-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

Thanks, Garry and Ben. Always appreciated. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

Thanks very much, Druxey. Aren't we all our own worst critics? Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

Thanks, B.E. You know that I feel the same way about yours. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

I'll join the chorus, Augie. Your work just gets better and better. Bob

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

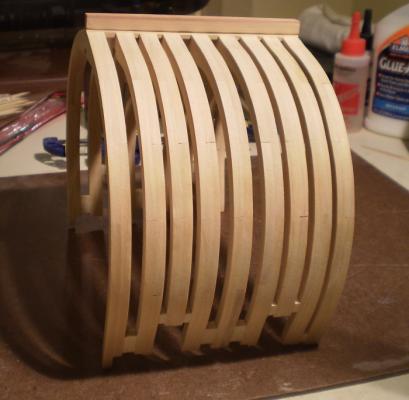

After three days of sanding my finger tips off, I've come to two conclusions: first, the frames are now ready to begin planking (the uppermost portion of the frames has not been fully faired yet); second, I don't like the frames enough to leave any part of the hull unplanked. I'm now starting work on the interior planking. Bob

-

Thanks so much to all of you for your continuing interest and kind words. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

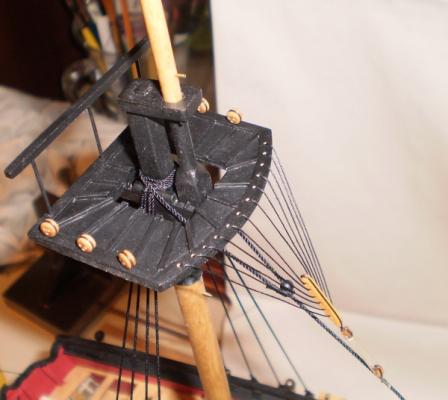

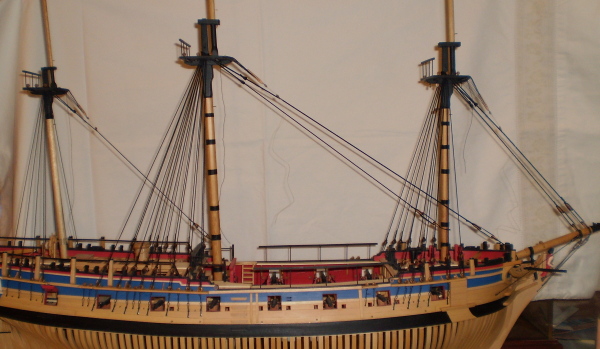

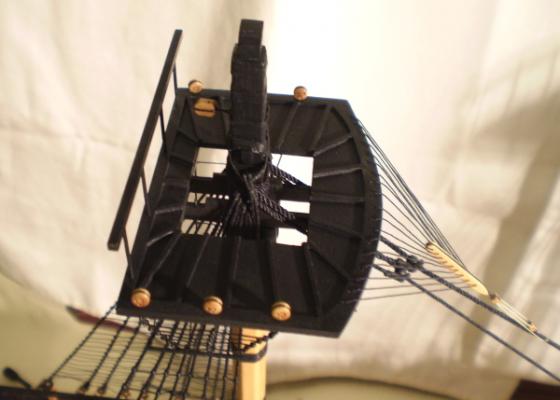

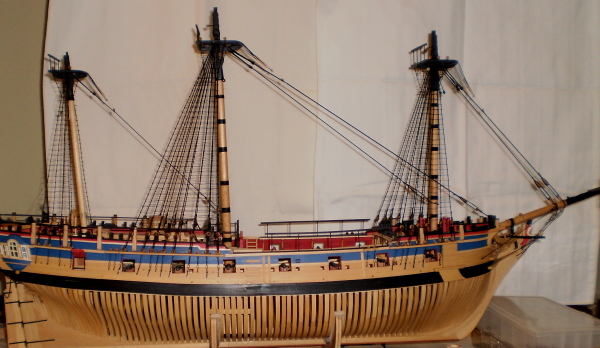

Time now to move on to the making and installing of the masts and the standing rigging. This installment will go through to the rigging to the lower masts. The kit contained neither materials nor plans for the masting and rigging. The work was done with reference to TFFM Vol. IV and to Lees, "The Masting And Rigging Of English Ships Of War". The bowsprit and the masts were all made from dowel, tapered and shaped as necessary. The square sections of the lower masts were cut in and flats filed for the addition of the cheeks, hounds and bibbs. On the top masts, the square heads were cut in and the other square and octagonal sections were built up. Lacking a lathe, I have found this easier than working from square stock. The caps and tops were made from boxwood. Having now seen the work of Remco and Blue Ensign, my list of "I wish I hads" includes the detailing found on their masts. The deadeyes used were all commercial, but all of the hearts and the long tackle and sister blocks in the standing rigging were made using boxwood strip. The standing rigging was all done with black Morope. As is my habit, I started with the bowsprit and then proceeded to the lower mizzen and worked forward. The rigging started with the bowsprit gammoning, bobstays and shrouds and then proceeded through the pendants, shrouds, stays, preventer stays, catharpins, futtock shrouds, ratlines and crowsfeet for the lower masts. I also added various lead blocks including those for the upper stays and the jeer blocks and pendants. I had never done crowsfeet before and found them to be a considerable challenge. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

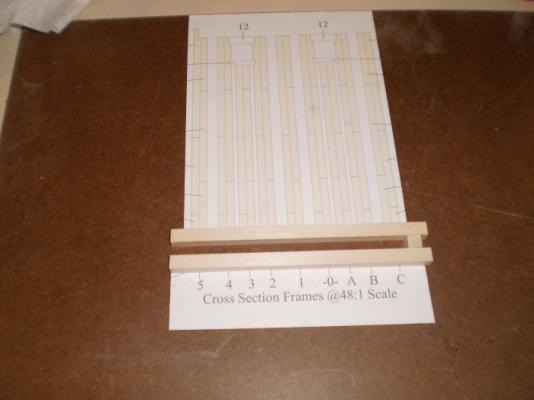

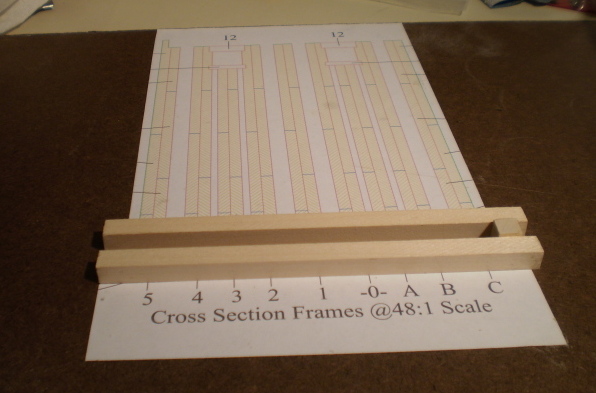

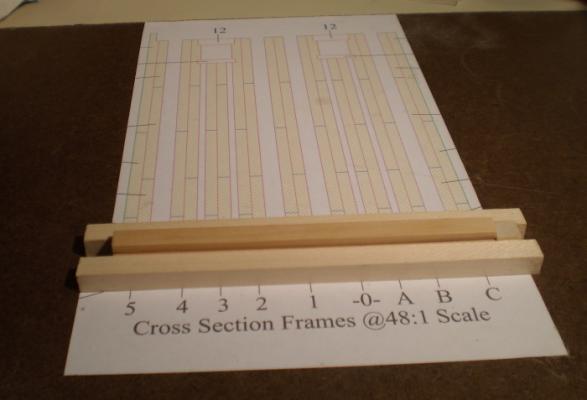

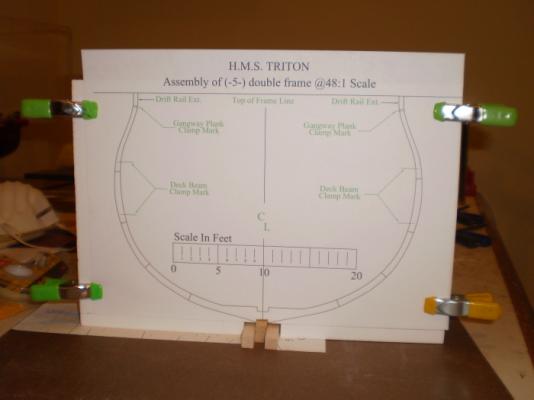

Time for another low tech tutorial. I've now raised all of the frames, using a very simple jig. My keel simply rests between two pieces of strip wood that come up to the bottom of the rabbet. The jig consists of a piece of foamcore, notched at the bottom to clear the keel and the supports, which is attached by double sided tape to two steel 90 degree weights. These slide along the keel supports as the frames proceed. A plan sheet for each frame was attached to the foamcore for reference. A temporary spacer was positioned on the keel between the frames and permanent spacers were glued to the tops of the frames as each was raised. Clamps were used to hold each new frame in place while the glue dried. Now it's on to the tedium of sanding. Bob

-

Thanks very much, Grant and Jeff. It's funny you should mention the blue color Jeff. I was just looking at the model and realized that the blue in the photos is considerably lighter than the actual color on the ship. A bad photographer using a flash is probably the cause. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

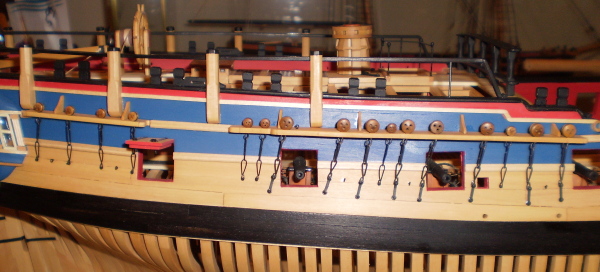

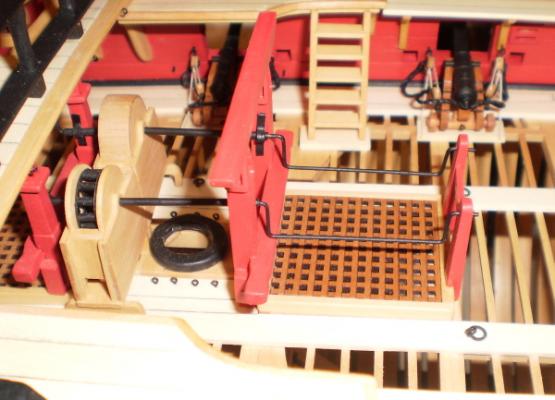

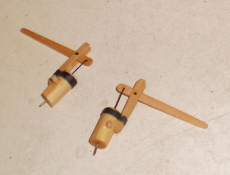

Thanks, Grant and Martin. Now it's on to finishing off the work on the hull portion of the build. The first item was the deadeyes and chains. The deadeyes are commercial. The chains are wire bent around simple nail jigs. The chain plates are brass strip. I also added the preventer bolts shown in TFFM. I then turned to doing the work on the head doing the knees, head rails, head timbers, gratings, seats of ease and boomkins. The cathead supporters and eking rail were not shown in the kit and were made in accordance with TFFM. I also painted and installed the figurehead casting from the kit. The fore outer hull was finished by making the anchor billboard assembly as shown in TFFM and added the remaining moldings and the eyebolts needed for the rigging. Last was the work in the midship area. This included the remaining cannon, the fixed gangways and their ladders and railings, the gangboards and their knees and and the gangboard railing. I also finished work on the chain pump handles and their supports. Two items were made but not permanently installed at this point: the elmtree pumps and the swivel guns. The guns were from the Lumberyard, like the larger cannon At this point, construction was suspended for about a year, waiting for the publication of Vol. IV of TFFM on masting and rigging.The last photos attached to this post show the completed hull prior to masting and rigging. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

Absolutely fantastic looking work, Rusty. The joinery looks perfect. Bob

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Good to have you back, Grant. I look forward to seeing the work product of that neat looking jig. Bob

-

Thanks, Garward. Alistair, you are much too kind, but your thoughts are certainly appreciated. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.