-

Posts

2,305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NMBROOK

-

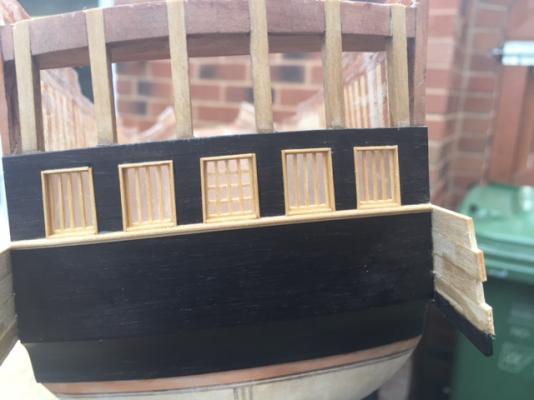

Thank you Nigel The windows actually form part of a fan whose centre is somewhere miles above the model.The dimensions were taken from the plan,at least an average was obtained as there were minute discrepancies comparing each window on the drawing.This gave me the shape.The internal framework is purely by eye.It is easiest to fit the central bars and then visually split the remaining sections in half when fitting the other pieces.Had there been an even number of bars,it would have been interesting Kind Regards Nigel

-

A little bit of a update More progress on treenailing.I then took a little break to concentrate on a job that needs doing before I can complete the framing of the stern.The lower set of windows need completing as access will be greatly restricted when the upper stern section is in place as this overhangs these windows. After the outer framework was installed,mica was used to glaze these from behind.The framing is in 0.8mm square boxwood.The mullions have been added in one piece.The transoms are being fitted in sections.Everything is being glued in place with PVA.The plan is to fill the panes with matt polyurethane as before.This should also fix everything in place and allow me to lightly sand the face of the framework flush with the aid of a custom made sanding stick. Now having a break as my eyes and head is spinning cutting 2mm long pices of strip and gluing them in position Kind Regards Nigel

-

Cutter Cheerful 1806 by rafine - FINISHED

NMBROOK replied to rafine's topic in - Build logs for subjects built 1801 - 1850

Wonderfully clean work Bob I don't know about the slow progress,the way you are going,you will have several completed builds under your belt before I have finished one Kind Regards Nigel- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I haven't come across a kit yet JP that hasn't required some tweeking to the bulkheads.Mordaunts were good but not perfect.I have come to expect not to take things for granted and always check both the deck sheer and fair run for the hull planks.Time at this stage pays dividends in the long run and avoids use of copious amounts of filler if any before second planking. I do agree that the Euromodel kit style,i.e. lack of a plethora of lasercut parts results in the builder producing a model very individual to them.I concur,this is no bad thing Kind Regards Nigel

-

Excellent work JP It is the same case with Mordaunt,the keel slopes 17mm in relation to the waterline.Easiest way I found to draw the line was to place a pack the correct height under the bow end of the keel then use the conventional block of wood with a pencil taped on at the required height. Kind Regards Nigel

-

I did consider that route Mark,the problem I foresee is that the spiled strip will be a severe arc.This can cause the strip to break easily across its depth when I try to bend it,I have had it happen before because you are cutting across the grain too much to get the correct shape.I hope that makes sense,not the easiest thing to put into words Kind Regards Nigel

-

Excellent work Mark Your second 'take' on the round tuck has paid off in spades. Kind Regards Nigel

-

I have just had a big catch up Sjors,your Aggie is looking great,fabulous work! Kind Regards Nigel

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Thank you Mike,unfortunately the biggest issue I have found with Ebony,is that the oil that adds to it's blackness drastically reduces it's ability to absorb water.Couple this with it's short grain and it can be a pain.I managed to bend the 2,5mm thick Ebony wales on Caroline using 72 hours of soaking coupled with inner and outer formers and a blowlamp!.The wales on Mordaunts bow though suffer from the fact that they are inclined by up to 45 degrees in cross section but appear horizontal when viewed form the front The top and bottom edges should also be in line with the horizon.The only way I think I can accomplish this is to shape the front sections from a billet rather than trying to bend stripwood. Kind Regards Nigel

-

Thank you Brian Yes I think I am up to date for now,number 94 I think .Definitely so much more than was just in his DVD.There is also Alex Banarov's build on the Ukranian forum of Pantelemon Victoria that is also a photographic step by step of his techniques.Some techniques only really applicable to his preferred scale of 1/36.Planishing nails flush on the scales I work to would make me cringe Kind Regards Nigel

-

Great work Jeff This particular model has always grabbed my interest,possibly because it offers a nice 'twist' to the more usual cross section.I have spent many years avoiding anything Victory related simply because it is so popular,however my viewpoint is changing and already have the reference material so we shall see Kind Regards Nigel

-

Thank you Brian and Bob I purchased boxwood 'stringing' from Original Marquetry in the UK.It comes in various square sizes from 3.2mm down to 0.8mm which is what I used in this instance.It easily fits in the drawplates largest hole.It comes in 1 metre lengths.The first ten or so holes in the drawplate progressively remove the corners,then the diameter starts to be reduced.Had I wanted larger nails,then I would have to use larger section.These nails are 31 thou which is a reasonably snug fit for a 0.8mm hole.I plan on taking the nails down to whatever works best in a 0.5mm hole for the decks etc. Kind Regards Nigel

-

Excellent work Nils The propshaft housings look fantastic as does the rudder.Plating the housings will no doubt create a different set of 'fun and games' Kind Regards Nigel

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

It has been a little hectic at work,but I have managed to finally get in the shipyard this weekend After much deliberation and the fact I now own a Brynes drawplate,I have decided to proceed with treenailing .This is being done exclusively in boxwood and includes the areas of Ebony.This contrast I noticed on the upper areas of Dr Mike's L'Ambiteux and is a feature I particularly like.I did a small area to get an idea of the finished result and have now started the mass drill and insertion.The idea with doing this as I go along is that I have the bulkheads as a guide and also to relieve what would be a mega monotonous job when the hull is fully planked.Also it is easier to sand smooth prior to fitting the wales above and below this section. Kind Regards Nigel

-

Great work Kevin and your last post really conveys just how large the model actually is Kind Regards Nigel

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

OK a little bit of an update Planking work is progressing extremely slowly.All boxwood planks have been glued with aliphatic resin but I have reverted to epoxy for the Ebony 'Black strake'.Slow going as it works out at four parallel planks from lower chainwale down to the black strake.These planks have to conform to the sheer and many compound curves of the hull.Some severe clamping techniques have been employed to allow this.Various 'dogs' have been spot glued to the hull allowing the use of wedges and 'stops' have been spot glued to get the planks to follow the sheer.These are only obechi so are easy to break off and sand flush.The pencil line represents the waterline,which is in abeyance yet as to whether I will splice the ebony/boxwood along this line. Received my Brynes drawplate this week ,fixings will be boxwood on boxwood and copper on the ebony. Kind Regards Nigel

-

Great attention to detail Michael!! Reminiscent of the joint on a cricket bat handle. Kind Regards Nigel

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.