-

Posts

449 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Landlocked123

-

Thanks Roger. I do hope it is easier than it sounds. Frankly, without pictures I'm not sure I know what you are talking about. Nevertheless, I appreciate your help. Best, John

-

Thanks Thanasis. I will also give that technique a try. BTW Chuck though it's a bit beyond my current skill set, are there plans available to build the Confederacy fully rigged? Best, John

-

Thanks Again Chuck, I have some tubing on hand and will give it try. If I pull it off I'll post a picture. Best, John ps What is the model in the instructions you attached in your post. Thx.

-

Thanks Chuck, I don't know if it's that easy. The 1.5mm micro tube has a 1.3mm ID which equates to a wall thickness of 0.1mm. I think I need a 4mm tube and the only Albion brass tubes in that I could find in that size come nested as a 4mm, 5mm, and 6mm set. I think that means the the wall thickness would be 0.5mm. Do you think that walls that thick can peen over as easily and evenly as the 1.5mm tube? I bought the tubes at Sprue Brothers. Are there other suppliers of Albion tubing that may have a greater selection? Thanks, John

-

Hi All, I Was captivated by Chuck's thimbles on his Cheerfull build log and went so far as to to order the thin walled Albion brass tube. I wish, though I'd paid more attention to the size of the thimbles he created with the 1.5mm tubes. Unfortunately, I was hoping to use them with the shackles I made. They will not fit on to those thimbles. Does anyone have other ideas on how to make thimbles larger than Chuck's? Thanks.I'm Best, John

-

Woodland Scenics makes great dry transfer letters. I don't recall off the top of my head, but one sheet has sizes from tiny to 5/16s" and come in a number styles and colors including white and gold. They're mostly designed for the model railroad crowd but they are easy to layout and apply. If you make a mistake you can lift a letter off with a piece of tape. Best of all they are designed to be covered with dull/gloss coat. Best, John

-

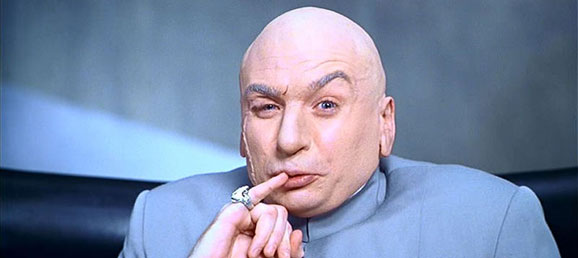

The way I see it Mark, this is no choice and the only way to go is with an even powerful tube for the DeathStar. DON'T FORGET THE SHARKS NEED LASER TUBES AS WELL!

-

Thanks Chuck and Druxey. Best, J.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Chuck, I just ordered some 1.5mm thin walled brass tubing. How do you cut it without crushing it? Thanks. Best, John

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I recently posted some pictures of my sharpening station which I'll post again below. I showed the flattening stone I use on my my water stones. You just crosshatch the waterstone with a pencil and run it against the flattening stone until the pencil marks are gone. It works great and is pretty inexpensive with Amazon prime. The stone is the Norton Flattening Stone for Waterstones, 3/4" x 3" x 9" it's about $29 including shipping from Amazon Prime. https://www.amazon.com/gp/product/B00067ZSJ0/ref=oh_aui_detailpage_o08_s00?ie=UTF8&psc=1 The other stuff in the pictures are a tub for the stones, the three stones I use, the Veritas sharpening jig, a Kell sharpening jig, and a cookie sheet with some non-slip cabinet liner. Best, John ps As you can see, using water stones can get pretty messy. I suppose I could have cleaned this stuff up for the pictures, but it will just get messed up the next time I use It . J.

-

Dave - here you go. I think it's all pretty self explanatory. But, the black pieces are the Veritas sharpening guide from Lee Valley. The other is the Kell guide and the stone in the plastic box is to flatten the water stones (a very important part of using these stones). If I recall correctly, the three stones are a 1000, 2000, and 3000. I've had them probably 20 years. Best, John Kell - http://www.garrettwade.com/kell-british-made-deluxe-honing-guides-gp.html Veritas - http://www.leevalley.com/US/Wood/page.aspx?p=33001&cat=1,43072,43078&ap=1

-

WOW!!!!! The finish makes all the difference. First rate build. Beautiful boat. Congratulations! Best, John

-

Hi Ed, Absolutely astounding as per your usual. When you soldered the copper rings, did you have a small overlap or did you solder butt end to butt end? Also, did you silver solder? I would imagine a soft solder joint would fail while stretching. Again, thank you for this wonderous build. Best, John

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Mike, Will you please share where you found that saw? Thanks. Best, John

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Dave, I've been quietly following along and I want to tell you that your work is absolutely first rate! I have this kit my workshop and when I start, this will be the first build log I refer to. I've looked at a number Bluenose build logs over the years and I think yours is the best. Best wishes for all your future builds. Best, John

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.