-

Posts

449 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Landlocked123

-

Jaxboat & Druxey, I guess given the scales most of us work at, what the hell, it's only a short step to the molecular level! Best, John

- 269 replies

-

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Dave, I made all the same upgrades to my Dremel 580. But I also got the no slip belt and geared pulley wheels from Bill. Get a set if he has any left. I've yet to have the saw bog down with these in place even sawing though 3/4" Cherry (though I am cognizant of the saw's limitations). One more thing I did was to add a strip of thin aluminum to fence from before the rear of the blade forward. It serves two purposes. Since the fence upgrade is made of stock slightly rounded on the corners, I've had problems with very thin stock trying to slip between the fence and the table. The aluminum strip is flush with the table. Also since it stops before the rear edge of the blade, it tends to minimize chances of kick back. Best, John

-

Mechanical Solar System by jim_smits - Eaglemoss

Landlocked123 replied to jim_smits's topic in Non-ship/categorised builds

Hi Jim, You're Orrery is beautiful. Do you know if anyone will be selling it as a kit? Thanks. Best, John -

Hi Jan-Willem, What does PET stand for? Is it the type of plastic which they make blister packaging? Thanks. Best, John

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Hi Gaetan, I've been following your build from the earliest posts. The combination of your build and photographs can only be described as model ship building porn! Best, John

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Can i live without a BYRNES TABLE SAW

Landlocked123 replied to shihawk's topic in Modeling tools and Workshop Equipment

Jim, After meeting you and Donna at a couple of shows, you should be writing her the checks!!!!!!! -

Hi Ed, Looking good.......the boat too! Best, John

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Cindy, I agree with those who say buy what you when you need it and buy the best quality you can afford. Buying cheap tools usually means you end up buying them twice. Though not a tool, my strongest recommendation is that you start a MSW biuld log, you will overwhelmed with sound advice, great suggestions about technique, and an amazing number of friends. Best, John

-

Hi Elia, I am going to try the Woodland Dry Transfer letters on my schooner. It is the Smuggler and I'm trying to figure out how to layout the letters. Do I figure the length of the name and Gloucester together and and center the letters below the monkey rail or do I center between Smuggler ~ Gloucester? I hope this makes sense. Thanks for your help. Best, John

-

Jack, It was great to see you in New London! Willie's looking great as well. I must say that every time I see those plans, it makes me scratch my head. Was the some kind of paper shortage when they were drawn?

- 250 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Sal, As I told you on Saturday there was never a DOUBT in my mind that you would win. I've only said this a few other times, to guys like Dan Vadas, that you inspire me to be a better modeler. That this was only your 2nd build still blows my mind. That we are members of the same club and that I can freely access your thoughts and help is invaluable. You have truly created something beautiful and with a great build log is fantantastic. You should be very proud. Best, Steve

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Tools and Supplies for My "Shipyard"

Landlocked123 replied to daveward's topic in Modeling tools and Workshop Equipment

One more piece of advise, absolutely start a build log on MSW. You will access more expert help and friendship than you thought possible. Best, John -

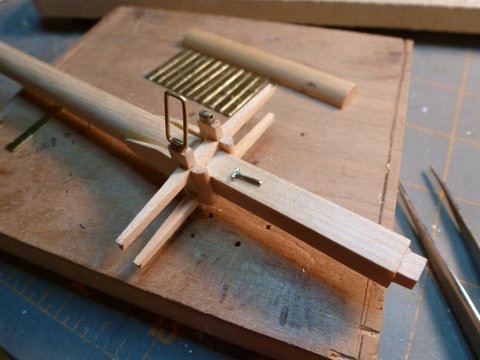

Hi Peter, I came up with a technique which worked really well for me. I was squaring up the end of a 3/8" dowel. I had some 3/4" scrap pine which I cut into 3/4" cubes and drilled 3/8" holes through the center. I then slid the jig down the dowel exposing the length I want to square and tacked it in place with a tiny drop of PVA, Using the jig as a guide, I then made 4 small cuts with a saw around the circumference parallel to the surface of the cube being careful that all the cuts were equal in length and depth, creating the basis for the squared section, After that I simply clamped the cube in a vise and filed away. The upper surface of the cube provided a great reference for keeping everything square as I rotated it in the vise. When done a few drops of isopropyl alcohol a the jig slid right off. I didn't take pictures of the process but you can see the results below. Best, John

-

Hi Ed, Be careful when you make/use stain made from black walnut shells. I made some about 25 years ago and ended up staining my hands a rich dark brown. It took months for it to go way completely. Best, John

-

About a week or ten days I saw a thread about various techniques for measuring the diameter of rope used for rigging. I meant to respond at the time but was unable. When I went to respond, I couldn't find the thread. I wanted to point out that Chuck Passaro has a great rope measuring tool available on the Syren website (go to the rope section and there's a link to the chart) I downloaded it and added a spreadsheet converting measurement into scale inches for most of the common scales (see below). If anyone like to have it, PM me your email address (I promise to ensure that it stays confidential) and I'll send over the Word file. Best, John

-

Glenn, The level of both your metal work and wood work is exemplary!!!!!!!! You have truly elevated yourself to level that only a handful of the craftsmen on MSW have risen to (you all know who they are!). It's work such as yours which pushes all of us to strive harder. After all, "a man's reach should exceed his grasp". Thank you. Best, John

-

Tool for Shaping Brass Strip

Landlocked123 replied to mikiek's topic in Metal Work, Soldering and Metal Fittings

Hi Mike, I suppose it would be possible to use a fine sanding drum in a Dremel to square off the rounded edge on the outside. But I'm good with getting them as the look in the pictures. But I do take an extra step. I line up the place where I want to bend square to the jaws, I then bent with my fingers, but then, while holding the pliers tightly I put the tips down on the bench and use a very small hammer to tighten the bend. I don't know if this makes sense so I will try to post a picture in the next few days. Best, John -

There is nothing left to say but AMAZING!!!!!! Best, John

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi Per, I believe the product you are showing is something very similar to Chair-loc. It's been around for a long time. Chair-loc not a glue at all. It is used to repair chairs where the a spindle has become loose in its socket. It actually works by causing the spindle to swell and lock into into the socket. It's not used by professional restorers because the joint can't be undone if for some reason you need to. Another reason is that if the joint becomes loose again, it won't work a second time as well as ruining a possible good glue joint. Best, John

-

Tool for Shaping Brass Strip

Landlocked123 replied to mikiek's topic in Metal Work, Soldering and Metal Fittings

Hi Mike, It's not really a score as much as a scratch to mark the location and angle of the bends. I use a Starrett pocket scriber, but an X-acto knife would work as well as. Best, John -

Tool for Shaping Brass Strip

Landlocked123 replied to mikiek's topic in Metal Work, Soldering and Metal Fittings

Joel, Mark, et al, Scroll down in this forum and you will see a thread called re-hardening brass. The basic answer is: one can't. I'm having a bit of a hard time imagining when you would need to do it. Under almost all circumstances where I'm worried about strength, I'm sure to silver solder my bands, eye-bolts, or whatever. There's a small learning curve but I now find it easier than soft soldering. Best, John Joel, Here's the pic.s and links http://www.micromark.com/parallel-jaw-plier-flat-nose-with-straight-jaws,11523.html

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.