-

Posts

1,871 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MEDDO

-

I am pretty dangerous with the power tools. Will need to take it slow if I decide to use it. Probably over multiple sessions a little at a time. Steve did you use a drum attachment or a disk?

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

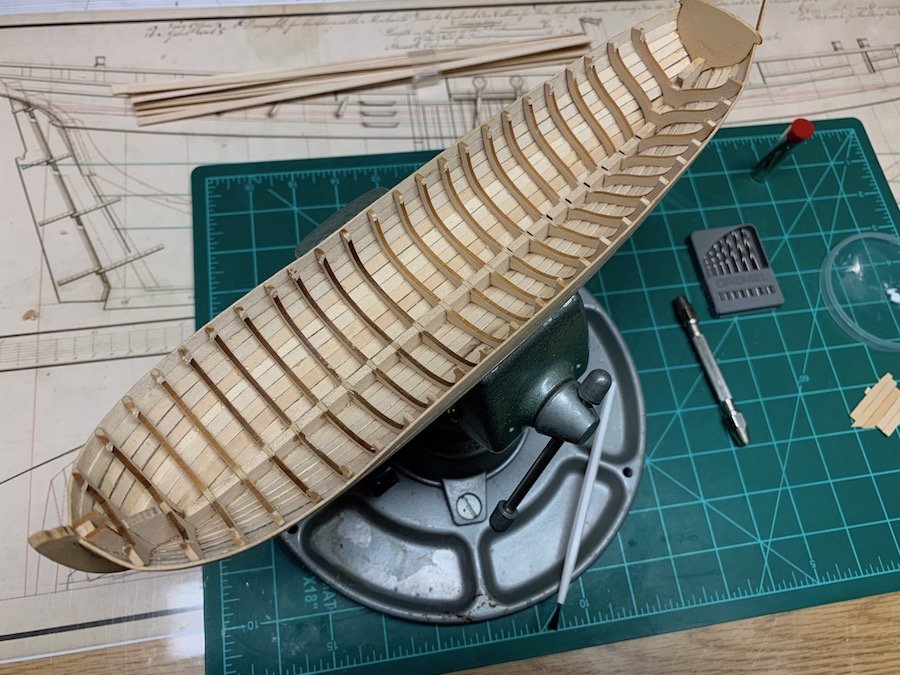

Wipe on poly to the outside. I decided not to go ahead with the treenails. Tried a few on a scrap plank and just wasn't getting great results. May rethink that later but for now just leave it alone. I did spend the day removing the center tabs. Now onto sanding and thinning out the frames

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

Plank length for longboats

MEDDO replied to tkay11's topic in Building, Framing, Planking and plating a ships hull and deck

Would also like to see a build log for this. Tony, are you going to rig this? M. Delacroix also sells the sail and rigging plan for this on his site. -

Excellent view there. Do you worry about the sunlight causing some fading/damage through that window?

- 692 replies

-

- eagle of algier

- chebec

-

(and 2 more)

Tagged with:

-

The serve-o-matic came together nicely. One issue I had was when it came time to glue the 'back' gears to the tube I used CA as suggested in the instructions. I accidentally ham-fisted it and slid the gear just a little too far up the tube against the support. Of course the ca bonded instantly. It didn't glue the rod to the support but the pressure is just a bit too much so it didn't rotate freely. Solution was to debond the support and move a mm out and worked fine. Every time I touch CA is a disaster.... I also like the Medway longboat but also need to focus on what I already have. Look forward to seeing your progress here on this kit. Seeing how well you did with the pinnace and the longboat I am sure this will be another impressive result

-

Yup. Steve I was thinking that. I have been going over some previous builds here (yours, BE, MikeB4, and Mike Y) and trying to decide. Done properly they are hardly noticeable. Done poorly they stick out like a sore thumb. Too big or too dark...yikes... On the other hand this is an experimental/learning build for me so at least trying on something like this will give me some good experience. I will definitely be treenailing the Cheerful/Echo/whatever is next

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

So now... To treenail or not to treenail, that is the question... Eventually plan for wipe on poly, seal, and then painted white bottom

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

I have been using the kit supplied basswood on the Pinnace. It is really brittle and dry and not uniform throughout. I have been using amodified Chuck method for the bends. First I soak the wood in water just for 30sec or so just to get it damp. Then I clamp it to a flat piece of something (here it is some fiberboard). Using a bunch of clamps and bending it a bit each time. Need to be careful as then wood will tend to rise/curl up on the inner radius a bit. I just use a clamp to smash it down. There is a fine line between this and the wood either folding and/or splitting. After a few you get a feel for the limit. Once all clamped up I then use the heat gun to warm the whole thing a bit and then alternately remove a clamp and dry the wood in between. Once dry replace clamp and then do next clamp. Once entire piece is dry I remove all clamps except for the 2 on each end and then go over the wood again with the heat gun to make sure it’s dry then it is done. Then wood does spring back a bit but if I needed you can repeat process for greater curve. The edge bent basswood piece below was made in less 5min. One thing though I am using a heat gun and not a hairdryer. It will definitely burn you and it scorched wood a couple of times when I got too aggressive. Also kinda melted the edge of the plastic clamps a bit.😳

-

You can find a basic summary (about 300 pages) in John Harland's Seamanship In The Age Of Sail. Very nice descriptions and diagrams for ship handling.

-

Nice use of the saw. It seems that it can provide a nice joint.

- 152 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Getting Back Into The Hobby After 45+ Years

MEDDO replied to Tom in NC's topic in New member Introductions

Welcome! Nice model! I like the walking beam engine vessels. -

Great work there. I know if I tried that for sure be rounding over the corners.

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

So first planking job somewhat symmetrical. It is going to need a few spot dust/glue fills but not too many. Need to practice a few more times.

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

After a bit of cleanup and a touch of sawdust/glue filling I think it will look better. Last plank only needed the front clamp... it was a really goofy shape...

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

Just 2 more to go. This wood is giving me angina. If it is not splitting then its folding over when bent and it is so soft if you even look at it wrong it dents. I guess I am getting a bit better as I need less clamps for each one.

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

Echo by davec - FINISHED - cross-section

MEDDO replied to davec's topic in - Build logs for subjects built 1751 - 1800

Looking good Dave. Definitely like the contrast in woods.- 127 replies

-

Impressive work and very inspiring. Eventually will be building this and will be referencing your build for sure.

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ryland, will be nice to see the start of this project.

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Dave. Now the real tapering begins. At least the next ones will not have such a massive edge bend on them.

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

-

Thank you Kevin. I am learning this stuff as well. My last few models haven't had any planking so this is basically a first for me.

- 90 replies

-

- english pinnace

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.