-

Posts

1,130 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by TBlack

-

-

-

-

Davits in, according to the book cover painting. They look very far apart for a small ship's boat. BTW, if there is a boat on the davits, would there also be a boat amidships?

You'll notice, also, that I've started installing rigged cannons. No training tackle. As Ron Neilson (hollowneck) points out: too small and finnicky.

- mtaylor, Ryland Craze, CiscoH and 5 others

-

8

8

-

3 hours ago, Chuck said:

But having said this, the goal is to have it NOT look like a kit when you are done. I strive to make my projects look as close to a scratch built model and contemporary model as possible.

From stern lanterns to ships’ boats to huge frigates, you certainly succeed at your goal. When you have a vision, you are unstoppable!

- mtaylor and Ryland Craze

-

2

2

-

-

12 hours ago, Keith Black said:

Tom, Are the cabin walls either side of the ladders going to remain as they are now?

Keith,

I thought I would leave them as they are. This is a pretty simple craft without much embellishment, like Fair American?

- Cathead, mtaylor and Keith Black

-

3

3

-

Keith,

I decided to use your idea on the rope lanyards for the ladders:

You'll also notice that I have installed the cap rail, the top rail on the transom and the gratings. The overall photo:

At this point I need to install the aft davits. Then the rest of the construct is pretty much the same as the kit with the exception of an elm tree pump in the bow (I have no idea why, but it's in the book.) The book also mentions royals which I am not going to include, having decided that O'Brian made a mistake.

- ct mike, Bill Morrison, Keith Black and 4 others

-

7

7

-

nice metal work. Invisible seams!

- mtaylor, FriedClams, Keith Black and 2 others

-

5

5

-

On 3/26/2023 at 8:04 PM, Stuntflyer said:

In the end I went with a Sherline tilt table which is predrilled at the factory for attaching the milling vise. It has an angle gauge in one degree increments as well. Thanks, guys!

Mike

Mike,

Interesting setup, but you do have to trust the angle gauge to be accurate Any way to double check the angle?

Tom

- Stuntflyer, mtaylor and FrankWouts

-

3

3

-

Nick,

I have a Unimat SL1000 lathe, which is not made anymore, but is available from time to time on EBAY. Also, I have a Sherline mill which is very well made and the company provides great customer service. I would assume their lathe to be of the same quality. You'll need to think about what kind of cutters you'll need, as well as a dead/live center, self-centering 3 jaw chuck. Maybe nice to have is a DRO setup, and a compound slide.

Tom

-

19 hours ago, Keith Black said:

You also can anchor your elbows and steady shaky ole hands.

Keith,

I know about those.

Tom

- mtaylor, Keith Black, FriedClams and 3 others

-

6

6

-

Wonderfully detailed description, with product links; fabulous!

-

2 hours ago, Spooky spoon said:

I've also been looking to buy some books (I know Lee is very highly regarded but it seems to be out of print here).

Spooky,

I saw this comment, and I thought, "Well, I'll just buy it down here and send it up there for him". Amazon has a used copy for $154.00! That was the end of that idea. The other option is to scan the build logs of Ed Tosti, David Antscherl, as well as Hollowneck. Probably others that escape me right now, but they all show you both what to do and how to do it.

Tom

- Spooky spoon, mtaylor and hollowneck

-

3

3

-

-

I’ll underscore your discipline, and perfection. Good going!

TB

- Dave_E, Knocklouder, FriedClams and 2 others

-

4

4

-

1

1

-

Ooh! Much better solution, but I can’t see how the rope is secured at the bottom. BTW, this is why mom always liked you best. She recognized your perspective and precision, not to mention your good looks!

- Keith Black and Oldsalt1950

-

1

1

-

1

1

-

-

I've gotten the balusters installed:

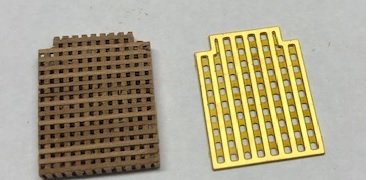

Before I put the rail on them I thought i would install the cap rail. I can't use the ones provided in the kit, because they are not the right shape. I need sheet stock 1/32" thick - not in my inventory. Which to buy pear or cherry. Pear is $12.50 per sheet and cherry is $5.00. I'll let you guess which one I've bought. While waiting for its arrival, I started working on deck furniture, specifically gratings. The metal etched gratings provided in the kit have openings that are 3"+ which I thought rather large, so I made my own:

My openings are 2" which is more to my liking.

Tom

-

15 hours ago, dvm27 said:

Congrats on the purchase of the Sherline lathe, Mike. There are a million useful accessories but personally I find the 90 degrees angle plate and rotary table the most useful. .

I've also found the slitting saw most helpful, especially if you have the DRO capability.

Tom

- mtaylor, dvm27, Stuntflyer and 1 other

-

4

4

-

The other interesting thing is the side table under the forward windows. Apparently the top comes off to reveal various piloting controls.

Tom

- mtaylor, KeithAug, Keith Black and 1 other

-

4

4

-

-

Keith have you seen this?

https://www.yachtworld.com/yacht/1901-custom-pusey-$-jones-steam-yacht-8030108/

Tom

- FriedClams, druxey, Keith Black and 1 other

-

3

3

-

1

1

-

Keith,

You've got a good idea. I'll need around 10-12. They are 11 mm high. Model Expo has what I need, I think. Anyway, ordered a bunch of their stanchions. Thanks

TB

- Keith Black, Cathead, mtaylor and 1 other

-

4

4

-

Keith,

I tried that approach with a razor blade attached to the tool post of my unimat lathe. The height is wrong and the blade flexes too much. Got any suggestions?

- mtaylor and Keith Black

-

1

1

-

1

1

Cyclone-Class Destroyer 1902 by Valeriy V - scale 1:45 - Russian Imperial Navy

in - Build logs for subjects built 1901 - Present Day

Posted

Really clever. This log keeps getting more and more amazing!