-

Posts

2,305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NMBROOK

-

Great work Ulises Sadly the link I gave you for the build on the Russian forum seems to have disappeared.They were doing some changes a couple of weeks ago,hopefully it will rematerialise in the future. Kind Regards Nigel

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Hopefully Panart have realised what a bad idea the balsa was .The book is extremely useful as a guide to providing more detail,however some 'creative thinking' is required as the hull lines in the kit differ from the book. I spiled every plank from 1.5mm pear sheet on mine.Perhaps unnecessary,but I was concerned as the planks work out at 6mm wide.It did however take around a month of 60 hour weeks to plank . I look forward to following along and don't be afraid to ask,I am only too glad to help in anyway Kind Regards Nigel

-

More great work and congratulations on your new model Dimitris My kit had been sat on the shelf for a few years when I got it,it came with both lime and balsa first planking,letting the builder decide.I tried the balsa route and sanded it off and used the lime instead.If you get a choice,I would recommend using the lime first planking,the balsa is more trouble than it is worth Kind Regards Nigel

-

Drill speeds and materials

NMBROOK replied to Captain Al's topic in Modeling tools and Workshop Equipment

Strictly speaking,every material has it's own optimum cutting speed.This is not an RPM value but measured in feet or metres per minute.Many variables come into play to determine the RPM you require,for modelling,mainly the diameter of whatever the cutting the device and how many cutting faces the tool has.A milling cutter with six flutes will want to run slower than that with two. When all these variables come in to play,you essentially have many tables of desired spindle speeds.Advances in cutting technology challenge the 30m/min I was taught was the optimum for mild steel.The latest CNC beam saw/drill lines we have at work have drills unlike anything elsewhere and can drill a 50mm hole through 40mm steel in around 5 seconds!! Sorry I can't be more specific,but the general rule to follow is too fast with wood,you get burning,too slow and you get poor surface finish.This is only with sharp tools,blunt tools can cause either even when the speed is correct. Kind Regards Nigel -

Too much gold-shining brass

NMBROOK replied to TomJonas's topic in Metal Work, Soldering and Metal Fittings

Thank you Tom Yes,Pear and box are available in the UK,however Arkowood in Germany may work out cheaper for you.I don't use them personally,but lots of other builders on here swear by them.They are a little cheaper but for me the postage would balance the cost,for you,it would probably work in your favour. Even when dry,Pear is extremely flexible.Only the worst bends require steam etc and this makes the pear able to take very tight curves.The only time you might snap a plank is sometimes the grain in the Pear takes on a sudden change in direction and results in a very weak strip. There is a link to the Arkowood site in the timber suppliers thread Kind Regards Nigel -

Too much gold-shining brass

NMBROOK replied to TomJonas's topic in Metal Work, Soldering and Metal Fittings

I agree,this is the result I achieved using a multi stage process incorporating gilding paste followed by sealing then an acrylic wash,finally drybrushing to accentuate the depth.More detail in my Caroline log. Kind Regards Nigel -

Wow,the display is as stunning as the model!! Kind Regards Nigel

- 227 replies

-

- cumberland

- 74 gun

-

(and 1 more)

Tagged with:

-

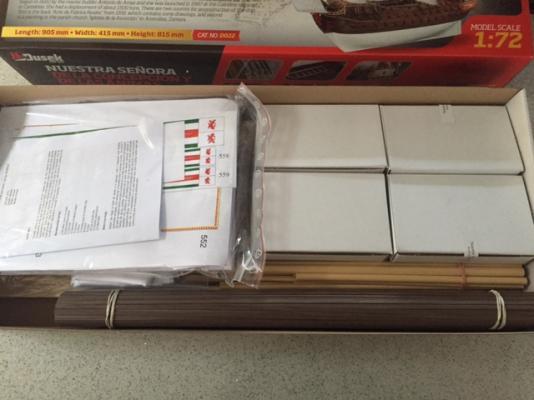

Well my Nuestra Senora has landed a mere six days after Daniel dispatched it !!!!!!!!!!.Firstly I would like to mention how well packaged the kit was.The kit box was packed inside a larger box and surrounded by those clear plastic 'pillows' that are full of air.The kit box was completely unmarked from it's little 'trip'. My first reaction was just how heavy the box is for it's size and upon opening it is full to the brim!!I have taken a couple of pics,but as yet haven't the time to start examining the contents,unfortunately I have just got up and have to set off shortly for a twelve hour nightshift However looking inside,although I am not a big fan of walnut,the wood in the box has to be the best I have seen in thirty years of building wooden models. I am now deciding as to whether to do a 'review' or start a log and show all the information as to the contents there.Everything both modelling wise and non essential domestic items is currently being packed up in anticipation of our house move,but I cannot see it being too long after settling in that I start making saw dust. Kind Regards Nigel

-

fairing technique

NMBROOK replied to michael101's topic in Building, Framing, Planking and plating a ships hull and deck

Michael,I would start above the waterline,with a thicker strip you should be able to assess the shape over the full length bar the first four bulkheads.Using an elastic band or tape,you should be able to hold the strip i position to judge how much packing and where.I would also temporarily fix a piece of card across the sides of the rearmost bulkhead with some graph paper glued to it.Lining the squares up with the true vertical of the false keel will allow you to check the symmetry at this position.Like you say a lack of symmetry amidships isn't overly noticeable,however the stern needs to be correct or you will have issues when building the stern galleries. Kind Regards Nigel -

fairing technique

NMBROOK replied to michael101's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Michael Looking at the photos I would add lime strip bent around the edges of the low bulkheads to bring them to roughly the same level as the others before you do any fairing.When fairing and checking the run of the edges,I would use a strip thicker than the planking material.This bends in more of an arc and will not follow the irregularities.It will be much easier to get a fair run building up these low bulkheads as otherwise you will end up removing far too much material and risk loosing the hull shape. Kind Regards Nigel -

fairing technique

NMBROOK replied to michael101's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Michael I have Mamoli's drawings and these have been enlarged to produce a model of 1/60.I can confirm that even the drawings are not symmetrical for the bulkhead profiles.Many of the slots for the false keel do not run vertically true.Even when this is corrected there are still inconsistencies at various positions around the profiles.If you have assembled the bulkheads to the keel,all I can suggest is to make templates for half of each bulkhead either side of the false keel and check these against the plan,yes there will still be discrepancies,but the idea being is that you ensure some symmetry to each side. Kind Regards Nigel -

Pandora by marsalv - FINISHED - 1:52

NMBROOK replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Superb work Marsalv Kind Regards Nigel -

Thank you Mr Pett The break is only a temporary one.Far too much going on in my personal life at the minute to devote the time to get back into the build. When things settle down,I have every intention of putting all my other projects on hold to move this one forward. I wish you well with your build,it certainly looks like you have done some great work so far. Kind Regards Nigel

-

I keep my workshop heated to roughly the same temperature as our centrally heated house.Theory being,store the wood in the same conditions as not only what the model will be built in,but also displayed in.Don't have AC,not many houses do in the UK,so regulating humidity is a bit hit and miss. I have found Swiss Pear to be far the most sensitive timber to moisture,any damp and it soaks it up from the air like a sponge and promptly warps. Kind Regards Nigel

-

I subscribed to this model when it was launched in the UK.The marketing pictures were not of the complete partwork but something else.The number of differences left me disgruntled and I cancelled the subscription.The model I started building ended up being modified to such an extent that my log has been moved to the scratch section.About two inches of the bottom of the bulkheads is all that remains. My advise would be to save up and buy the Sergal kit,I wish I had! Kind Regards Nigel

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.