Ronald-V

Members-

Posts

1,934 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ronald-V

-

It's a homemade wipe-on poly. So I thinned a polyurethane varnish with thinner that you can use like you would use wop. But for these small areas I use a brush and wipe off the excess after a few seconds. Never used a airbrush for this, because after a few coates it looks really equal in coverage. And because I have it quite thin...it doesn't look thick or something. So I don't see the need for an airbrush here 🙂

-

Just a little update in the form of a video of what I'm doing. I've been waiting for this for a long time... finally some varnish on the "stern counter." That bare wood was staring at me all this time😩, while the rest was already covered in varnish or paint. But now that I'd attached the wooden trim, I could finally brush on the first coat. I think I'll add another coat or two later, and then it should all fit together nicely. 😁

-

Welcome to MSW 🙂

-

Very well done indeed! Congratulations...the model is quite high 😦

- 24 replies

-

- Santissima Trinidad

- OcCre

-

(and 2 more)

Tagged with:

-

What's the plan now? Working further on your beautiful Mary Rose? Or do you have new projects in the pipeline?

- 97 replies

-

- Corel

- Große Jacht

-

(and 2 more)

Tagged with:

-

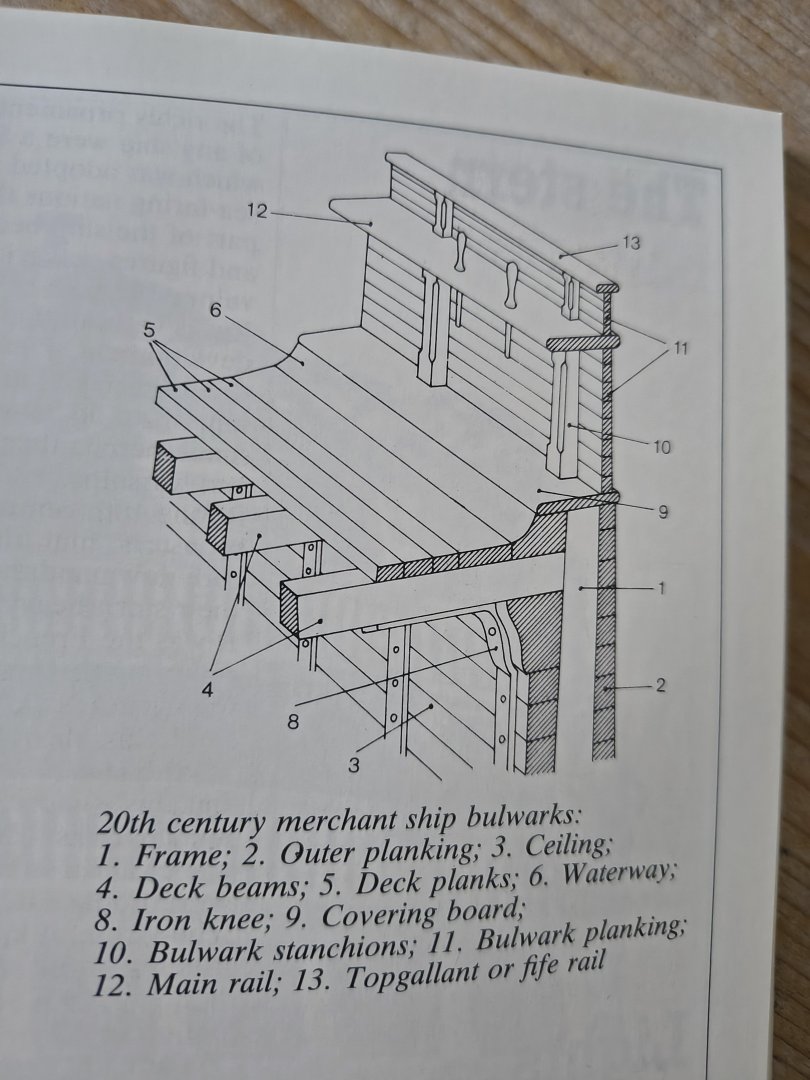

Finish of the Waterway

Ronald-V replied to RossR's topic in Building, Framing, Planking and plating a ships hull and deck

If you look at the pictures from the HMS Victory, they seem to be unpainted. If I understand correctly, they're part of the deck, a sort of L-shaped plank that starts on the deck and ends in the bulwarks. That's why I consider them a deck component and leave them bare (varnished, of course). This isn't based on facts, but on my own observations, haha. 😄 I hope someone with real knowledge will come along Edit: I have included an illustration from Mondfeld's "historic ship models" where you can see how the waterway as I see it is part of the deck. Obviously this isn't a picture of the ship you're working on (not even of the time period), but personally I don't think there would be much difference? -

Side note...the scale of the Amati kit is 1:64

- 6 replies

-

- Pegasus

- Victory models

-

(and 1 more)

Tagged with:

-

Welcome back

-

Congratulations Baker! A very nice vessel, and I like the upgrades...well done 👏

- 97 replies

-

- Corel

- Große Jacht

-

(and 2 more)

Tagged with:

-

Thanks Frecap! I understand your thoughts on photoetch. In general...not sure i'm the biggest fan of it, mostly through it's flat appearance...but it can add a lot of details for the less skilled amongst us and sometimes you can get things more in scale with PE. But I also prefer to see as much wood as possible where possible.

-

Welcome to MSW and lovely work so far!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.