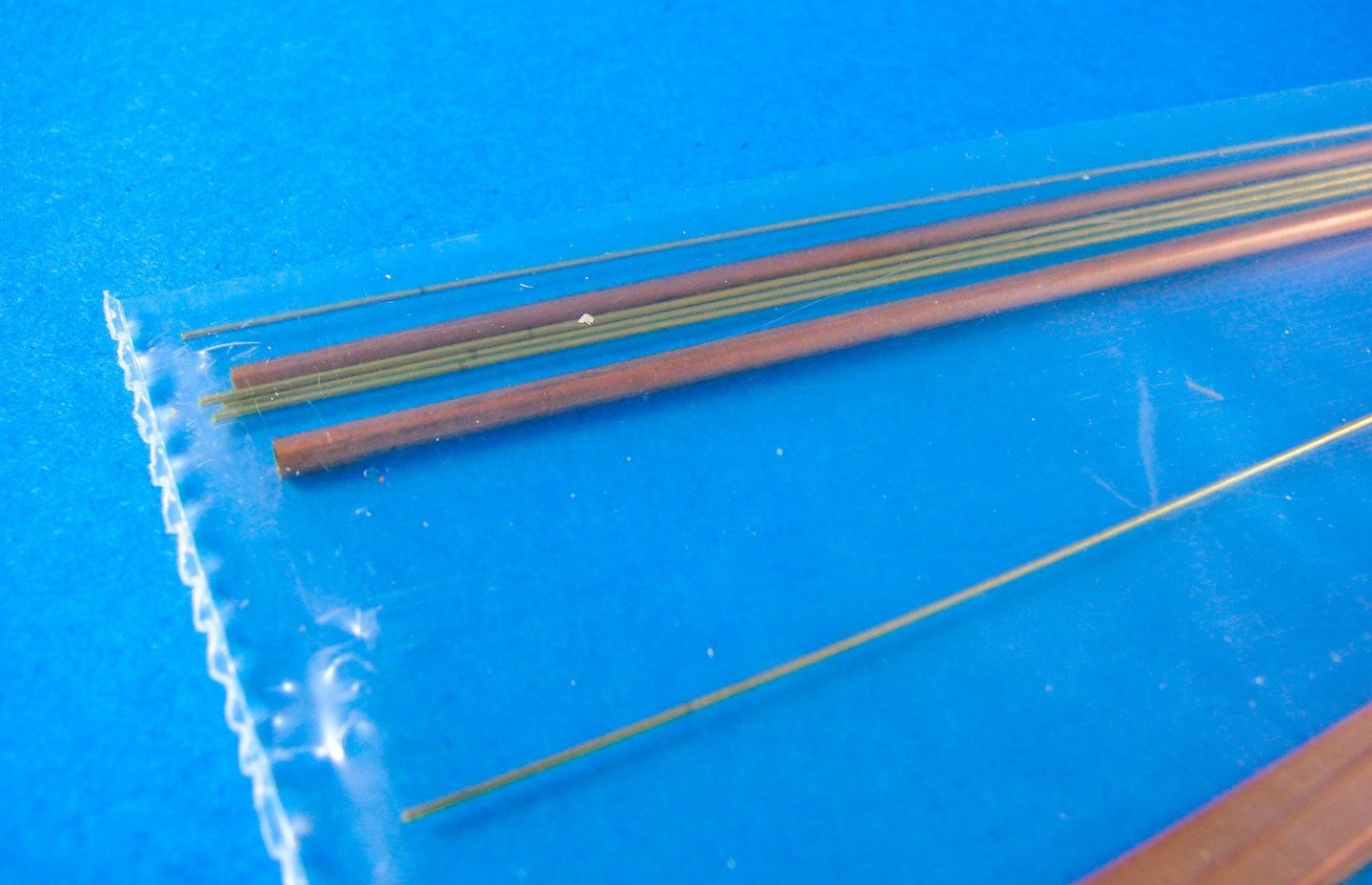

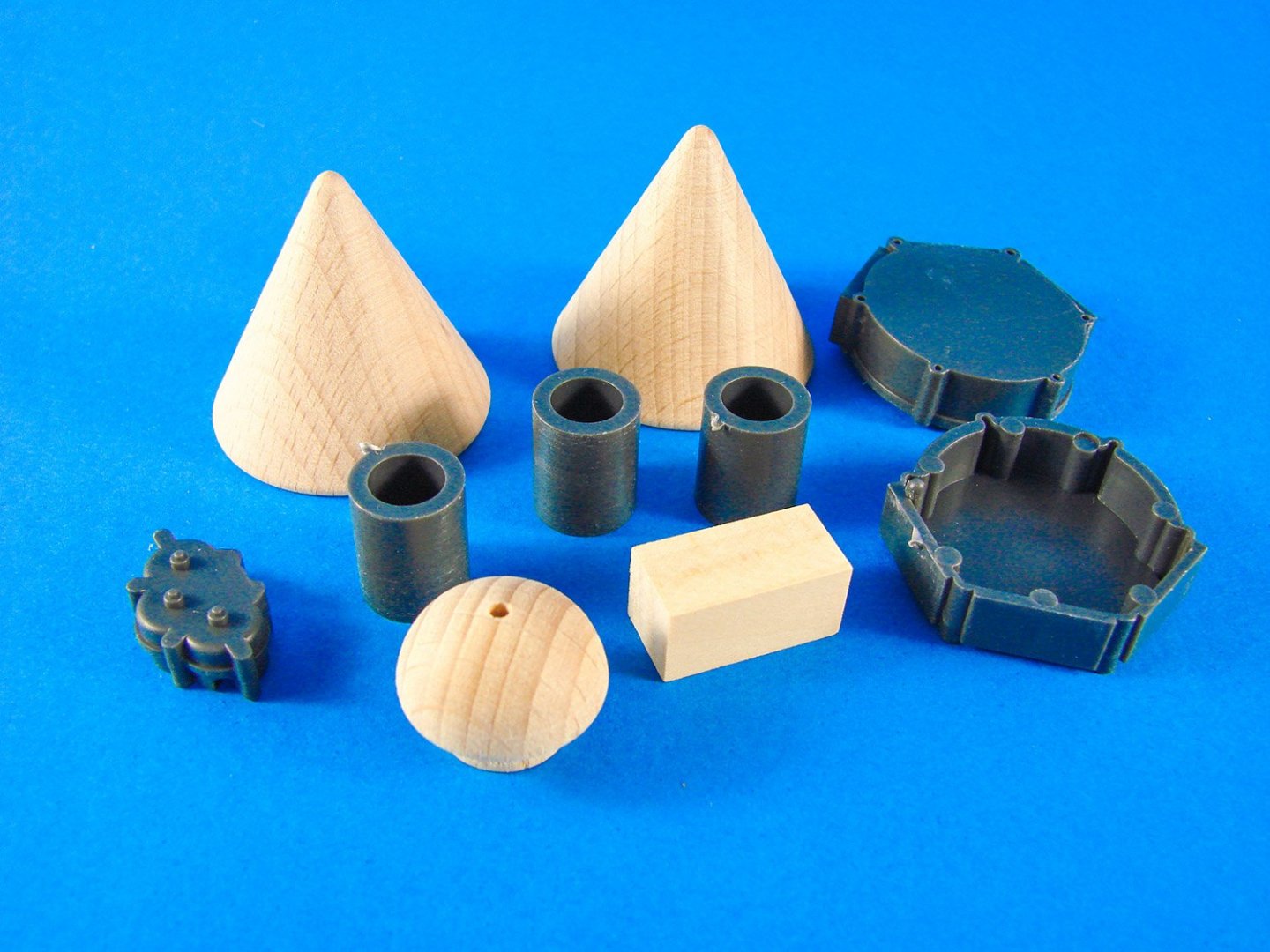

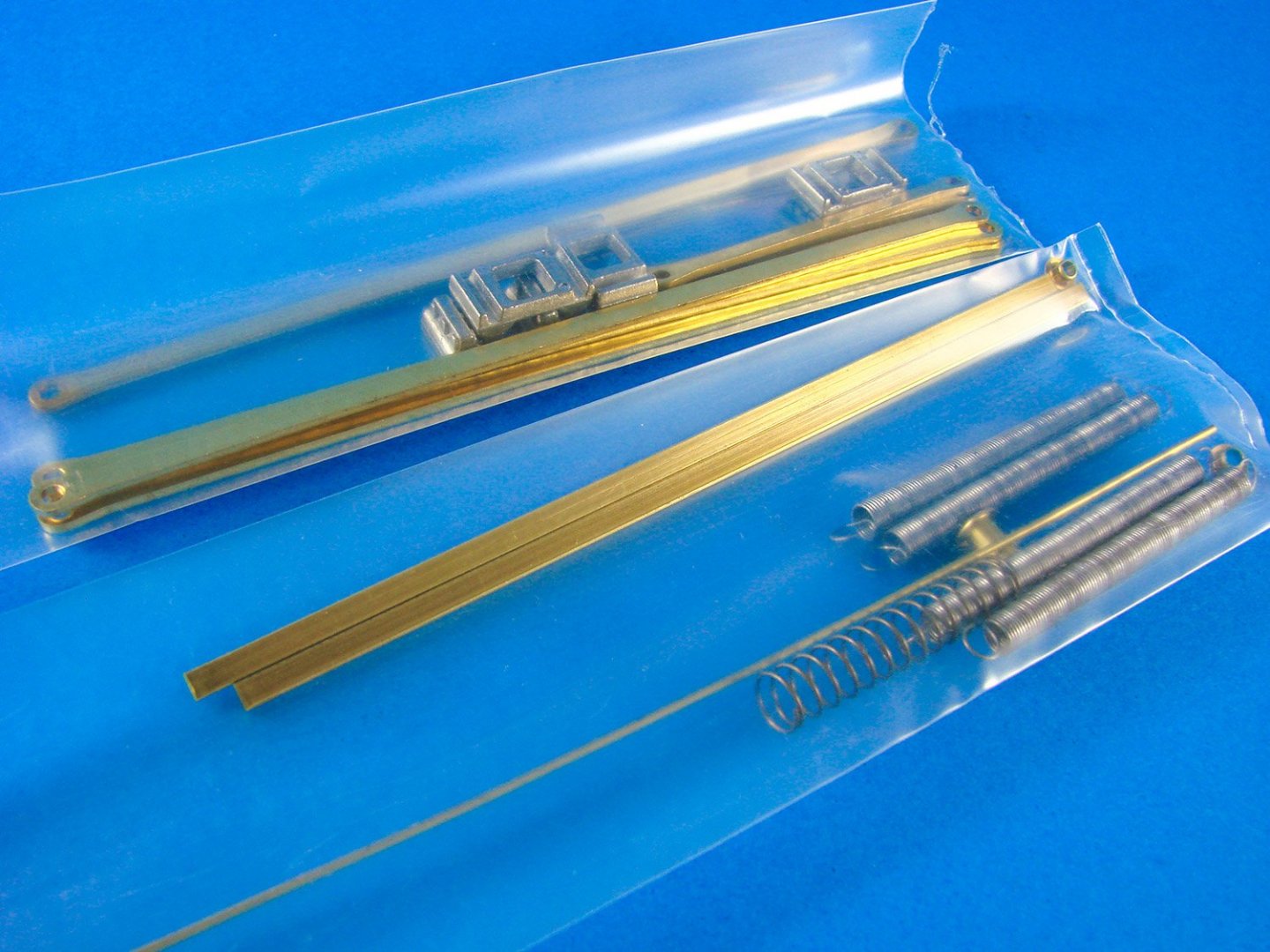

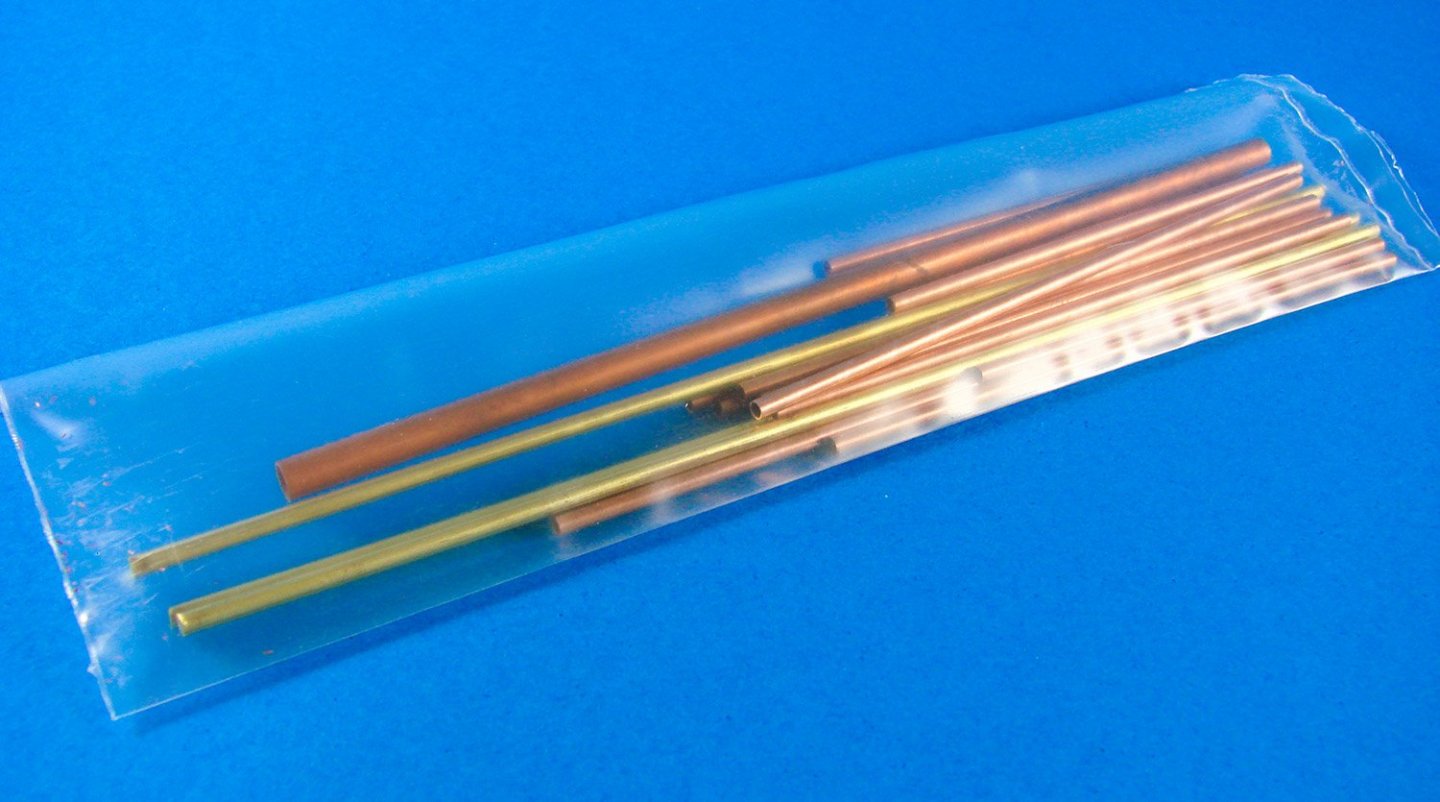

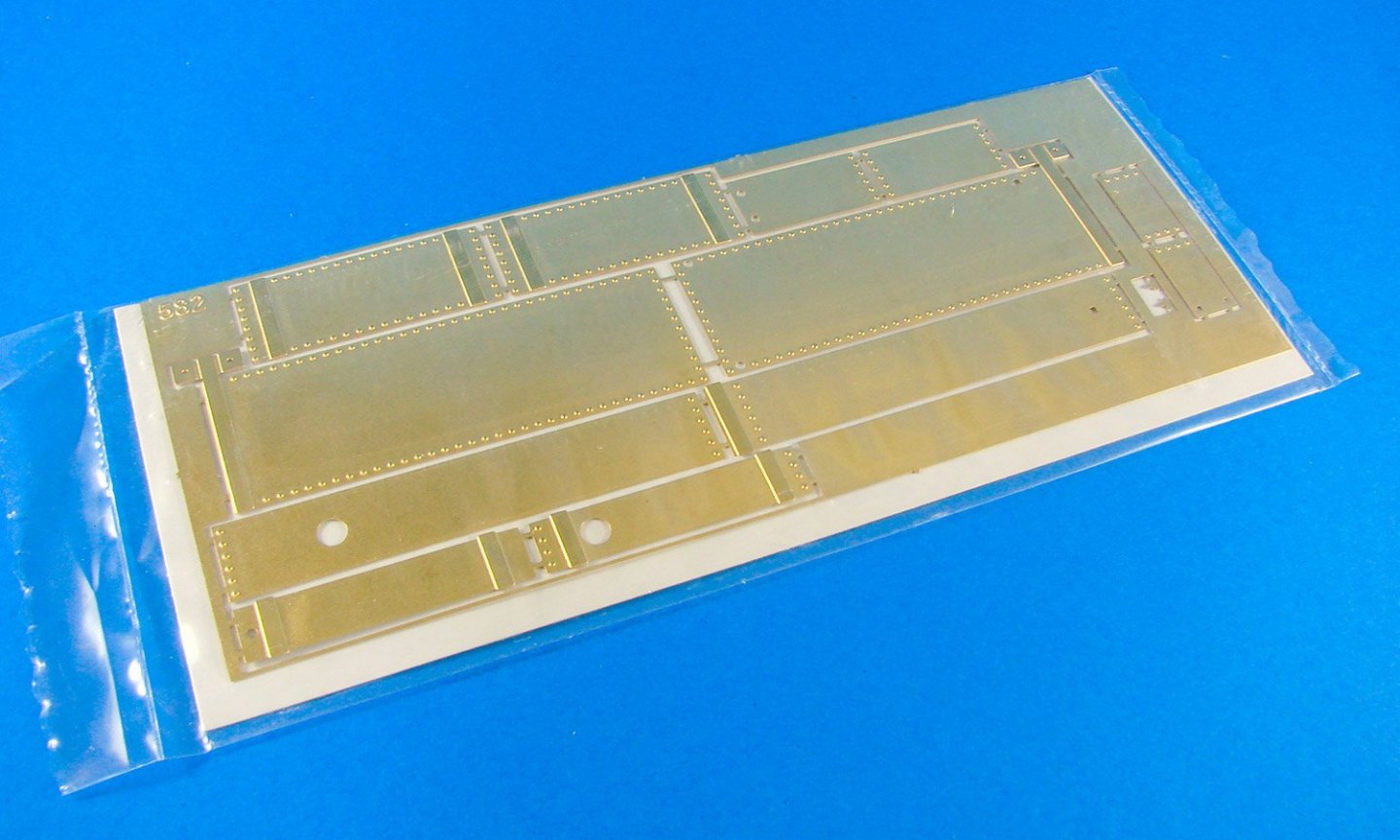

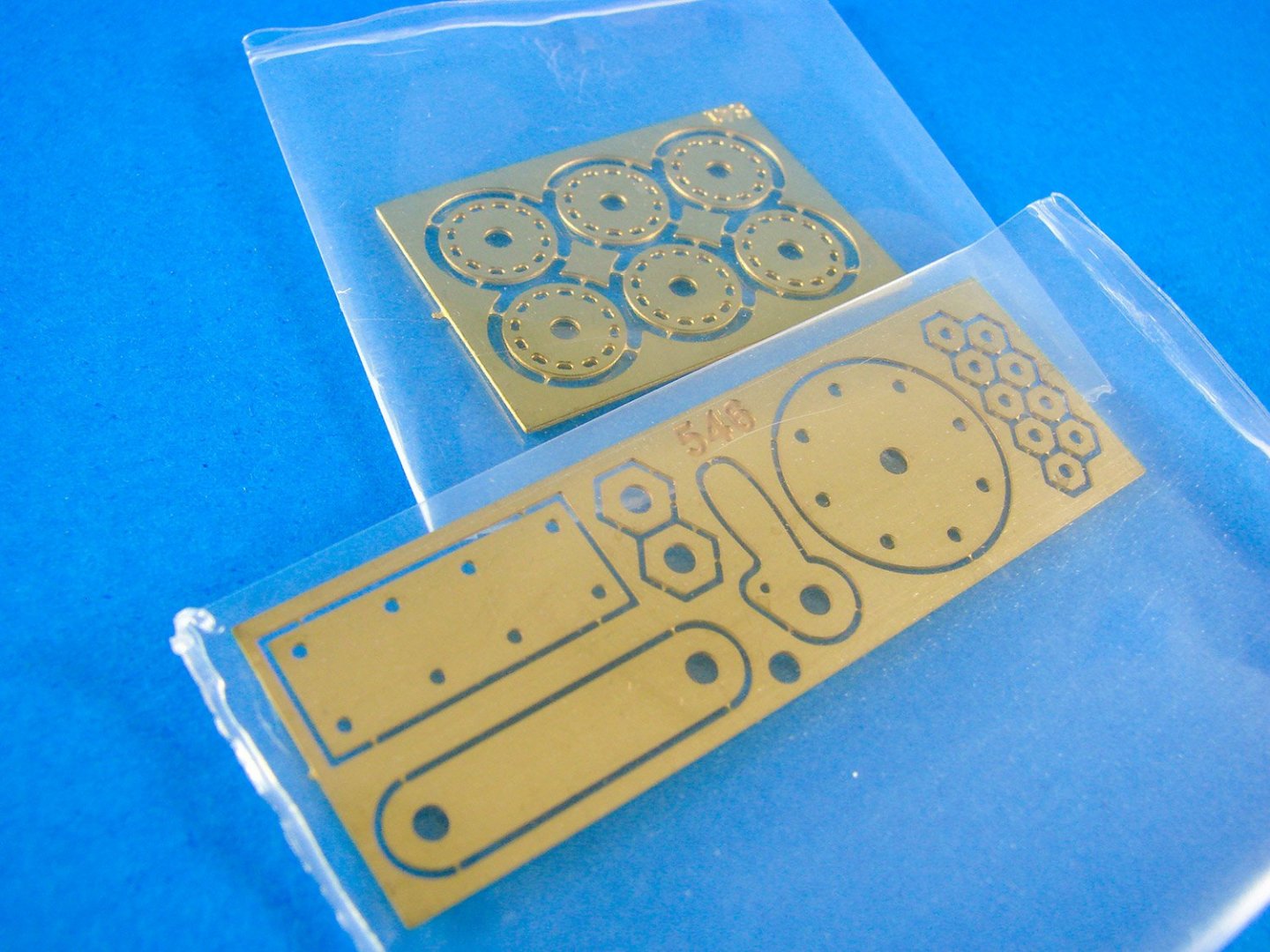

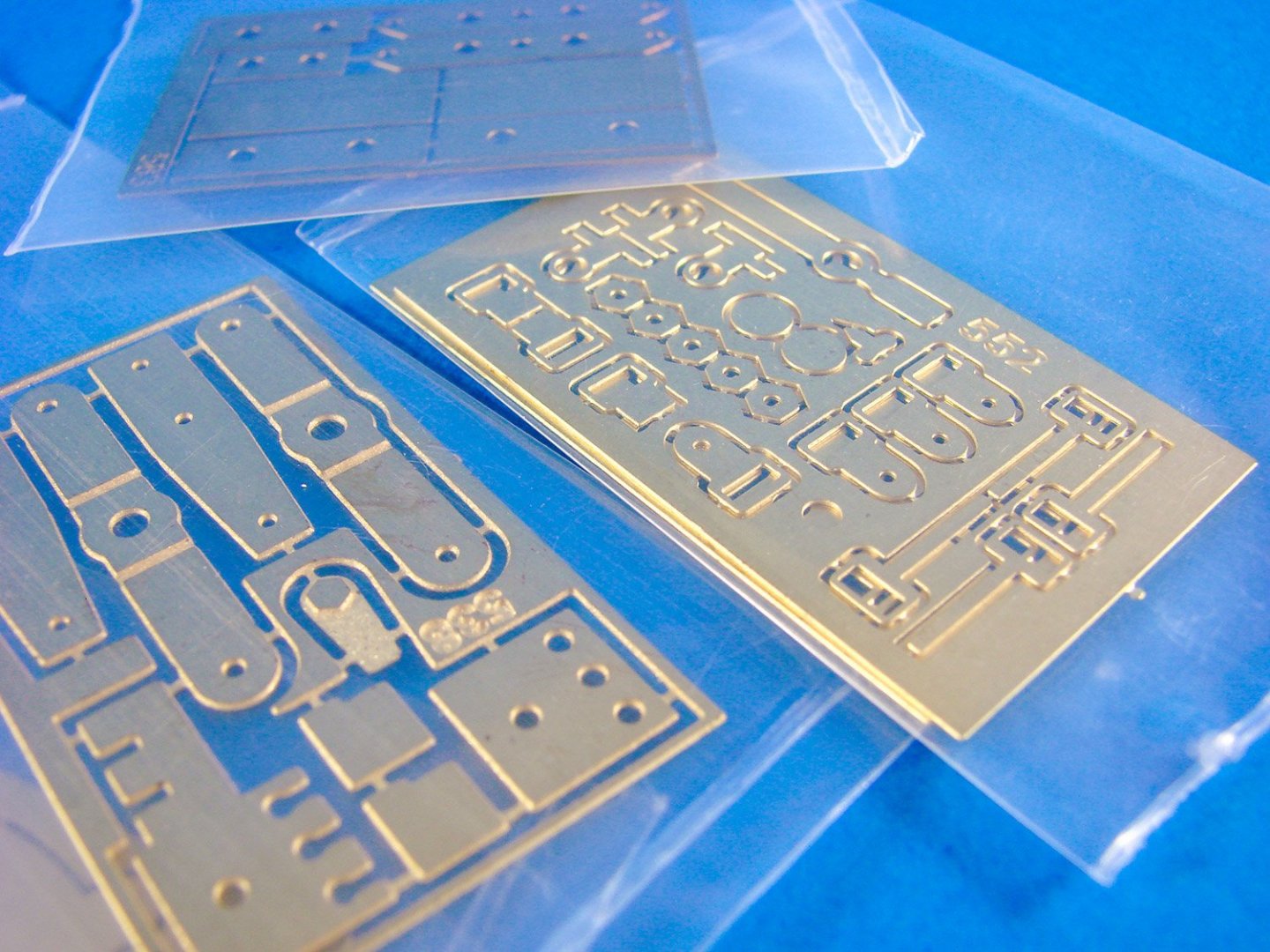

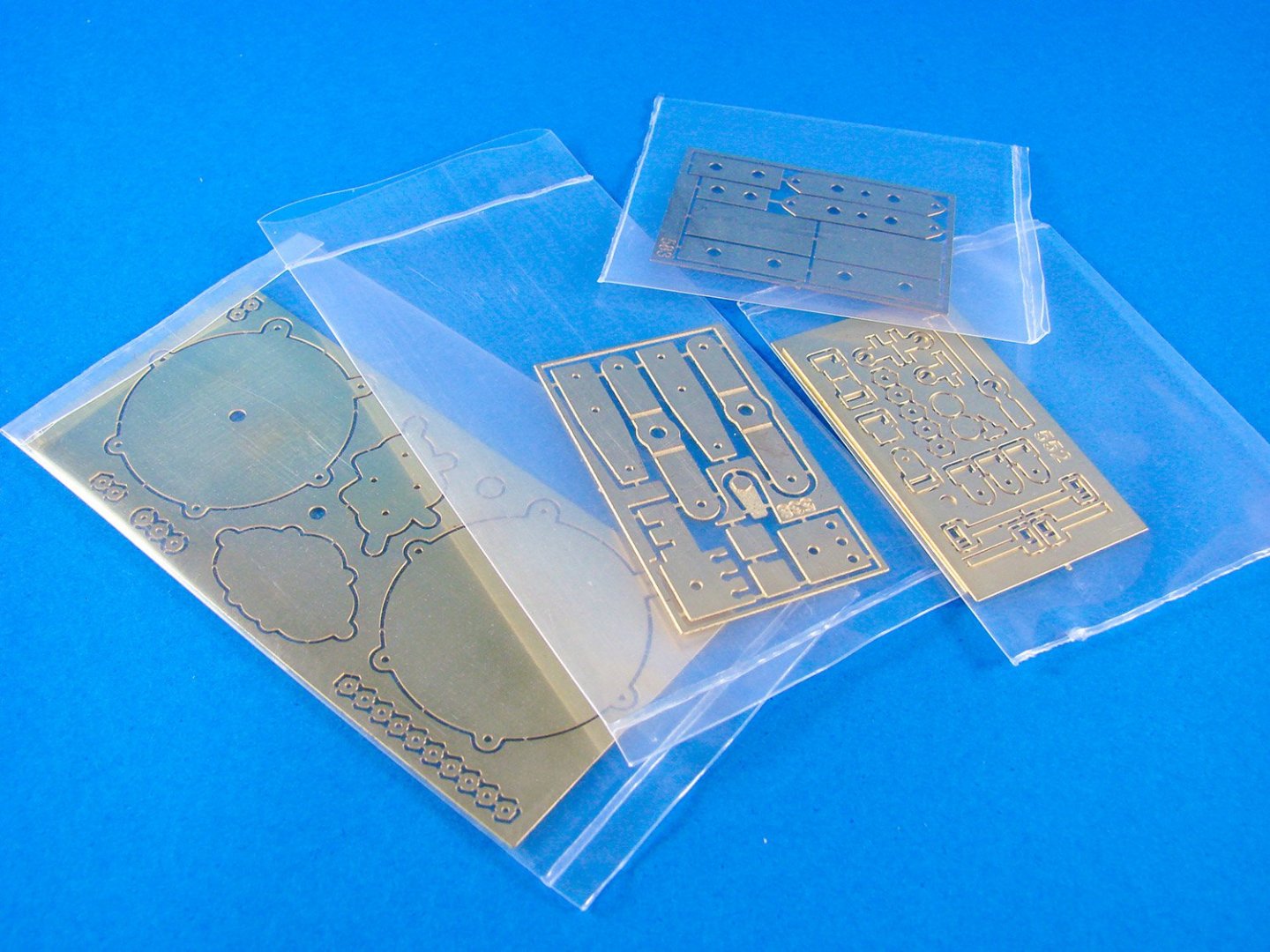

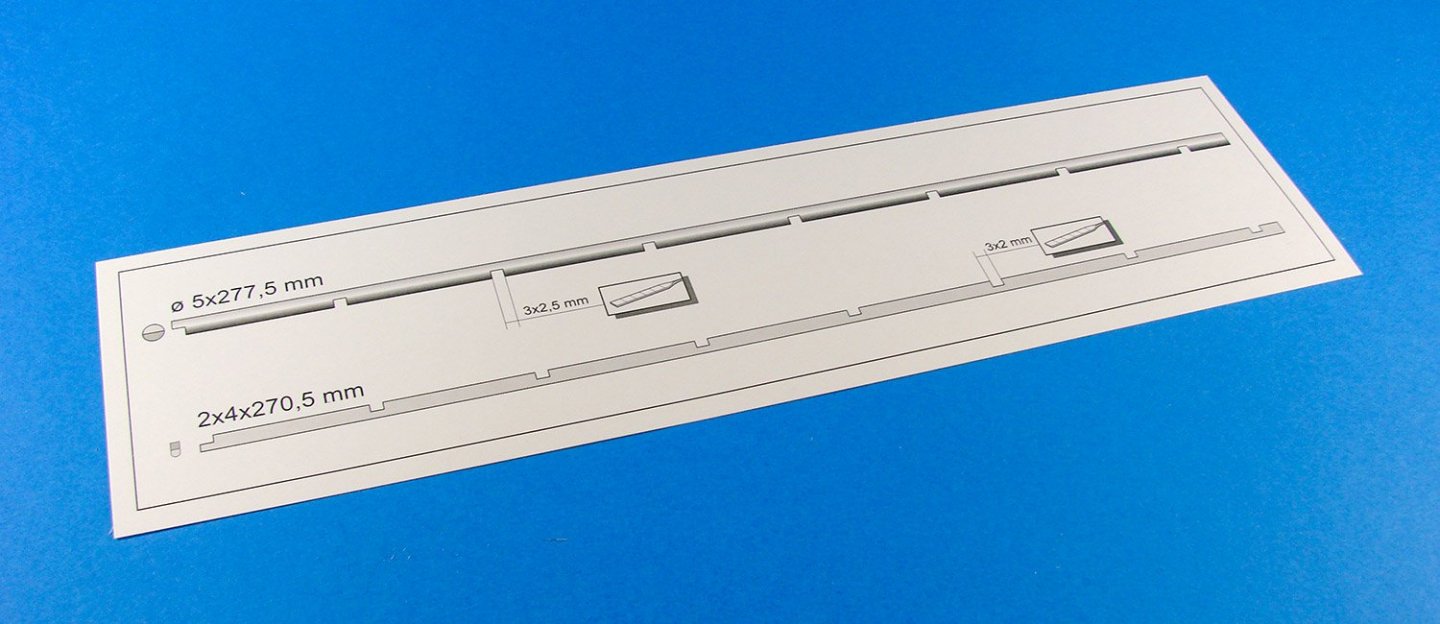

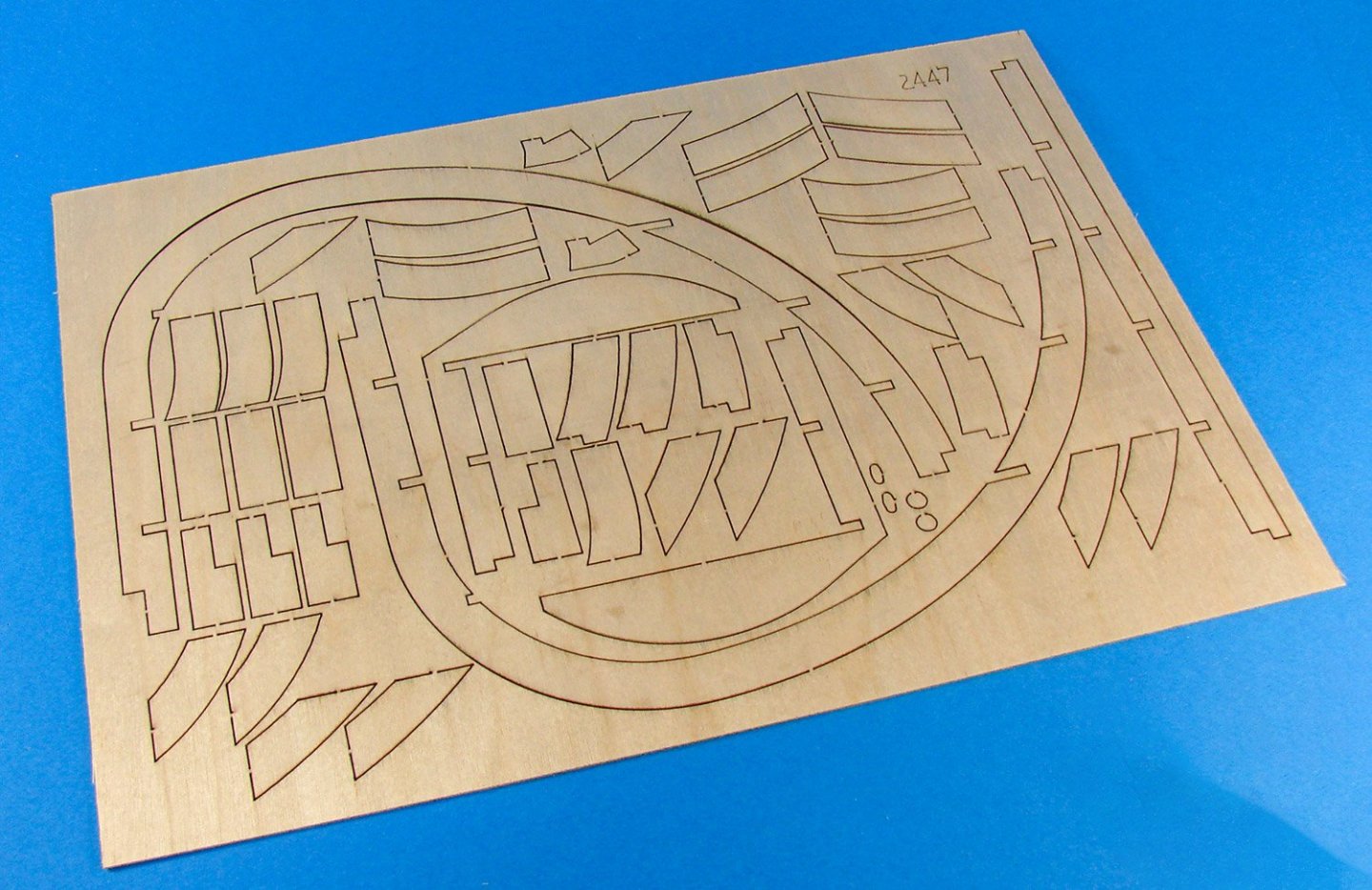

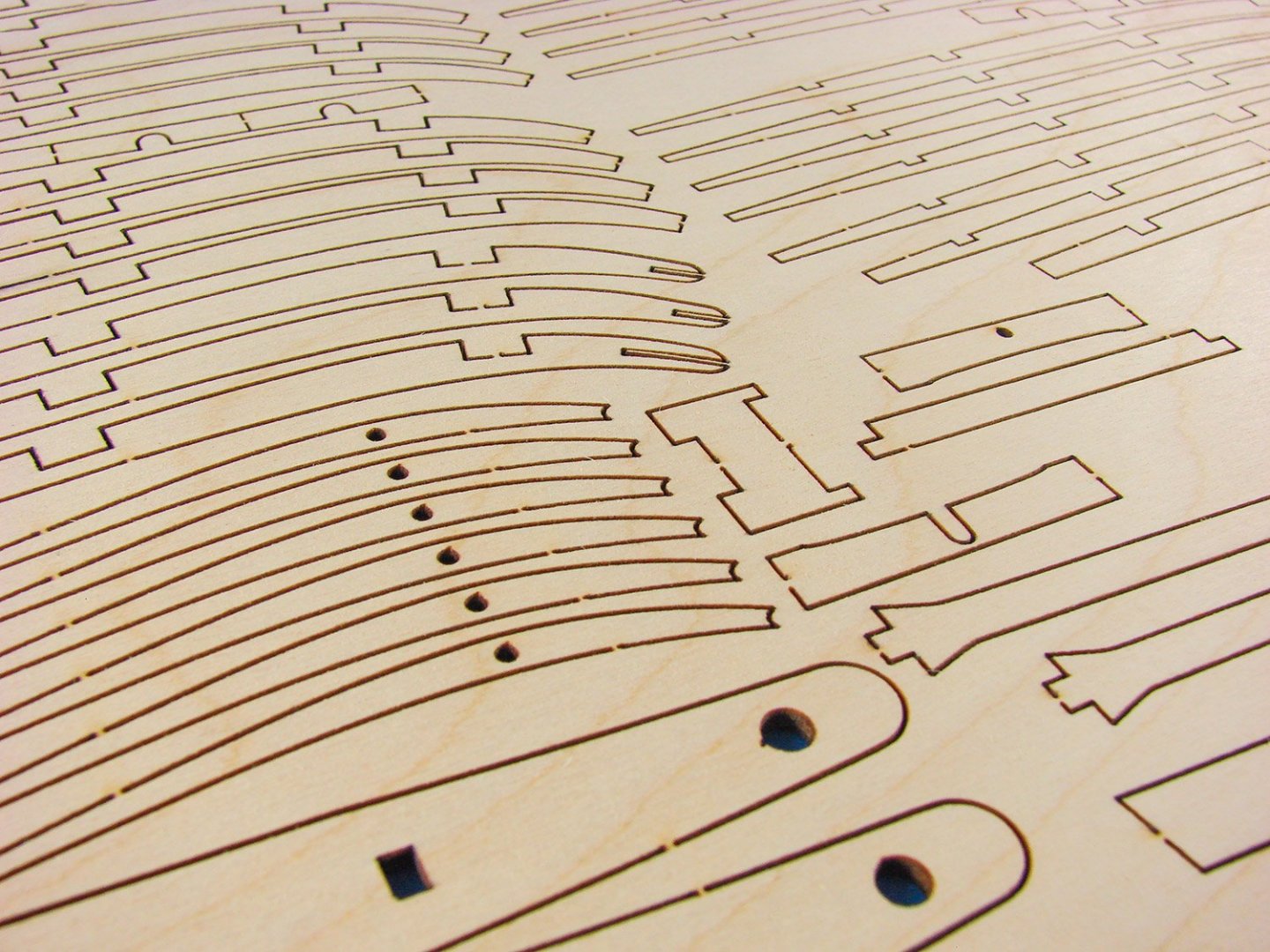

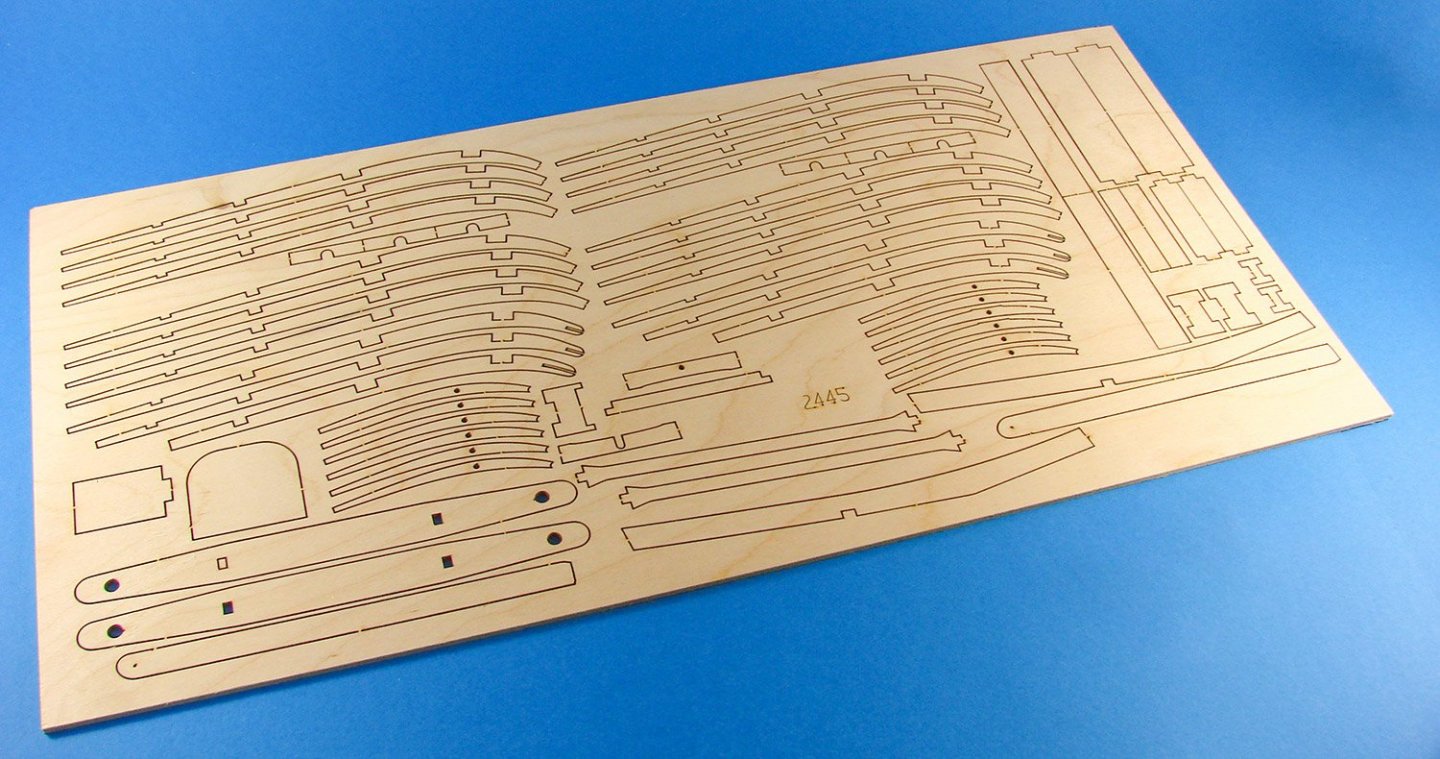

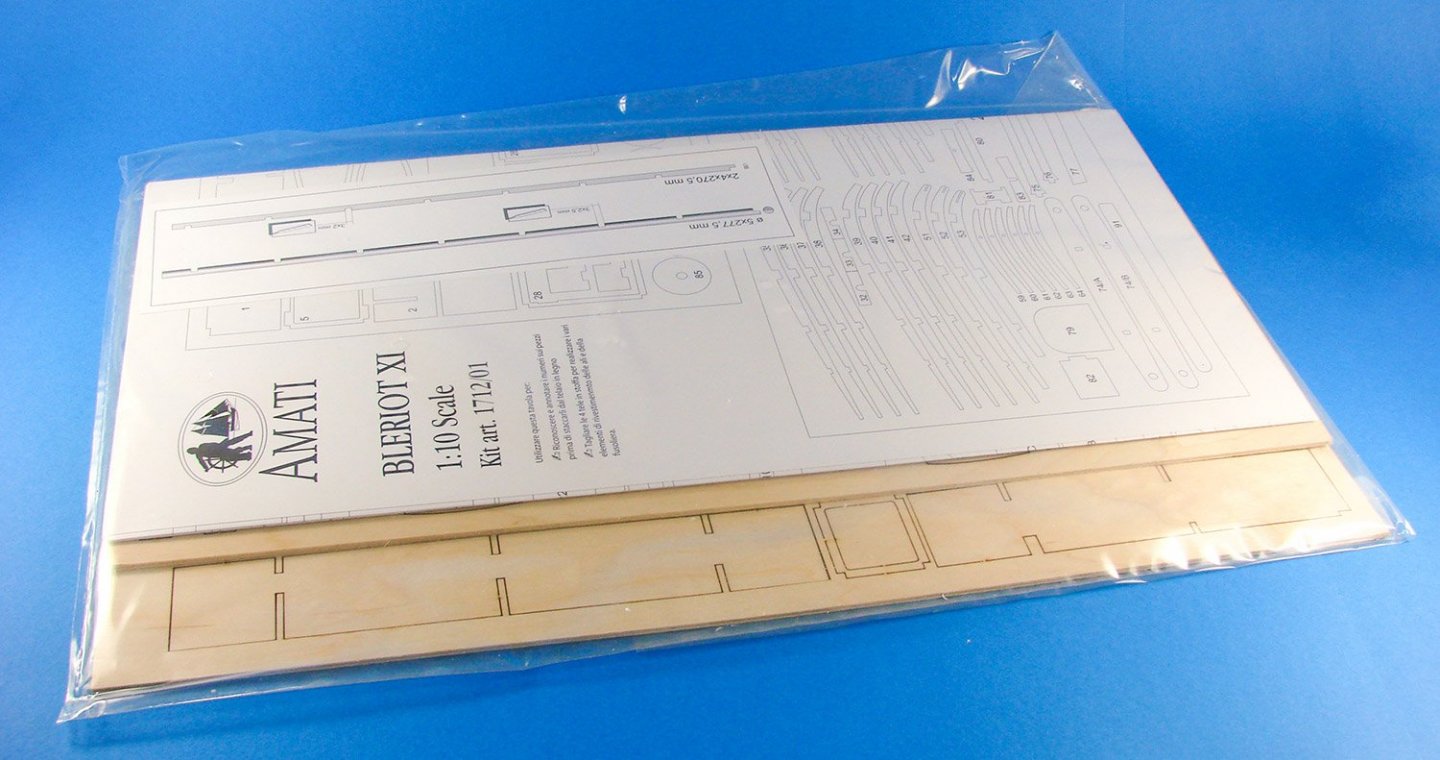

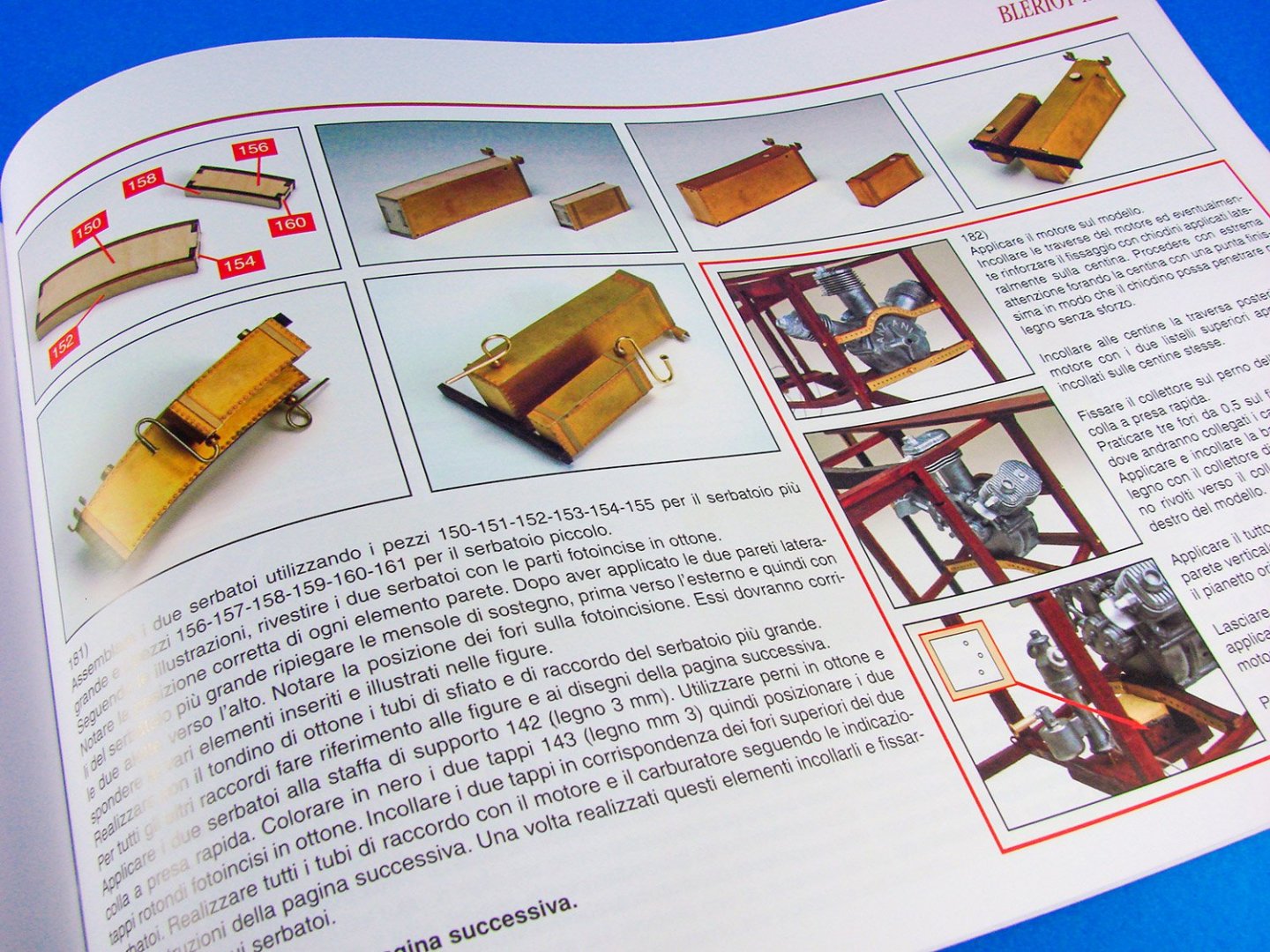

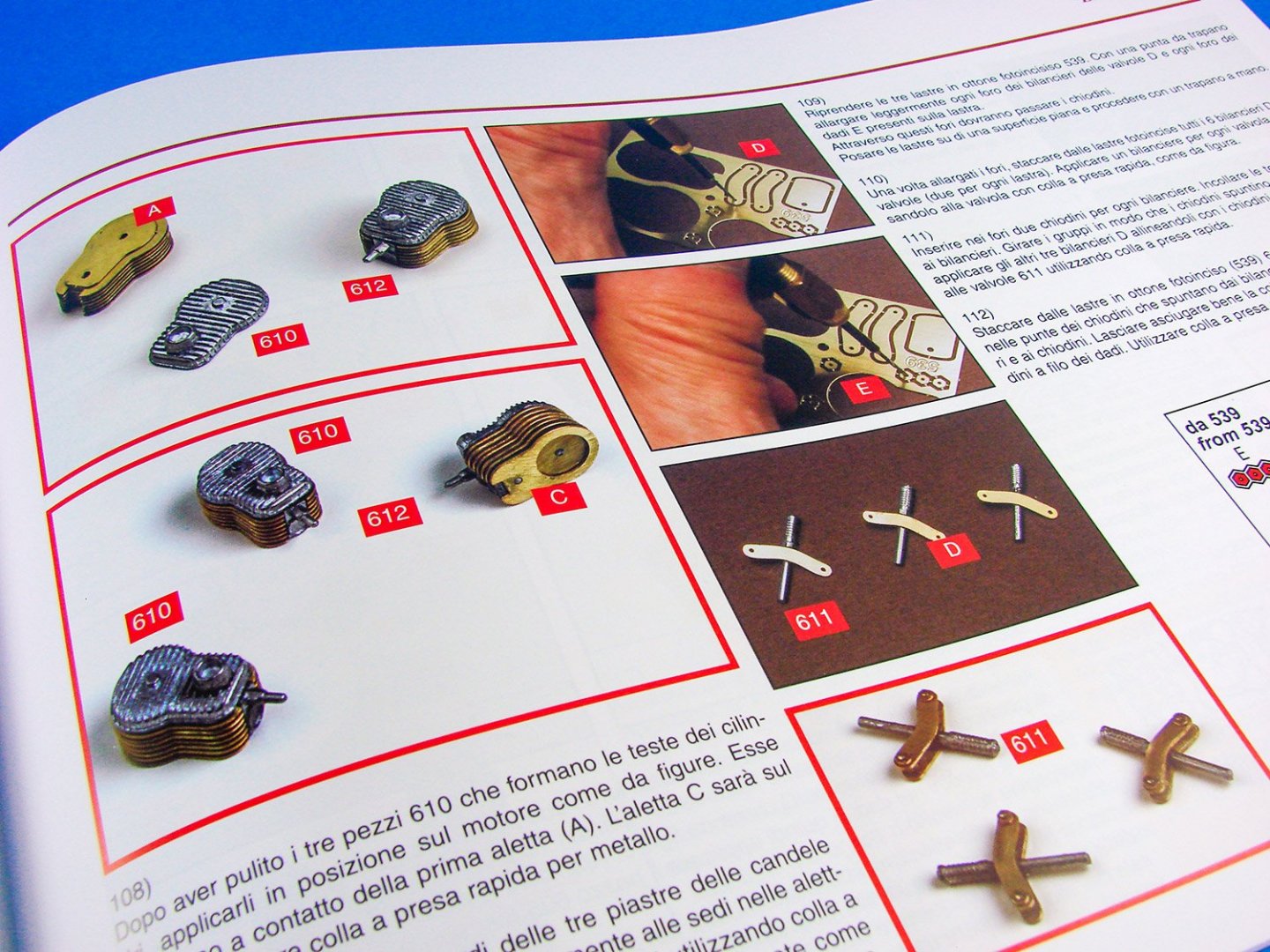

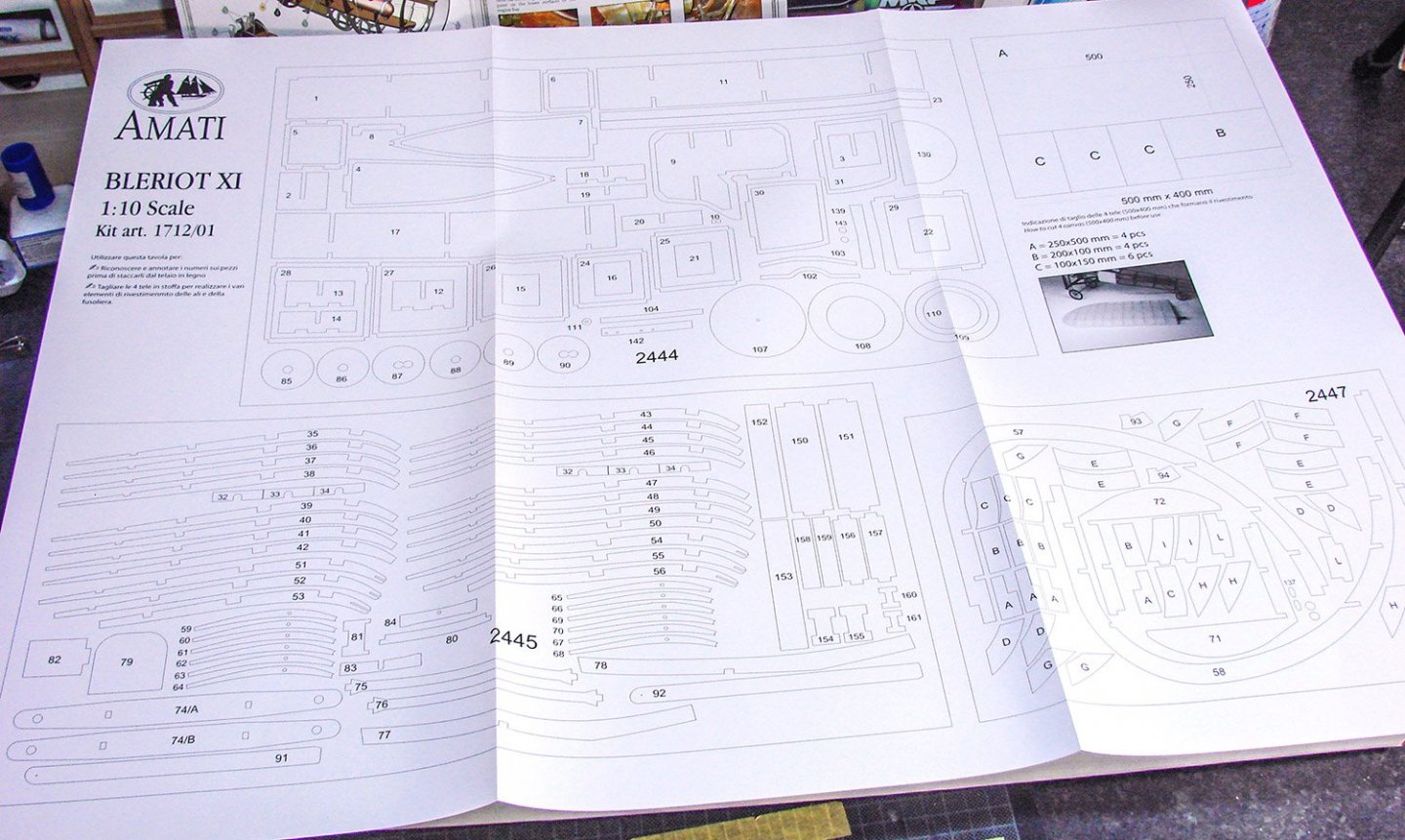

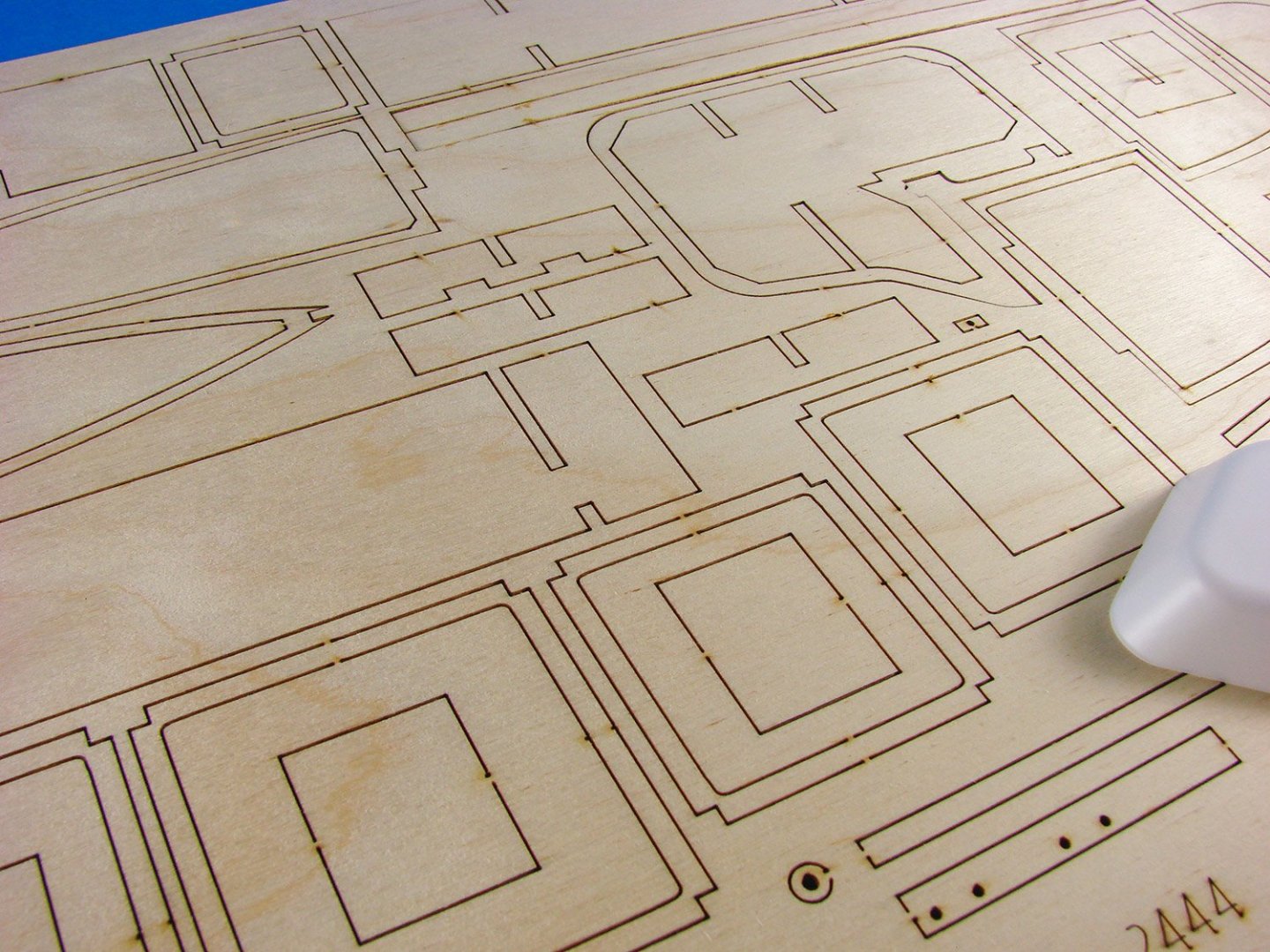

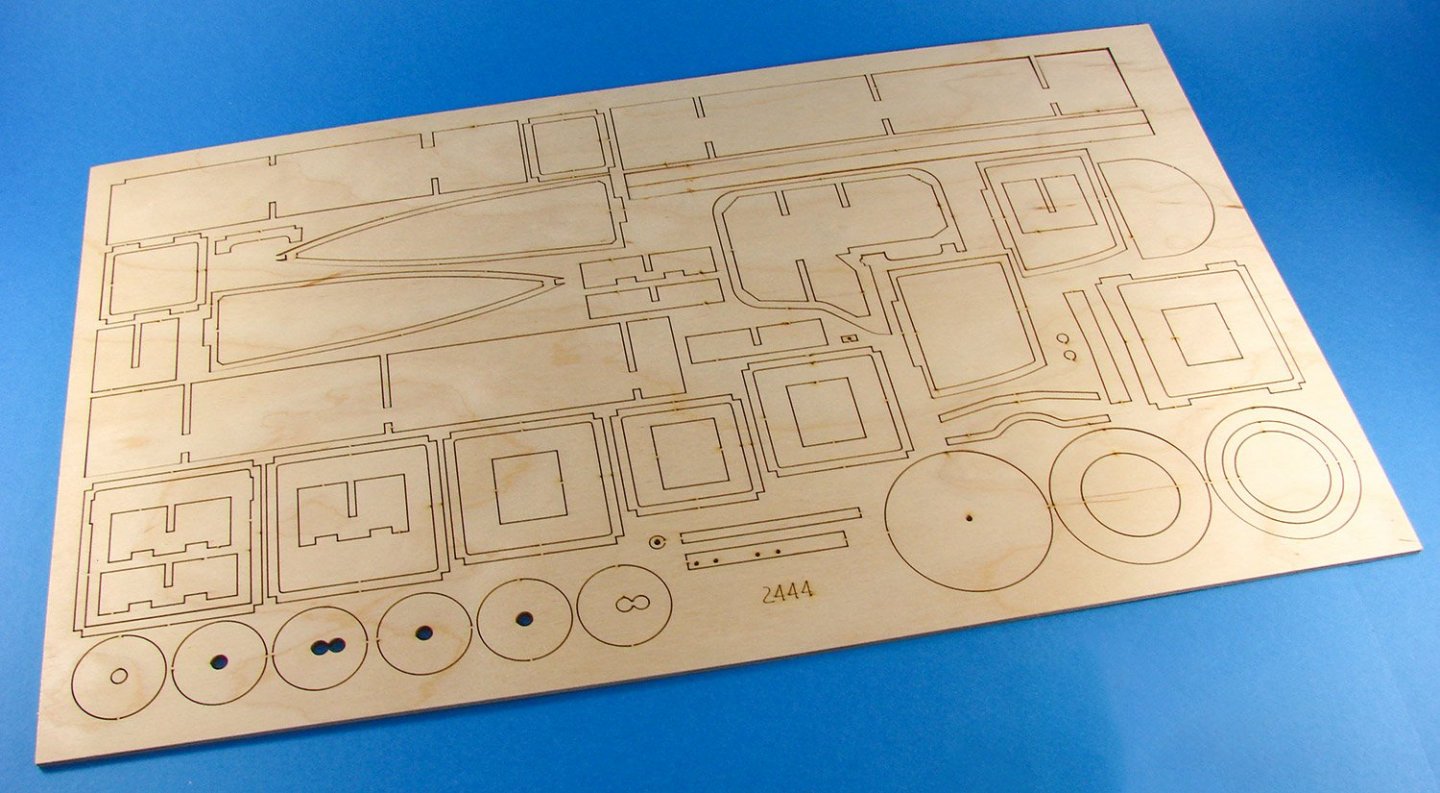

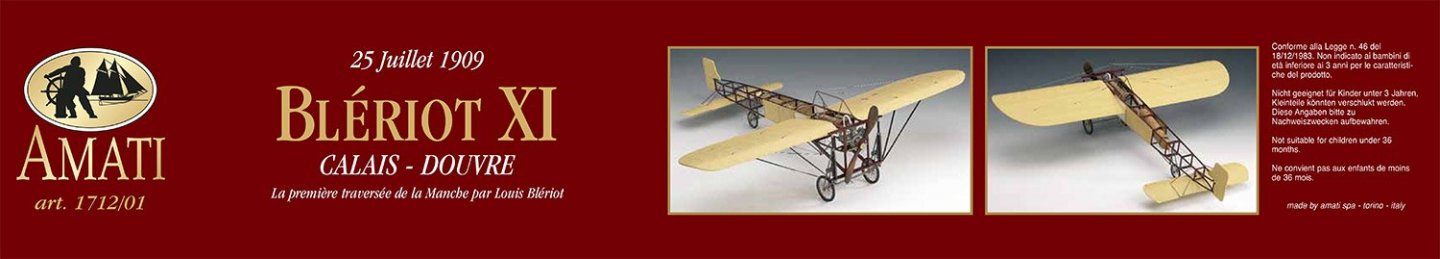

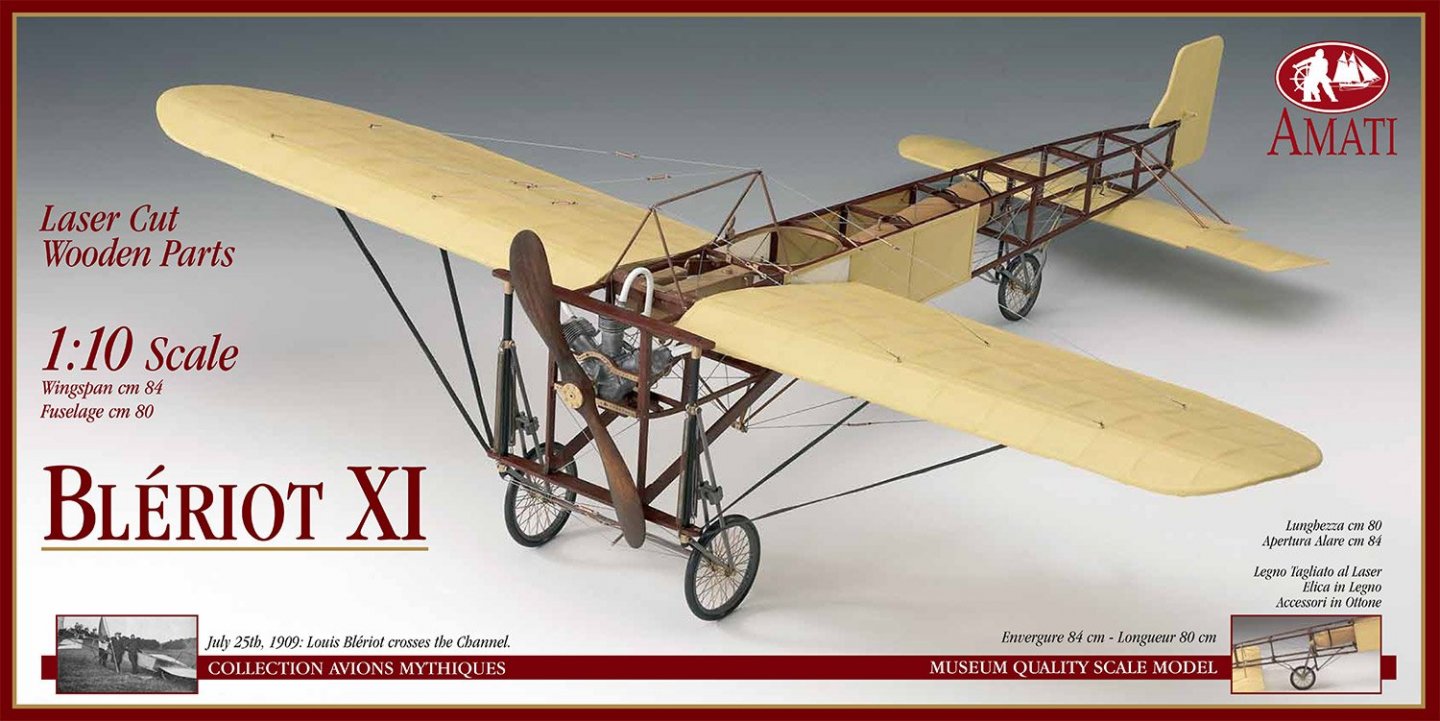

1:10 Blériot XI Amati Model Catalogue # 1712/01 Available from Amati for €284.43 “England’s isolation has ended once for all!”, so was written in an English newspaper, on the day after Louis Blériot flew across the English Channel from France. The French aviation pioneer, in his modified type XI monoplane, took off from Les Baraques near Calais at 4.41am on July 25th 1909, and landed at 5.17am in Northfall Meadow, near Dover. The Bleriot XI made its debut at the Paris Salon de d’ Automobile et de l’ Aeronatique in December 1908, along with two other Bleriot planes; the type IX and the type X. In October 1908 the London Daily Mail had offered a prize of £1,000 to the first aviator to cross the Channel in either direction. Bleriot’s exploit was proceeded by the unsuccessful attempt of another aviation pioneer, namely Hubert Latham. Designed by Louis Blériot and Raymond Saulnier, the Bleriot XI was a light, sleek monoplane built using oak and poplar wood with cloth-covered wings and was powered by the very reliable but simple Anzani 3-cylinder 25 HP engine. The plane's sporting achievements, robustness, functionality and piloting ease contributed greatly to its commercial success, and it was actually the first aircraft in the history of flight to be used in war, when Italian Capitano Piazza piloted a Bleriot during the Libyan campaign between 1911 and 1912. Sourced from Amati and Wikipedia The kit This kit is certainly not a new release, but it is one for which you can’t really find an unboxing/summary/review. After talking with Amati, we thought we’d redress that issue and bring you an article on this kit, in the style of our regular ship reviews. As you would guess from a 1:10 aeroplane, the box for the Blériot isn’t too small, with it taking up a reasonable chunk of my worktop real estate. Whilst being fairly average in weight, it’s a little top heavy with the parts packing, so careful if you prop it up against a wall like I originally did! Amati always ship in beautiful boxes, and this sturdy and glossy crate is no exception, with a very nice photo of a finished Blériot model on the lid, along with a period photo and detail image. You’ll also get a good idea of the size of this project when completed, with the given sizes being: Wingspan: 84cm Fuselage length: 80cm A note of course that the timber parts within are all laser cut, as we’ve come to expect from this and many contemporary manufacturers. The box sides contain more imagery of the finished model at various angles. Lifting the lid, you can see why the box is top heavy. Most of the parts are sitting on a card plinth within the base of the box, designed to stop the various elements rolling around within. Right on top is a large and thick cellophane sleeve containing all of the laser-cut wooden sheets, plus the two sheets of plans. We’ll look at the latter in a short while. The fist 3mm thick ply sheet contains parts for the fuselage and tail frames, plus some jigs for creating those spoked wheels. Jig parts are also included for creating fuselage sections, ensuring that the various frames etc. are correctly aligned. As you can see from the sheet, none of the parts are numbered, as you wouldn’t want that with a model whose frames are very visible timber. These can be checked off against the supplied parts sheet. Laser cutting is also excellent with very minimal scorching. Being quite light, you will be advised to stain the frames when the time is appropriate. This second sheet, again in 3mm ply, contains mostly parts for creating the wings and horizontal tailplane. Here you can see the various ribs with their notches for wing spars etc. We have another ply sheet here, but this time in a much thinner 1mm material. The larger curved parts here are the enormous wingtips, with the thin material designed to be able to create the curved underside of the thin wing. The smaller parts are mostly infills, which will then sit on top of the moulded wingtip and pack its thickness up to a more realistic 2mm. This small slip was packed into the sleeve, and it depicts the cut-outs needed in both dowel and strip for the main fixed tailplane section. This is supplied at full size for easy reference. There are three trays of components in this release. This first tray is the most obvious as it contains the large propeller/airscrew. These are standard Amati trays and the packets and parts inside are held in situ by a clear plastic lid. The prop/airscrew is finished in a dark varnish. Not sure how accurate this is, and I may consider stripping this and making it look laminated, along with a lighter varnish. The prop hub is a series of PE parts which need to be fitted. We now have several frets of photo-etch, all individually packed in thick plastic sleeves. All PE is of different gauges, but the connection tabs are quite small, so it won’t take long to remove them from the frets. A small file can then we used to smooth off the connection points. You will note parts here for the engine and engine framework etc. These are the cylinders, comprised of parts which stack upon one another, creating a cooling-fin effect. That should look quite nice when done, and beats using plastic where you’d need to remove an awkward seam. This is the material for covering the wings, tail and part of the fuselage. After being cut to size, this is applied with PVA and CA before being painted all over in dilute PVA. This will give it a smoother and more drum-like surface and of course, pull it taught. For a model which at first glance, appears to be mostly stick and string, there’s a surprising amount of photo-etch. The second fittings tray. Let’s take a look… As the aircraft has numerous pivoting surfaces and pipework, we are supplied with a range of both brass and copper tubes of various lengths and gauges. You will of course need some nails too, and some eyelets for things such as rigging. As well as brass eyelets, a bag of copper eyelets are also supplied. The bag of copper rods you see here are actually the wheel spokes, and they have a flat end on them to secure them in the jig whilst you assemble the wheels. Yet more brass nails and also brass strip parts which appear to be undercarriage related. Our last components tray. In here, we have various brass eyelets, engine components such as cylinder heads, large turnbuckles, undercarriage suspension springs, brass rod, riggings cord, plumbing parts etc. Quite a few parts here are cast in zinc alloy as they are stronger and hold detail far better than white metal or Britannia metal fittings. This little pack of curios contains parts in both timber of plastic. The cones form the ends of the large fuel tank for which you’ll need to construct a planked drum. Parts here exist for the control stick base, cylinder bases and the engine crankcase etc. Some minor clean-up of the plastic parts will be needed. Injection moulded rims are supplied for the wheels, with two per wheel. These will be assembled on the jig, and along with the brass hubs, they will be spoked just like the real thing. Minor clean-up will be needed to remove the sprue attachment gates. Large rubber rings are supplied for the tyres, and these will sit neatly into the recess between the two rings that make up each wheel. Yet more brass and copper tubes/rod. Of course, we can’t have a wooden model without timber strip. This will be used for some frames, wing/tail spars, leading edges etc. Timber quality is Amati standard, as always. Some flexible pipe is also supplied for plumbing the engine, fuel tank etc. As always, Amati’s instructions are excellent and productions all of their own. This 62-page A4 (landscape format) manual is produced in full colour with photographs that describe the various stages, step by step. Whilst the text is in Italian, there is an English translated sheet for those who need it. As well as photographs, a series of illustrative drawings helps the modeller throughout, and everything is also annotated superbly. A parts list is supplied here, as it on the English translation. Two plan sheets are included with one of these depicting various views of the Blériot for constructional reference, and also a sheet with plan parts supplied. These can be married up against the unnumbered parts on the laser-cut sheets. Conclusion Despite the minimalistic look of the Blériot, this isn’t a weekend project, by any means. There is still going to be a concerted effort needed, as with any model whose main assembly is in timber. Overall, the skeleton of the model is actually straightforward and only minimal tools will be required. Some care will be needed in covering the wings and tailplane, and you may opt to use an antique style material which is used for covering flying model aircraft wings and applied with an iron. Overall, the timber parts are superbly cut with little scorching, and the numerous PE sheets/frets will keep you entertained for many hours, as will those wheels which are built up from individual spokes. If you are a super-detailer, then you could also rig the fuselage with wire and use reproduction turnbuckles, instead of the supplied rigging cord. There are many possibilities, should you wish to deviate from an already excellent kit. You will need a large area to display this model, or it could hang from the ceiling in your study, recreating those stylish days of yesteryear. This kit is also very reasonably priced, so if those memories of the Flambards TV series or the original books by Kathleen Peyton etc. are what fire your imagination, give this kit a shot! My sincere thanks to Amati for sending the kit you see under review here. To purchase directly, click the link at the top of this article.

-

Great stuff! If you want to add to this topic by showing a few photos on how you use it with your model, feel free.

-

Still waiting on the laser stuff and PE/cannon. I do have the 30+ sheets of plans already. The Bismarck kit had to be prioritised for Nuremberg toy fair in late Jan, so I expect the parts will be sorted for me very soon.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.