BobG

-

Posts

3,094 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by BobG

-

-

3 hours ago, Blue Ensign said:

I have worked several hours each day on this model over the past six monthsBeautiful, BE! All of those hours you have spent crafting this lovely model has paid off grandly!

- Blue Ensign and mtaylor

-

1

1

-

1

1

-

-

Very nice, Will! I feel like the rigging brings the model to life.

I'll be very interested to see how you rig the topsail. I'm building the Pen Duick and I can't figure out the rigging for the gaff topsail from the vague instructions.

-

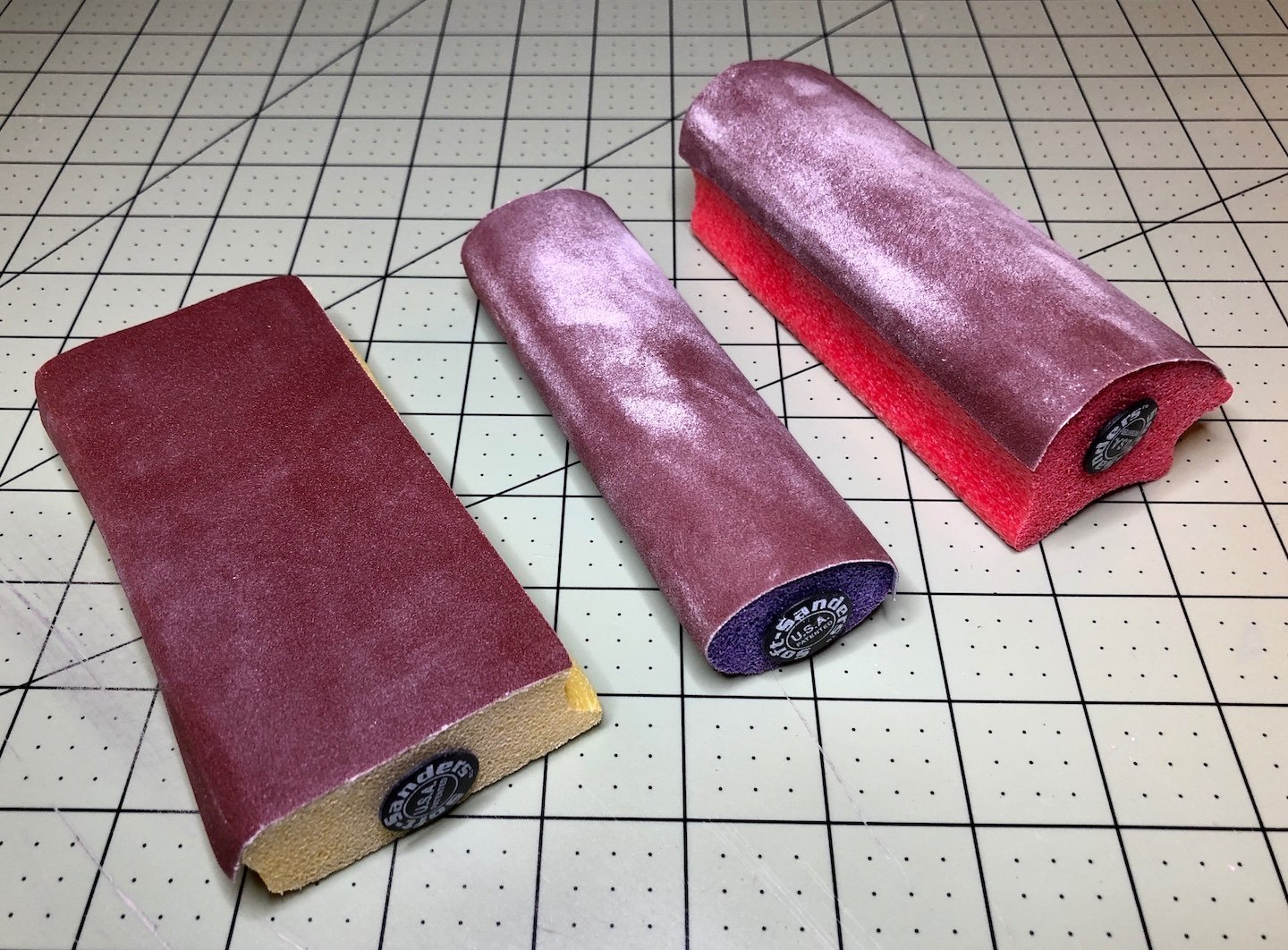

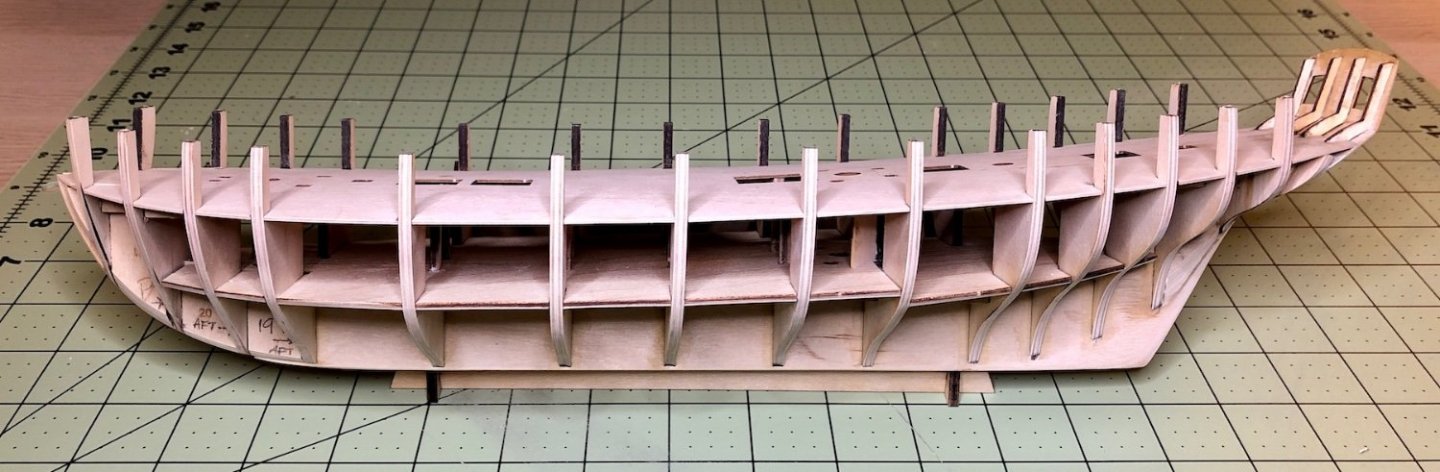

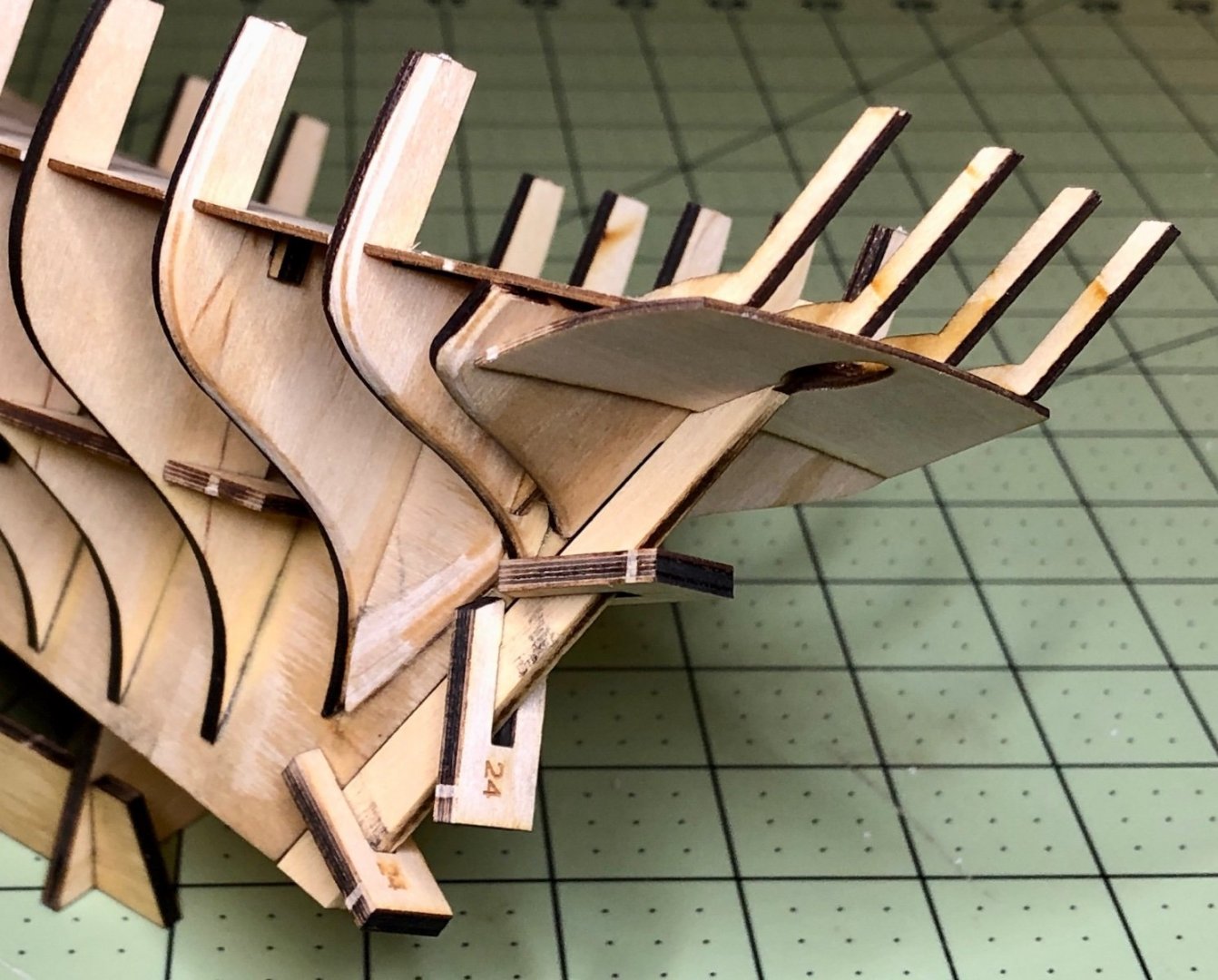

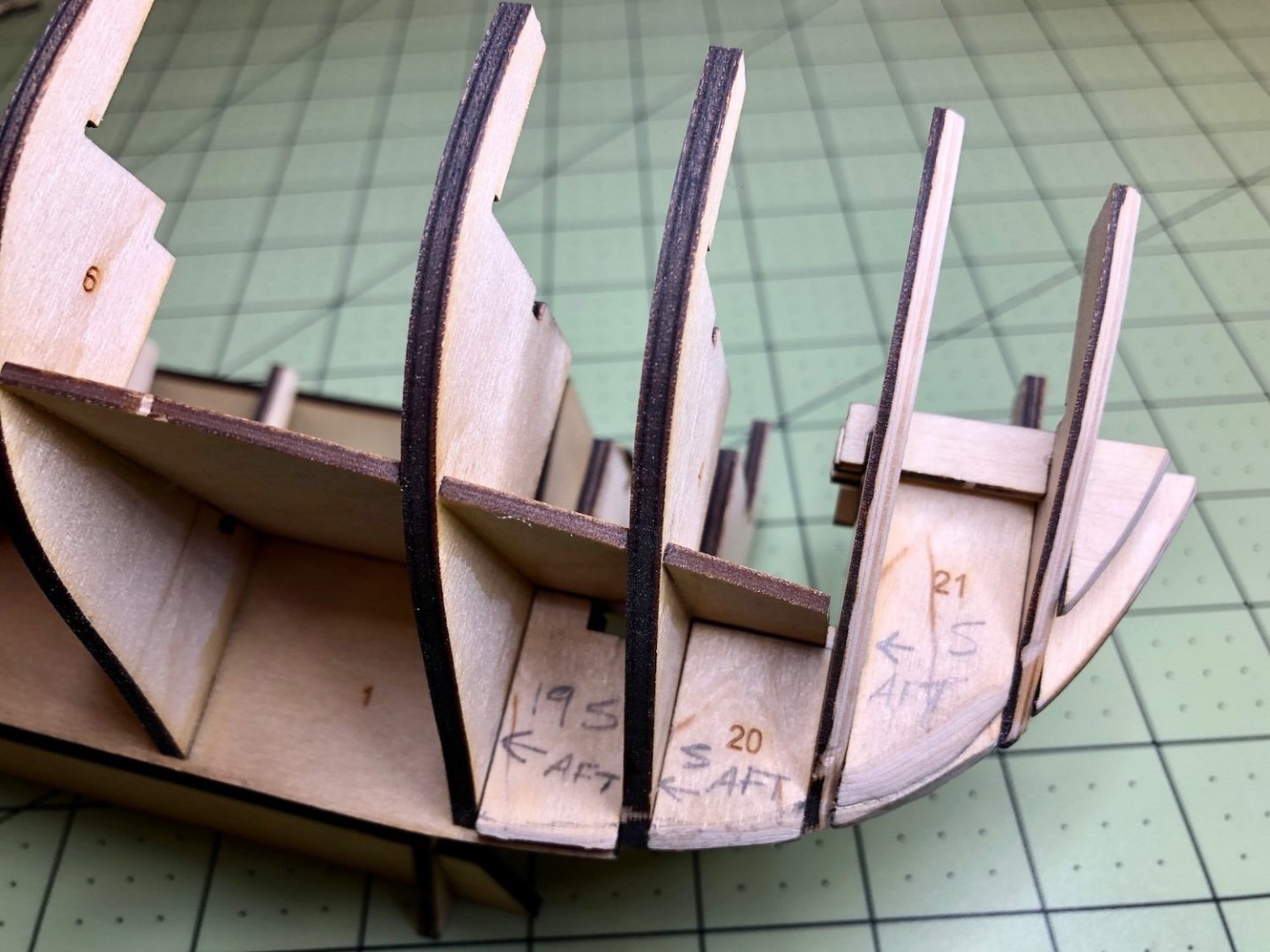

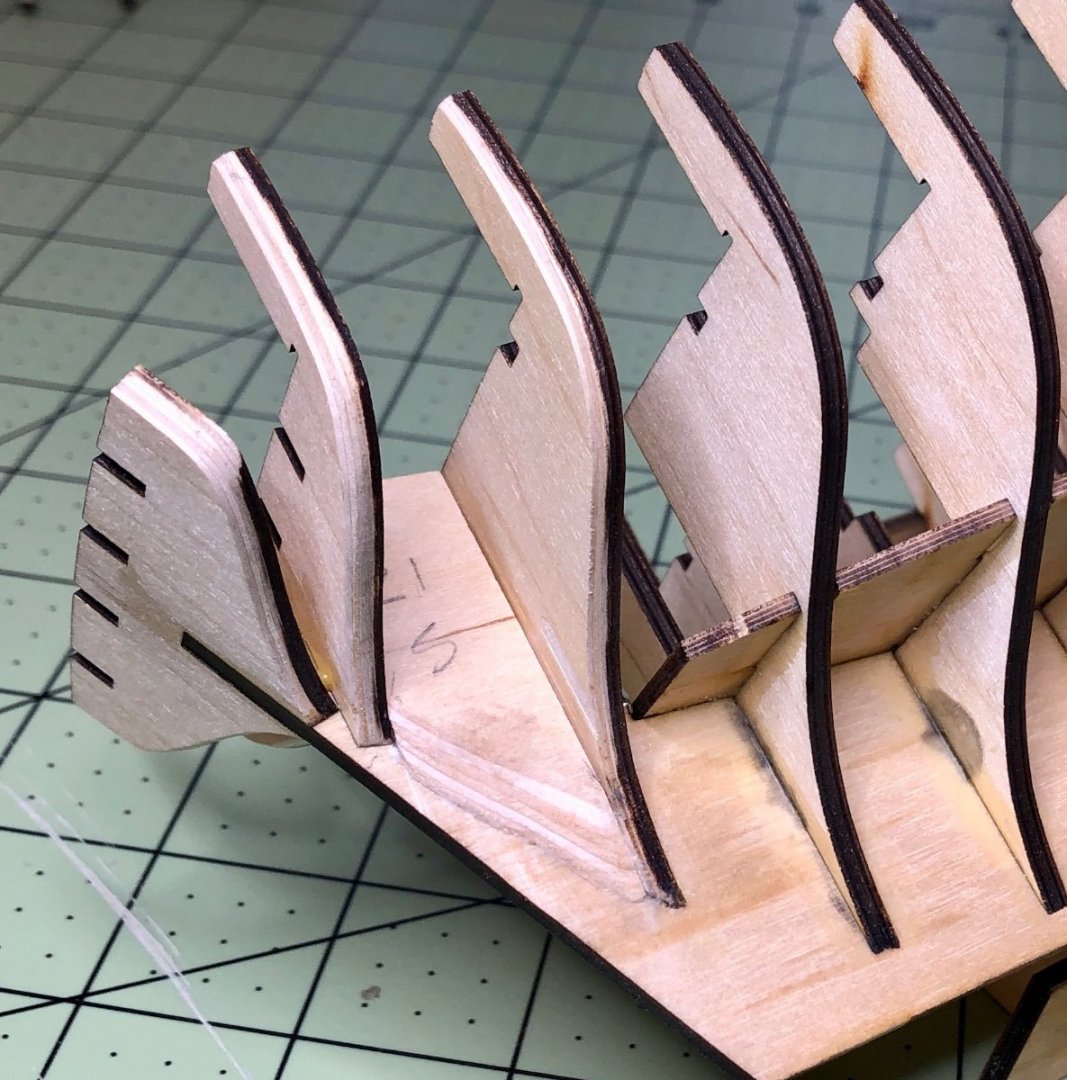

It was a beautiful day here in Sacramento today so I pulled up a yard chair, put on my shop apron, grabbed my soft sanders and began fairing the hull. I actually enjoy sanding and shaping just about anything and I really enjoyed the whole process today. It took me 5+ hours of sanding and constantly checking my progress with a thin batten until I decided I was done.

The run looks fair everywhere I lay the batten spanning 3-4 bulkheads at a time with no noticeable bumps or dips and with the batten making good contact with the bulkheads. Of course the bow and stern areas took much more time. I find the most difficult area to fair is from about bulkhead 4 to the bow where the curve is more severe. It took quite a bit of sanding in that area until I was happy with it. The stern area from bulkheads 13 to 16 also requires more attention. I found my round and curved soft sanders worked really well in that area.

I tapered the false keel where the stern post will be added to about 2 mm in width along with the deadwood area from bulkhead 13 to the stern.

One thing I did notice while I was fairing is that there was a bulge in the deck near bulkhead 6. On closer inspection, I could see that the deck was not seated into the notch in the bulkhead. I tried to press it down but it wouldn't budge because the of dried PVA glue in the gap between the deck and the deck beam. Luckily, I was able to take a scalpel and clear out the dried up glue and then snap the deck down into the notch. I'm getting pretty good at fixing my mistakes!

Next up are adding the bulwark patterns which everyone seems to "fun" with! 😏

Thanks for coming by everyone. Cheers!

- Moonbug, jpalmer1970, hollowneck and 15 others

-

18

18

-

1 hour ago, glbarlow said:

The batten needs to contact at least 90% of the bulkhead

Does the entire length of the bottom of the false keel get faired down to 2 mm just like the stern and deadwood areas get thinned as you continue to sand and fair along the the bottoms of the bulkheads from stern to bow? In other words, will the entire length of the false keel be about 2 mm think from stern to bow? I hope this makes sense...

I can't quite tell when I blow up your photo showing the entire keel on your build but it looks like the 2mm thinned area around the deadwood gradually flows into the full, original, 3mm width of the false keel with maybe a little tapering into it from the bottom edges of the bulkheads. Is this right?

-

-

-

1 hour ago, glbarlow said:

Looks like you have some fairing to do, this is the most important step on every model and critical to what comes after.

I like sanding and shaping but my problem is that I'm never quite sure I'm getting the shape correct especially on the forward bulkheads in the bow area . I'll be checking the flow of the fairing often with a thin batten and hope for the best. Thinning the deadwood the area where the stern post attaches to the false keel is new to me also. 🤞

-

-

4 hours ago, glbarlow said:

I think he went thinner and I wasn’t comfortable with that.

Like you, I'll be more conservative doing that too.

-

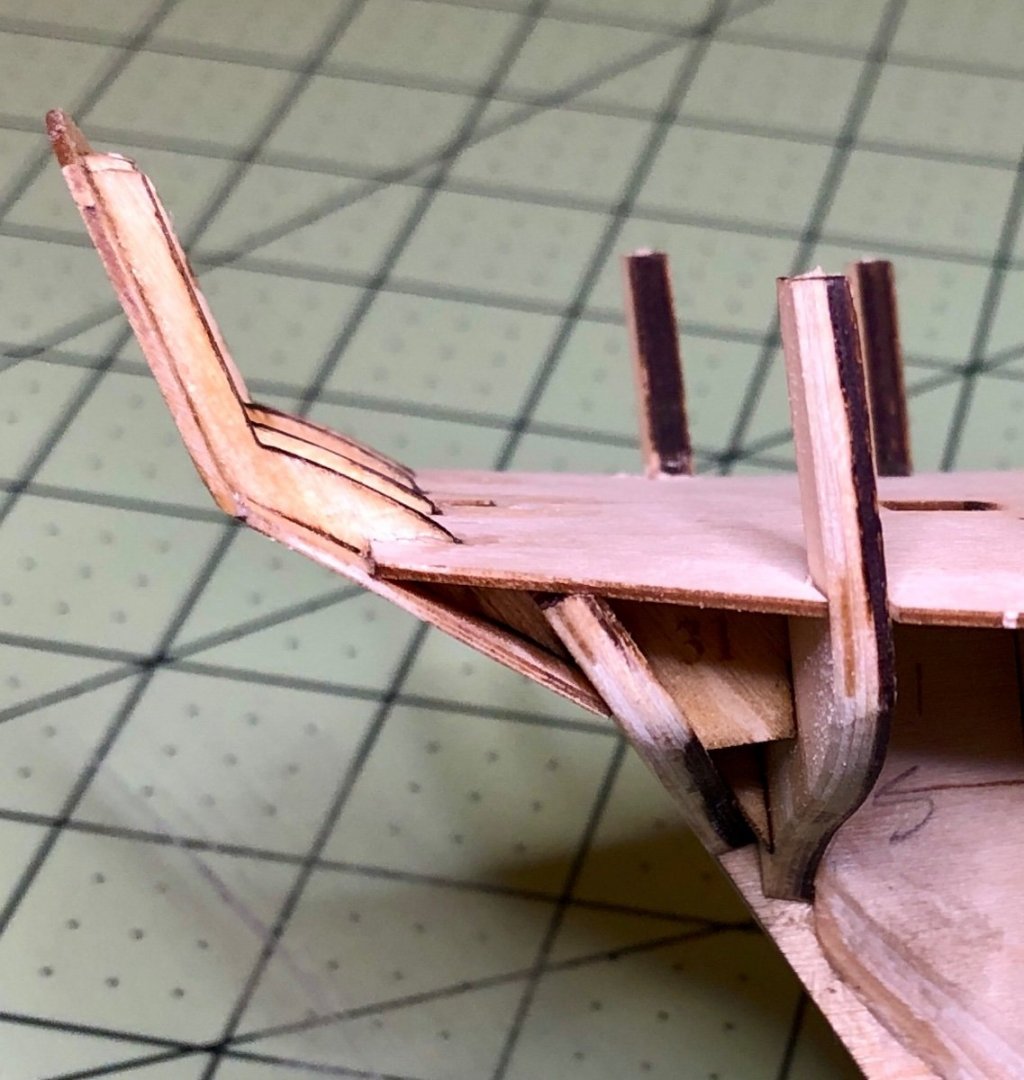

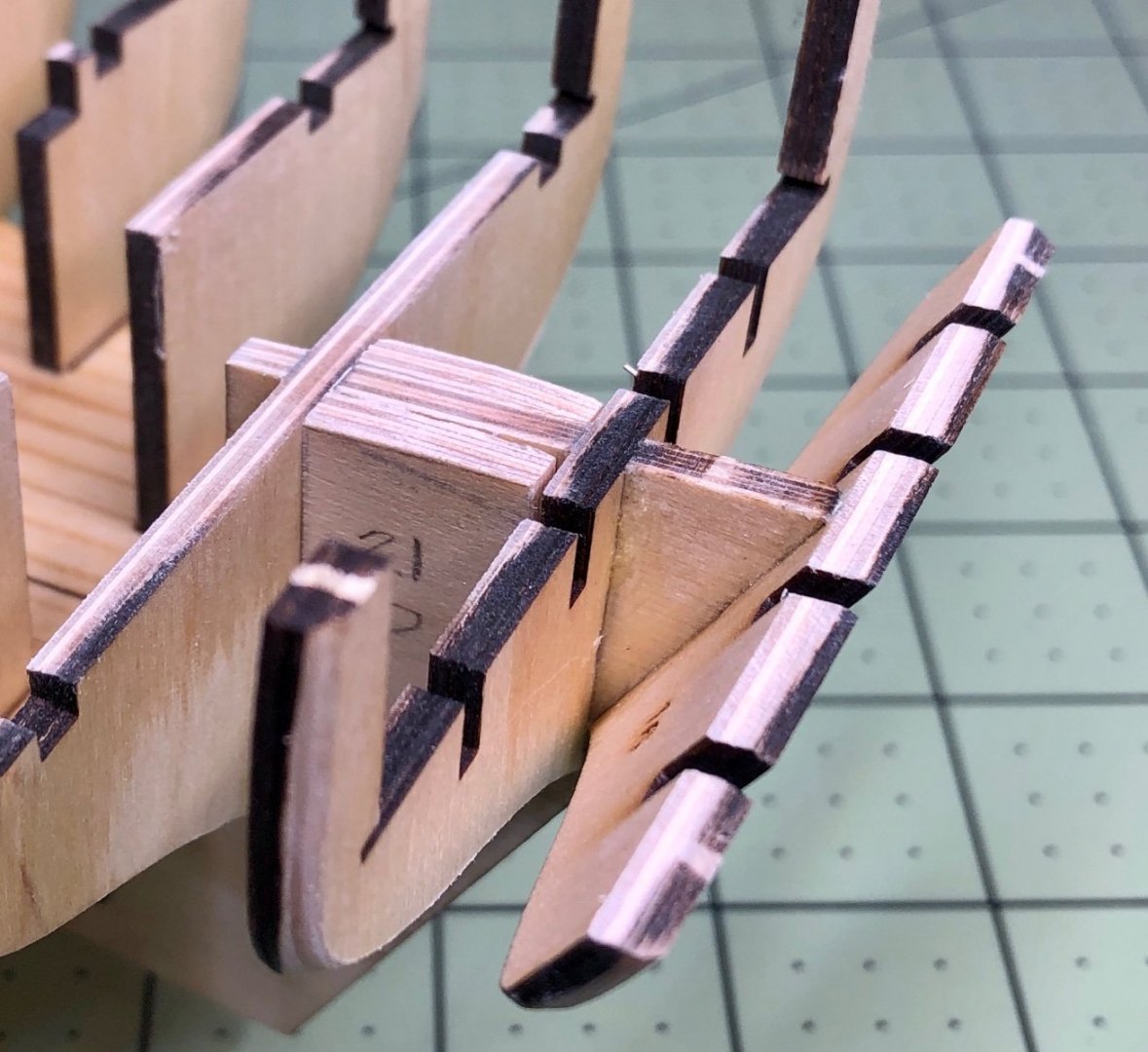

I added the stern counter and the stern board to the stern frame patterns today and, unlike yesterday's ordeal, I was able to get this done without breaking anything!

I used the securing pegs to temporarily hold the the rudder post in the correct position as illustrated in the instructions. This is a great idea and it worked really well. The stern counter lines up nicely this way. There's a very slight curve to the stern counter but it's only 0.8 mm so it's quite flexible. I was able to simply hold it tightly onto the bottom of the stern frame patterns while using medium viscosity CA to glue it on. The medium CA gave me enough time to make adjustments as needed. I practiced my "moves" a couple of times before doing this though! 😅

I added the stern board next that sits on top of the stern counter and attaches to the back of the stern frame patterns. I used Titebond Thick & Quick for this step so I'd have more time to make adjustments. Again, I practiced my placement and eyeballed the stern frame patterns so I knew which ones I needed nudge slightly so that the spacing looked correct in relation to the windows in the stern board.

I was able to complete this step by just holding the stern board in place with my fingers and adjusting the stern frame patterns as needed so that the spacing looked good but many modelers prefer using clamps. The Titebond Thick & Quick starts getting tacky fairly quickly and provides enough hold at that point that I can still make small adjustments before holding everything in place for a couple of minutes until the glue is set firmly. I often will drizzle a drop or two of thin CA into any tiny gaps and apply some pressure to close them also. Just be mindful of gluing your fingers to the model

Thanks to everyone for their comments and likes and for taking the time to stop by and take a look. Cheers!

-

Thanks, Theodosius. I'm getting better at covering up my mistakes!

Are you still working on your Flirt?

-

On 8/9/2021 at 6:16 PM, glbarlow said:

Though I didn't take a photo beforehand I thinned the deadwood and along the sternpost before adding any of the bulkheads using my finger plane and chisels (easier to do with the former laying flat). I elected to thin the area to 2mm, I still want enough for the sternpost to attach to the former. There is plenty of meat in the first planking, I can thin as needed to eventually match the sternpost to the thickness of second planing.

Glenn, I'm not sure I'm understanding this step completely looking at your photo.

Are you essentially tapering the deadwood area that is formed from the bearding line as it curves up from the bottom edge of bulkhead 12 to the the bottom edge of bulkhead 16 so that the final thickness of the keel former is 2 mm thick at the stern all the way to the bottom of the keel?

-

-

-

-

-

-

-

9 hours ago, glbarlow said:

You’re not alone in this, I sorted it out but not without challenge.

We all like parts that fit well and Chris has certainly done that well with the precise laser cutting in his kits. I'm wondering, however, if the tolerances on the deck could be just slightly more relaxed and still fit very nicely given that it will be covered up when the final scribed deck is laid on top of it anyway? I'm not talking about a big change in the size of the notches in the deck but just ever so slightly larger so this task might be less challenging while still keeping the integrity of the framing intact.

-

-

15 minutes ago, hollowneck said:

Do flip ahead in the kit's manual and scrutinize the plans BEFORE proceeding in a logical manner. It's the logic that sometimes defeats us!

I read all the way to the rigging last night. No more surprises for me...I hope! 😅

- hollowneck, Moonbug and Ryland Craze

-

3

3

-

Thanks Bug and Glenn for your comments and others for the likes.

Glenn, I had read in the manual about slotting the deck into the bulkheads notches by bending it and I tried doing it that way but I couldn't get it entirely into the notches on the side I started placing it on. Then I thought I should try and get the other side started before the glue got too sticky and, when I tried to get it in, I ended up with neither side fully into the notches and the glue was sticky enough now to make it even tougher.

My error, as you noted, was not getting the first side all the way into the notches in the first place. I'm not sure how I finally got the deck all the way in while fighting the sticky glue but it finally happened much to my relief! I'm sure I made it a lot harder than it actually is though...

- Cathead and hollowneck

-

2

2

-

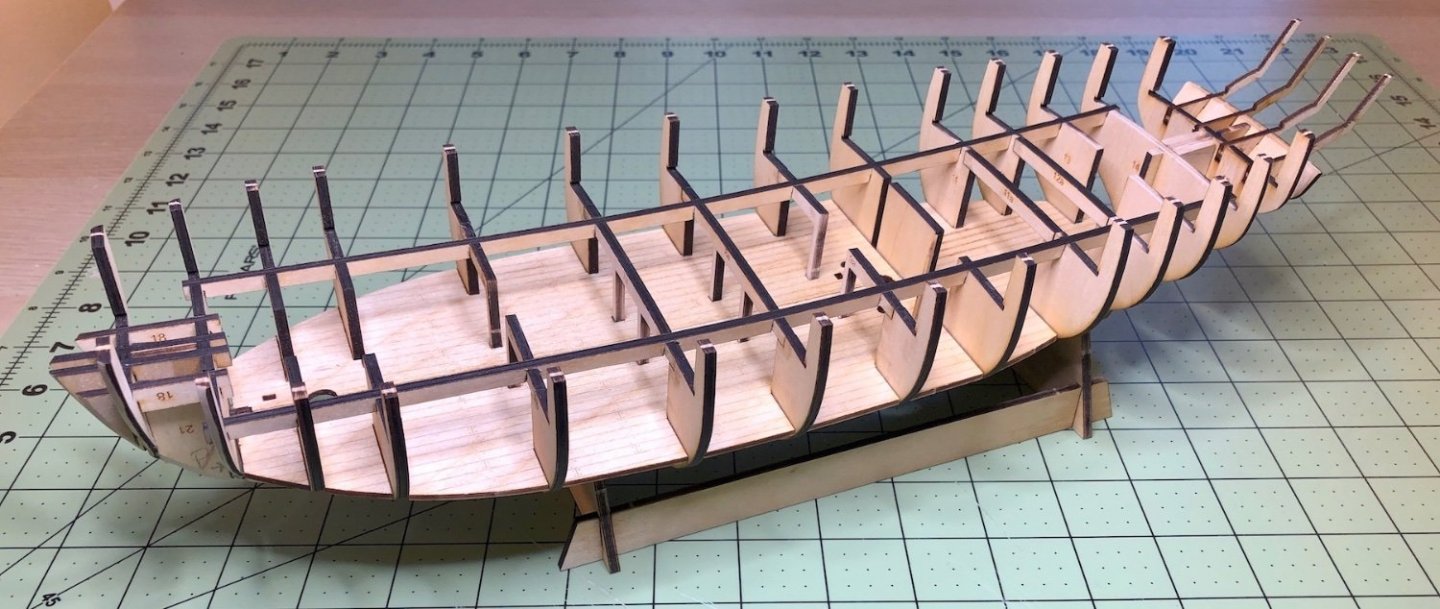

Well, it's been an interesting 2 days. I've made some progress but it hasn't been without some hiccups and one major disaster. Read on to see how things went a little haywire and how I think I managed to bail myself out and, yes, it's ok to roll your eyes! After today, I may need to rename my build log "A Comedy of Errors and Repairs." 🤣

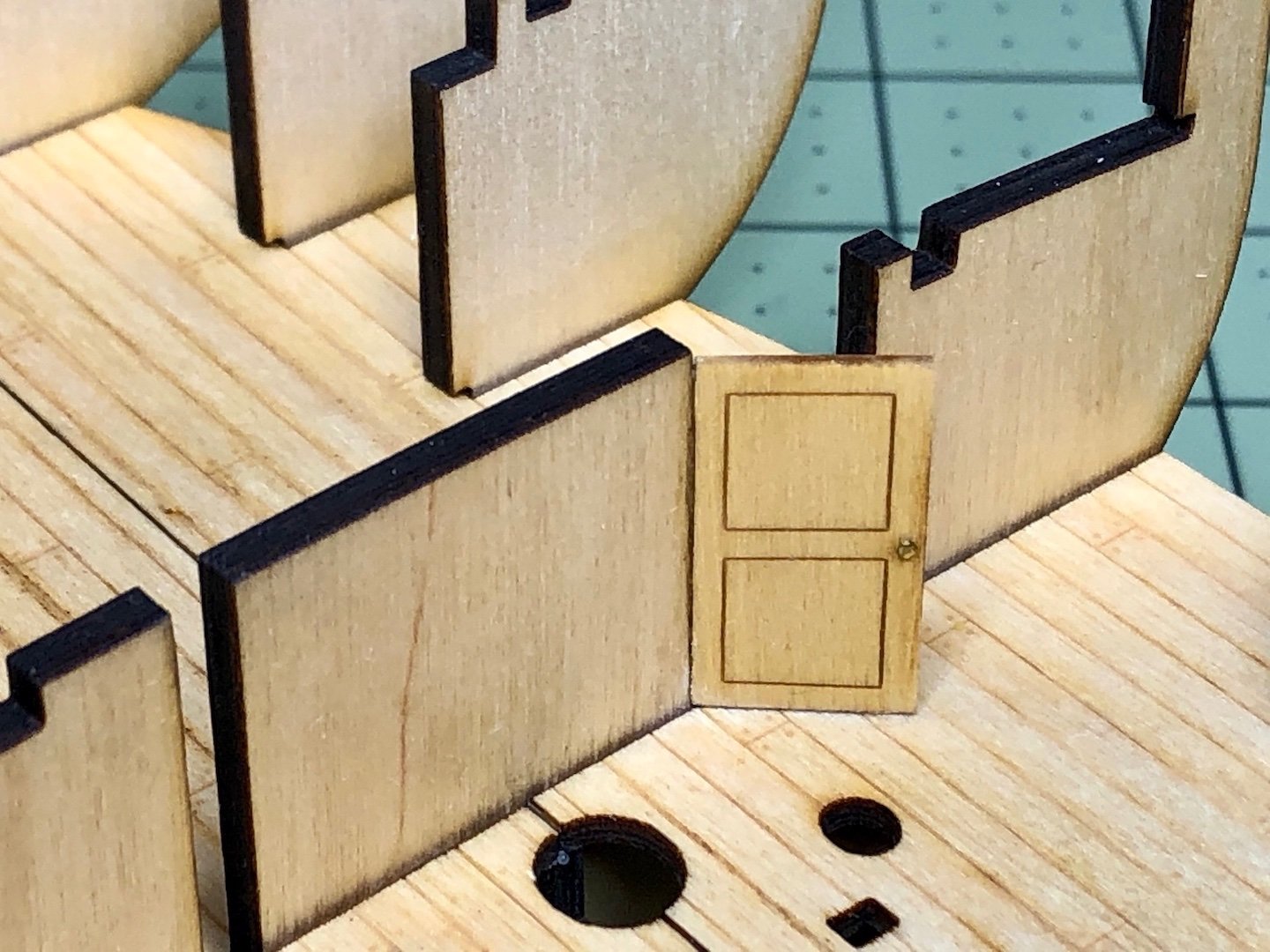

First off, I added the little door to the sub deck and used a cut off pin for the door knob. Then I gave the deck and door a single coat of satin WOP.

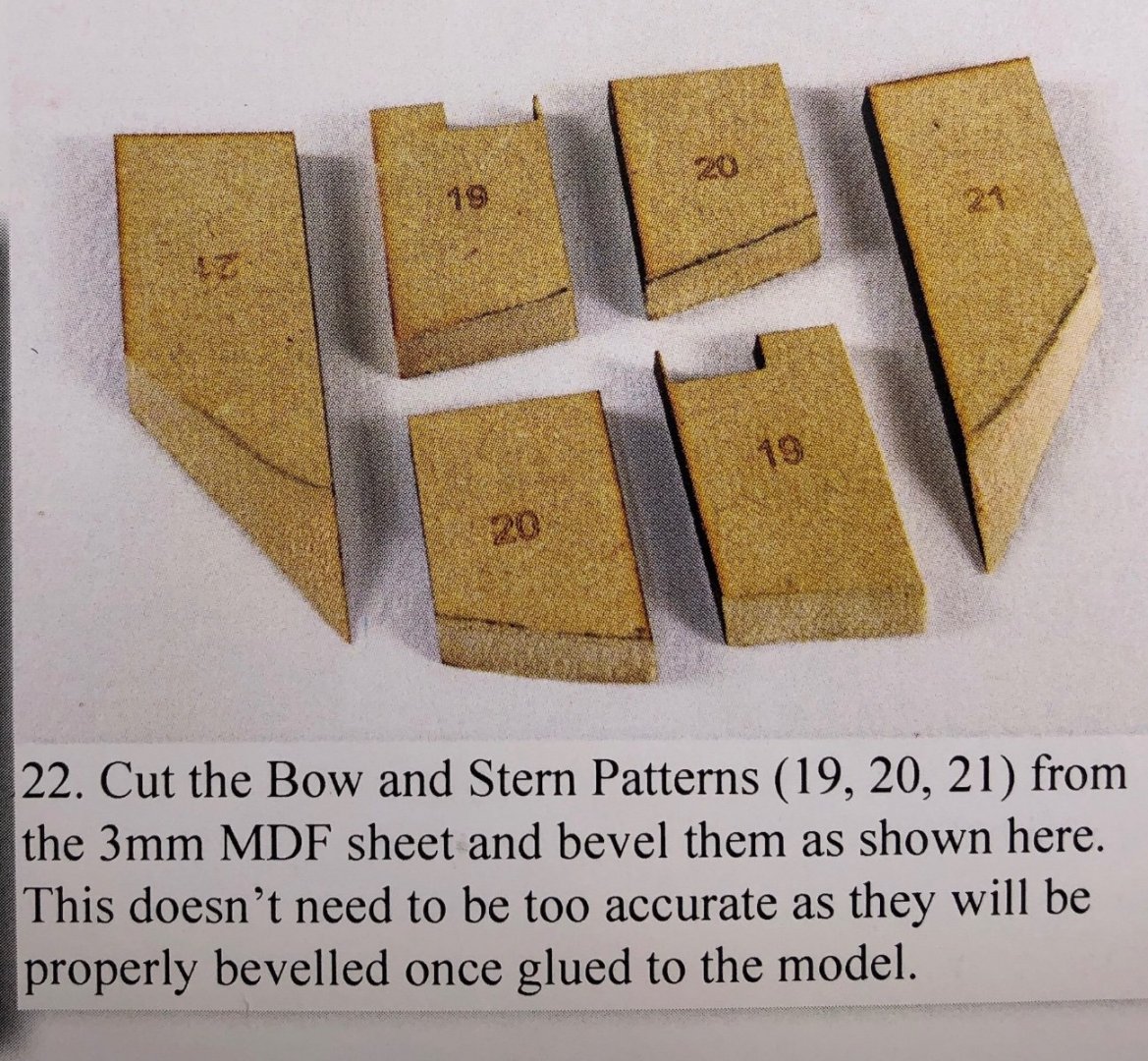

Next up was to add bulkheads 2 and 3 and the 4 bow pattern pieces. The manual suggest beveling these pieces before installing them. I've always just shaped the bulkheads when I fair the hull so I was hesitant to do this but I decided to try it. I used my new Proxxon rotary tool with the Proxxon Flex-Shaft attached to it. I really like this tool. It has a nice variable speed dial and the Flex-Shaft is so much more comfortable to hold rather than the bulky rotary tool itself.

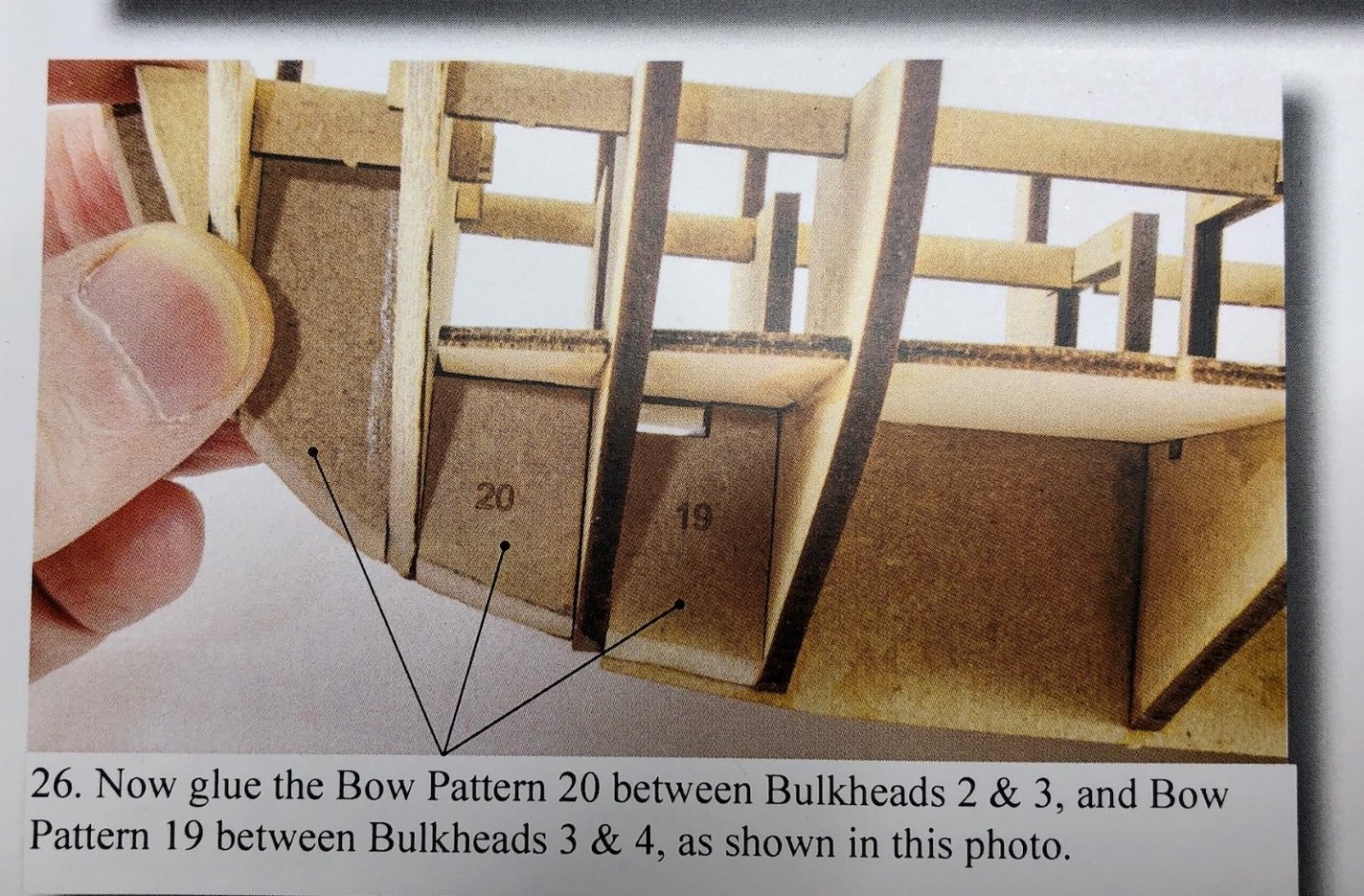

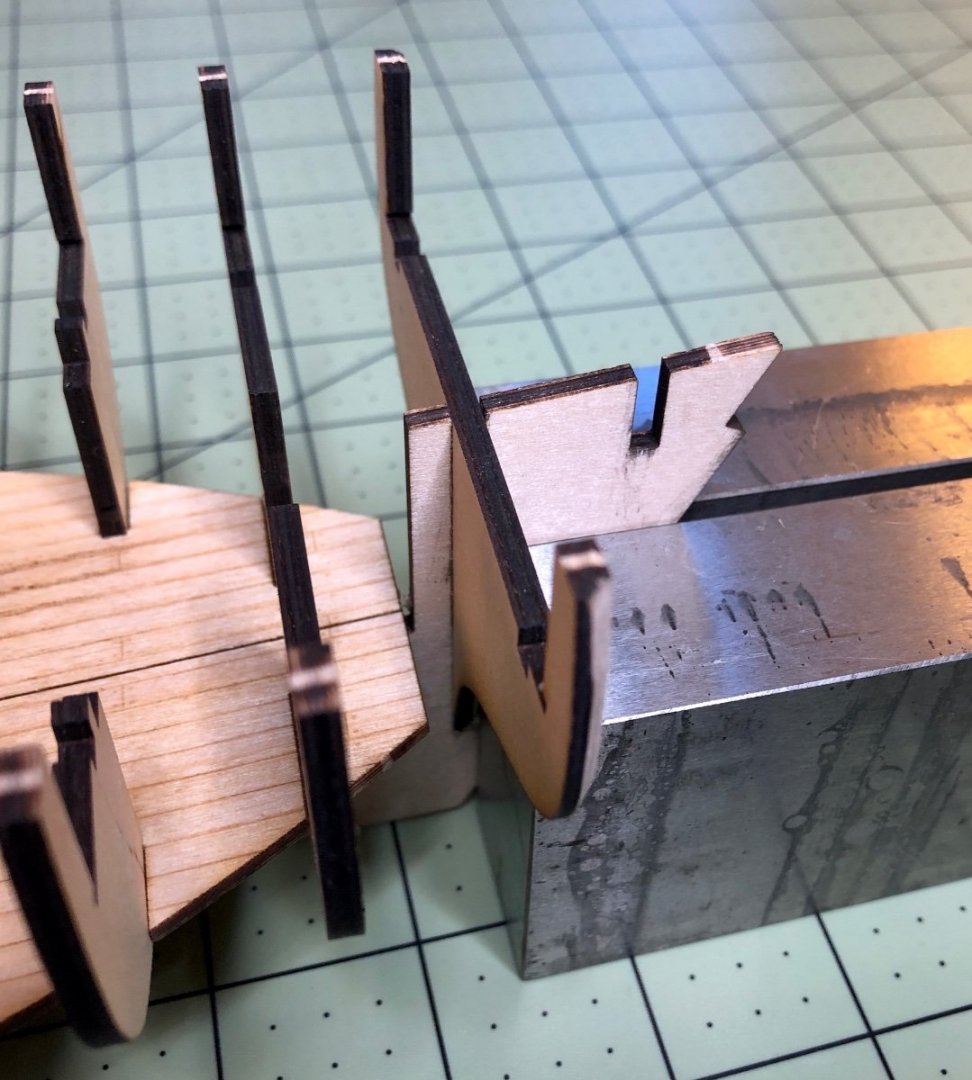

Now here's where I began to get ahead of myself by not thoroughly reading ahead in the instructions. I was relying too much on the great photos in the manual. The first photo below is from the manual and it shows the beveled Bow and Stern Patterns 19, 20, and 21. The second photo is also from the manual and it shows that pattern 19 is placed between bulkhead 2 and 3 and pattern 20 goes between bulkhead 3 and 4.

However, there are 3 arrows in the photo and one of them is pointing to the space forward of bulkhead 2 and 3. I simply assumed that the arrow meant that pattern piece 21 would go there (i.e. 19, 20 and then 21 where the arrow was pointing).

Wrong! Pattern 21 goes between bulkheads 14 and 15 near the stern which is actually shown in the next photo in the manual but I didn't read ahead. The arrow that points to the space ahead of bulkhead 2 should not be in the photo but I could have avoided the error by reading more carefully.

After I realized what I had done, a little bell went off in my head where I thought I had read about this same error somewhere before. So I checked out the other Flirt build logs and, sure enough, Glenn (gbarlow) did exactly the same thing when he was building his Flirt. I had read about it some time ago but had forgotten about it. Hilarious! Glenn and I must think alike! 😂

Here's a photo of pattern 21 wrongly glued ahead of bulkhead 2. It won't cause a problem being there.

Bulkheads 14 and 15 were very loose so I used my machinist blocks to square them up to the false keel.

The very last bulkhead #16 was very loose so I took my time eyeballing it and using a narrow, 90 degree angle square to line it up perpendicular to the false keel. This was a bit tricky but I think I got it squared up pretty well. The tops of bulkheads 14, 15 and 16 also need to be sanded quite a bit so they are level with the top of the false keel. I think I may have needed to sand it even a bit more but it looked and felt level so I stopped. I'm always afraid of sanding too much.

Having glued pattern 21 in the wrong place simply meant that I needed to make a new set from the same parts sheet. I cut the new patterns with my razor saw and glued them in the right place between the stern bulkheads 14 and 15.

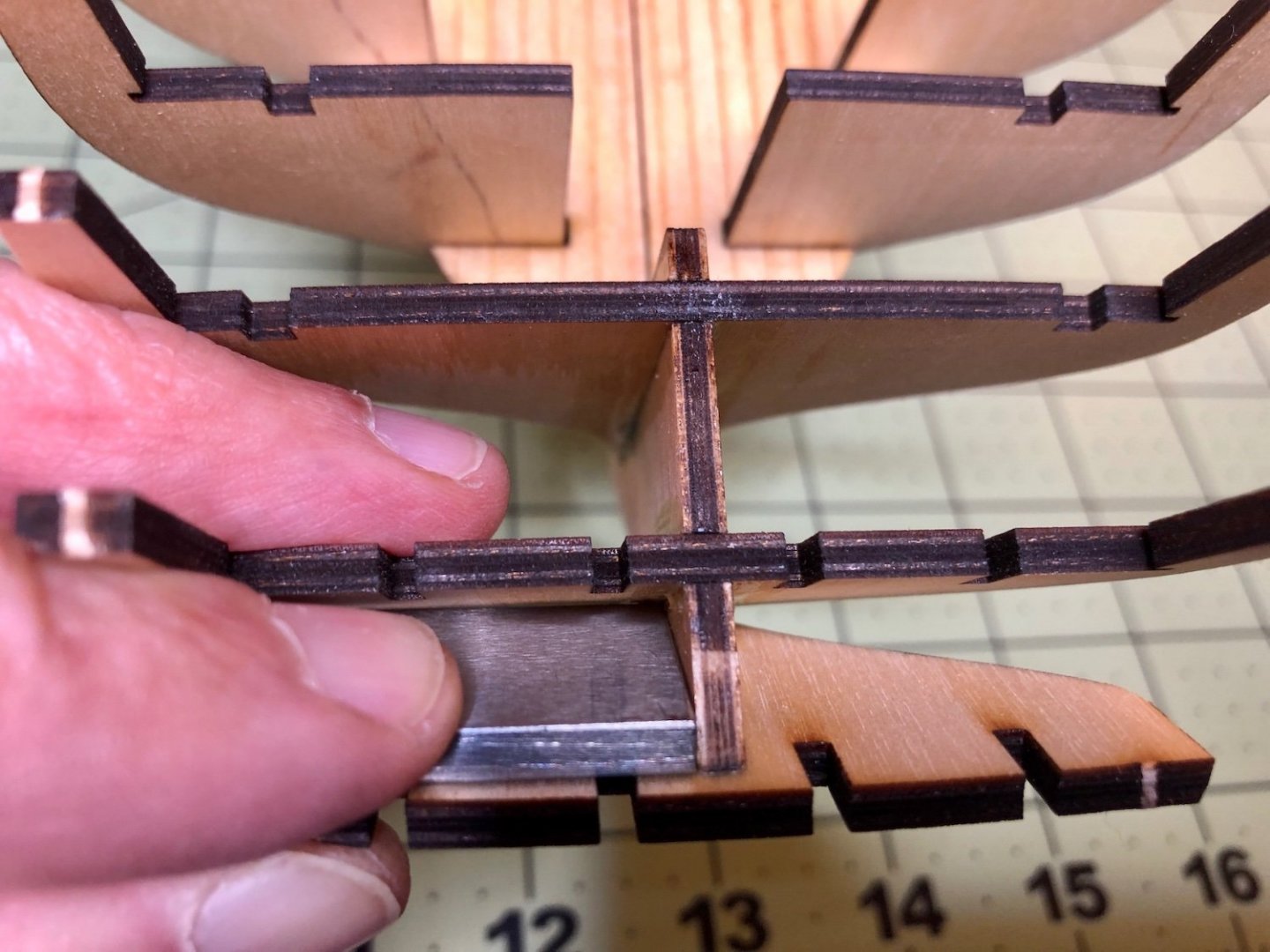

I went out of sequence from the manual a little and waited until I had all the bulkheads and patterns installed before I added the deck beams, the upper deck longitudinal support and the stern frame patterns which are very fragile. I took my time with these parts as nearly all of them required some sanding to get them to fit properly and I still managed to snap one of the stern patterns when my elbow hit it while I was adjusting one of the deck beams. The tolerances between the these pieces and the slots are very tight. I was able to carefully glue the stern pattern back together also.

Adding the main deck is when things really began to get crazy! The 2 mm birch plywood main deck is an extremely tight fit. I tried to test fit it but I was afraid I would never be able to get it off in order to glue it down. I tried to check the spacing of the bulkheads and the slots in the in it also as best I could and then proceeded to put glue on all the supports. Even though I used regular PVA for this, I knew I needed to work fairly quickly since there's a lot of notches in the bulkheads to get lined up right and to get the deck to sit down properly.

Try as I might by flexing the deck until I thought it was going to break, I couldn't get it to seat properly and I had a bulge in the middle. So I kept wresting with it by pushing down between the bulkheads. I even tried to get it off but it wasn't cooperating so I just keep at it. Little by little and with a bunch of frightening snaps and pops, it began to seat better but it was still not seated down flush to all of the deck beams and was not all the way into the notches in the bulkheads.

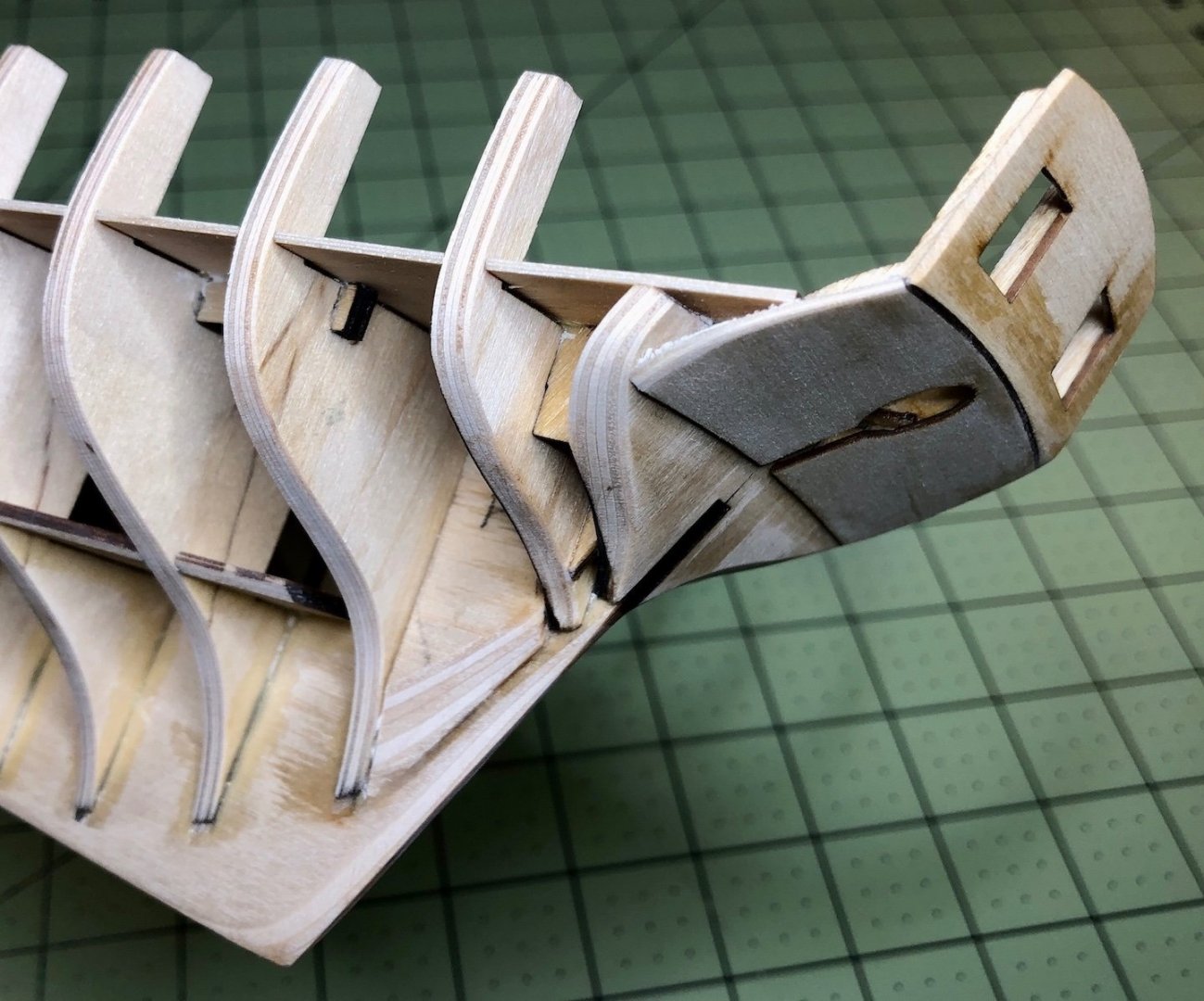

Then disaster struck. I was holding the model in my lap and still working on getting it to seat when it slipped. The stern bumped into my forearm and all of the fragile stern frame patterns broke off! After a few choice words, I realized that if I didn't get the deck to seat properly, the model would pretty much be ruined so I focused my attention on manipulating the deck and finally I got it to seat.

All I can say is that the deck is an astonishingly tight fit and that it was really difficult to finally get it to seat properly. I'm not sure how I could have done it any different given how tight it was. I wonder if anyone else has had this problem?

Now I needed to see if I could repair the stern frame patterns. Fortunately, I was able to correctly match the broken off pieces with their mates when I looked at them closely under magnification. So, little by little with PVA, thin CA and a lot of patience, I was able to get them glued back together and properly aligned...I think! Fingers crossed!🤞

So there you have it folks. Another adventurous day of errors and repairs in Bob's shipyard. You'll certainly be able to learn a lot about "what not to do" here!

So stay tuned, there's probably more bloopers to come! 😂

Thanks for stopping by. Cheers!

- Tomculb, jpalmer1970, hollowneck and 13 others

-

16

16

HM Brig-Sloop Flirt 1782 by BobG - Vanguard Models - 1:64

in - Kit build logs for subjects built from 1751 - 1800

Posted

Welcome, Derek, and thanks for coming along. I'm learning to "enjoy" fixing my mistakes as long as they actually can be fixed adequately!