-

Posts

2,482 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by JSGerson

-

-

-

Nikolay - If you are referring to the tapering at the bow and stern, I bent the planks first, then tapered them to fit. I knew how wide the planks had to be at each bulkhead and sanded them down by hand till they matched what I had calculated prior. The planks were tapered no more than half the original width. Because I had already formed the plank curve prior to tapering, I did not induce much stress to break the wood.

- JeffT, Nirvana and Ryland Craze

-

3

3

-

- usedtosail, Ryland Craze, J11 and 1 other

-

4

4

-

Well, I got lucky. I was able to slice off the excess portion of the stove hood as disassemble the back plate from the remaining portion of the stove. The stove was held together with PVC glue because it gave me a chance to make final adjustments before the glue set. I had used just enough glue to hold everything together but not super bonded that I could pry it apart.

- usedtosail and Ryland Craze

-

2

2

-

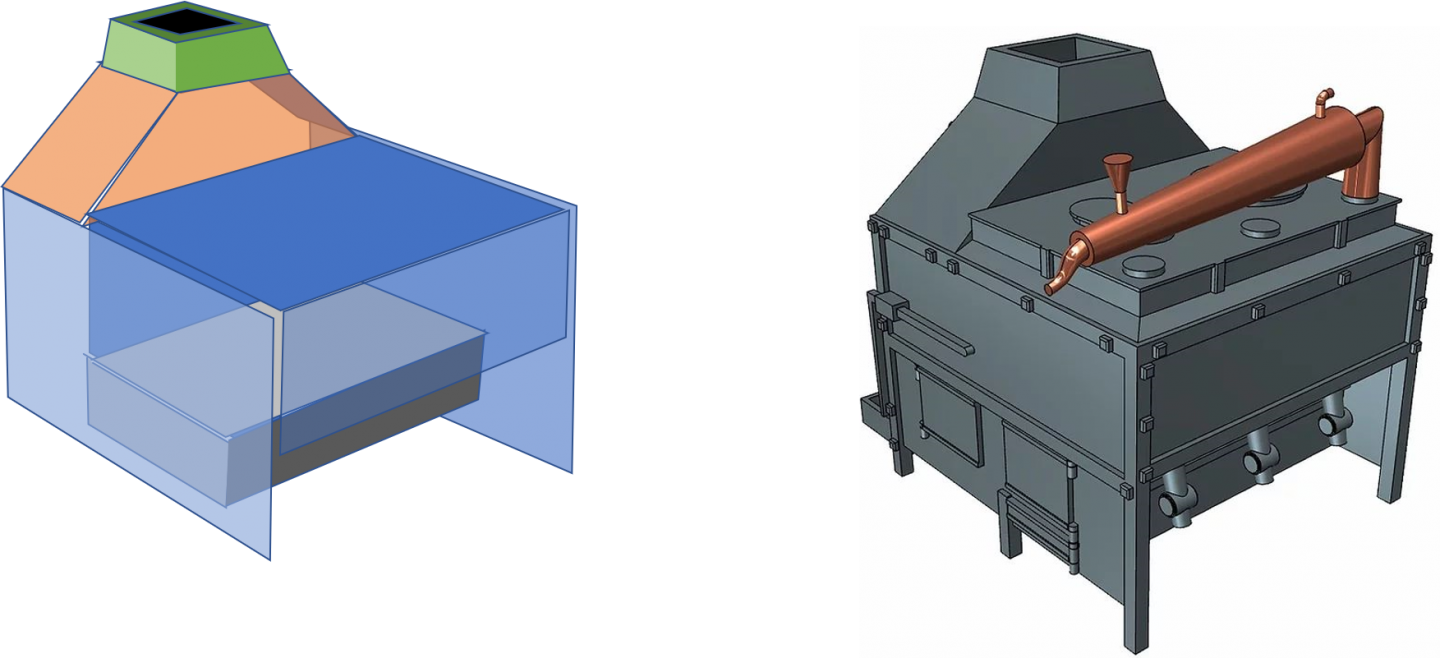

If you look at my original PowerPoint layout and the computer drawing, you will notice the stove hood is shaped like a trapezoid with a somewhat square box on top. The BlueJacket stove parts just had the trapezoid which made their stove’s height correct. When I converted my original design to match BlueJacket’s configuration, I incorporated the box’s height which I shouldn’t of. So, either I can somehow slice off the stove’s hood and rebuild a proper one or I must start over.

-

- Tigersteve, J11, Nirvana and 1 other

-

4

4

-

JJT - The reason the kit does not provide a stove is that the kit was not designed to have a viewable gun deck. All the kit has is the stove's Charlie Noble (stack) protruding on the spar deck. I chose to add the gun deck which means everything on it has to be scratch built if it's going to be seen or partially viewable.

- JeffT and Ryland Craze

-

2

2

-

At this point I said to myself, “awe what the hell” and added a couple pieces of 1/64” plywood to each side of the stove to simulate side door panels and some eye bolts and rings. I also added a thin whitewash to the surface of the tray as well as to the surface of the tray inside the stove. This again is to reflect what I saw in the photos. Unless there is a strong light on the stove, most of these minimal details will be lost to the viewer in the completed model. Final mounting of the stove to the gun deck will after I have constructed and positioned the chain bitts and their associated accouterments

-

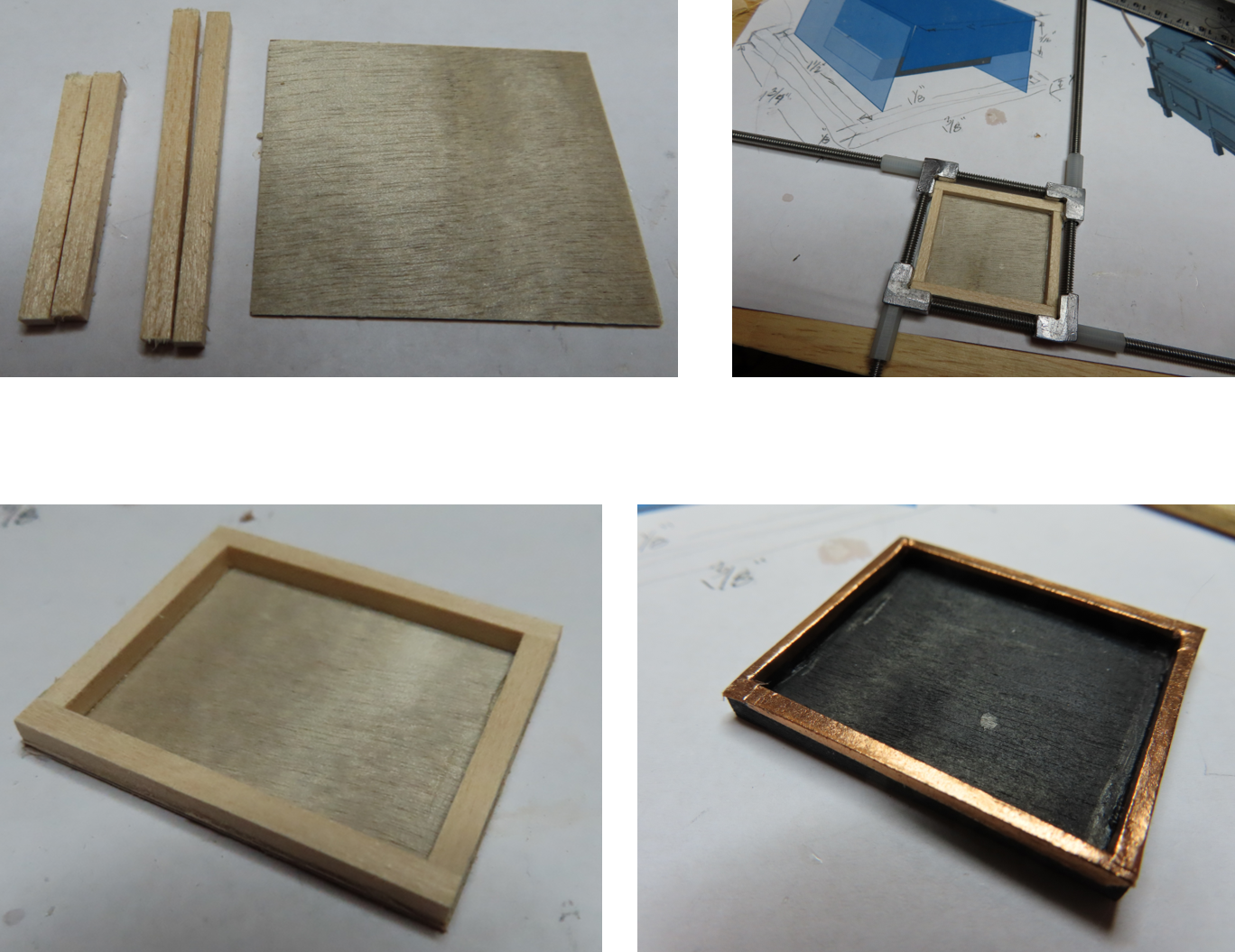

The stove tray dimensions were eyeballed and guesstimated from photos of the stove. The construction was simple enough. I used 1/64” plywood as the base and 1/8” x 1/8” basswood stock for the sides. I finally got to try out my clamp for making square frames for the first time after having purchased it so many years ago. All my other attempts to use it were failures because as small as it is, it was too big for most of my constructs I was attempting.

I got a nice result but trimmed off 1/32” from all four sides because the walls just looked too wide to my eyes. Based on the photos, I first painted the tray black, then used copper tape I got at a crafts store, to plate to top of the tray walls and partially down the sides. This copper tape is much thinner than the copper tape supplied by the kit for the hull plating.

- usedtosail, Ryland Craze, mtbediz and 2 others

-

5

5

-

-

I might add some other details such as eye bolts and rings. However, considering that the whole stove is going to be painted black and place in a dark area below the spar deck, the effort to add more handles, a rod railing on the stove top, rivets which just can’t be seen, among other doodads is not worth the effort.

-

Once the plates were formed, I had to think a bit as to how to make their handles. I elected to use thread. It’s strong and easily handled. With a No. 80 drill, two holes were carefully drilled into the plates and then threaded to form a loop. CA glue was applied on the underside which was drawn up through the hoes. The thread became solid when the glue set. The excess thread below was cut off and the bottom surface was sanded smooth. Finally, the stove top was glued into place.

- usedtosail and Ryland Craze

-

2

2

-

The last section to be completed was the forward-facing stove top. This was made from a piece of 1/64” plywood with beveled edges sitting on top of a piece of 1/32” plywood. Shown on the Navy plans and seen in the photographs, there are three oval and circular plates with handles. These things are exceedingly small and difficult to hold and shape. I tried slicing a thin dowel, but tiny pieces kept breaking off because the grain of the wood was perpendicular to the sliced flat surface. After numerous attempts only one survived. I ended up using 1/64” plywood filed to shape. The results were a bit ragged.

-

-

- Ryland Craze, Papa and KurtH

-

3

3

-

The edge of the tray was formed using card stock. It was initially glued on with CA glue and then lightly covered with addition CA glue to solidify it. BTW, most of the gluing was with PVC glue as it gives me a chance to make final adjustments before it sets. I also added some posts as a gluing surface.

-

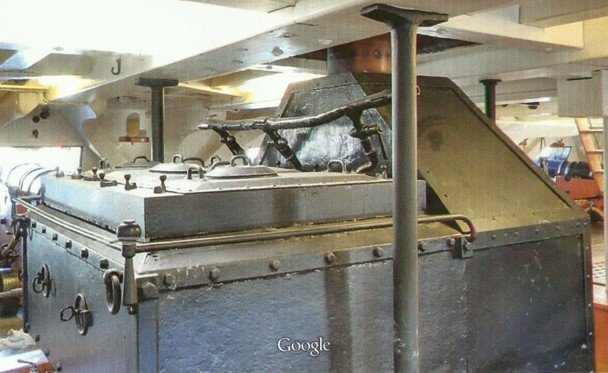

In addition, I found a computer-generated image of that stove based on those parts. I now had a simplified image from which I could work from.

Using my highly sophisticated CAD program, MS PowerPoint (that’s a joke), I worked out how I was going to construct my stove. At the core, would be a solid block with 1/64” plywood side panels. This would provide the basic shape. All the other parts would be added to it.

- Ryland Craze and KurtH

-

2

2

-

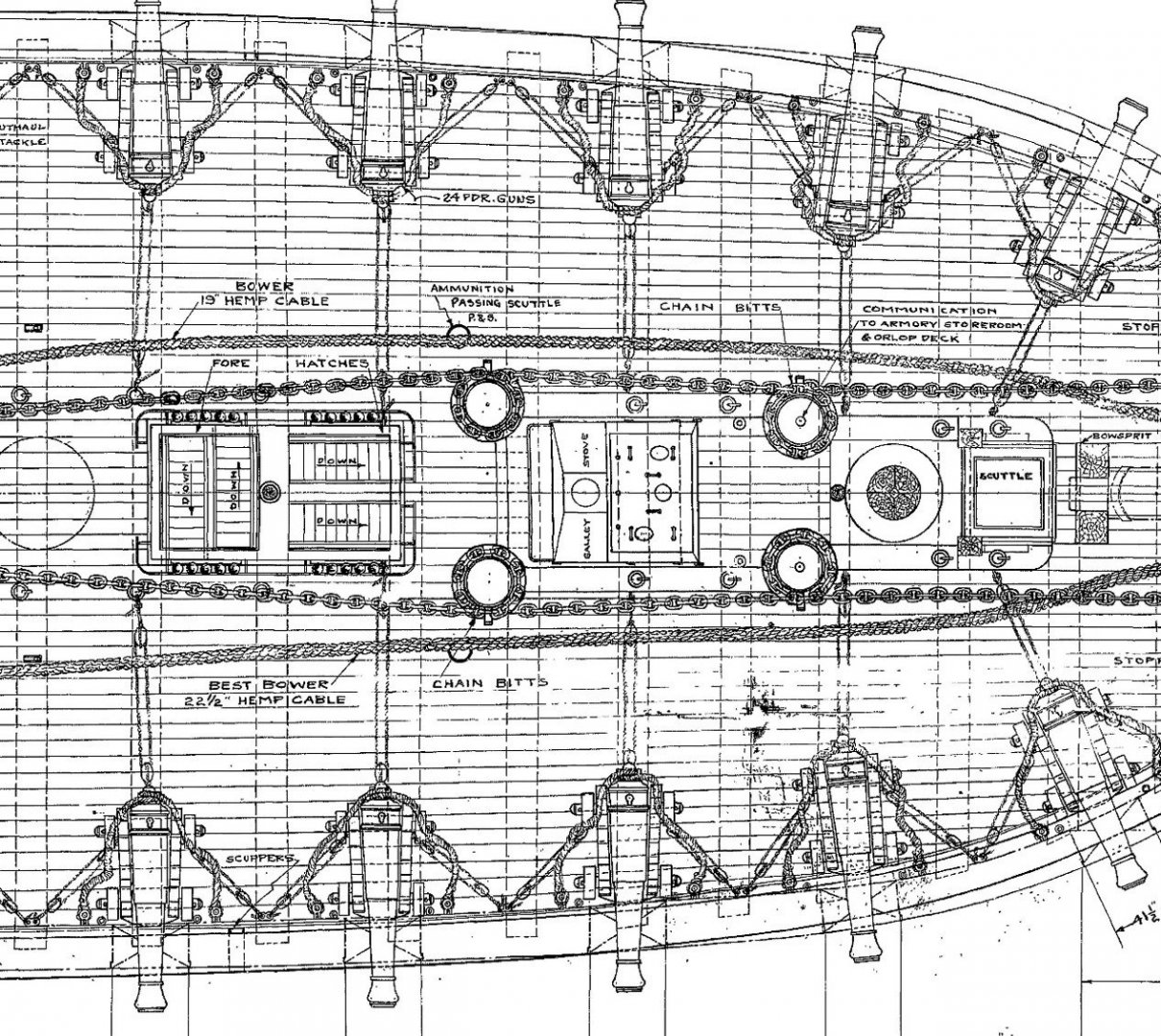

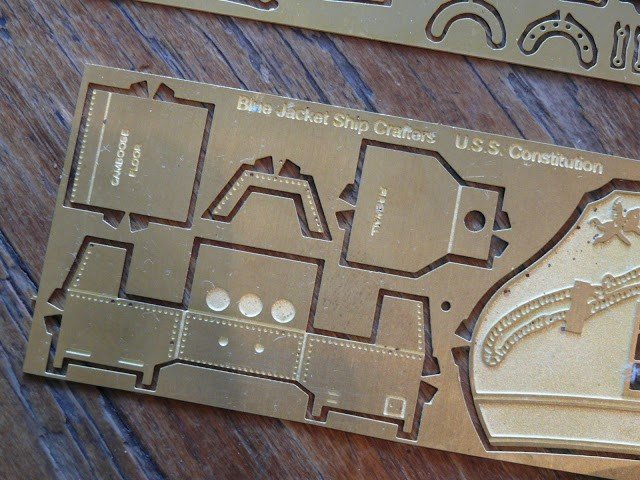

Ship’s Stove (Camboose)

This ship’s stove is totally scratch built without any solid plans to go by. The Camboose is more than likely a variant of a Brody Stove of which I have found some plans but none matched exactly what is on the ship today. As most of us do, I follow numerous other builders to see how they handled certain problems and challenges. In doing so, I discovered that BlueJacket’s model of the Constitution is supplied with photo etched parts to construct a stove albeit at 1:96 scale. Fortunately, I found a particularly good image online of these parts.

I scaled the image of the photo etched parts to match the US Navy arrangement plans of the gun deck at 76.8. Now I could measure the photo etched parts directly for my dimensions. I constructed the BlueJacket stove using card stock to get a feel of what I needed to do when I designed my stove out of wood. Stock and plywood.

-

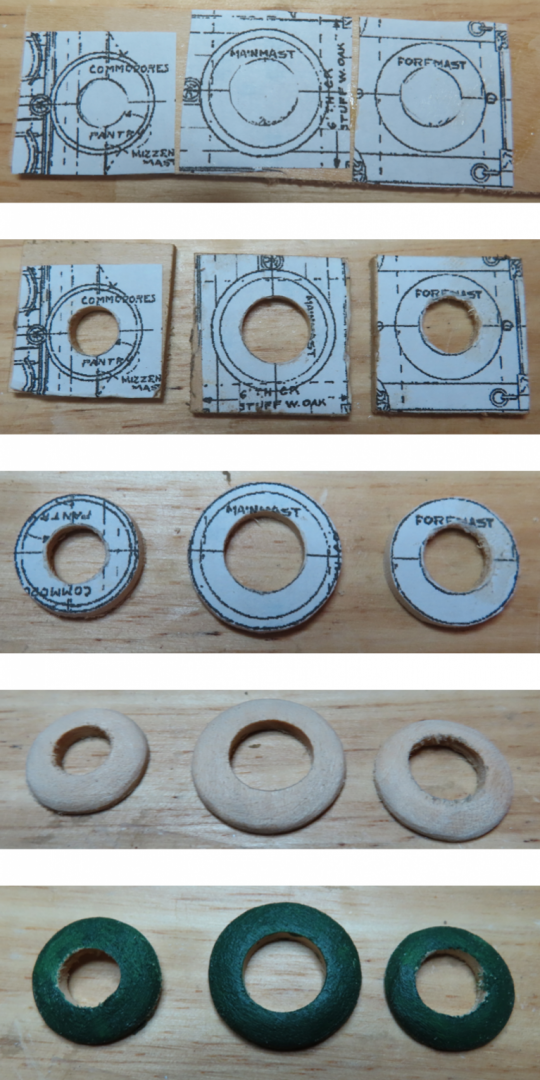

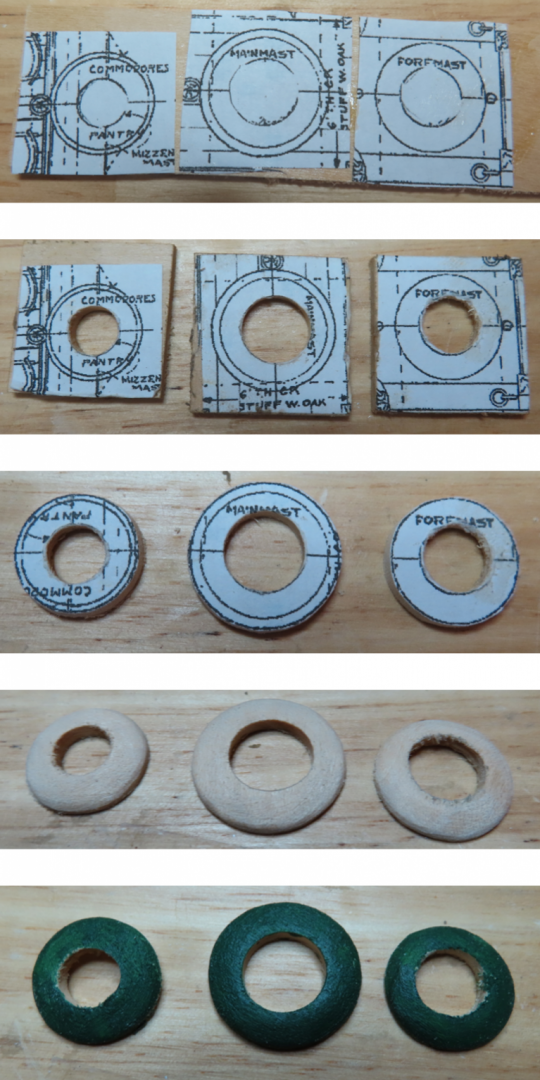

It was at this point I realized something was wrong with the foremast ring. It didn’t fit completely over the hole on the gun deck. It seems I had made the grating next to the mast a bit too long. Knowing this error would be difficult to see, I chose to flatten on side of the ring. Unless you knew, you wouldn’t know.

- usedtosail, Duanelaker, JeffT and 6 others

-

9

9

-

- usedtosail, RichardG, GrandpaPhil and 2 others

-

5

5

-

- GrandpaPhil, Ryland Craze and JeffT

-

3

3

-

Gun Deck Mast Rings

The first things to install on the gun deck were the mast rings. The kit provides mast rings for the spar deck, obviously none for the gun deck. Because I could not find a US Navy plan that showed mast ring details, all I had to go on were the Navy’s deck plans and a few photos of the main mast ring. Because the bilge pumps were photographed a lot, a few captured the main mast which was next to them. As many photos as there were, very few included the main mast with a clear view of the ring. I could not find any photos of the mizzen or foremast rings.

- GrandpaPhil, Ryland Craze, JeffT and 2 others

-

5

5

-

Those guns and carriages look great. I'm going to have to be creative on my gun deck armament. For some reason, if I use the carriages that came with the kit (I have extras as the kit does not provide any for the gun deck), they are a bit low in the gun ports. I know of someone else who had the same problem and remade their carriages a bit taller. I have a ways before I get there to figure out how I am going to do it. That really is a nice carriage jig. A word of caution, the kit cannonades for the spar deck are based on the 1926 renovation, which in turn are based on British cannonades, but they are the wrong period. A couple of cannonades on the actual ship, are correct and they have a vertical screw for vertical barrel adjustment and a different design for the carriage than what the kit provides. Something to think about.

-

Ohhh, she's a beauty!! You wouldn't perhaps have a build log?

USS Constitution by JSGerson - Model Shipways Kit No. MS2040

in - Kit build logs for subjects built from 1751 - 1800

Posted

The lower portion of the bitt worked out to be ½” diameter while the upper portion came out to be approximately 3/8” diameter. What makes the construct a bit more complex is the top surface of the lower wider portion has a tilted surface, a difference in height of 1/8” scale between one side and the other. My solution to this fabrication puzzle was to first drill a hole 3/8” in diameter straight through the ½” dowel on a lathe enough for 4 bitts using progressively larger drills. Next, I sliced 4 pieces off making 4 tall wooden donuts. Then, using my disc sander, I tilted the sanding plate 9° and sanded one surface to create the bitt’s tilted surface. Then I sliced a 3/8” dowel into four 5/8” pieces. Each of the pieces were then inserted into the donuts and voila…I have the basis of chain bitts.