-

Posts

789 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ChrisLBren

-

The Bitumen Experiment

ChrisLBren replied to ChrisLBren's topic in Painting, finishing and weathering products and techniques

Mitchel - this thread is about finishes not shows. JerseyCity - i bought this Bitumen thru Ebay UK -not sure if its avail in the US. Gaetan your expert advice/input is always appreciated ! And Nigel - yes you are spot on - Dimitry's 74 model and his advice are my influence on this finish. The Bitumen works as a wash. Just a few kinks to work out - but I'm close..... -

Hi Group, I've been playing around with my typical finish -3 Coats Pure Tung Oil (first one cut 50 percent by mineral spirits) and I've added Bitumen to the top coat and here are the results - thanks to Dimitry on the Russian forums for giving me this tip to age wood. No simulated caulking added here - just wood sanded to 600 and then finish applied This is the finish I will apply to my next build - La Jacinthe in 1/36th. Ive added some photos to compare this new technique to my usual on Confederacy. Your thoughts as always are appreciated, Chris

-

Thanks for the feedback everyone - my first preference is to do brass pedestals on an ebony stained display board. I think it can be done - Ill just need an assistant to hold the ship steady on the work table while its partially off its building board. Ill have to duck under the table and drill each hole in the keel from the underside with a pin vise. I've ripped out the fenders and am re working them - i wasn't happy with the angle on the hull and one of them got a bit blotched by some Fiebings dye at the rail on a touch up. I'm going on 5 years now on this build - might as well not compromise now. i have built a jig on my vise to make bending these parts easy and hope to have both sides wrapped up and on to gunport lids after Labor Day.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Im looking forward to following this build Jack. I love Frolich's model in Art of Ship Modeling - I've often considered this one myself. Some of the Ancre monographs do not provide drafted frames, Le Cygne, Venus, La Belle Poule and La Jacinthe all come to mind - nothing wrong with building them plank on bulkhead. I agree with Frolich that a fully planked model like this one will look really good masted, rigged and fitted with sails. Im considering La Jacinthe as my next project with a similar approach built POB. Take care, Chris

-

An update ! Ive committed to setting aside an hour a night 5 days a week - and Ive added the fenders and ships ladder. The fenders were tricky to get right - I used an old planking iron to get the correct bend to fit flush with the hull. After i add the channels, I suppose i need to start thinking about some sort of stand - open to suggestions - Im bummed i didn't predrill the keel to accept rods so i can use brass pedestals.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

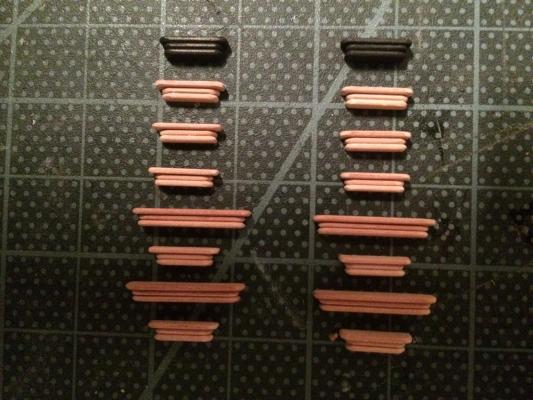

Thanks guys - top ones are pear dyed with 5 coats of Fiebings Leather dye. I'll apply a base coat of 50/50 diluted pure tung oil to the other steps before installing them to the hull and then finish them off with pure tung oil as a final coat.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Well at last made a few hours of modeling happen this weekend - boarding ladders completed and ready to be mounted on the hull. Baby steps - feeling re energized to wrap this one up.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Thanks for the input Toni ! Your build is coming along so nicely. I really love this little schooner and want to build her. I did rip out some wood this morning for the boarding ladders for Confederacy - so we will see if this helps re motivate me to finish her.

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Hey Mark, Frolich chose to draft frames and build it over a plug (much like building a ships boat) in the Art of Ship Modeling. The most common approach is to use bulkheads - this Monograph is designed to be the introduction to ship building for novices. You could probably cut out all 11 bulkheads and former with your scroll saw over one weekend easily. Chris

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Actually the monograph depicts 11 bulkheads for a POB approach - no drafting necessary Mark !

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Thanks Michael and Ben for your feedback. Ben - cross sections aren't really my thing at the moment. What's attractive about the La Jacinthe is that it is an elegant little ship - @ 1/48 the hull is only 19 inches long and rigged and masted it would be 30 inches. Its shouldn't be too much of a challenge/stressful - but a great ship to focus on perfecting the basics while learning some new techniques. I really want to fully rig and add sails to a model. Theres some modest carving and metal work. And only two guns. If done right this ship can be a museum piece. This example won many awards in Europe. http://5500.forumactif.org/t1490-la-jacinthe-de-snarlev-au-1-48eme Based on my schedule a 120 gun monster is off the table for the next 18 years - I am going to give Confederacy a go again this weekend and see if i can get re energized. But I've been in love with this pretty little schooner for some time now. So we will see, Chris

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Thanks for the responses guys - honestly because my time is so limited - maybe a more complicated full frame build is not the answer - but rather an easier subject where I will see payoff a lot sooner - and I can focus on improving the fundamentals (planking, metal work, rigging, and possibly sail making etc). I've had my eye on this beauty for some time - Frolich built this one and called it a "ship modelers holiday" between lengthy builds in "The Art of Ship Modeling" The price is about the same as enlarged plans of Le Gros Ventre @ 1/36th http://www.editions-ancre.com/Product.aspx?ID=3807269&L=EN Thanks for chiming in Mike - you know my world right now !!! Chris

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Thanks Nils. Group I am stuck - I haven't had any motivation to build (which is a shame because I can see the finish line on this one). I used to work on Confederacy every day when I started her in Nov of 2009. I do have 18 month old twins and can use that excuse but there are others on this board in the same situation as me. About the best I've done with Confederacy lately is dust her off. I still follow builds on this site as well as the Ancre site and do research. I'm wondering if I should just go ahead and buy the Le Gros Ventre plans blown up to 1/36th from Gerard Delacroix (I already own the monograph and plans at 1/48) and and start assembling some frames on that build. Maybe sawing some wood for a new project will get me motivated again about ship modeling and enthusiastic about wrapping up Confederacy. This lethargy has nothing to do with not being happy with my build - in fact this one is the first build I'm proud of. Can anyone else out there relate ? Chris

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Hi Gaetan - Curious about this Hahn build - what ship is this ?

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi Jay, My process with pure Tung Oil is simple - apply first coat thinned 50 percent with mineral spirits (this is key for your base coat for maximum absorption) - let dry for 24 hours. Lightly steel wool with 0000 - then apply second coat full strength - let it sit for 10 -15 minutes then buff with t shirt - watch for seepage (you shouldn't get much - since you thinned your base coat). Again let dry for 24 hours - steel wool and apply final coat full strength and remove excess after 10 minutes or so. Let dry 24 hours and you're done - I don't steel wool final coat. Keep in mind this is using pure Tung Oil on a hardwood (in my case Pear) - you should be good to go after letting the final oil coat cure for a few days. I've never had a problem glueing a part to a surface i have applied this finish to - again you do need to sand or scrape the area you will be glueing the part to - then just reapply some oil after the part has dried - works like a charm. Chris

-

Looks terrific Remco - cant go wrong with Fiebings. Personally i think treenails standing out against dark/black wales looks odd. Subtlety is always better. Chris

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Hi Mike, Kit bashing to me always sounds way more difficult than just buying a scroll saw, quality wood, source whatever fittings you need (from Chuck for instance), and doing it yourself with solid plans (smile). Look forward to watching your progress ! Chris

-

Looking really nice Danny - I'm at a similar point on Confederacy - i know how difficult it is to scribed parallel grooves on the headrails and cheeks. Ben to answer your question - swiss pear is softer to carve than box. Euro box is the best if you can find it, costello box almost as good. I had some costello crumble on me while attempting these rails on my build. Can't imagine them coming out half as good as yours Danny in swiss pear - kudos ! Chris

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.