-

Posts

1,553 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by G.L.

-

-

Nice repair on the prow, Peter.

- thibaultron and mtaylor

-

2

2

-

16 hours ago, KeithAug said:

Very nice woodwork GL. I note you work in a T shirt. Is it particularly warm in Belgium at the moment - unlike this side of the channel?

Thank you also Keith.

No we don't have a micro climate here. At our side of the channel it is as cold and wet as at yours. Like I mentioned in my first post, the project started in August and the keel was made in that period. I waited some time to start this log because at that time I still had to loft out the 22 frames for the model. I am a digital illiterate, so I have to do that at the drawing table with pencil and compass which took me almost two months. To avoid week after week post which the only mention that I drew two or three frames during last week, I let some time pass until that job was done. I like to give every week an update with some progress and I have also the experience with that the time advantage will be quickly overtaken by the real time. Within a couple of weeks my other project 'the gaff sailing boat' won't be a retroactive project anymore.

- KeithAug, thibaultron, mtaylor and 2 others

-

5

5

-

19 hours ago, vaddoc said:

Very nice work on the rabbet, I guess your chisels are razor sharp! Very crisp edges, I always struggle and end up with wider margins and irregular surfaces.

Thanks for your compliment Vaddoc.

Before every use I give my chisels a series of hauls on the whetstone. That keeps sharp.

- luponero, FriedClams, thibaultron and 5 others

-

8

8

-

Continuation part 7: Finishing the hull

7.2. Painting the hull

Time to paint the hull. I start with painting it with primer.

With a primer layer on the hull a lot of the imperfections of the planking become conspicuous.

I apply a layer of paint putty and sand it. After that again primer, putty and sanding. Now the hull is more or less acceptable for the finishing coat.

My system to mark the waterline is very basic: I slide a set square with a pencil attached to it along the hull. The waterline marks join at the bow and at the stern, so I can be confident that they are fairly accurate.

I tape the rub rail and the waterline and paint the above water part with satin paint in cream color. The paint is laid in three layers with sanding in between it.

Same procedure below the waterline: here I use dark red.

The finished hull.

Thank you for the likes

Thank you to follow

Thank you for the constructive comments,

Till next week

- vaddoc, Tigersteve, cog and 13 others

-

16

16

-

-

On 12/1/2019 at 3:32 PM, FriedClams said:

What an insightful observation G.L. and it put a smile on my face first thing this morning. I think most people love small boats. Perhaps it has something to do with childhood and remembering the first time you tentatively stepped barefoot into a row boat on a summer morning in a world without cares.

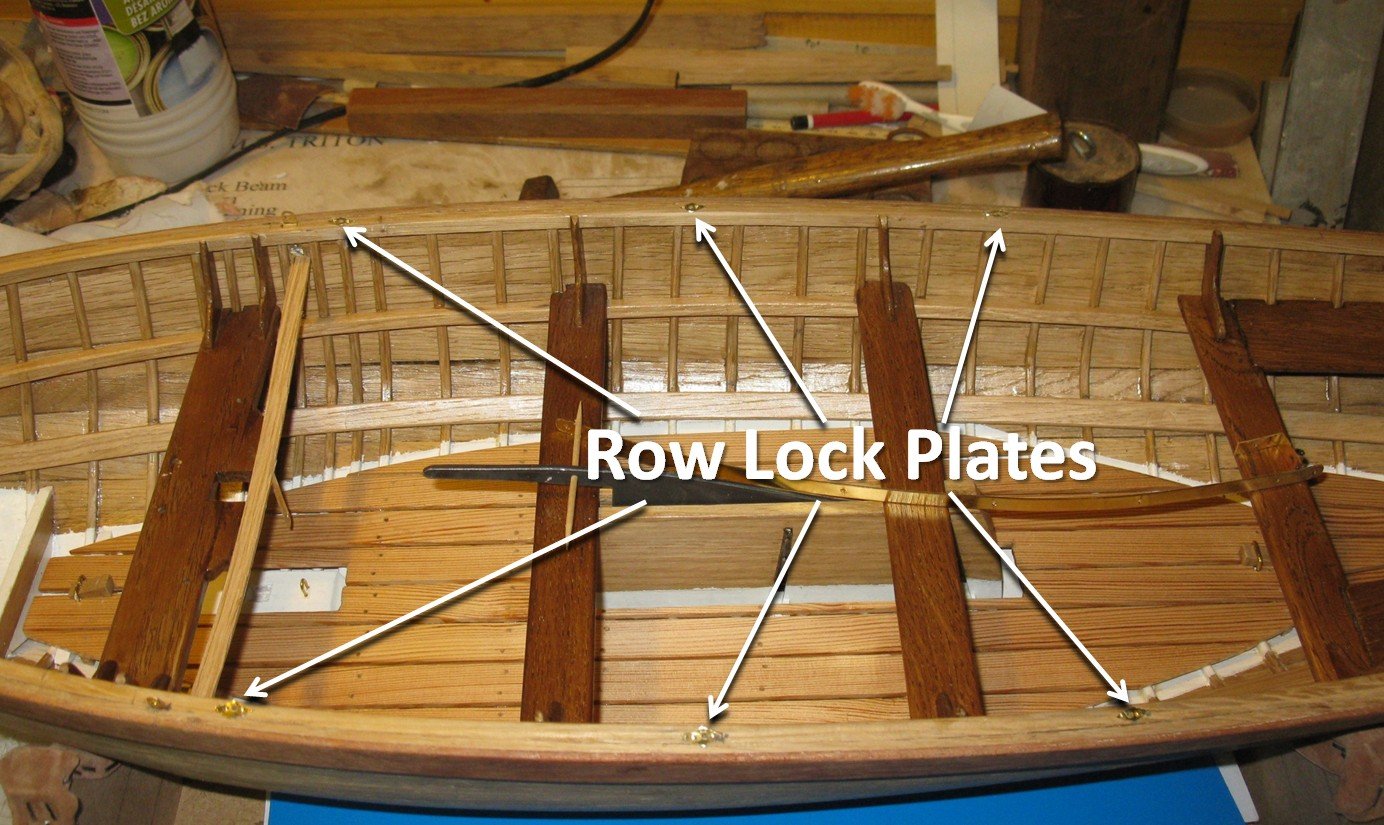

The oar lock plates are an elegant detail and I like the sheet traveler as well.

Gary

Thanks Gary

- FriedClams and mtaylor

-

2

2

-

On 12/1/2019 at 6:01 AM, PopDavid said:

I live with snail mail and just got my invitations. Sign me up! There is a You Tube series by the Sampson Boat Co rebuilding the SV Tally Ho. These guys are doing this full size. Worth a visit.

David, Thanks to mention to me the Sampson Boat Co YouTube movies. They look me perfect to watch while my wife in to the evening course in the art school.

- mtaylor and thibaultron

-

2

2

-

The real boat had a cast iron ballast keel. Gerd Löhmann gave his model a wooden keel, painted in black to imitate the lead. I want to give my model a real metal keel. I will make my keel of tin. I first make a dummy keel in spruce wood which will serve as template to make the casting mold.

Filling up the dead wood.

All the wooden parts of the keel are now made. I screw the ballast keel template provisionally on the keel to glue the dead wood pieces in place to shape the sides of the keel.

I draw the rebates which have to be made on the stem.

Before chiseling the stem, I will make the stem knee to give it some more strength.

I make also the stern knee.

Now I can make the rebates.

Checking the depth of it.

The round groove of the sternpost has to continue on the back of the keel and the dead wood. I file it out with a round wood file and sand it afterward.

The forward part of the bow has to be narrowed. Cutting the bow in shape with the chisel.

The keel is wider than the bow. It has to narrow gradually to the fore end to the width of the bow. It is also done with the wood chisel.

The keel as it is now.

Thank you for the likes

Thank you to follow

Tank you for the constructive comments.

Till next week!

- hexnut, thibaultron, cog and 14 others

-

17

17

-

On 12/1/2019 at 6:01 AM, PopDavid said:

I live with snail mail and just got my invitations. Sign me up! There is a You Tube series by the Sampson Boat Co rebuilding the SV Tally Ho. These guys are doing this full size. Worth a visit.

On 11/30/2019 at 9:29 AM, amateur said:Sir,

The bridge was open, and all the traffic lights went red. Sorry, I'm a bit late.

Am I still allowed to enter class_room?

Jan

On 12/2/2019 at 1:02 AM, luponero said:If it is not a problem I would be in the school desk with Patrick, I know I am a little late, but to recover I cut a cherry tree, a pear tree, an apple tree, a plum tree and then my wife "inflated" me!

apart from the "jokes" I follow you willingly

black Wolf

On 12/2/2019 at 8:39 PM, KeithAug said:Great project GL. I will be interested to follow developments.

Gentlemen, there is no numerus clausus for this class. Everybody is welcome and for the latecomers: it is going slow enough to catch up.

Thank you so much for your interest.

- mtaylor and thibaultron

-

2

2

-

14 hours ago, vaddoc said:

The reason is that the initial tries show planks very curved at the transom end, which would need 50 cm wide blanks to come from and would have the grain running almost vertically at the aft end.

I had similar entanglements while planking my gaff sail boat. Towards the floorhead it became difficult to find knotfree planks which were wide and long enough to cut the strakes.

- KeithAug, thibaultron, mtaylor and 2 others

-

5

5

-

Amazing what you can do with such a drawing software. I wished I could do that also.

- mtaylor, thibaultron and FriedClams

-

3

3

-

Beautiful hull, Svein Erik. Will be almost pity to paint it.

- Nirvana, FriedClams and mtaylor

-

3

3

-

-

-

On 11/29/2019 at 6:17 AM, michael mott said:

I will also follow along, it looks like and interesting project.

Michael

Michael, welcome in the anatomy of a boat story.

- thibaultron and mtaylor

-

2

2

-

On 11/29/2019 at 4:59 AM, mtaylor said:

That's not a small signalling cannon is it? Might just be a decorative piece.

6 hours ago, GrandpaPhil said:The field gun would be awesome!

Yes Mark, I think also that it is more a decorative gun than a signaling gun.

Phil, that's also my idea. The main problem with a field gun is that it will be such a huge piece to place somewhere. I foresee a strong opposition by the Commander in Chief Home Fleet.

- FriedClams, thibaultron, mtaylor and 1 other

-

4

4

-

10.5 Main sail sheet traveler

To make the main sail sheet traveler I bow a 2 mm brass tube in shape and slide the traveler ring over it. The travel area of the ring is limited by two brass rings which are soldered at each side of the traveler.

To make the base of the traveler I slide again two brass rings and two 4 mm tubes over both ends and solder them together.

The bottom ends of the 4mm tubes are hammered flat.

The traveler in place on the transom.

Thank you to follow.

Thank you for the likes.

And thank you for the constructive comments.

Till next week!

- mtaylor, FriedClams, Bedford and 10 others

-

13

13

-

- FriedClams, Moab, druxey and 4 others

-

7

7

-

On 11/23/2019 at 3:57 PM, FriedClams said:

Excellent work on these small brass details G.L. I find small open boats so appealing and your model here is very nicely done - every detail. A pleasure to watch it come together.

Gary

On 11/23/2019 at 4:33 PM, ccoyle said:Catching up on your log, G.L. What an outstanding model! It is a testament to the fact that the model builder's art can be as much in evidence in a "small"craft as in any 1st-rate man-of-war.

Cheers!

On 11/23/2019 at 9:20 PM, Jim Lad said:A beautiful job of work.

John

On 11/23/2019 at 10:55 PM, KeithAug said:Very nice detailing GL. Always a pleasure to catch up.

On 11/24/2019 at 12:25 AM, luponero said:Laboratory, technique and model

simply beautifulsincere congratulations

black Wolf

Gary, Chris, John, Keith and Black Wolf,

Thank you very much for your encouragements. It stimulates to continue.

And as for the small boats: I like small open boats , they have also the right to be made in model.

During my career at sea I saw many people sailing pleasure craft of all sizes and I have a kind of theory: 'The happiness of the crew is inversely proportional to the size of the vessel.'

What means in normal language: The smaller the boat, the more fun the crew has.

- mtaylor and FriedClams

-

2

2

-

9 hours ago, Katuna said:

I hope this hasn't been too boring. A lot of pics and yammering for not much progress. If I get 5 minutes to myself this holiday weekend maybe I can get a little more done.

Katuna,

It is not boring at all, on the contrary it is fascinating! I signed in to follow your log.

-

20 hours ago, vaddoc said:

Hope I am not too late!

Great project, I ll be following. What is the massive gun in the background?

Vaddoc

Hello Vaddoc,

Welcome to join the club.

I bought the gun on an online flea market auction. I made a bid of 20€ and the gun was mine. It is a cast iron gun of 55 cm long. I do not know what it what it was for. Certainly not to shoot with.

I still have to decide what I will do with it: rig it like a naval gun or like a field gun what it probably portraits, but in the case it will become very big (see example below). All suggestions are welcome!

- coalman, thibaultron, cog and 6 others

-

9

9

-

CHAPTER I. The Boat

1. Keel and stems

Starting with the keel, the prow and the stem. To saw them in the right shape I glue a copy of the plan on the different pieces of wood.

For the right cuts, I clamp my work piece with the cutting line along two steel L-profiles in the vise and saw with a hand scrub along the profiles.

Where I have to saw curves, I use the jig saw...

.. and the band- (outer curves) and drum (inner curves) sander to finish.

In the back side of the stern post there has to be made a round groove to give room for the rudder. I made it before sawing the sternpost. I have no precision tools to do it, therefore I make a much longer piece then needed; that gives me the opportunity to choose the best piece to make the sternpost from.

At the bottom of the sternpost is a pin which fits in a hole in the keel. Sawing the pin.

Making the hole in the keel.

Keel and stems glued together

Thank you for the likes

Thank you to follow

Tank you for the constructive comments.

Till next week!

- Mirabell61, FriedClams, jgodsey and 23 others

-

26

26

-

On 11/23/2019 at 1:19 PM, Backer said:

I'm going to follow this shipbuilding lesson.

I will be quiet in the classroom, and pay attention

Also did some homework. I have also had to cut down a cherry tree, the suitable pieces are dried and ready for further processing.

Patrick, I have good news for you: this will be a course without exam.🤩

Cherry is a fine wood to work with. It works a lot easier than oak and when sawing, planing and sanding it smells very good.

On 11/23/2019 at 4:08 PM, FriedClams said:This is so sad to see happen.

I've pulled up a front row seat for this build log G.L. A great idea and I know I will learn a lot from it.

Gary

It is so with a lot of things Gary. At a certain moment things become old fashioned and are thrown away and after a while when almost nothing is left of it any more, it becomes vintage and everyone wants it again.

Welcome in the classroom, take a seat next to Patrick.

On 11/23/2019 at 4:48 PM, thibaultron said:I'll be following, with interest!

Also welcome Ron.

On 11/25/2019 at 4:51 PM, yvesvidal said:Le Chasse Maree is an excellent magazine which has been published for many years and covers various subjects related to the sea and boats, in depth.

I have a few issues at home and really like it. You picked up an excellent and traditional subject for your build.

Yves

Hello, Yves. I have also several editions of the magazine and some other publications of le Chasse Marée. They contain indeed a treasure of information on traditional boat building. This model will be something total different than a type German VIIC submarine, a lot less technical and complicated, but I like very much the lines of this traditional Breton sloop.

On 11/25/2019 at 7:12 PM, Mike Y said:Interesting take, it would be great!

Thank you Mike, welcome in this project.

- thibaultron, FriedClams, Baker and 3 others

-

6

6

-

Pequot 1908 by svein erik - FINISHED - 1/48 scale - Coast Guard Cutter

in - Build logs for subjects built 1901 - Present Day

Posted

The plates are showing nice through the paint.