BobG

-

Posts

3,096 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by BobG

-

-

Congratulations on your photo, Eric! I swear, I'm just about to give up on 35mm photography and just shoot with my iPhone. It's just so convenient, compact and darn good! Now, tell us about your photo...what is it?

-

Beautiful, Paul!

16 minutes ago, Paul Le Wol said:After the holes were drilled in the chain plates I annealed them again but quenched them in the blackener. The finish is very durable.

So you quenched the brass in the blackener while it was still hot?

-

-

Great work on the mackerel seine, juju! It's very realistic!

-

-

1 hour ago, md1400cs said:

If Sergal had kept the solid bronze 600+ bits as well as the kit’s new upgrades this kit might be one of the best, in general, kits on the market today.

It’s hard to recommend this current kit given its high retail price point – North of $1000 USD

First of all, wonderful work, Michael, on this immensely ornate and historic model.

I would guess that the changes that Sergal has made to the current kit were done to save on production costs. However, I think that most modelers who pay over $1000 USD for a kit, expect to get a superior quality kit and wouldn't mind spending a couple hundred more to get outstanding quality in the materials of the kits. These higher end, expensive kits have a limited market and I believe that the people who buy them want the best and are willing to pay for it.

- fmodajr, Bill Morrison, Baker and 4 others

-

7

7

-

-

I just saw your Cutty Sark in the gallery also. Wow, what a masterpiece! Both the model and the display case are magnificent! Great job, Harry.

You should add a link for it under your signature so others can find it too. What a treasure!

- mtaylor, Old Collingwood, hof00 and 1 other

-

4

4

-

5 minutes ago, glbarlow said:

Where’s your build log, I want to follow

It's in the the Build Logs for Kits from 1751-1800 or just click on the HMS Flirt under my signature - current builds. It could well be a comedy of errors!

-

On 8/9/2021 at 6:16 PM, glbarlow said:

I added filler parts 19 and 20 to the bow area, and thinking I knew what I was doing without consulting the instructions I added part 21 next to those. However part 21 is for the stern area, not the bow. It won’t hurt anything to be there and in fact probably helps, so I just fabricated part “21b” from the bulkhead sheet scrap and added it to the stern, problem solved.

OMG, I just did the very same thing! So I'll be a scratch making a part "21b" tomorrow too. This is too funny! 🤣

-

-

It sounds like this was very challenging work, Bob, but from the looks of it, you've done a beautiful job!

-

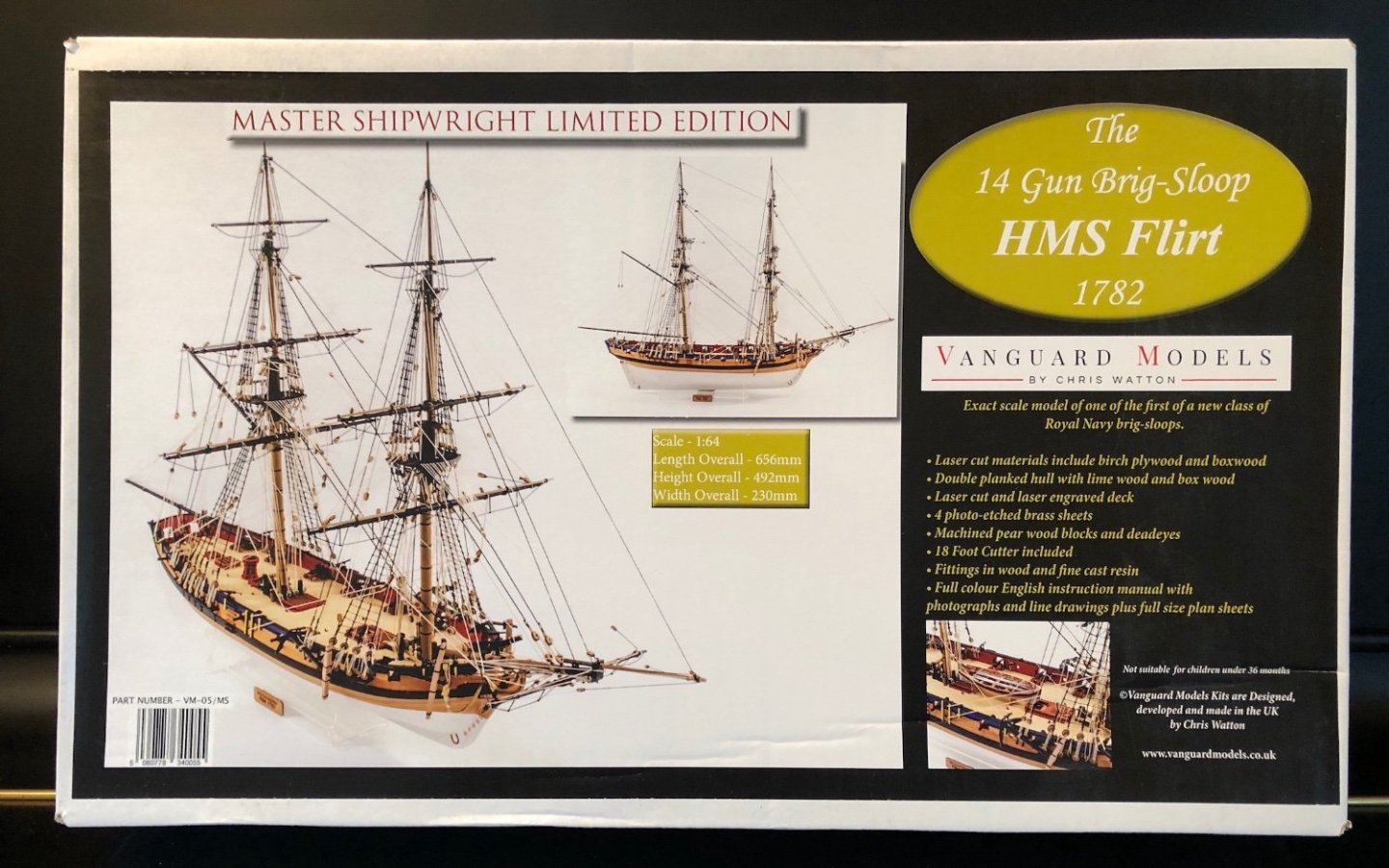

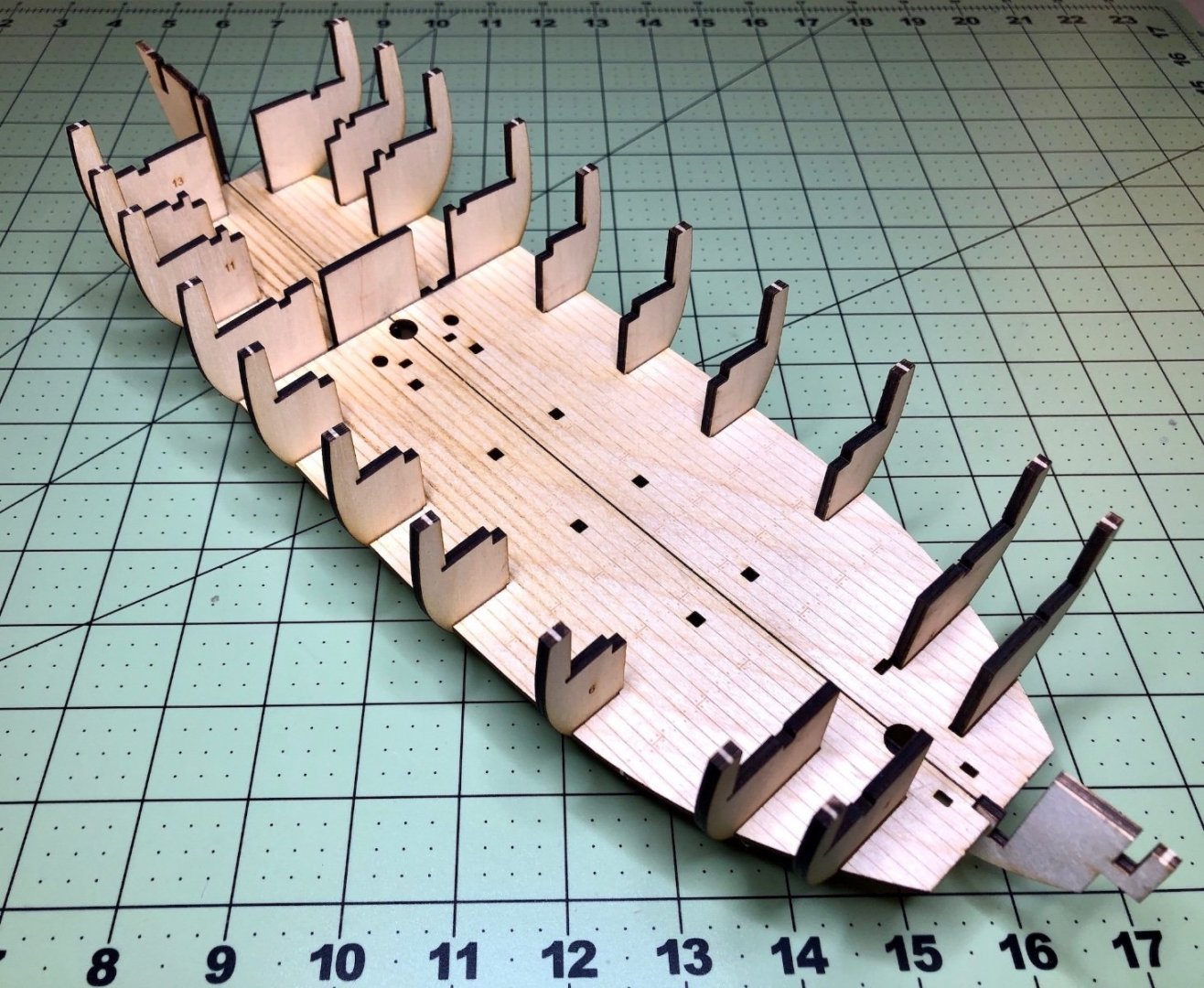

Hello and welcome to my build log of the HMS Flirt by Vanguard Models. I've decided to start building the Flirt in addition to my current build of the Pen Duick after a significant hiatus from doing any ship modeling as I grappled with the vague and confusing, instructions by Artesania Latina. At this point, I just need to build something that has excellent instructions, great materials and is historically authentic and the Flirt fits that bill for me.

My goal to improve my overall modeling skills while taking my time to slow down and carefully execute each step without rushing the process. I want to thoroughly understand what I'm doing before I do it especially when it comes to fairing and planking the hull. I will be using Chuck's method of planking for lining the hull, shaping and bending the planks. Those who use this method well end up with beautifully planked hulls and it's time for me to learn it too. Finally, I plan to simply have fun and enjoy the journey without getting overly perfectionistic. I can get obsessive about the smallest details at times and I have found that there's a point at which I need to say "enough" at continue forward.

Of course, I will be relying heavily upon the expertise of other modelers whose work I admire here on the forum such as gbarlow, DelF, Blue Ensign, Hollowneck, desalgu, WalrusGuy, Moonbug, gjdale, James H and many others.

So here we go. I will be building the Master Shipwright Edition of the Flirt. I chose this edition particularly because of the extensive use of boxwood rather than pear wood which is used in the standard version . I've heard ship modelers sing the praises of boxwood over the years but I've never used it before and have wanted to see what it like compared to woods like yellow cedar and pear which I like very much.

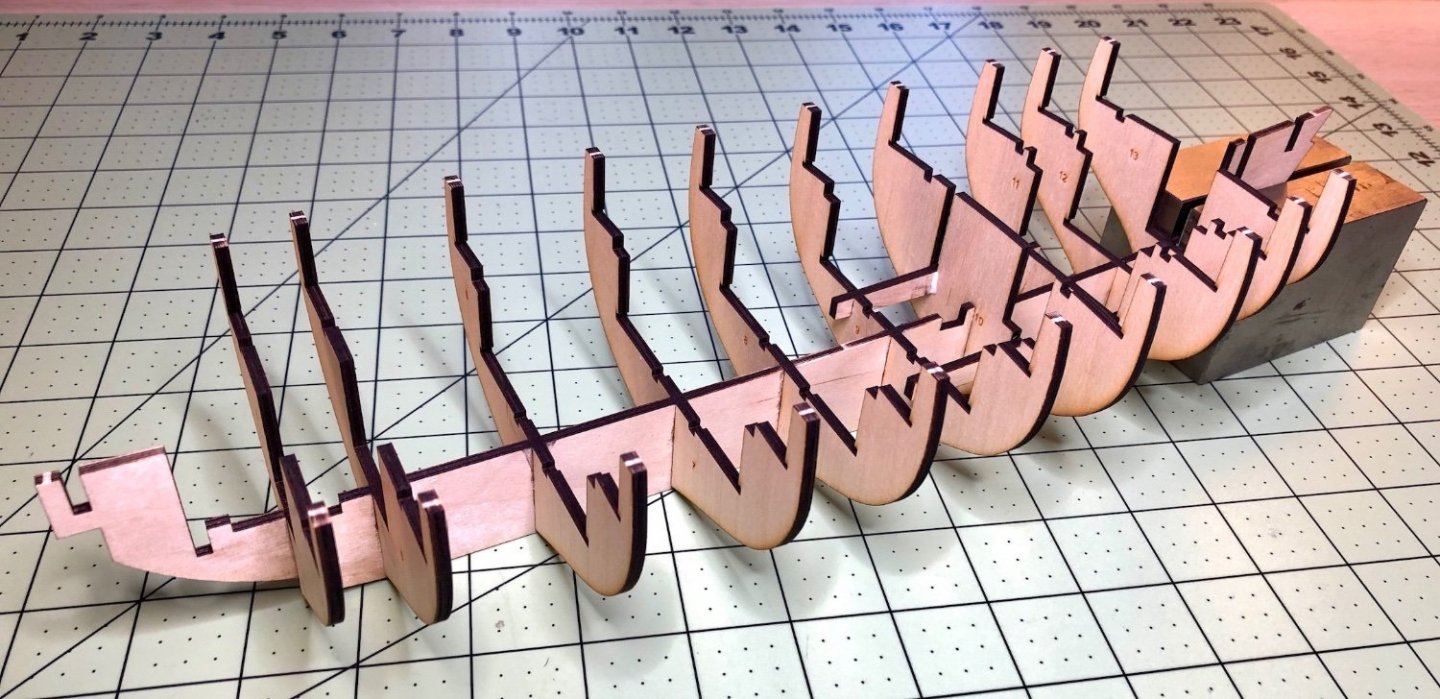

The false keel and the bulkheads are birch plywood which is very smooth and quite hard and the laser cutting is excellent. The cuts are extremely accurate with minimal laser burn.

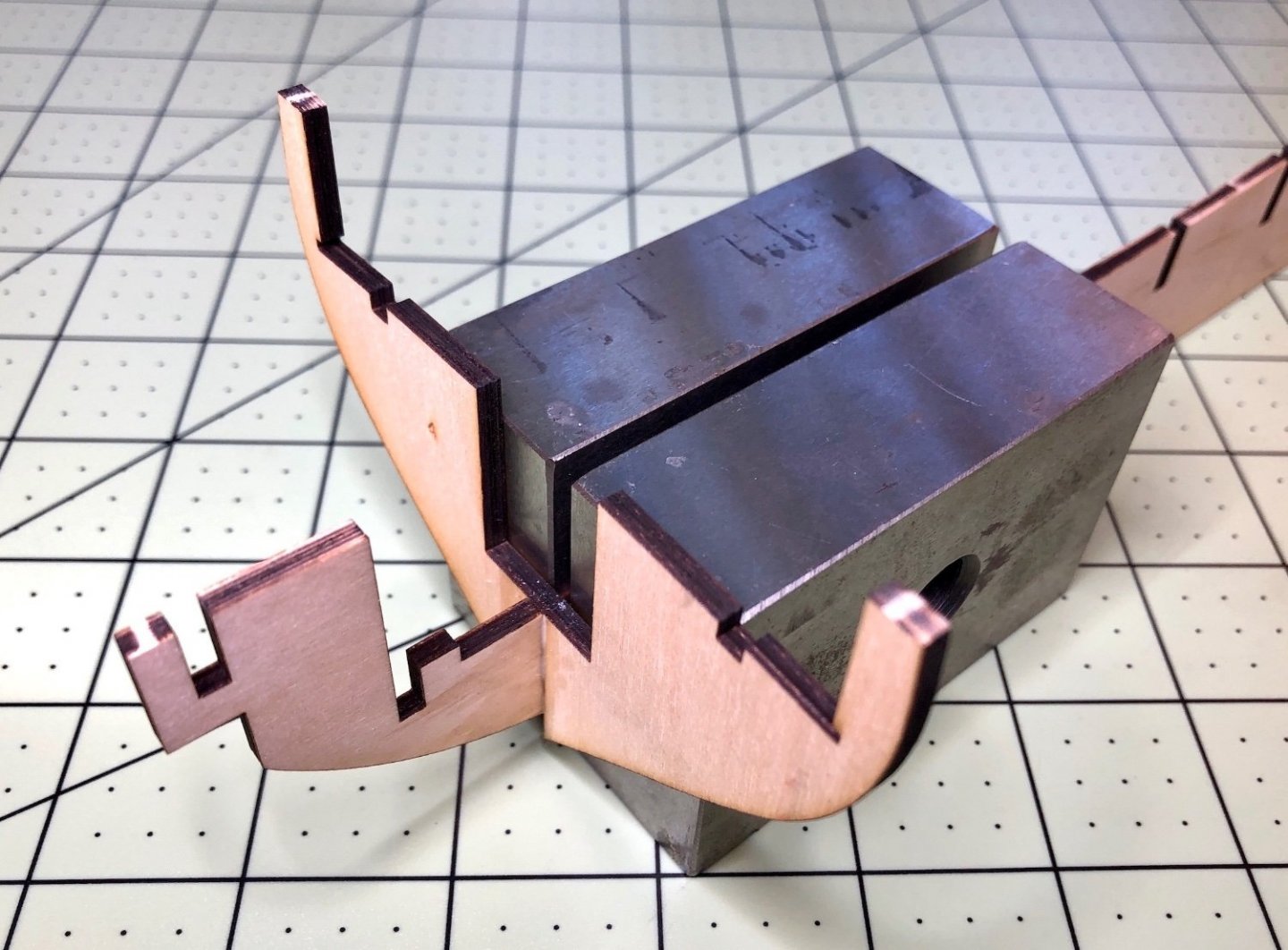

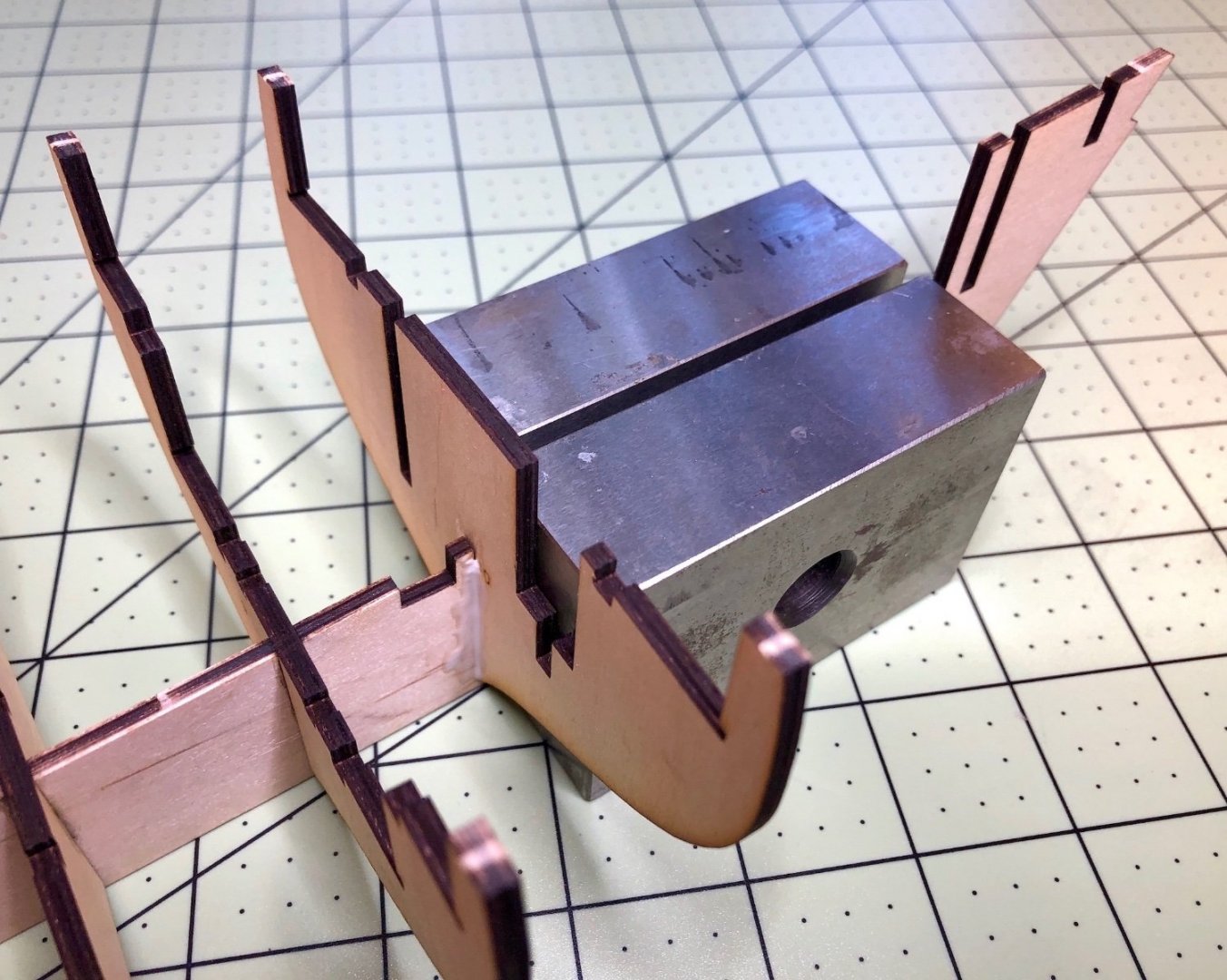

The first step was to add bulkheads 4 -13 to the false keel. Bulkhead 4 had a little wobble in it and bulkheads 10 - 12 were quite loose so I used my machinist blocks to insure they were all accurately perpendicular to the false keel. I primarily use Titebond Thick & Quick glue which sets up faster than regular Titebond but still gives me plenty of time to make adjustments as needed. It also doesn't run down vertical surfaces.

I added the scribed lower deck next. These fit very snuggly and I'm glad that I practiced test fitting them first before gluing so I could see how they click into place with a careful amount of pressure. Lastly, I used regular Titebond to brush glue on all the joints which makes for a very solid frame at this point.

Many thanks to everyone for stopping by and taking a look. Your comments and advice will always most welcome.

Cheers!

- bruce d, jpalmer1970, BenD and 21 others

-

24

24

-

-

Bummer, Mark, I've been enjoying following your build. Will you be able to get your eyes examined and get some new glasses pretty soon?

- mtaylor, Moonbug, Keith Black and 4 others

-

7

7

-

-

-

Nice to see you back in your model shipyard, Vaddoc, and congratulations on putting your health and fitness first and foremost. A lot of people have gained weight during the pandemic from what I have read. I'm looking forward to seeing you continue to make progress on this wonderful model.

- Wintergreen, mtaylor and FriedClams

-

3

3

-

17 minutes ago, jpalmer1970 said:

So glad to see you are continuing with this build Bob. I'm going to be relying heavily on this log when I start my Pen Duick later this year!

I hope my log will be of some assistance to you although, at the rate I'm going, I may be getting assistance from your log especially figuring out the rigging. She is really is a beautiful racing yacht and I look forward to your build. Thanks for looking in.

- jpalmer1970 and Ryland Craze

-

2

2

-

Fantastic work, Ron, she looks great! I always feel like the rigging really brings the ship to life.

- chris watton and mtaylor

-

2

2

-

-

29 minutes ago, Nunnehi (Don) said:

Bob, nice to see you back at work on your beautiful model!

Thanks, Don. I've been enjoying your Winnie build. Really fine work!

-

-

HM Brig-Sloop Flirt 1782 by BobG - Vanguard Models - 1:64

in - Kit build logs for subjects built from 1751 - 1800

Posted · Edited by BobG

Well, it's been an interesting 2 days. I've made some progress but it hasn't been without some hiccups and one major disaster. Read on to see how things went a little haywire and how I think I managed to bail myself out and, yes, it's ok to roll your eyes! After today, I may need to rename my build log "A Comedy of Errors and Repairs." 🤣

First off, I added the little door to the sub deck and used a cut off pin for the door knob. Then I gave the deck and door a single coat of satin WOP.

Next up was to add bulkheads 2 and 3 and the 4 bow pattern pieces. The manual suggest beveling these pieces before installing them. I've always just shaped the bulkheads when I fair the hull so I was hesitant to do this but I decided to try it. I used my new Proxxon rotary tool with the Proxxon Flex-Shaft attached to it. I really like this tool. It has a nice variable speed dial and the Flex-Shaft is so much more comfortable to hold rather than the bulky rotary tool itself.

Now here's where I began to get ahead of myself by not thoroughly reading ahead in the instructions. I was relying too much on the great photos in the manual. The first photo below is from the manual and it shows the beveled Bow and Stern Patterns 19, 20, and 21. The second photo is also from the manual and it shows that pattern 19 is placed between bulkhead 2 and 3 and pattern 20 goes between bulkhead 3 and 4.

However, there are 3 arrows in the photo and one of them is pointing to the space forward of bulkhead 2 and 3. I simply assumed that the arrow meant that pattern piece 21 would go there (i.e. 19, 20 and then 21 where the arrow was pointing).

Wrong! Pattern 21 goes between bulkheads 14 and 15 near the stern which is actually shown in the next photo in the manual but I didn't read ahead. The arrow that points to the space ahead of bulkhead 2 should not be in the photo but I could have avoided the error by reading more carefully.

After I realized what I had done, a little bell went off in my head where I thought I had read about this same error somewhere before. So I checked out the other Flirt build logs and, sure enough, Glenn (gbarlow) did exactly the same thing when he was building his Flirt. I had read about it some time ago but had forgotten about it. Hilarious! Glenn and I must think alike! 😂

Here's a photo of pattern 21 wrongly glued ahead of bulkhead 2. It won't cause a problem being there.

Bulkheads 14 and 15 were very loose so I used my machinist blocks to square them up to the false keel.

The very last bulkhead #16 was very loose so I took my time eyeballing it and using a narrow, 90 degree angle square to line it up perpendicular to the false keel. This was a bit tricky but I think I got it squared up pretty well. The tops of bulkheads 14, 15 and 16 also need to be sanded quite a bit so they are level with the top of the false keel. I think I may have needed to sand it even a bit more but it looked and felt level so I stopped. I'm always afraid of sanding too much.

Having glued pattern 21 in the wrong place simply meant that I needed to make a new set from the same parts sheet. I cut the new patterns with my razor saw and glued them in the right place between the stern bulkheads 14 and 15.

I went out of sequence from the manual a little and waited until I had all the bulkheads and patterns installed before I added the deck beams, the upper deck longitudinal support and the stern frame patterns which are very fragile. I took my time with these parts as nearly all of them required some sanding to get them to fit properly and I still managed to snap one of the stern patterns when my elbow hit it while I was adjusting one of the deck beams. The tolerances between the these pieces and the slots are very tight. I was able to carefully glue the stern pattern back together also.

Adding the main deck is when things really began to get crazy! The 2 mm birch plywood main deck is an extremely tight fit. I tried to test fit it but I was afraid I would never be able to get it off in order to glue it down. I tried to check the spacing of the bulkheads and the slots in the in it also as best I could and then proceeded to put glue on all the supports. Even though I used regular PVA for this, I knew I needed to work fairly quickly since there's a lot of notches in the bulkheads to get lined up right and to get the deck to sit down properly.

Try as I might by flexing the deck until I thought it was going to break, I couldn't get it to seat properly and I had a bulge in the middle. So I kept wresting with it by pushing down between the bulkheads. I even tried to get it off but it wasn't cooperating so I just keep at it. Little by little and with a bunch of frightening snaps and pops, it began to seat better but it was still not seated down flush to all of the deck beams and was not all the way into the notches in the bulkheads.

Then disaster struck. I was holding the model in my lap and still working on getting it to seat when it slipped. The stern bumped into my forearm and all of the fragile stern frame patterns broke off! After a few choice words, I realized that if I didn't get the deck to seat properly, the model would pretty much be ruined so I focused my attention on manipulating the deck and finally I got it to seat.

All I can say is that the deck is an astonishingly tight fit and that it was really difficult to finally get it to seat properly. I'm not sure how I could have done it any different given how tight it was. I wonder if anyone else has had this problem?

Now I needed to see if I could repair the stern frame patterns. Fortunately, I was able to correctly match the broken off pieces with their mates when I looked at them closely under magnification. So, little by little with PVA, thin CA and a lot of patience, I was able to get them glued back together and properly aligned...I think! Fingers crossed!🤞

So there you have it folks. Another adventurous day of errors and repairs in Bob's shipyard. You'll certainly be able to learn a lot about "what not to do" here!

So stay tuned, there's probably more bloopers to come! 😂

Thanks for stopping by. Cheers!