-

Posts

541 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FrankWouts

-

Again such a lovely and beautiful build with such amazing warm wood colors… I rather like the variance in plank colors by the way. Considering ships where build in months or around a year time or maybe some more, shipwharfs weren’t selecting their planks in the right color tones too I guess... They were happy when they got the right and enough wood in time… So too even and perfect wood coloring isn’t that realistic in my opinion. Time will solve the color variance though, lighter becomes darker and darker becomes lighter. You simply will have to grow older to witness it Rusty… Frank.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work and almost there Mike! Great to have a such a beautiful build as yours with clear explanations to follow! Frank.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Joe, it's only a small correction in my opinion, so please do so, as your build looks very, very good and will turn into a beautiful Winchelsea when finished. Keep up the good work and don't be afraid of posting mistakes, I posted quite a few myself and got plenty of help on this build log, which it is all about! Cheers! Frank.

-

You're making great progress and looking gooed Gary! Keep up the good work, I'll stay tuned! Frank.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You're making great progress Glenn, all looks fantastic and I'm following with great interest! I hope to catch up someday, I don't seem to have as much free time as you do 😉 Frank.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful progress Glenn! Frank.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nice progress and beautiful work Matt! I always shake my little bottle or tube with CA gleu before using it. For some reason the sticky part of the emulsion sinks when the bottle or tube is in rest for a longer period of time. You then do not only apply only solvent instead of the full glue emulsion. Frank.

-

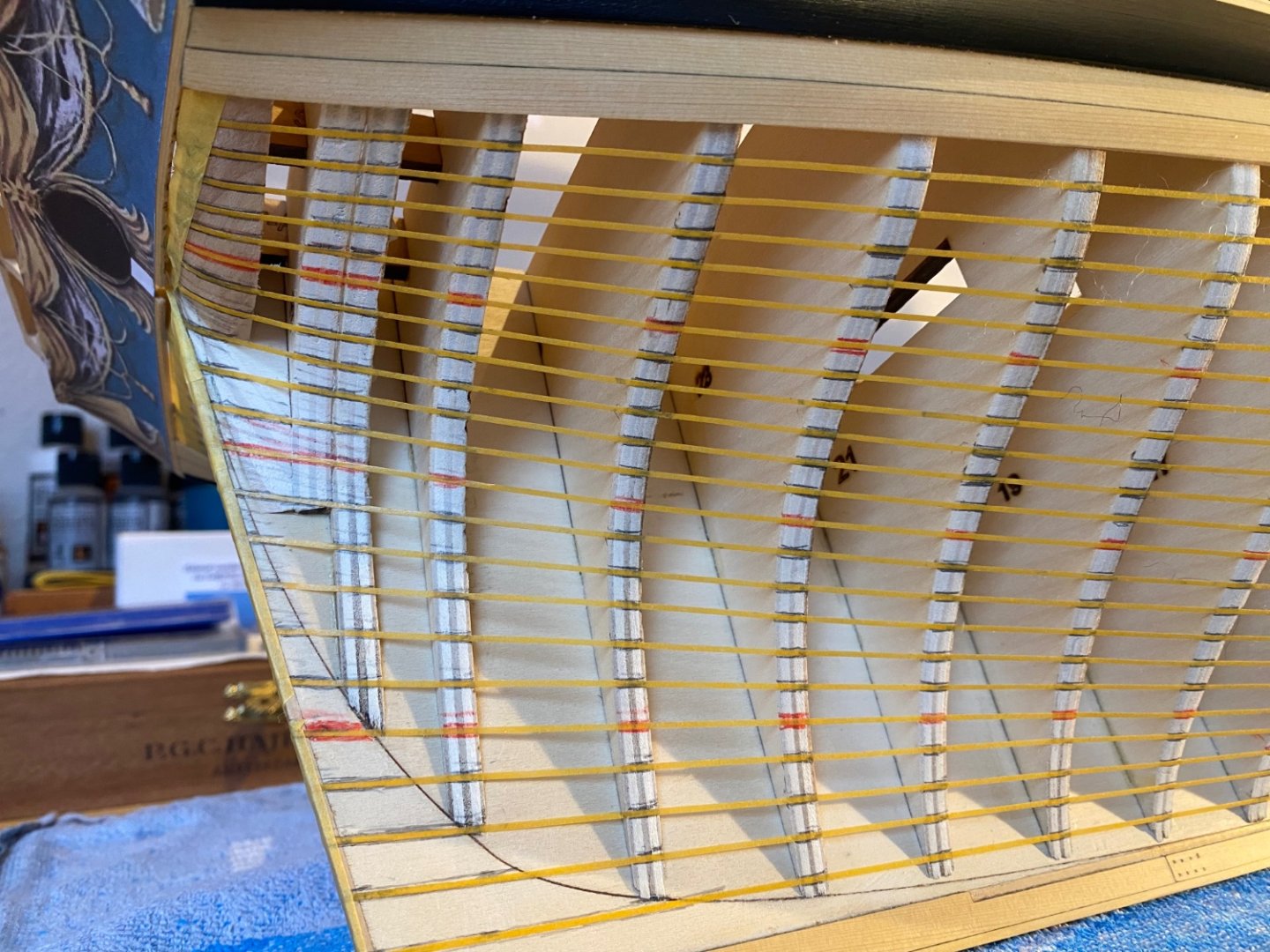

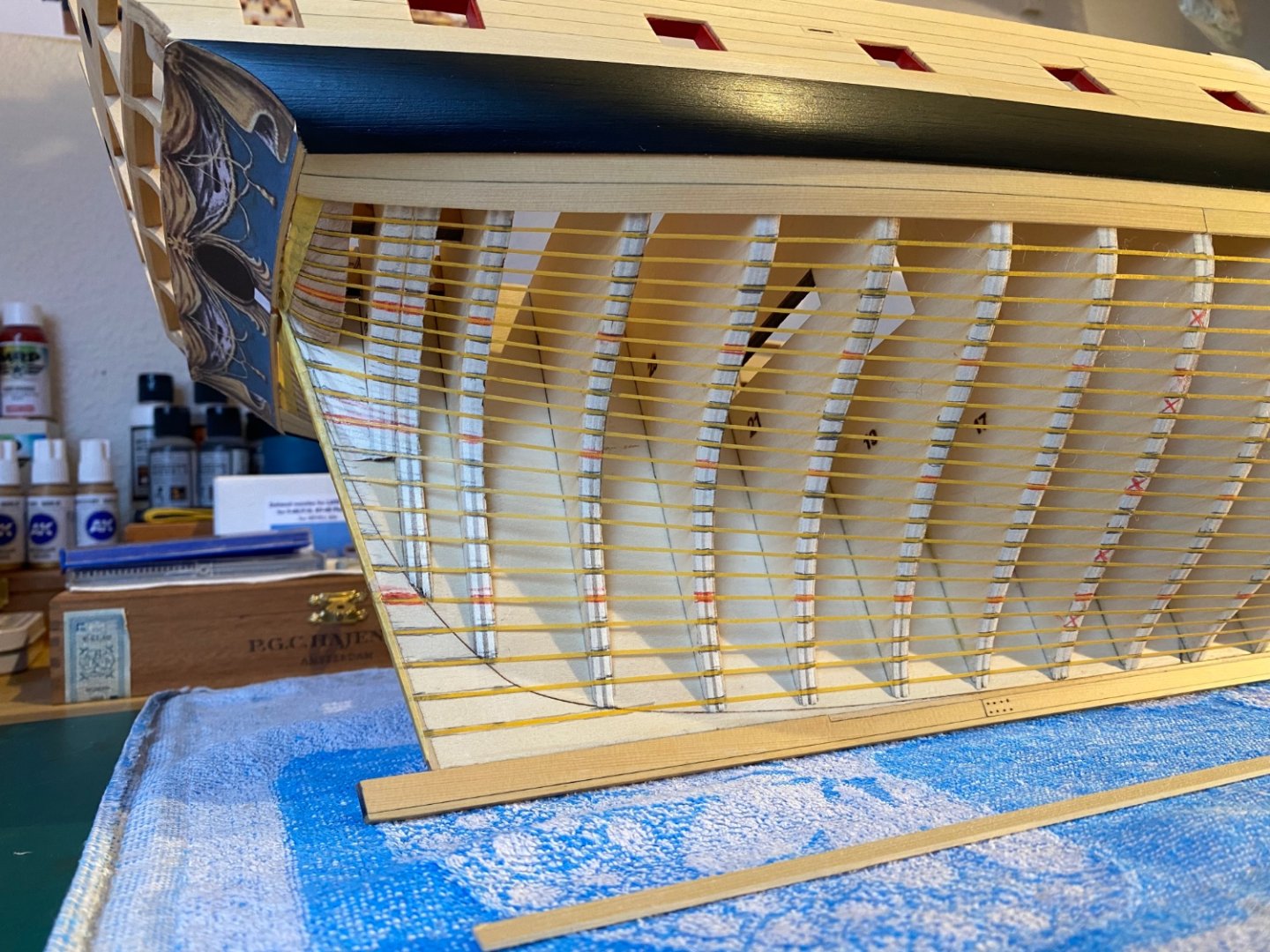

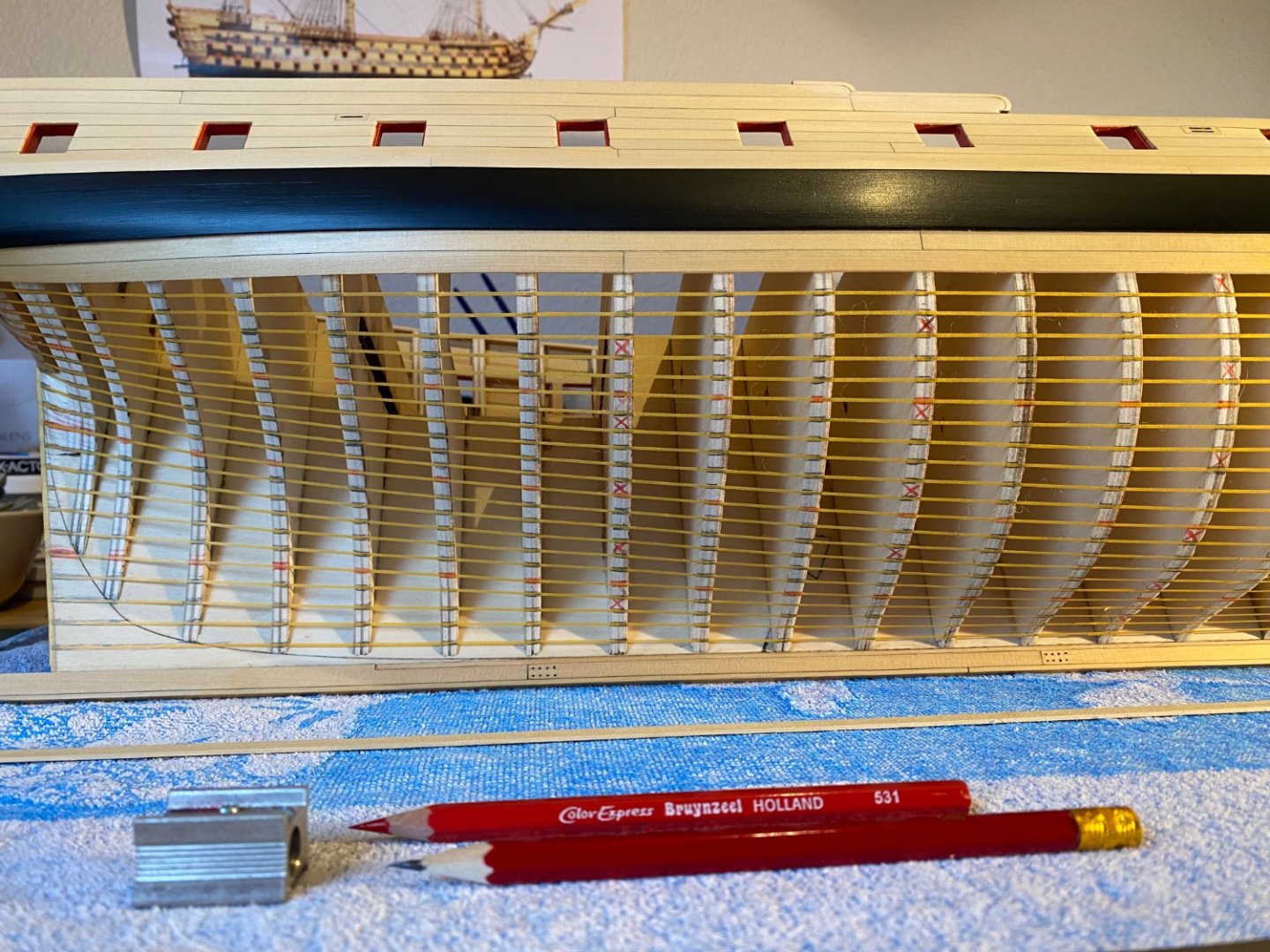

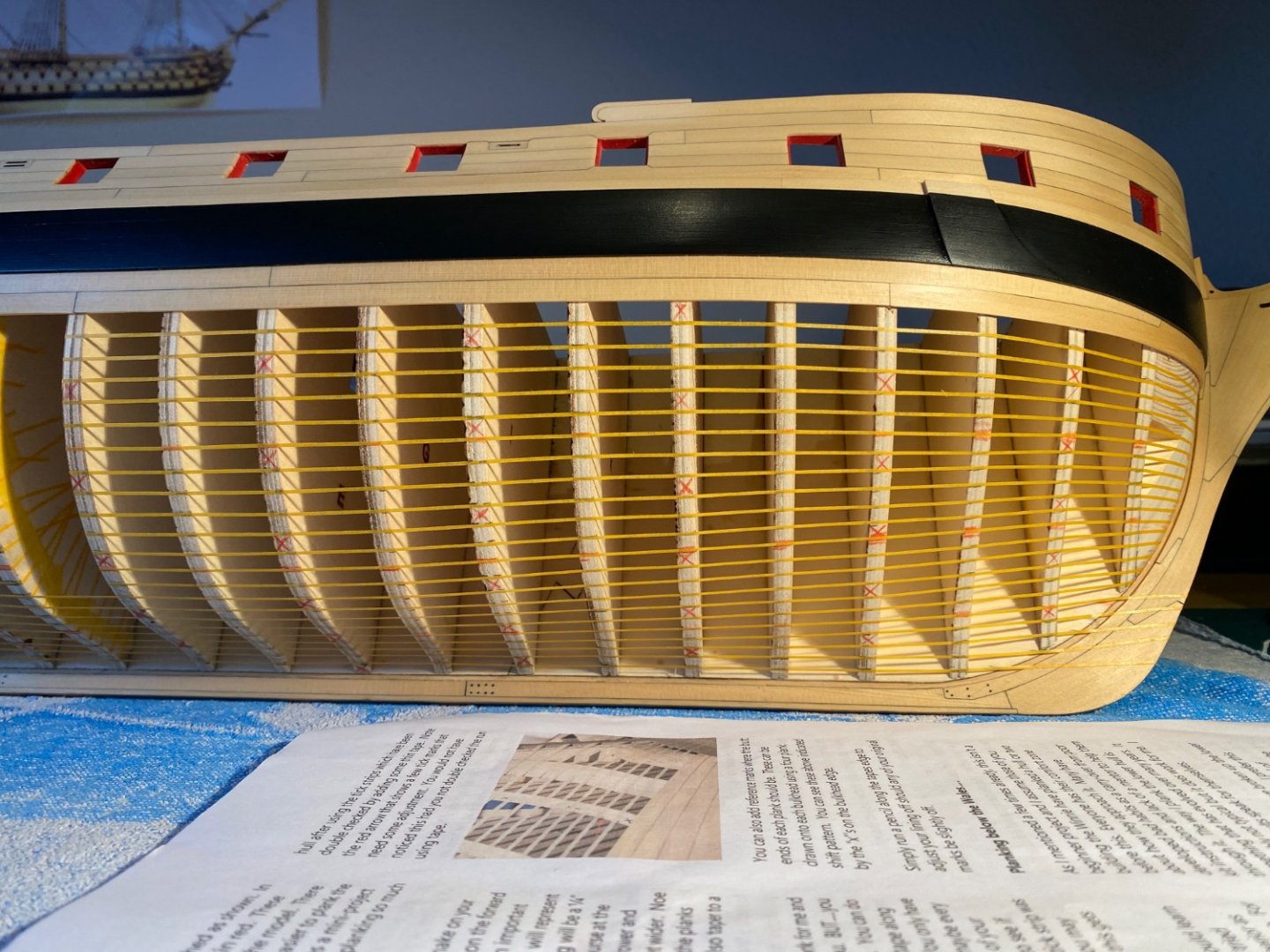

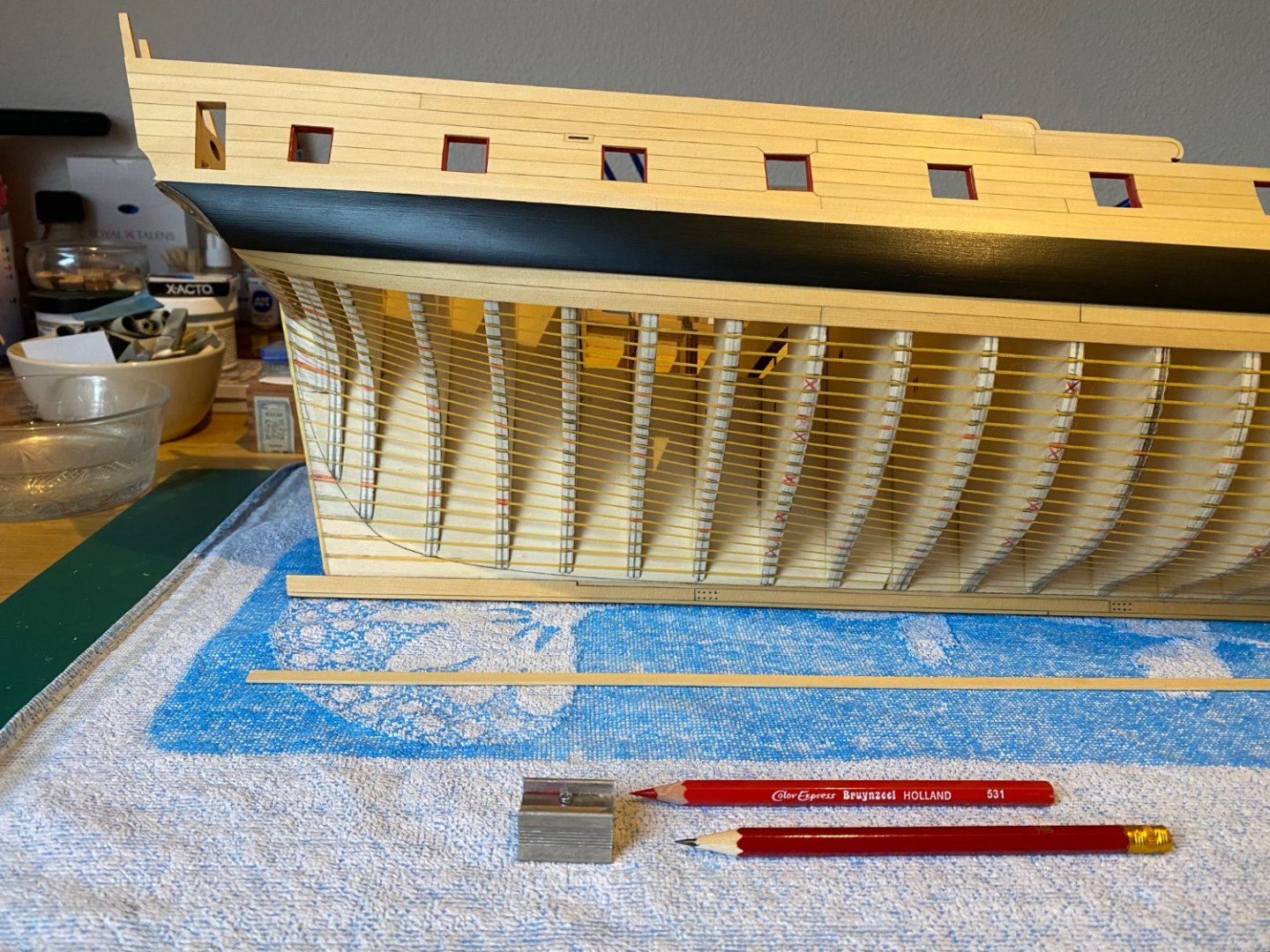

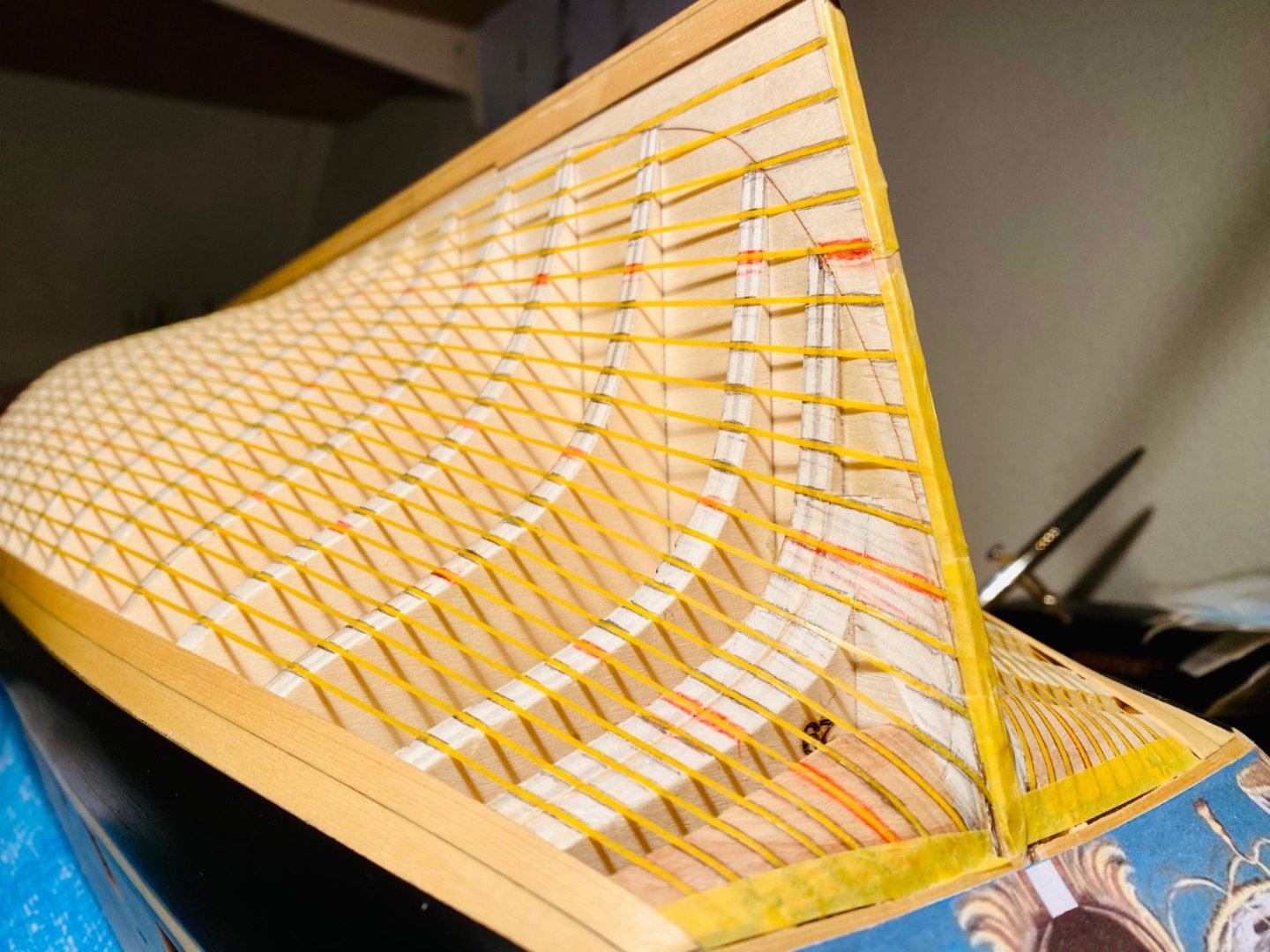

Thanks Chuck, Here some pictures of my beginner’s planking layout…It takes a very long time this way, but I just want to get it right…hopefully no anomalies anymore…I’m eager to start planking now after all this fiddling with fine tape and pencil…though I still have to find some plank joints and mark with a red cross… and tweak some tapes to an average in lining and spacing now that I look to these pictures.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.