-

Posts

1,553 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by G.L.

-

8. The cockpit coamings While making the rail at the portside (see part 7) I made also the coamings around the cockpit. Round the opening of the cockpit comes a coaming to prevent the flooding of the water which is splashing over the deck . I draw the deck rounding on the forward and astern plank with the same template that I used to draw the deck beam shapes. ... and saw them out. Fitting the forward plank. Gluing the planks. The reinforcements of the after corners of the coamings are at the same time bollards. The two forward corner pieces are just reinforcements. The model in its current state. Thank you for reading Thank you to follow Thank you for the likes and thank you for your constructive comments, Till next week

- 168 replies

-

Thanks Vaddoc, On the drawings of Mr Lohmann there is only one pair of stringers. I guess there will be also one pair of stringers to carry a kind of floor in the cockpit.

- 168 replies

-

Felix is my man!😸 I am also glad to see some movement in the shipyard. Very nice and detailed block.

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

14.6 Rope fenders I want to have four rope fenders on board of my boat. I make first some wooden tubes (Ø 8 mm and length 3 cm) and some copper rings (inner Ø 4mm). Then I pass the rope four times through the tube, in this way I have at each side and end of rope and a loop of rope. I stick the copper ring through start to make half hitches around it. When I am fully around the ring, I continue to make half hitches, but now in the loops of the previous half hitches. And that continues downwards the tube. When all the half hitches are made the loose end goes through the bottom rope loop. Then the loose end has to be pulled tight until the top loop has the desired size and the bottom loop disappeared in the tube. Before cutting the loose end I fix it by injecting wood glue in the tube. When that it dry, the loose end can be cut off and there is no more risk of pulling out the upper loop from the fender. I soak the fenders in dark stain to give them a more realistic look. Two of the rope fenders hanging outboard. On this last picture you can also see that meanwhile the main sail is hoisted, but that is for next week. Thank you for reading Thank you to follow an thank you for the likes Till next week!

-

14.5 The bailer The body of the bailer consists of a small wooden cylinder which I drill hollow. I saw it diagonally. After the excess is sawed away and the piece is sanded, the handle can be placed. The bailer.

-

You're welcome, Yves. Some more progress: 7. The rail The boat has a low rail, supported by 21 stanchions which are not part of the frames. To be able to place the bottom side of all stanchions on a smooth line, I fasten a lath to mark the level. The bottom side of the stanchion is sawn at 45°. I insert some wood glue in the stanchion hole ... ... and push the stanchion into place. Checking if the stanchion is standing vertical. The stanchions are glued against the inside of the wale. Below deck they are held into place by small temporally wedges between the beam clamp and the stanchion. All 21 stanchion into place. They are a little bit longer than needed. The excesses will be sawn when the rail plank is placed. Wedges and level lath removed. Gluing the rail plank. In between the rail and the waterway I put small wooden spacers to form the scuppers. Cutting off the excesses of the stanchions. Making the gunwale: I trace the outer shape of the wale on the bottom of the plank from which I will saw the gunwale. Sawing the outer bow of the gunwale. The outer shape is sawn an sanded. Fitting it. Now the inner edge is sawn and sanded also. The whole gunwale consists of three parts. The three parts have to be joined together to become one gunwale. Drawing the forward joint. I use the vise also here to saw the joints. Tracing over the shape of the joint on the neighbor piece of gunwale. The joint. Gluing the whole gunwale. Sanding the gunwale even with the wale. I glue a thin frame on the outside of the gunwale. And also one on the inside. When the glue is dry the edges of the lists are rounded off with sand paper. At the positions of the stanchions the gunwale is tree nailed with the stanchion. Thank you for reading Thank you to follow Thank you for the likes and thank you for your constructive comments, Till next week

- 168 replies

-

14.4 The boat hook To make the make the boat hook, I use a brass rod and two brass tubes with different diameters which can slide in each other telescopically. I turn a globule on the top of the rod. Then I slide the whole again in each other like on the first picture and solder them. They go again on the lathe to turn them off conically. I file also the hook on a smaller brass rod. The hook is soldered on the top. I make the stock from a piece of pear wood. The assembled boat hook. The hook is now varnished and ready for use in the boat.

-

14.3 The life belt To make the lifebuoy, I start with making a wooden ring. To give it a canvas look, I wrap and glue the ring with a strip of cotton. Then I paint it in white It has two layers of paint. Between each layer I sand it lightly with sanding paper. On top comes a coat of varnish On the buoy come four canvas rings at which a line is sewed. The rings are made of cotton strakes of which I ply over the sides to the middle. Next is sewing the line in the rings. I glue the rings on the buoy ... ... and paint them red. And my boat is ready for a 'man over board'.

-

Nils, Maybe that is the missing link for which you were waiting to continue your Zeesboot build😉

-

Thanks Moab! A little while ago I received the suggestion in this forum to become seamstress, now you want me to become oar maker. I think that I prefer to remain 'pensionado'⛱️. Gives me more time for non-profit modeling.

-

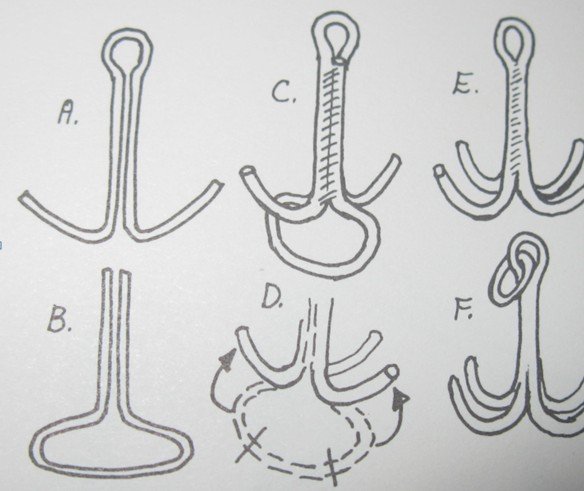

Thanks for your kind words, Mark. A boat's grapnel is often used in small boats to go at anchor for a short while. But in most cases it are grapnels with folding arms which can be stowed away easily on board. My choice for that sort of anchor is inspired by the fact that I am not such an experienced metal worker and I found a very easy build description for it in the book 'To Build a Whaleboat' by Erik A.R. Roonnberg.

-

Jon, Seeing your progress I am sure you will meet your deadline. I really like the scene.

- 69 replies

-

- diorama

- Glad Tidings

-

(and 2 more)

Tagged with:

-

Starting to plank the deck. The aim is to make a dissected ship model, therefore I will only plank a part of the port side of the deck. I begin with the middle plank on the forecastle. One plank follows the other (The riding bitts will not be as high as shown in the pictures. They are not fully pushed down). I 'overplank' the carling of the cockpit, what is too much will sawn off later. Once again: this will be an dissected model, so that will be all for the deck planking. Now I start the tree nailing. Drilling the holes. Before putting the nails, I erase all pencil markings from the deck. Erasing with the heads of the nails sticking out doesn't work so good and it is lethal for the eraser 😫. I use bamboo tree nails (they are self made; plenty of bamboo in the garden). The tree nail is dipped in some wood glue ... ... pushed in the hole ... ... and pinched. Now I saw out the edges of the cockpit... ...I scrape them also with a cutter knife blade... ... and sand them. Next is scraping and sanding the deck. After it is done (the red clamp at the stern holds a little part of the waterway, which needed some more glue, in place): Thank you to follow Thank you for the likes Till next week

- 168 replies

-

Mike, you are right. I used a spliced eye out of ignorance. Thank you very much to inform me about the anchor bend; yesterday I rectified my poor seamanship and gave my anchor an anchor bend.

-

14.2 The anchor The inventory contains also a small brass anchor. Thank you for the likes Thank you to follow Thank you for the constructive comments. Till next week!

-

For the moment I am continuing the sewing of the sails. Reporting each week how many cm of the leach is sewed or how many thimbles are sewed in the sail during the last week would be boring, because it has been showed already when making the jib. Therefore while continuing to finish the main sail, I will make some posts of the making of some pieces of the boat inventory which are already made during the last months and didn't found a place in this log yet. 14. The boat inventory 14.1 The oars. This boat can not only be used as a sail boat but also as a double row rowing boat with 6 oarsmen and a coxwain. Normally it should have 6 oars. I present the vessel as a sailing boat. Laying 6 oars in the boat would be obstructive for the sailing crew so I will limit to two oars. To make the oars, I start with gluing the rough shapes of them, using two sticks of maple wood which will become the shafts. The blades are made of gluing two strips of walnut at each side of the shaft and another two pieces of maple at the outside. Shaping the shafts: first I scrape them to an octagonal shape, afterwards I sand them round, just like I would make a spar. Before shaping the blades, I saw them straight at the end and glue a piece of walnut in place. The shaping of the blades is mainly done by sanding them. The handles are turned out on the lathe. The two oars are shaped and can be varnished. My oars need a collar to prevent them from wear and tear by the oarlocks. Unfortunately I made my oars before Steve (Bedford) made the oars for his 'Miss Caroline'. I made a collar with a tackle of rope. A leather collar like Steve's would be better. I will not change it any more, that would be too plagiatic. Making the tackles: To finish them, I stain them dark. The oars:

-

Thank you Keith. But I am sure that I had a lot more fun in the Navy than I would been having in a sewing workshop.

-

Indeed a very charming model, Javier. How do you write the name and the number on such a small scale?

-

6. The deck Small reminder: this is an instruction model to teach the different parts of a small wooden sailing vessel. Keeping that in mind, the deck will only be laid partially at the port side. The starboard side will be left open, even without a railing. Here I will also deviate a little bit from the ship drawing. I am not building the mackerel cutter 'Marie', but I am using the plans of 'Marie' to build a generic instruction model. I think that I can afford this freedom. The drawing below shows my intention. I first make the waterway. Marking the shape of the wale on the bottom side of the plank. The outer edge of the plank is sawn, fitting it. With the inner edge sawn. I make the plank wide enough to make the nicks for the deck planks. The waterway will be made in three pieces. Here you see the two outer pieces. I make them long enough to have a large overlap to make the joints between the different pieces. The three pieces on top of each other. Marking the spots where apertures have to be made for the top timbers which support the bulwark. Those top timbers are not a part of the frames. They are short squared bars which are going through the waterway. To make the apertures. I drill first a 1mm hole in the corners and then cut out the opening with a wood chisel. The hole that I drilled prevents the wood to split when giving some pressure on the chisel. In any case the cutting has to be done with some care. The forward piece: Marking the second piece. The holes must correspond where there is an overlap. The decision where to cut the joints between the pieces can still wait a bit. The three parts of the waterway are ready. I am now looking where I will make the joints between the different parts of the waterway. Here I marked the forward joint of the middle part of the waterway. On the waterways you see also a pencil line, parallel to the inner edge. This breath is the space in where the nicks of the deck planks have to fit. Sawing out the joint. I use the vise to saw pure in straight line along the marking. The two pieces waterway fit together. The two joint of the waterway are finished. Thank you to follow Thank you for the likes Thank you for your constructive comments Till next week

- 168 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.