-

Posts

2,170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by JSGerson

-

-

-

Well, the Thanksgiving bash was all it was hyped up to be. By herself, my Sister had 18 people around her table, not once for the Thanksgiving meal, but three times over the course of two days, a total 31 people coming in and out through the course of the week. How she did it, with appearing to show little effort, I’ll never know.

Trailboard Preliminaries Continued

OK, not enough praise for my Sister, but it’s back to business. Using the pin marks I made on the stem, I drilled out the opening and fine tuned it with an X-acto knife. I’m going to assume the opening might be a bit bigger than I made it, but I’ll address that when the trailboard carvings are made and attached.

- DocBlake, Ryland Craze, CaptainSteve and 1 other

-

4

4

-

Per the USS Constitution Museum’s Restoration Log, “Constitution’s Modern Armament,”:

Her first 20th century restoration in 1906-1907 saw fifty-five replica guns made for the ship. All of the present guns were cast for the 1927-1931 restoration with the exception of two 1812-era replica carronades on the after quarter deck. Cast in 1981, these carronades are closer to Constitution‘s 1812 spar deck armament. The gun deck guns were cast in the Charlestown Navy Yard in 1929. The pattern of these guns was based on a British siege gun that was abandoned in Boston during the American Revolution and is currently displayed near Harvard University. The decision to cast “British” guns was made by Lieutenant John A. Lord, Supervisor of the 1927-1931 restoration. He based his decision upon inaccurate research that led the Navy to mistakenly believe that Constitution was outfitted with British guns in 1812.

So, the odd ball cannonade with the elevation screw is the more accurate version. The choice is yours as the model maker…and mine too when the time comes for me to make the choice.

- CaptainSteve, MEDDO, mtaylor and 2 others

-

5

5

-

Any details as to how you made the binnacles? They look really good. In the photo, they look silver as opposed to brass but that could be just the lighting. Did you use foil or metal plate? How did you construct the ball on top of the housing? I'm trying to glean all the info I can so I know what to do when it's my turn.

Thanks, Jon

-

From the pictures, it appears that the square stock passes through the chuck and through the rotary motor so you could work the wood at the end. Is that correct? I know that Ken would sometimes drill a center hole for a pin to attach two pieces. Since you didn't mentioned that, I assumed you didn't attach the tapered ends to the yard ends.

I don't have a Sherline lathe, but want one. I have no real experience with a lathe/mill. Did you get a package deal on the lathe and mill combo? Was there any additional accessories that you bought that I should also consider and is there any accessory you did buy (or came with the lathe/mill) but have not found a need for? Ken told me not to buy a toll until you need it. I have learned that to be very true. I've purchased many a tool/gadget for this hobby only to find I've had to use it. On the other hand, I don't want to start something only to find I'm missing an important accessory to do the job right.

If you feel these questions are off course for this log, could you PM me? Thanks

Jon

-

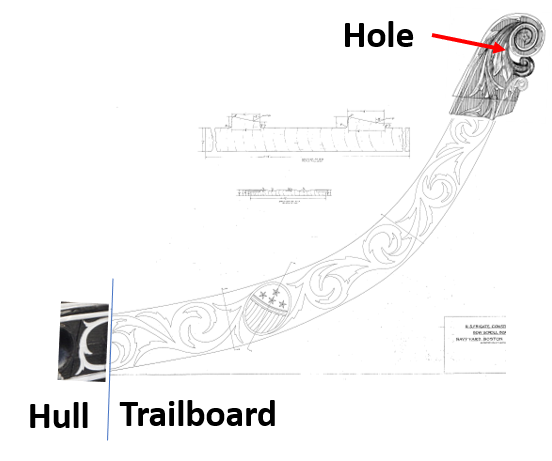

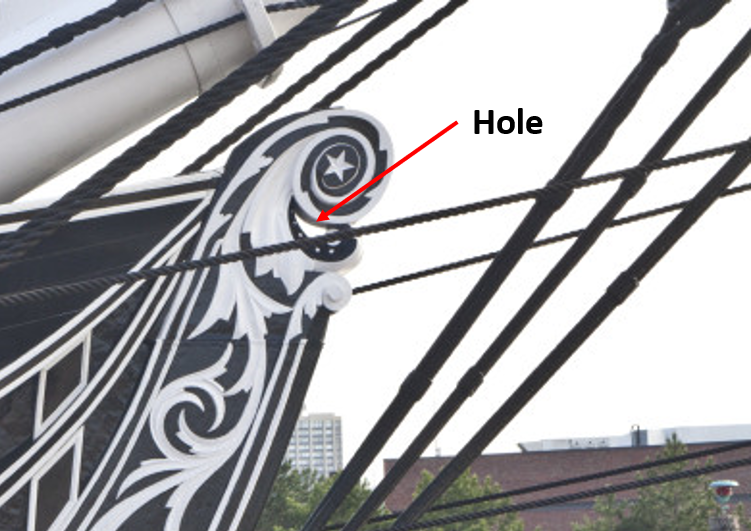

Trailboard Preliminaries

Looking at the stem piece, it seemed to me that now would be a good time to think about the trailboard decorations. Because I have the US Navy plans CD from the USS Constitution Museum, I have the plans for the decorations and the billet head so why not use that instead of the kit’s rendering? The billet head is a separate drawing. I merged the two images on the computer and printed a kit size template. The reason I did this, is because the billet head has a carved hole which does not appear in the kit plans, but is obvious when looking at the real ship. I laid the template on the stem and marked the shape and position of the opening with pin marks.

One other thing I have not seen in other builds. The trailboard decorations are not completely on the trailboard. Just a bit wraps onto the hull. Strangely, the CD does not have that part of the decoration plan, so I used an image of the real ship to complete the design on my template.

But before I can move forward anymore, I have to make preparations for my Thanksgiving trip to colonial Connecticut. It’s going to be a big shebang at my Sister’s house with relatives coming as far away as Tokyo, Japan, Seattle, WA and myself from South Carolina.

-

Wow, it’s been about a month since my last post. I’ve been a bit busy, but not so much directly with the model. I went to St. Petersburg, Florida for the 2017 NRG Conference which is always worth the trip. Then since I was already in Florida, I visited my Mom for a week. Once I got back home I had about two weeks of mail, bills, etc. to work my way through, and other sundry things. Oh, and while I was away, my toilet leaked, so I had to get that taken care of. Finally, I got my head back in builder mode.

Right now, I’m thinking of replacing sections of the keel with the authentic oak from the ship and then inserting flush vertical tubes through the oak section of the keel. The oak would be nice and strong, and the tubes would hold thick pins sticking up from the pillars mounted on a board. This would allow me to remove the model from the display as needed and would, should I decide to, allow me to use a cradle interchangeable.

So far, I have created the rabbet on keel bulkhead and tapered the stem and rudder post pieces as indicated in the plans. The three pieces of the keel bulkhead have been glued together and the two joints reinforced with 1” x 2” 1/32” plywood. I used wax paper so that my weights would not be glued to the wood. The glue did adhere slightly to the wax on the paper which gave the wood a water stained look.

-

-

I keep promising myself that I'll buy a mini Lathe (probably a Sherline) but other expenses keep getting in the way, not to mention I have to learn the skills too. I still have time as I won't be needing one for a good while at the rate that I build. I suppose I could have made those sheaves with a Dremel and a file. I got pretty good making cleats that way.

Jon

-

The brass sheaves, how did you make them? It looks like there might be a rope groove on them. Also, I'm curious if you used any pins where the rails meet at right angles with each other, for structural joint strength. I can see the pins for anchoring them to the deck.

Jon

-

I just got back from Florida having attended the NRG Convention in St. Petersburg and then a week long visit with Mom on the other side of the state in Southern Florida, so I'm just catching up. That was a nice job with the gun ports. My only fear is that they have a tendency to get knocked off while manipulating the model during the build process. At least I had that problem with my Rattlesnake build. I like the cut out as well. I did the same type of thing with the "Ratlter." So take care and handle her gingerly from now on. She looks great.

- Piet, mtaylor, CaptainSteve and 3 others

-

6

6

-

The Main Build

So much for the appetizers, now the main course!

With a deep breath, I took the sheets with the keel parts from the box. I carefully removed them from the sheets and marked them with their respective reference lines. Nothing has been trimmed or glued, just laid out on the table. Some major decisions need to be made now.

First – Am I going to use the simulated guns or opt for showing some of the lower deck which would require buying additional guns and carriages?

Second – How is the model to be displayed, with pedestals or a cradle? If with pedestals, I want to ensure that the pedestal screws won’t break the keel should the model get moved or handled a bit rough. I want to re-enforce those areas. If a cradle is used, how is the model held down during transport, should it need to be moved. This is a problem I presently have with my Rattlesnake.

Third – I have a couple of pieces of authentic USS Constitution oak wood which I would like to incorporate into the model. The pieces are approximately 2 ¼” x 2 3/8” x 7/8 – 5/8” and 2 3/8” x 2 3/8” x ¾”. They were purchased just before the ship went into dry dock 3 years ago. I have not been able to procure any additional wood since, let alone different sizes or shapes.

I would welcome any and all suggestions especially on how to use the oak wood pieces.

-

- Geoff Matson, SUBaron, Jim Rogers and 8 others

-

10

10

-

1

1

-

Whaleboat Steering oar oar-lock

Unlike the gig, the whaleboats have an oar lock on the port side for a steering oar. Following xKen’s lead, the oar lock was made by twisting 22-gauge wire tightly around a nail to form a loop at one end. I then silver soldered the twisted wire and filed it to simulate a solid shaft. The loop was cut and form into a U-shape. According to the plans, the lock was to be fastened to the inside face of the rail with a bracket. But due to the scale, I elected to just drill a hole into the rail and inserted the lock with a spot of CA.

- DocBlake, Geoff Matson, CaptainSteve and 1 other

-

4

4

-

- Geoff Matson, DocBlake, Tigersteve and 2 others

-

5

5

-

- Tigersteve, Jack12477, Geoff Matson and 2 others

-

5

5

-

-

Whaleboat Rudders

Using the US Navy Plans, the rudder plans were made into templates and rubber cemented to 1/64” plywood. Because most the parts were to be painted, the plywood was used for its strength. Like the gig, the rudder was made of four components: the main rudder blade, the re-enforcement plates for the tiller, the tiller, and the yoke. The tillers and yokes were stained. The rudder assembly will be installed later. You will note in the last picture my hand vise (holding up the ruler) which I used to file and shape the tillers and yokes.

-

Whaleboat Paint Job

Using the paint from the paint package I purchased from Model Expo for this kit, I painted the hulls dark green. The first thing I noticed was that the paint dries very quickly both on the models and on the brush. This is some sort of water solvent paint at least for thinning and clean up. I found that I had to add water to the paint to make it flow better on the hull surface but that reduced the its coving effect of the white primer (also from Model Expo’s paint package). Because it dried so quickly, the thickness of the paint on the surface would vary. Because of that, I let the paint dry 24-hrs and gave the surfaces a very light sanding and applied a second coat. It improved, but I still did not like the effect I was getting. Not only that, these hulls are supposed to be somewhat glossy, whereas the painted dried flat.

So, I bit the bullet and purchased Model Master Green Gloss, an acrylic paint. After another light sanding of the hulls, I painted them with the acrylic…much better. I don’t know much about the different types of paints, their pros and cons, the do’s and don’ts, etc. Hopefully I haven’t violated any taboos on mixing paint types.

- Tigersteve, CaptainSteve, Jack12477 and 3 others

-

6

6

-

Whaleboat Keels

It was time to install the keels. The kit called for a cross section of 1/32”w x 1/16”h. Per the US Navy plans, I figured it to be 1/32” x 3/64” not that anyone would notice. I cut some stock boxwood to my dimensions for the straight length on the Byrnes saw. I cut to size the curved sections of the bows and sterns from a cardstock template based on the actual model, not the plans. Once glued into place, they were painted with white primer.

- CaptainSteve, DocBlake, Jack12477 and 2 others

-

5

5

-

-

-

First off let me say Mom rode out Irma just fine. She lost power for four days, but she and her temporary 24-hr aid survived with only minor discomfort. And, it appears that Maria will leave her alone.

Whaleboat Stern Benches and Aft Decks

I attempted without success to create the stern U-shaped bench from straight planks. I thought I would use the plans as a pattern cutting, fitting, and gluing the pieces so that I could insert the whole assembly as a unit. That didn’t work because the gluing surface were the edges of the planks and they would snap apart just looking at them.

I tried assembling them in situ, but there was no support for the planks to be attached to during construction.

I admitted defeat, and used 1/64” plywood and with an X-acto knife, etched in the board marks. Then I stained it which brought out the etched lines. Note: these images are dry fits.

- DocBlake, CaptainSteve, tasmanian and 4 others

-

7

7

-

Work on the model may slow down a bit due to hurricane Irma. As I have mentioned in past posts, I visit my Mom in Florida every couple of months or so. She is now in the crosshairs of the storm. All my relatives who could have helped her, were too far away. I tried to get someone to board her condo windows up, but there was no plywood to be had. Luckily, my Sister (lives in Connecticut) managed to get someone with experience with elder care (she’s 99 years old) to stay with her 24-hours-a-day till the storm subsides. They are going to hunker down and hold on to it other. I wish I could have done more, but I’m 600 miles away. By that time, I’ll be feeling the effects here in South Carolina.

I don’t know what kind of condition Mom or her condo will be in, whether she will be able to stay there, or will have to come to live at my place for a while once the worst is over. It’s going to be an interesting and bumpy ride

USS Constitution by JSGerson - Model Shipways Kit No. MS2040

in - Kit build logs for subjects built from 1751 - 1800

Posted

Note: This text is for the images in the last post. I was getting an error message when the text was pasted in.

Installation of the Keel

The keel was glued on in sections. First the oak wood from the actual ship was inserted into the forward and aft keel pieces. The position was dictated by where I planned to use pedestals to display the model. You can see where I marked the keel bulkhead with arrows. The length of the oak was limited to the approximate 3" square pieces of oak I had.