-

Posts

541 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FrankWouts

-

Beautiful work and very steady progress Glenn! Frank.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

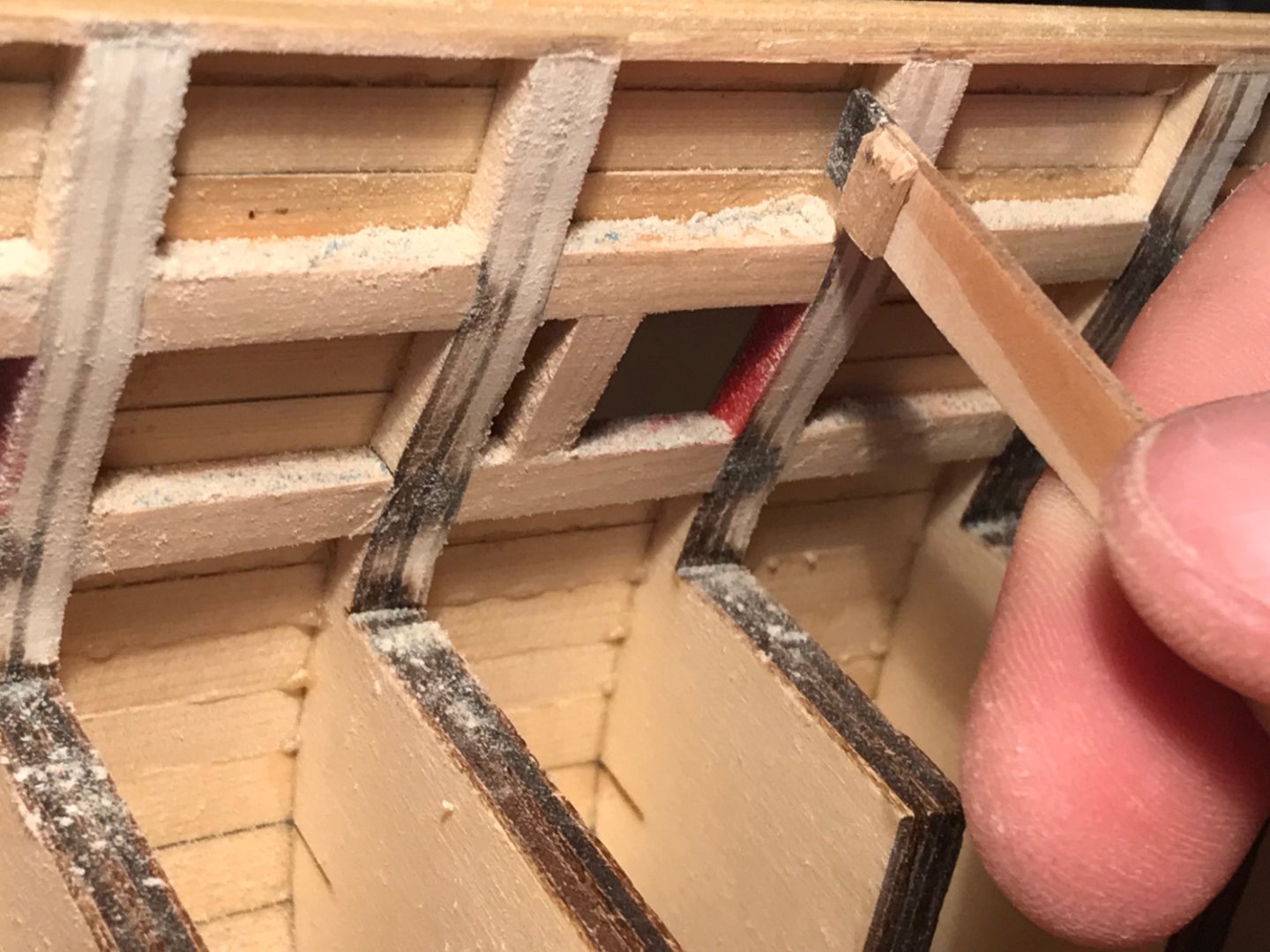

I finally finished chiseling and sanding the inner gunport framing…man, what a lot of chiseling and sanding that was…it took me weeks…I’ll check the thickness at every frame again though before planking it later on. I’m now trying to line off the lower hull… I hope I’m doing allright like this using Chuck’s tick strips. Frank.

-

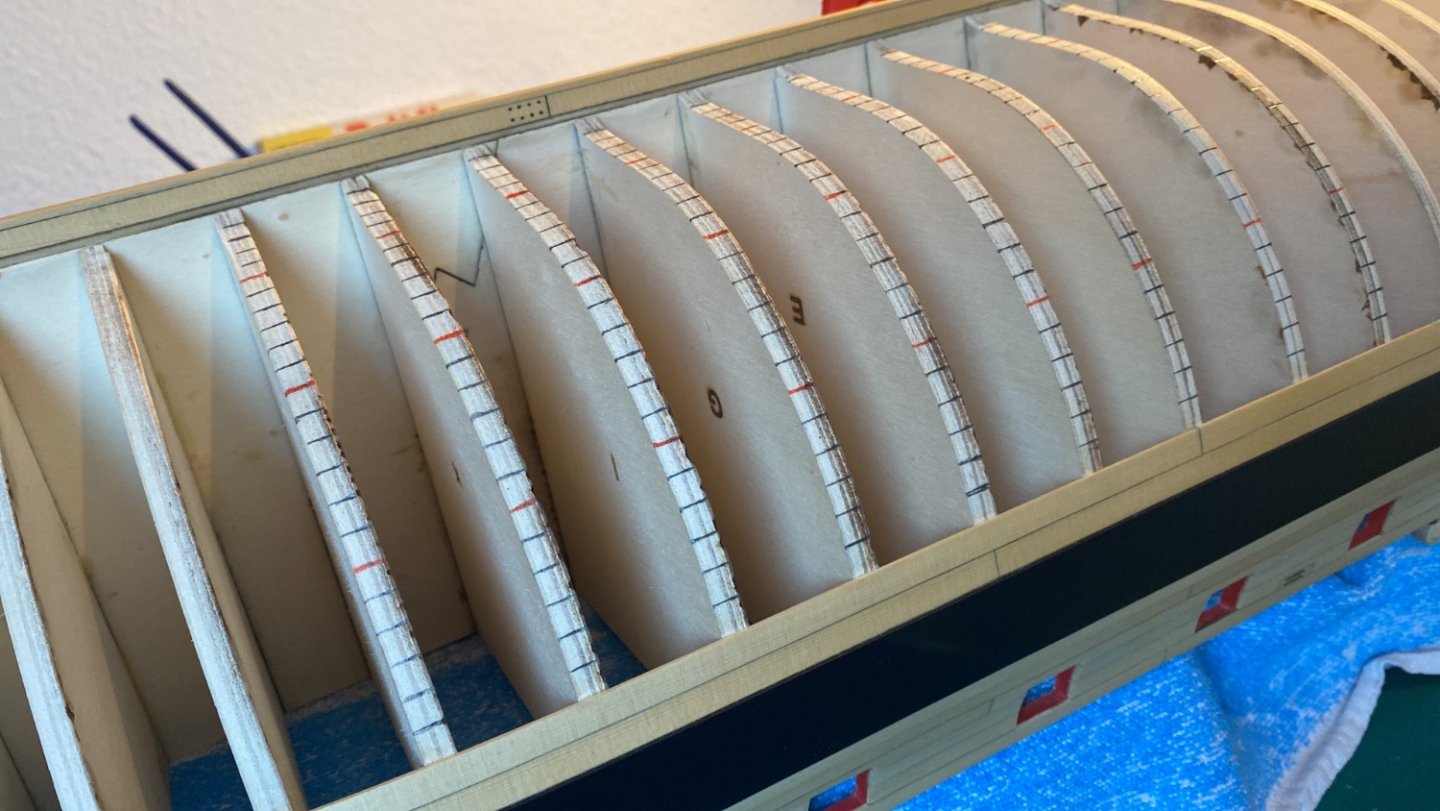

Hi all, I’m almost at the point of planking the underside of my Winchelsea hull. But first I have a question about fairing the inside of the hull above deck level. It says the inside should be faired till 1/8”. I have made a wooden rudimentairy 1/8” measuring device as seen in the photograph. But is this from top to deck level the same? Shouldn’t it be a hair more than 1/8” on deck level? The bulkheads all seem to be cut that way as well and with POF models one also sees the thickness taper gradually. Thanks, Frank.

-

Congratulations on your exquisite achievement, a beautiful work of art and inspiration for us all! She’s a real beauty! Frank.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Great the chimney is safe now Rusty and great tip keeping the inner curvature of that deck planking the same and symmetrical while adjusting the outer curvature to the inner bow. I spent most of my time measuring to keep as symmetrical possible portside and starboard...but in fact when getting the micrometer at it, our wooden models are asymmetrical wonders (they're not plastic kits as Chuck said)...and yet they're beautiful, specially yours with these warm pear tones and teints of red... I love your build! Frank.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Mostly blockades or sieges of harbours, effectively enough...though I believe Toulon could be recaptured on the English/Spanish in 1793 by good old emperor Napoleon without firing a single shot at any English ship in harbour....so no harm done then to any mouldings too, which was a good thing! https://en.wikipedia.org/wiki/Siege_of_Toulon_(1793)

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work Glenn! I'm again astonished how you can keep up this pace of working and still deliver such quality work! You much have six fingers on each hand.... Frank.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

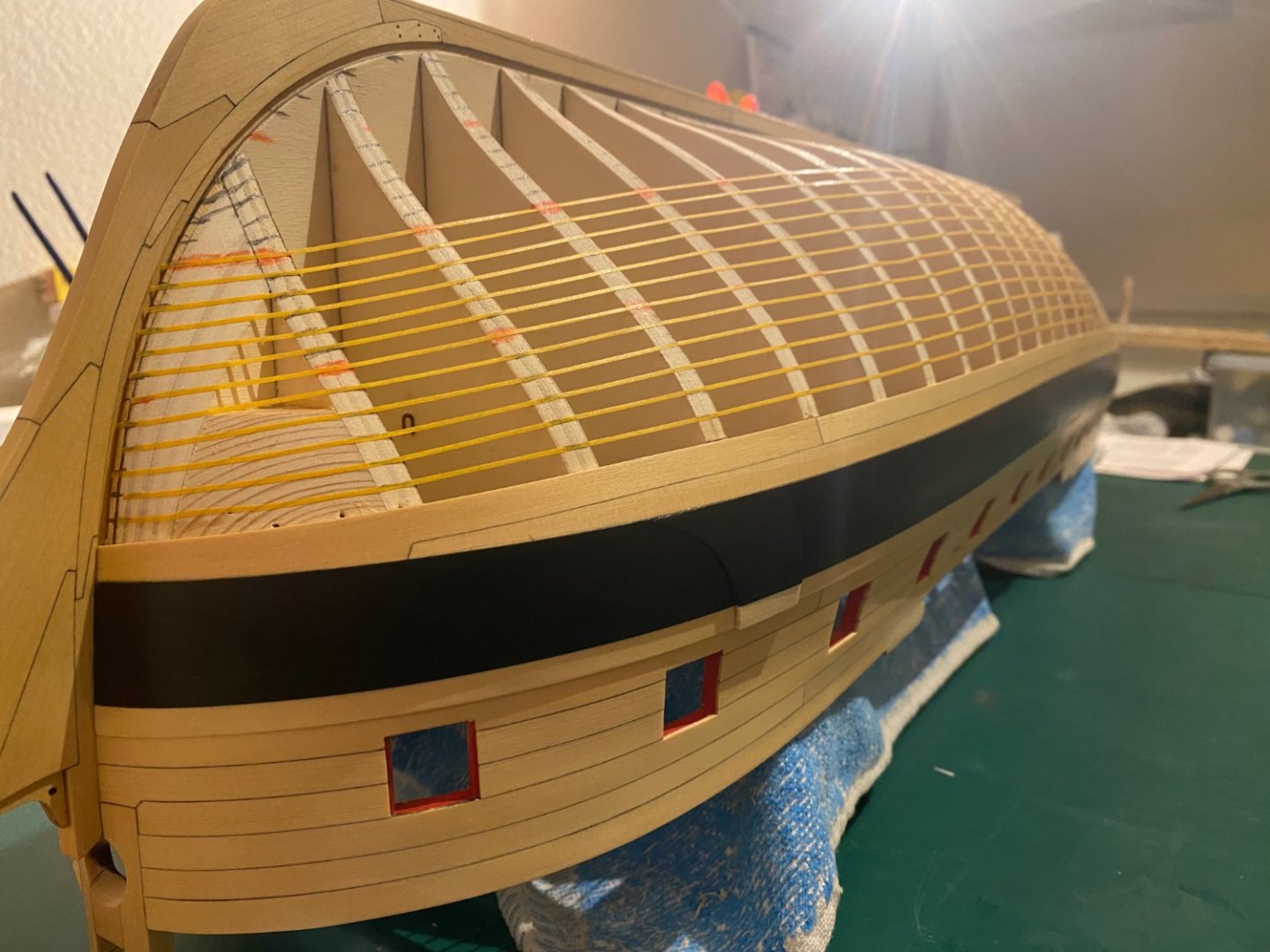

I’ve been away for a while with work, family, holidays, but am still very much committed and finally have some spare time to pick up my Winchelsea project again. First learned to use my Byrnes thickness sander, switch sandpapers with different grid and how to sand sheets and strips to the correct thickness without shooting sheets and strips through the room….I learned this by experience ofcourse… Both starboard and portside whales finished and painted now. Only portside blackstrake still has to be and will be done this week. Frank.

-

Hi Gary, I may understand you wrong, but are you going to paint the first layer of whale planks black? That's not necessary, you only have to paint the second layer of planks. I think it's more necessary to sand the two outer stern frames thinner at the top, check the dotted lines on the plans of the stern framing. It might be the picture, but in the picture the top of the outside of the outer stern frames seem a little too thick still. This will give problems with the positions of the outer two stern windows as I understand. Frank.

-

Beautiful work Rusty, I love the warm colors on your Winnie, and on such an exact and clean build they're a treat for the eye! Frank.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.