-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

It's looking great Rusty. Bob

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks so much Sjors ,Michael, Steve and the "likes". Michael, "somewhat of a pain" is somewhat of an understatement. Steve, everything is easy -- once it's finished. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

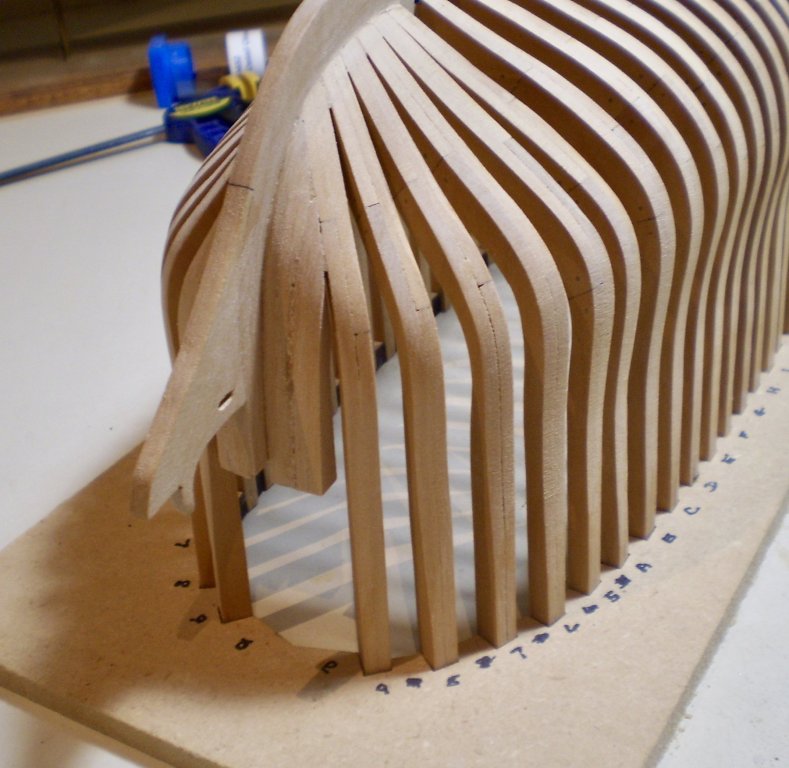

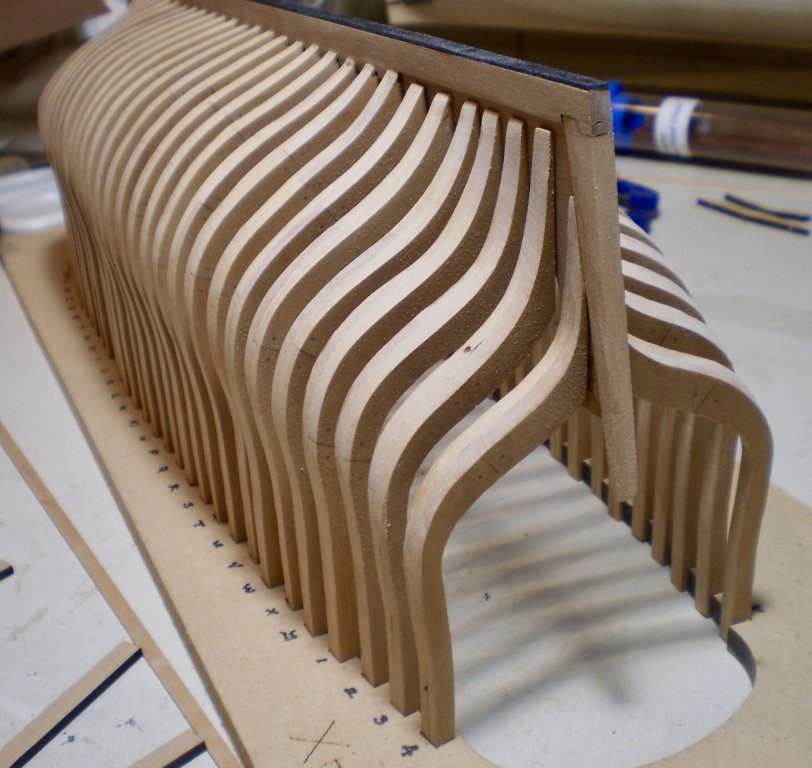

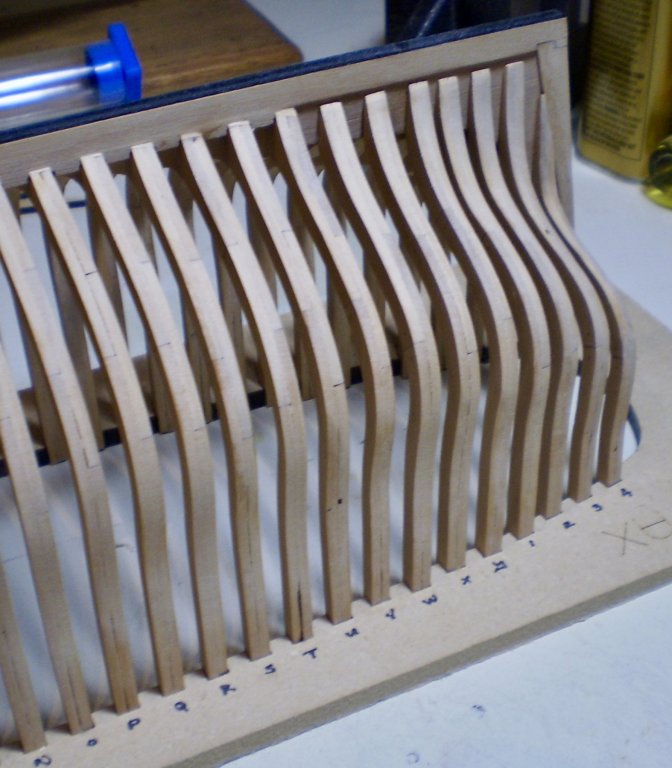

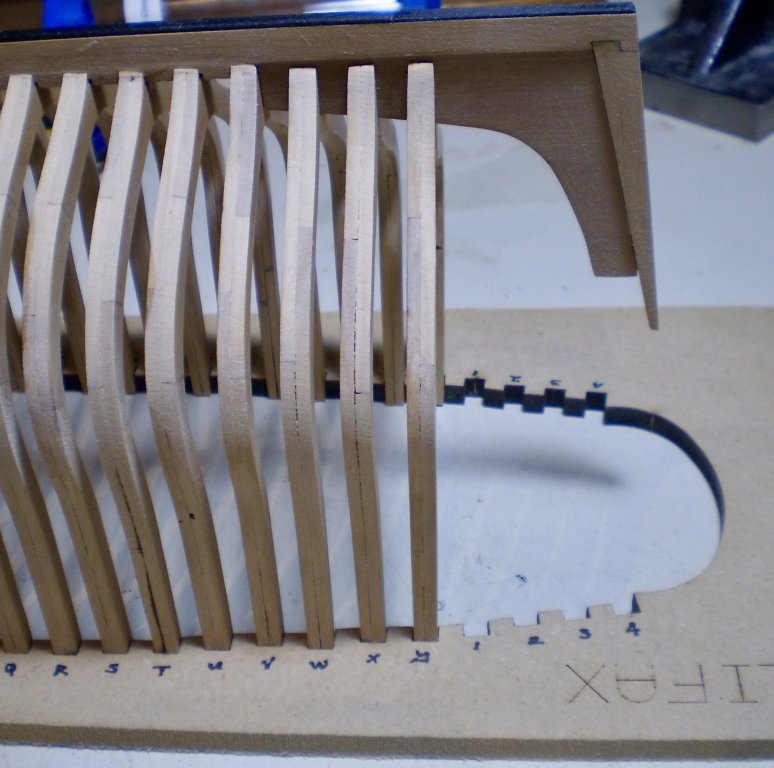

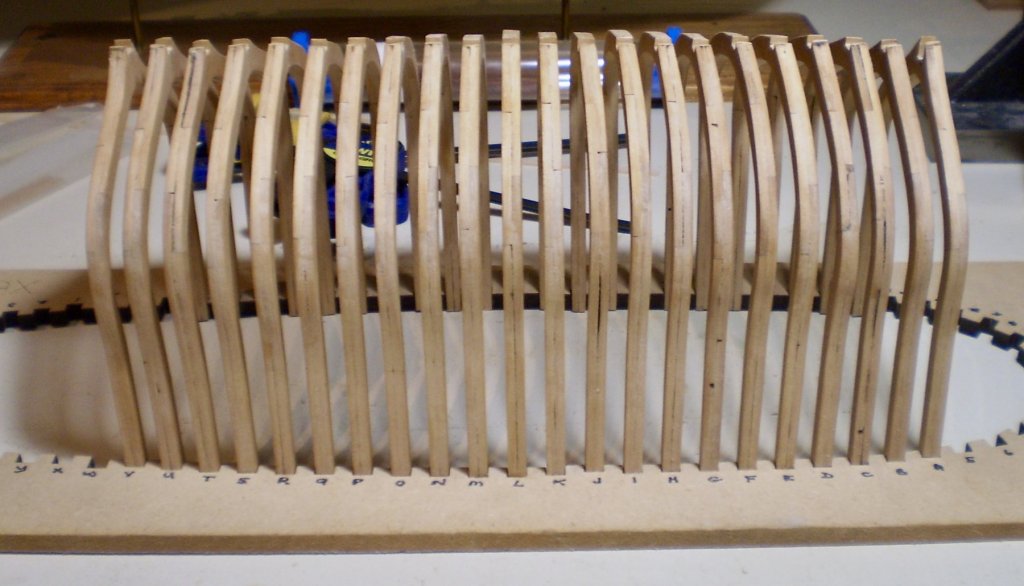

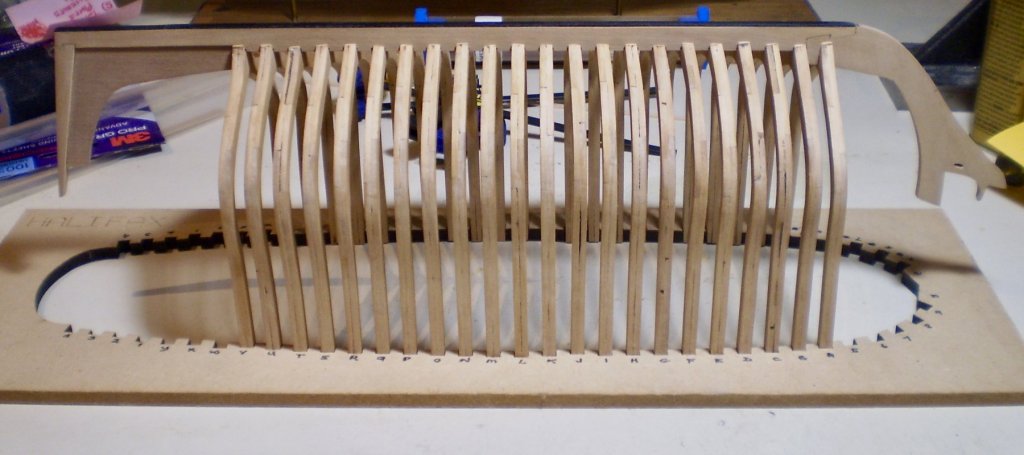

I've now completed making and mounting the bow cant frames and hawse timbers. As at the stern, some discrepancies between the parts, jig and drawings required some tweaks and adjustments to be made. As with the previous work on the framing, I've done the rough fairing of the outside of the hull. For the most part, it seems to fair up well. The exception is at the upper portion of the frames ( at the bottom of the photos because of the upside down construction), where it seems that a few of the notches in the jig are misaligned, causing some low areas. This will be corrected by adding boxwood strip to the outside of the affected frames and then sanding them fair. There should be no visible evidence of this because those areas are to be planked over anyway. Next up is the framing of the stern, starting with the transoms and stern timbers. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

A great deal of progress Don, all beautifully done. Bob

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Thanks so much guys for your continuing interest and the "likes". Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

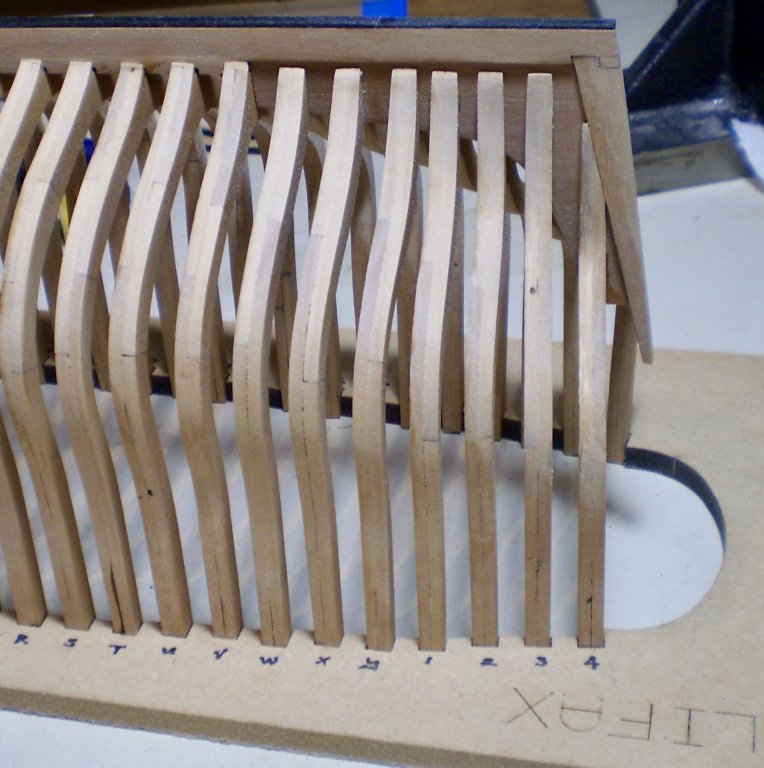

I've now completed the stern cant frames. These presented two problems. The first was the expected difficulty of cutting and sanding the required angles to get a proper fit. That went reasonably well. The second, however, was more troublesome. The aft most frame did not match the plan and had to be tweaked to get it to fit. it remains to be seen after final fairing and assembly of the stern framing whether this will turn out correctly, or whether I will need to remove it and make a new pair of frames. As I have been doing, I did some rough fairing to get a feel for the fit of the frames. I'm now working on the bow cant frames. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Once again Nils, what is there to say but "fantastic". Bob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

It's coming along beautifully Denis. I never cease to be amazed by what you accomplish in this small scale. Bob

- 453 replies

-

- thermopylae

- sergal

-

(and 1 more)

Tagged with:

-

Thanks Dave. I appreciate that. Thanks so much Elijah. I wish that were true. Hopefully with more sanding I can make it so. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Dave, Rich and the "likes". Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much guys for the "likes". Working on the stern can't frames. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

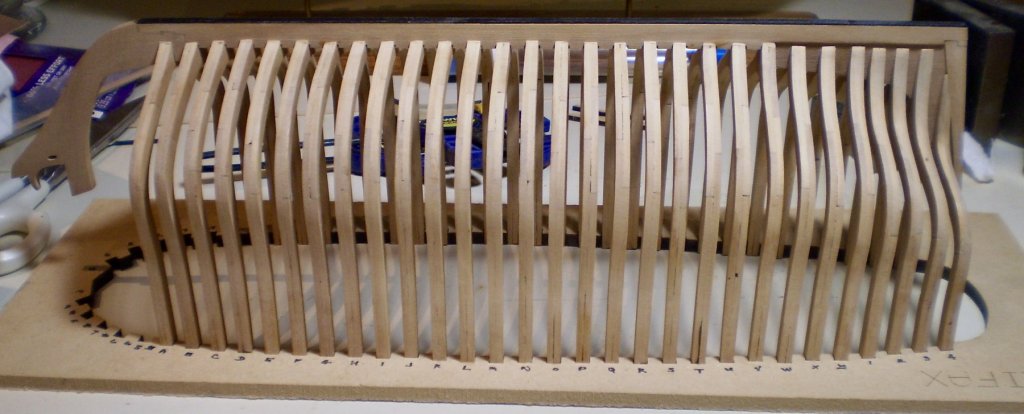

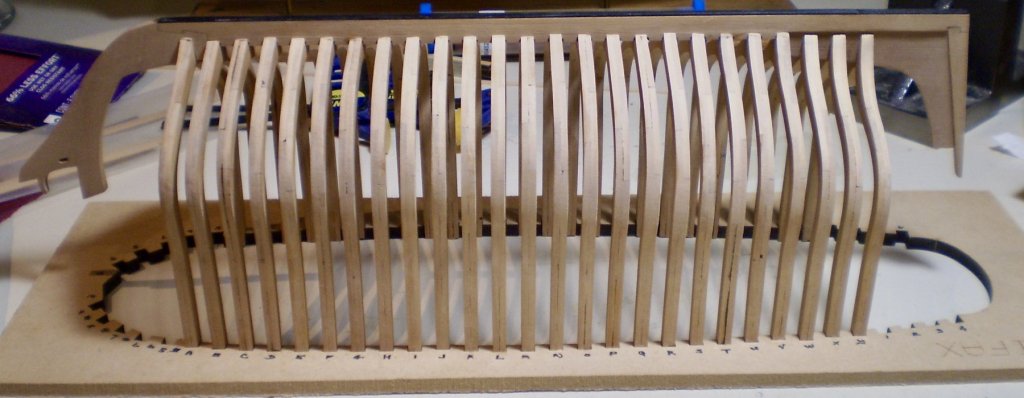

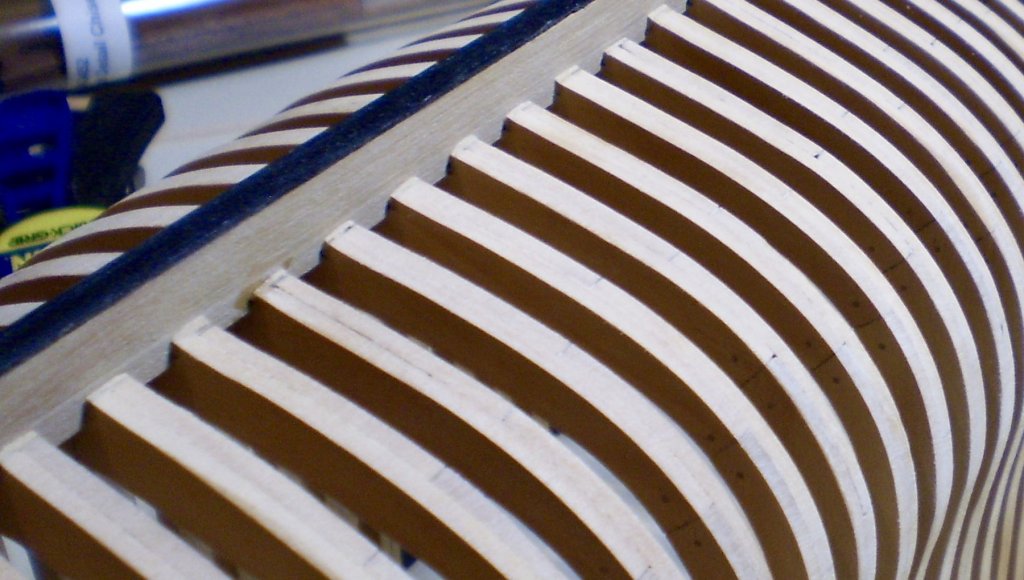

Home again and back to work, so time for an update. I've made up and mounted the three square half frames at the stern. Same procedures as for the full frames. I also did some fairing while waiting for glue to dry. This was primarily in the midship area and consisted of using various sticks and blocks with 60, 100 and 120 grit sandpaper. Final fairing will be done when the frames are complete. I'm now working on the stern cant frames. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Dave, I almost forgot that I built and rigged a Halifax from the Lauck St kit years ago. I don't have the model and my memory is that I rigged it from the Hahn plan and just figured out the belaying. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Martin, Dave and the "likes". Martin, you've expressed my own feelings about scale . Dave, I'm not aware of any belaying plan. The good news is that the rig is fairly simple and there are a lot of cleats shown for the masts and shrouds. We should be able be able to figure it out ( I hope ). Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

As usual Nils, your work leaves me with nothing to say but "amazing". Bob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Beautifully done coils Mike. Bob

- 452 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks so much John, Grant and the "likes". Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Michael, Denis, Anja and the "likes. Appreciated, as always. Michael, I continue to look forward to further progress on your Halifax. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

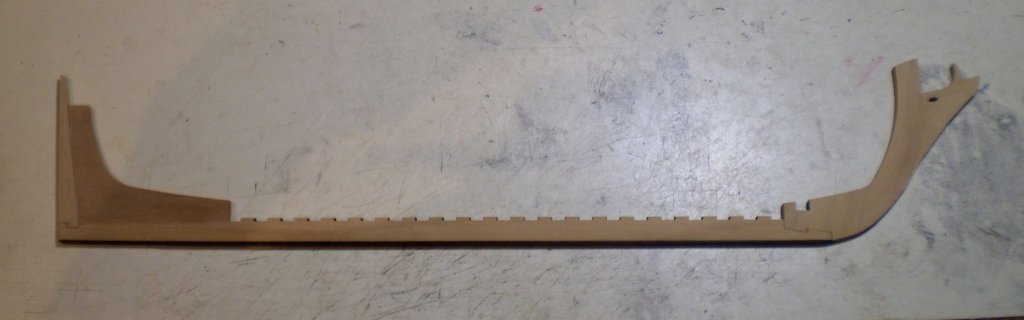

All of the full frames have now been made up and mounted. The next step was to permanently mount the the keel-stem-stern assembly to the the full frames. Before doing this, I did some work on the stem that could more easily be done before mounting. This involved drilling, cutting and filing the gammoning slot, and cutting and tapering the upper forward portion to accommodate the fitting of the figurehead. The figurehead is a 3D printed resin piece supplied by the Lumberyard. I am attaching a photo showing it in place temporarily. It will be painted to match the wood before permanent mounting at a much later time. I will be away from the shipyard for about a week, and will then begin on the stern half frames. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Sjors, John, Don and the "likes". Don, Kingfisher was built upright, using a jig created by Bob Hunt that I recall was difficult to work with when setting the frames. Planking and other work was relatively easy ,since the hull was set free and could be manipulated.. The Hahn method is easy to use to set the frames correctly, but it remains to be seen how subsequent work will go. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Absolutely magnificent B.E. I don't think I exaggerate to say that this is probably the finest build from a kit that has ever been displayed on MSW. Congratulations. Bob

- 366 replies

-

- pegasus

- victory models

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.