-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

Thanks so much Elijah. I only wish that my aging body joints were as good as the wooden ones. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Michael. With regard to Fair American, as I said to Dave, "go for it". Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Nils, Dirk, Sjors, Dave and the "likes". Nils, I intend to leave as much of the deck open as I can without sacrificing or compromising the above deck detailing or the attachment points for the rigging. I've been trying to work it out in my mind, but have reached no final decisions as yet. Dave, I would think that Fair American would lend itself to an enjoyable exercise in interior detailing, and I look forward to watching you do it. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

An absolutely masterful piece of work Nils. Like so many others, I am sorry that the build has come to an end, as it has been a joy to watch. Congratulations. Bob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

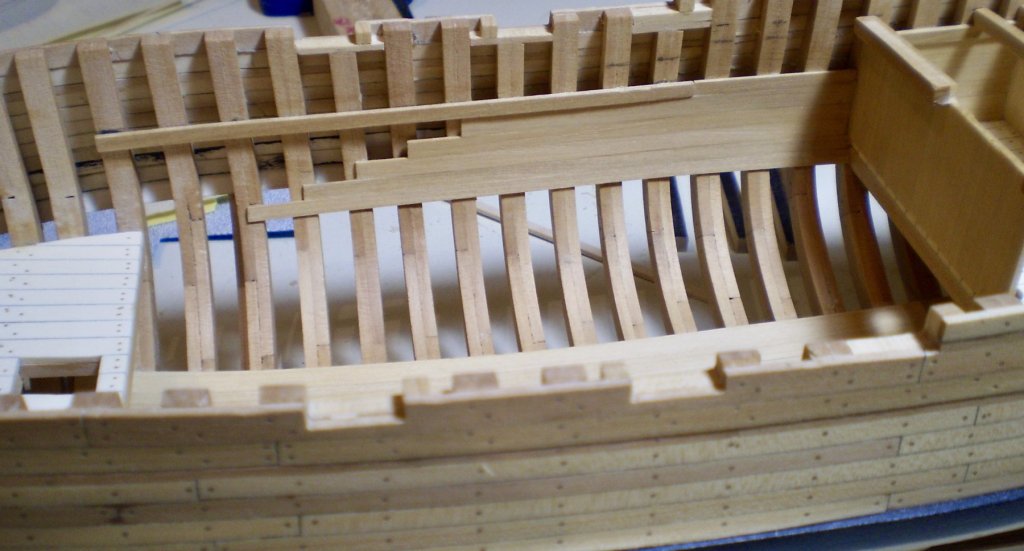

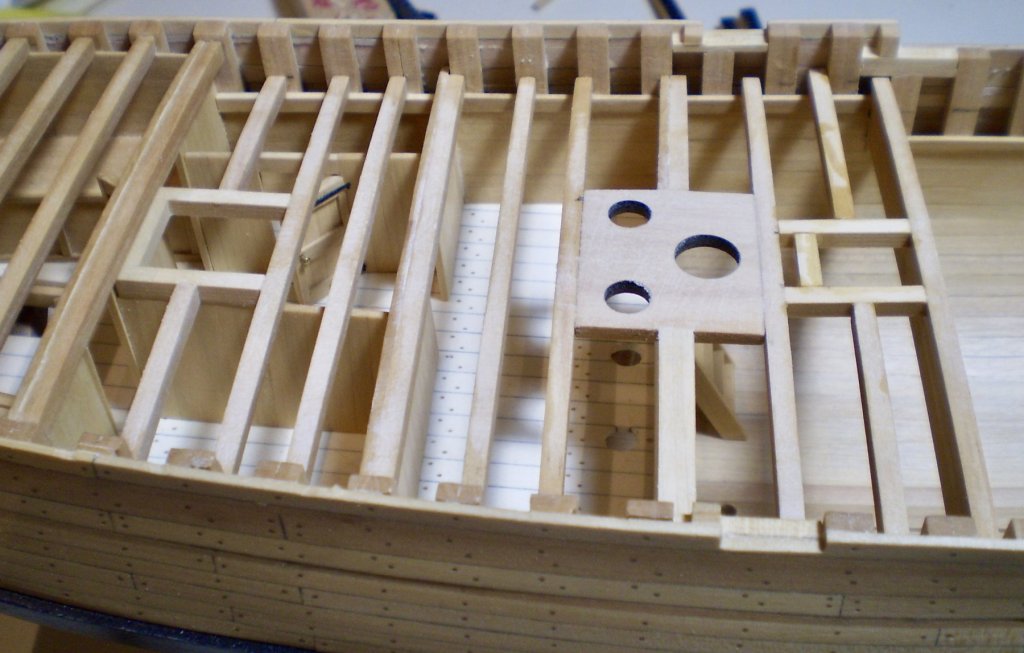

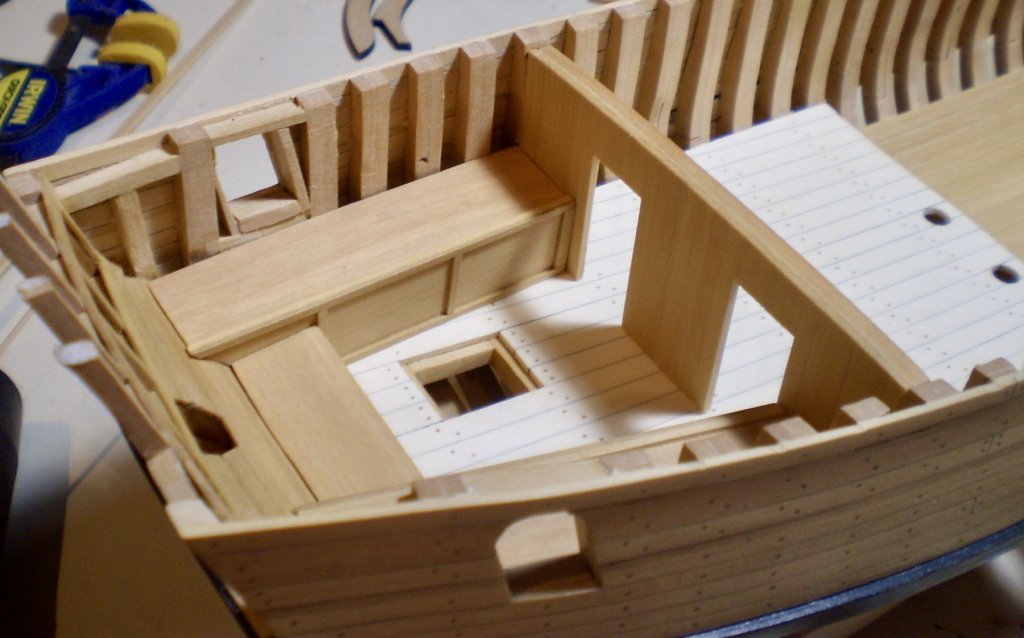

Work on the aft interior hull planking and framing for that portion of the upper deck is now complete. I also added the main deck clamp, the first main deck beam, and further interior hull planking in the hold. The planking all follows the same methods and materials previously used. The deck framing again uses laser cut beams and also a laser cut partner for the main mast and the pumps. I added the first main deck beam at this point because the forward most beam for the aft portion of the upper decks rests upon it. I also drilled a hole in the keelson for mounting the main mast, after test fitting a dummy main mast through the partner. Work will now shift to the bow before finishing the main deck. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Ken for the nice words. Greatly appreciated. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Is there a true POF kit in the market?

rafine replied to Ulises Victoria's topic in Wood ship model kits

The Lumberyard , among their Hahn timbering sets, has a set for the schooner Halifax which has full laser cut framing for the hull. You can see the product (and some of it's problems) in my current build log here. Bob -

Thanks so much Nils, Dave, Jason and John for the kind comments and thanks also to the "likes". Jason, there is a companionway. In the last two photos, you can see the framing for the ladder opening in the upper deck. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

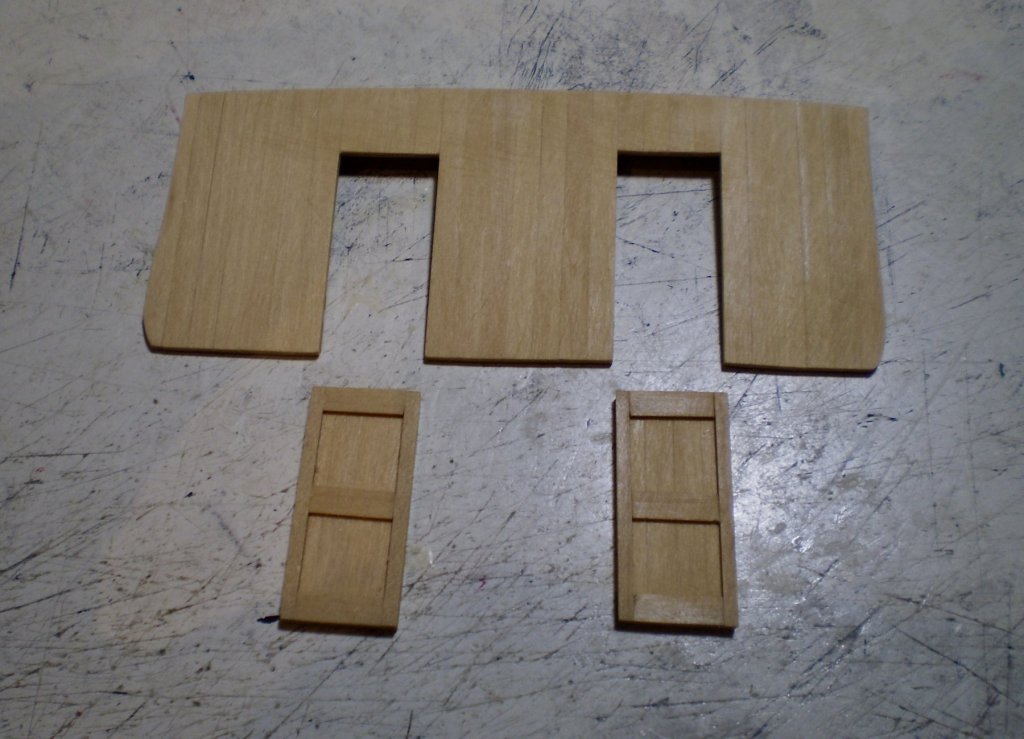

Moving forward on the aft lower deck, I've added the last transverse partition, the inner hull planking in that section, the ladder to the hold from the lower deck and the beginning of the upper deck beams. The partition and the hull planking were done exactly like the previous ones and need no further description. The ladder was made from boxwood strip and fitted to the curvature of the hold planking. It looks a little strange, but I'm not aware of any alternative. The deck beams are laser cut boxwood pieces that I cut to fit each location. It was certainly a timesaver to have all of the roundup precut and consistent through the beams. I'm also attaching a photo of the doors mounted at the rear cabin, which I had neglected to attach with my previous update. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Rusty. Glad to have you back. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Jason. As is often the case, there is a lot of sanding and fitting, more sanding and fitting, and then some more sanding and fitting. That's what makes it fun. isn't it? Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Beautifully done rudder and rigging Don. Bob

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Nicely done on the gang boards and gangways Martin. I like the posts and would vote to keep them if you were putting it up for a vote. Bob

- 467 replies

-

- fly

- victory models

-

(and 1 more)

Tagged with:

-

Thanks so much Don, Thomas and the "likes". Hey guys, it's really not so quick -- just an old retired guy with plenty of time doing something he really enjoys. What can be better than that. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Denis, Robert and the "likes". Denis, there are actually four different levels of decking on this small vessel. Makes for a lot of interesting work. Robert, my wife often wonders why I don't do something useful, like make something "real". Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

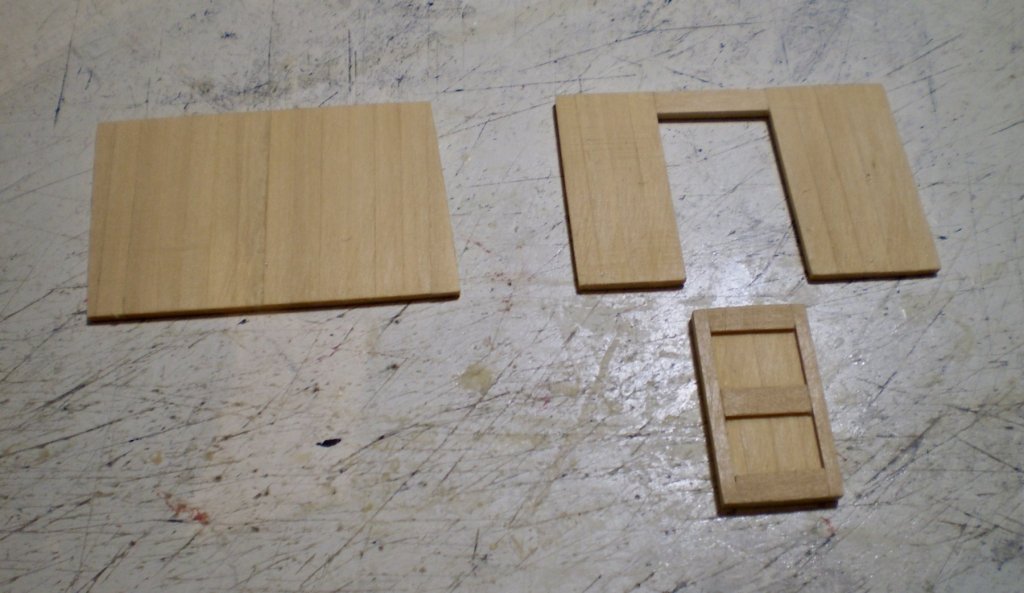

Moving forward on the aft lower deck, I've now completed the next set of partitions. These are the the second of the three transverse portions (and it's attached upper deck beam) and two fore and aft partitions which create what the plans refer to as the captain's bed place and the mate's cabin. I also did the interior hull planking in this area. All of the partitions were made up from boxwood strip, as was the hull planking. The doors were made from boxwood strip, with cut off round head brass pins for handles and blackened brass hinges from a PE set in my stash. As always, everything was finished with Wipe-on Poly. My next work will be to finish the work on the aft lower deck and to add the remaining deck beams for the upper deck above the lower deck area. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

US Brig Syren by Gahm - Model Shipways

rafine replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Not just finished Thomas -- beautifully finished. Bob -

Thanks so much Michael and Russ for the nice comments and thanks also to the "likes". Russ, The Hahn drawings provide only a plan view schematic of the cabin, with no detail of the cabinetry. I estimated the height from a couple of photos in the Hahn book and then tried to create a simple, but believable, appearance with the trim. I'm glad that you like the way it came out. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Dave, Rony, Mark and the "likes". I'm sure that I'm not alone in believing that you work much better at things that you enjoy doing. The stuff I'm doing now is certainly in that category. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Thanks so much Dirk, Albert, Grant and the "likes". Always appreciated. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

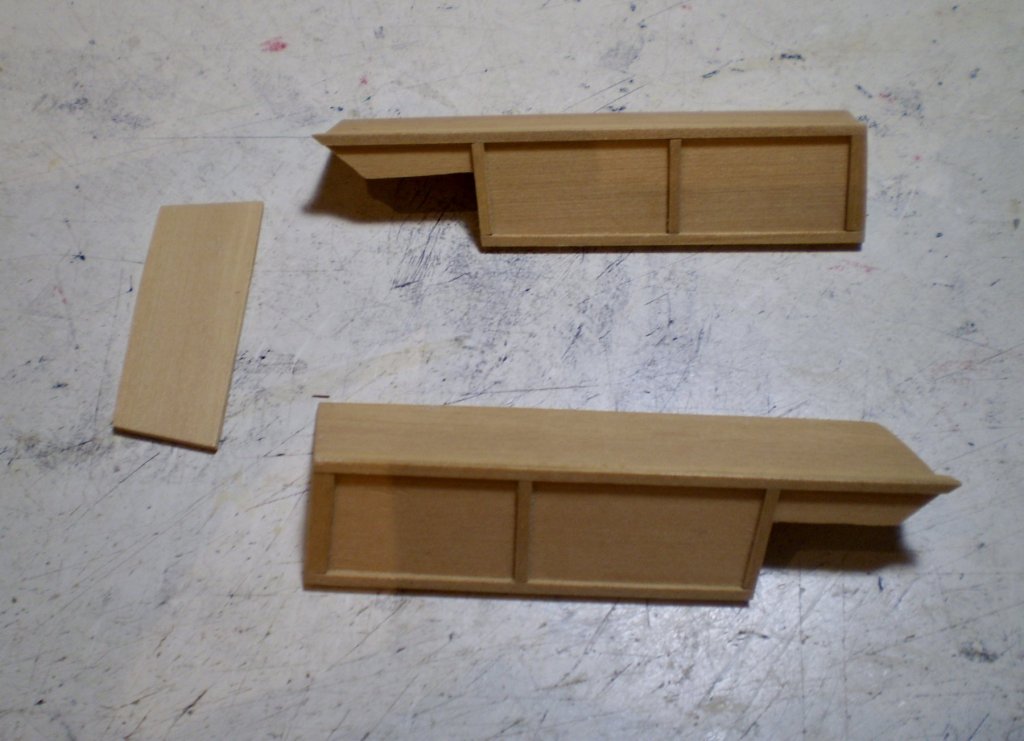

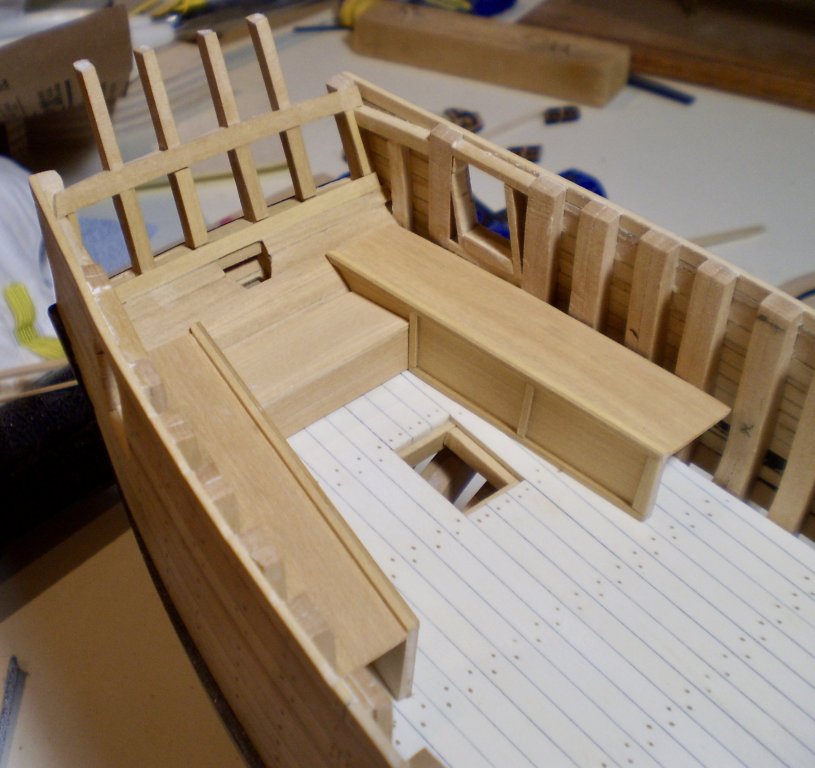

Work on the interior of the stern cabin is now essentially complete. All of the work was done with boxwood strip and sheet and was finished with Wipe-on Poly. In order, the work done was as follows: 1) Planking of the interior of the stern frames; 2) Fitting and mounting of the facing of the bench; 3) Making up and mounting the cabinetry described in the plans as "lockers with bed places"; 4) Making and mounting the bench top; 5) Making and mounting the forward partition for the cabin, and the upper deck beam to which it is attached (the doors are made, but not yet mounted); 6) fitting and mounting the interior wall planking to the level of the upper deck beams. The work entailed a great deal of fitting and adjusting to get a proper fit of the various interconnected pieces, but was really an enjoyable and fun part of the build -- probably my favorite part to date. Bob

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.