-

Posts

781 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ChrisLBren

-

Hey Kevin, We are all our own worse critics - trust me - I almost gave up on my Confederacy build a half dozen times - mostly because it wasn't meeting my own perception of "perfection" Stick with the build - again I admire anyone who can build like you with plastic - lord knows I can't….. Happy holidays, Chris

-

Looks great Rusty - i can't tell from the photo - do you have a top finish on it or not ? Ive seen the dyed used with or without - personally i like a bit of glow on my dyed wales so in my case Danish OIl Worked well as does Tung Oil. Im sure Wipe On Poly wood have a similar effect.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Rusty, Good luck with the Fiebings - love this stuff - just make sure to mask everything - it splatters easily. Chris

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Nice work Bob ! I know how tricky building those lights can be from my experience on Confederacy. Really well done

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks man - I'm merely imitating Bernard Frolich's approach - using boxwood, swiss pear and dyed swiss pear to resemble Ebony - all woods sourced from Hobby Mill - which I can not recommend highly enough.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Thanks guys - next up the head timbers - which should be fun/challenging. I've got plenty of 1/8 costello boxwood! Then its really all down hill from there to finish her up.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Thanks Chuck and Mark ! Trail board is dyed swiss pear and the humanity - thanks to you Chuck - are your resin copies painted to resemble boxwood. Now if one day I can carve as half as good as Chucks sculptures…..

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

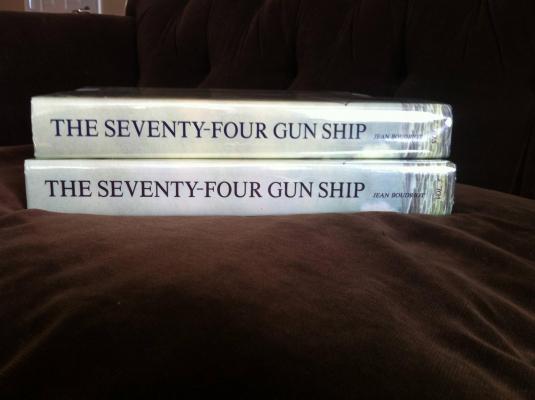

They arrived today - Volumes 2 and 3….. Now I can become an expert on French Naval Architecture thanks to Mr Boudriot!

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Thanks Bob ! Appreciate you checking in - I've always admired your work - and watching your progress on Essex.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Thanks Ben - was just editing a better photo when you sent your reply. Honestly i think carving is the most important skill for scratch building - making frames and repetitive assemblies doesn't scare me with a full frame build - its being able to do justice to these gorgeous vessels with sculpture - which is what draws the eye - thats the artistry. Im feeling semi OK with carving rails/filargee - next is being able to carve humanity and not relying on Chucks beautiful resin copies painted to resemble wood.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Hey Kevin, Enjoying watching this build - I'm horrible at plastic models - in admiration. Growing up every weekend my Dad would take me to the hobby shop to buy a Tamiya or Hasegawa kit that I would trash. Most recently I destroyed a Pocher Monza back in 09. Damn - sticking with wood... Chris

-

Hey Ben, Looks great - perfect proof of concept - now the big question is - are you completing Confederacy or jumping to the Pegasus ? Congrats! Chris

- 147 replies

-

ancre Le Commerce de Marseille by Zbigniew

ChrisLBren replied to Zbigniew's topic in - Build logs for subjects built 1751 - 1800

Wow - beautiful work !!! I recently purchased this monograph - I'll be following your log closely, Chris

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.