russ

Members-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by russ

-

Aldo: Thanks. This restoration will always be one of my favorite projects. It was a good subject, a great client, and the finished model has gotten more than a few ooos and aahhs. Russ

- 43 replies

-

- restoration

- finished

-

(and 1 more)

Tagged with:

-

Michael: Thanks for your kind words. I appreciate it. Russ

- 43 replies

-

- restoration

- finished

-

(and 1 more)

Tagged with:

-

Anja: Thank you. It was an enjoyable project. The term "white winged queen" was very likely coined by a local journalist, Walter Fountain. He wrote many newspaper stories about the annual schooner races. Russ

- 43 replies

-

- restoration

- finished

-

(and 1 more)

Tagged with:

-

Bob: In all of the photos I have seen of Biloxi schooners, they had the boom on the forestaysail as I have shown. The jib does not. Thanks for the kind words. Russ

- 43 replies

-

- restoration

- finished

-

(and 1 more)

Tagged with:

-

I agree with Gary. I do not think there is a "right" color for blocks. I have seen them lighter and darker. In working boats, I have seen them painted. I think for 18th century blocks it would be some shade of "natural". Russ

-

- 43 replies

-

- restoration

- finished

-

(and 1 more)

Tagged with:

-

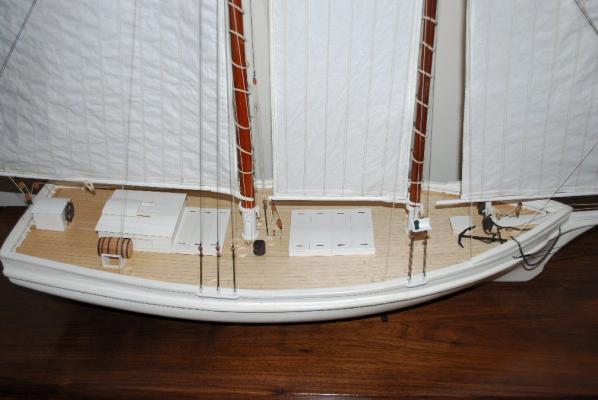

New gaffs and booms were made and the sails were sewn out of japara cotton. Rigging was created from Egyptian cotton. I can heartily recommend Egyptian cotton for rigging. It is some of the best stuff I have used. Here are some photographs of the completed model. More to come. Russ

- 43 replies

-

- restoration

- finished

-

(and 1 more)

Tagged with:

-

There were several photos of detail in the original build log that I no longer have. So, descriptions will have to suffice for the most part. After fitting the deadeyes and chainplates, I had to work on the masts. The original mainmast was one long stick, but it had been broken about two thirds the way up, so it made sense to cut the mast off and then add a proper masthead. Here you can see what I did. The white area is a separate piece of wood shaped and fitted to the lower mast. A dowel was used to connect the two pieces, using the dowel as a spline. This same procedure was done on both mastheads. Russ

- 43 replies

-

- restoration

- finished

-

(and 1 more)

Tagged with:

-

The deck framing looks very good. So long as the paper you use is not too thick, the caulking lines should be okay. Russ

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

The tub would be for water to use when sponging out the gun. That battlestation model is generic in nature. I am not sure what time period or country it represents. Russ

- 601 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

- 601 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

Wow. That sounds like a bit of work. The results are good. Russ

- 601 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

Apprentice: I am not sure what time period or nationality you are talking about, but I have always read that planks were spiled and tapered, at least in British and American shipyards. For framing they would look for timbers that had naturally curved grain, but in planks, that would be very difficult to find in most cases. It is far more likely that they would use what they had an spile the mating edge and taper the other edge from a wider plank. If it was just a minor bit of edge bending, they would do it, especially on the ceiling plank, but for any significant curve, that almost certainly had to come out of a wider plank. Certainly in the mid to late 19th century in American merchant shipyards, they were spiling and tapering. There is plenty of evidence for that and the same is known of British merchant shipyards of the period. Maybe you are referring to an earlier period or larger ships? Russ

-

Those barrels look pretty good. Did you add the staves on the outside of the barrel? The bands look very good. Russ

- 601 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

Mark: I would go for the hand tool solution. Make up a jig to hold the piece and plane down the corners, one at a time, to get the shape you want. So long as the plane is headed away from your body, you should be okay. Russ

-

A question on drop planks

russ replied to apprentice's topic in Building, Framing, Planking and plating a ships hull and deck

In that photo, they used four strakes between the drop planks and the butt joints as I recall, so that would fit. I think they had to work within the rules as best they could. So long as they did not violate the rules, they were okay. Russ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.