-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

Thanks so much Thomas, John and the "likes". Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Ofencer29350. Greatly appreciated. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Dirk, Grant, Nils, Dave and Michael for the nice comments and thanks also to the "likes". Getting her out of the jig was a big deal for me, since I like to work with the model in my lap and it's a lot easier right side up without the jig. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

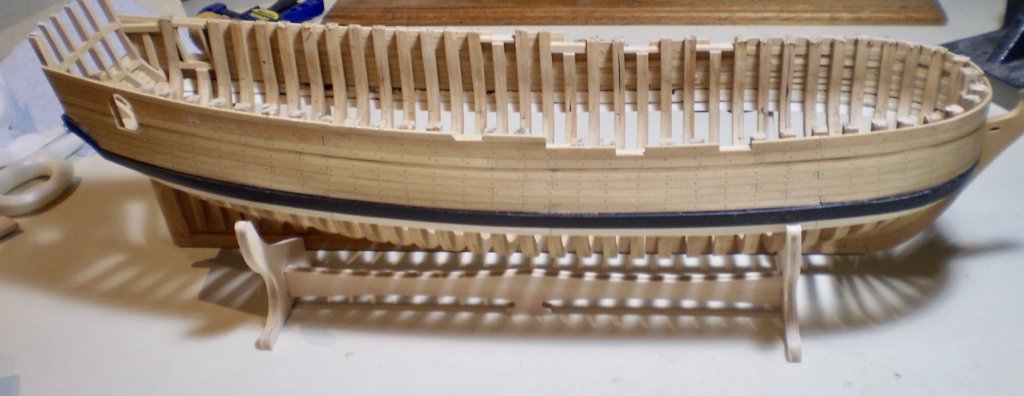

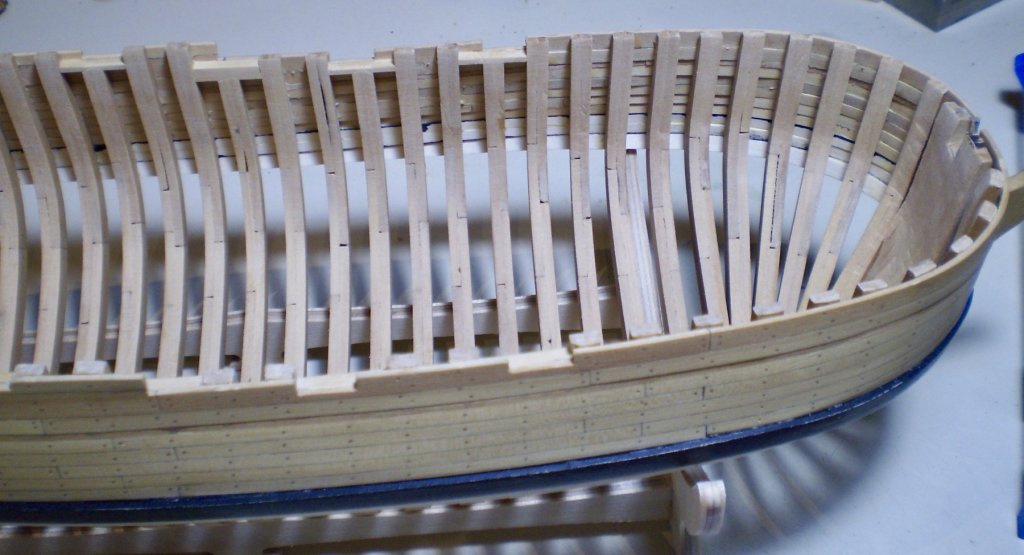

Rain, rain, and then more rain. That was the weather in sunny Florida for a week. Bad for golf, but good for modeling. With all that indoor time, I was able to get by a couple of tedious tasks. First, was cutting the hull loose from the framing jig. This proved more time consuming and difficult than I had imagined it would be. I first tried to do it with keyhole saw blades in an X-acto handle, but this seemed like it would be an endless job, and I have no patience for those. I rummaged through my tool box and found a Stanley handle with a hacksaw like blade and this ended up doing the trick, although still slowly and carefully. It is pictured below. After freeing the hull, I then turned to the task of fairing the interior. This turned out to be quite a chore, because the frames needed to be thinned considerably to reach their proper final proportions. Beginning with a Dremel with a sanding drum, and then using various grades of sandpaper with different sticks and blocks, and some freehand sanding as well, I worked my way through it. This took me days of tedious work. It's likely that I may still need some more work at the bow and stern as I proceed with interior work. My next job was to add the keelson. Although this is a laser cut part , it still required considerable fiddling and adjustment to get it to fit tightly and properly. Lastly, I added the first strakes of interior planking along the keelson in the hold area, just to get a feel for that process. I'm now deciding just what interior work to do and how to go about it. I would like to show as much of it as I can, but we'll have to see how that works out. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Thomas for the generous comments and thanks also to the "likes". Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Chuck, Michael, John and the "likes". Absolutely right Chuck. The moldings will be painted before mounting them. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Denis, Dave and the "likes". I think it will look even better when I ultimately put on the black moldings. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Denis, you are a tough guy to keep up with. I would be confused beyond hope if I tried to do so many projects at once. This one is looking good ( as do all your others). Bob

- 140 replies

-

- jolly roger

- lindberg

-

(and 1 more)

Tagged with:

-

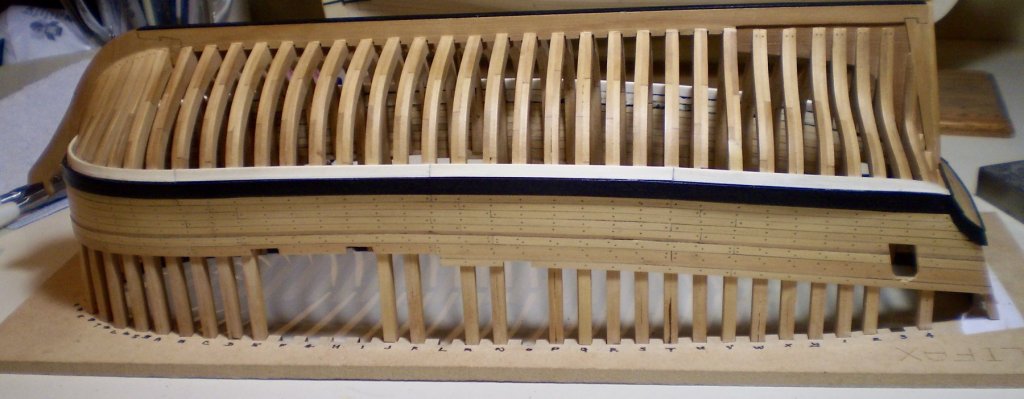

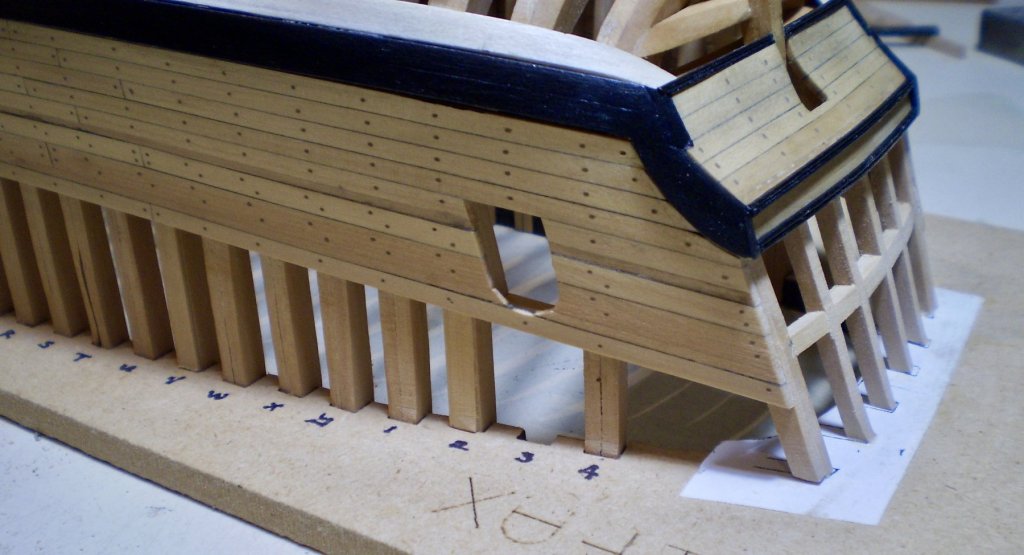

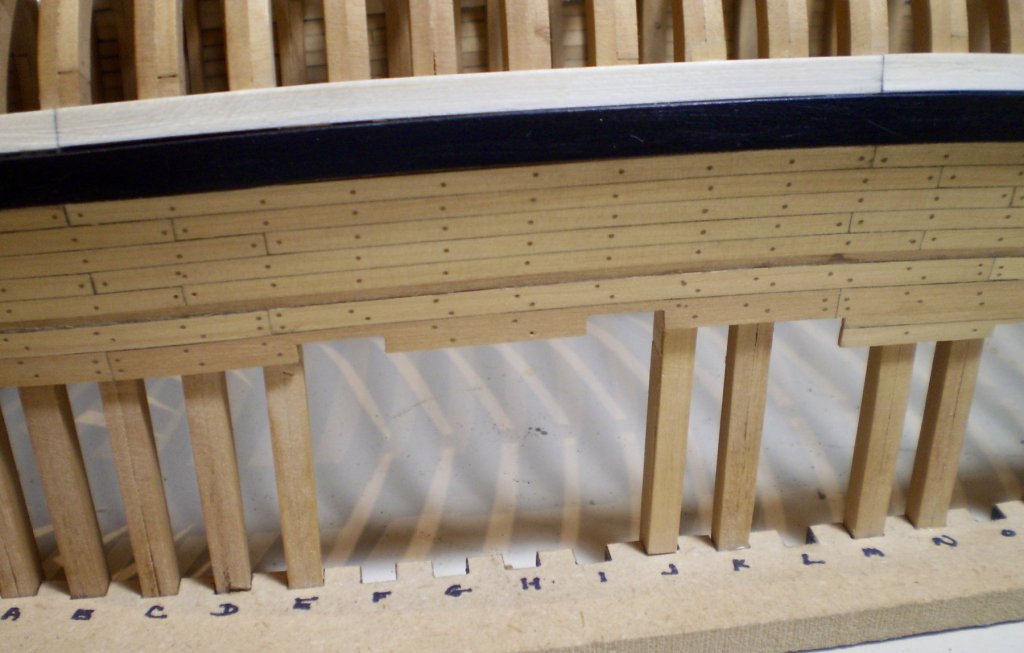

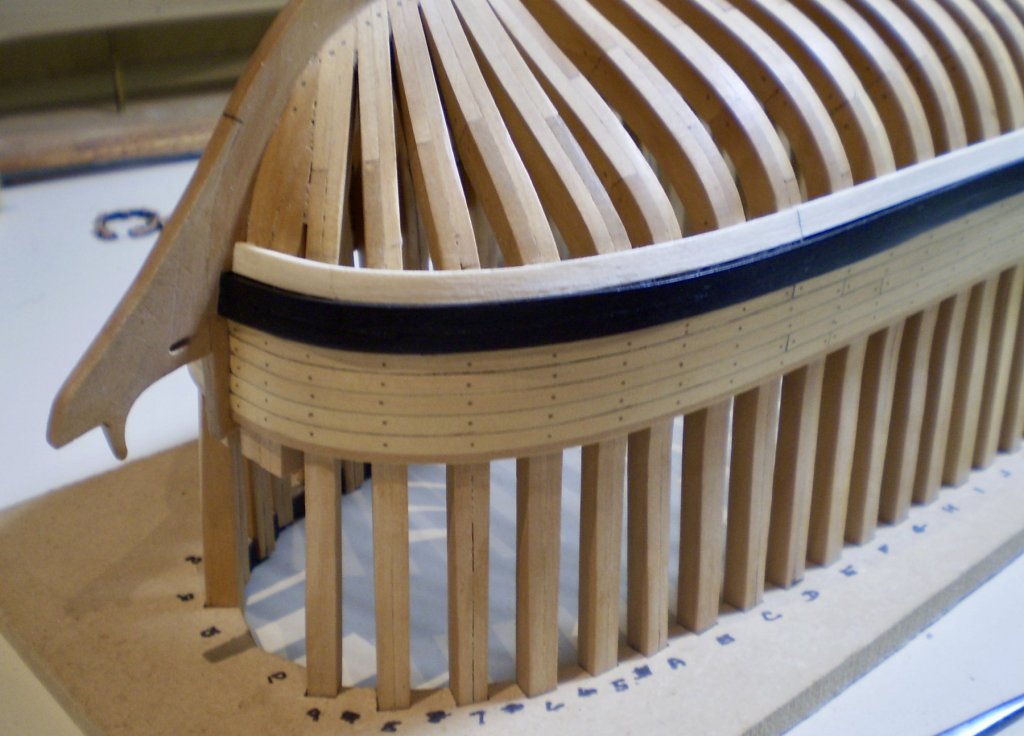

I have now completed the upper hull planking. Before beginning, I had to cut away three of the frames to allow for the small gunport openings. As with the previous belt, this was done with boxwood strips without taper, first edge bent and then bent again horizontally to fit the severe bow curve. This planking was done with a combination of 1/16" x5/32 ", 1/16" x 3/16" and 1/16" x 1/8" strips to fit the dimensions shown on the drawings. BTW, the Lumberyard provided pear strips to do this planking, but I didn't like the material supplied and chose to use boxwood that I had on hand. The treenailing was done as before. After treenailing, the area was final sanded and finished with a coat of Wipe-on Poly. No further work will be done on the outer hull at this point The next task is to cut the hull away from the jig. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Looks great Michael. You have every reason to be proud of this work. Bob

- 372 replies

-

Thanks so much Michael, Denis, Grant and the "likes". Grant, all I can say is that it works better than any other method I've tried -- and I'm getting too old to learn anything new. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Before beginning the upper hull planking, I had one more task: framing the quarter window opening. I first cut down one of the aft frames and then added strip pieces to create the framing. After that, it was on to the planking. The main belt consisted of five strakes of 1/8" x !/16" boxwood strip.I also added a 1/16" square strip as a base for the molding that will go above this planking belt. The good news was that the planks are of even width throughout their length and did not require tapering. The bad news was that the bow is extremely blunt and required compound curves to obtain a good fit. My method to do this was to first soak the planks in boiling water, then edge bend them and then use my old heated plank bending tool (an Aeropiccola product that I've had for decades) to make horizontal bends. Some beveling was employed where necessary to ensure tight fit. I used a carpenters pencil to simulate caulking on one side and one end of each plank and glued each in place using carpenters glue on each frame and the mating edges of each plank. I'm sure that some will laugh at my "clamping" method. I've always found it more difficult than useful to fit fancy clamps to planking, and rely on low tech "five finger clamps" (my hands) to hold the planks in place with pressure until the glue grabs sufficiently. After rough sanding, I drilled and filled for the "treenails", using a #75 drill and walnut filler. After final sanding, I applied a coat of Wipe-on Poly and touched up the black paint on the wales. Now, it's on to the remaining planking. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Rusty, Dave and the "likes". Dave, at this point it is my intention to do only the one holly strake. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Don for the very kind words. Model building, like so many other things, is more perspiration than inspiration. Keep at it, don't get too self satisfied and you can only get better at it. Time to get off my soapbox. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Mike and the "likes". Actually Mike, the planking that I'm doing is not too bad. I did do the wales in two layers to make the bending easier. I 've started the upper planking and it's going pretty well. I have to admit that at least some part of my decision to not plank one side of the bottom was based on the degree of difficulty that it might involve. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Michael and the "likes". Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Wonderful, Nils. The boats are just another example of your incredible attention to detail at this small scale. Bob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

A number of things have been accomplished. First, I added the single strake of holly planking that I intend to have below the wales. Then, I made the fashion pieces that border the counter at the stern. These were cut from boxwood sheet and sanded to shape to fit. They were painted black and mounted. Next, I added black painted moldings to the lower and upper counter. Lastly, I applied a coat of Wipe-on Poly to the counter and the lower hull from the wales down. Next up will be the planking above the wales. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

The work may have been tedious, but the result is wonderful. Bob

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

She looks great Mike. Terrific work. Bob

- 452 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Really nice Michael. The wale looks much better to my eye. Bob

- 372 replies

-

Thanks so much Anton for the very kind comment. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Albert, B.E. and the "likes". Why do the frames B.E., if you're not going to let them show. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

ancre La Salamandre by tadheus - 1:24

rafine replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Really nice work Pawel. Bob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.