-

Posts

797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Seventynet

-

Thank you Al. I just had a look at your Halifax. Now that's an inspiration. Ian

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Greetings shipmates, thanks for looking in. I'm getting closer! Lots of fiddly bits: transom boom holders, chainplates, posts, channels and boarding ladders, only some of which have been installed. Unassembled catheads Jib outhaul block: Carronade carriage assembly line: Carronade factory: Trunion cap jig: Eye-bolt jig: Uninstalled carronade: Rudder works: Bowsprit assembly: Current state of progress:

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Gorgeous Don! Good to see you back in the shipyard. Ian

- 223 replies

-

Love this Mike. Great work as usual! ian

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Good job B.E.! I think it looks great. I’m sure you will feel a tremendous sense of accomplishment when you’re done. Keep the faith. ian

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Great job B.E., it will look even sweeter with a sanding and finish.

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Steve that is an absolutly beautiful job. A pleasure to behold. Ian

- 48 replies

-

- first build

- bowdoin

-

(and 2 more)

Tagged with:

-

Well this thing has been gathering moss hasn’t it! Hi Ronald. It’s been a while but I think I used masking tape, cut to measure after laying it over the bulkhead edges and then spray painted (can) the interior. I sort of wonder why I would even have done that but I may have completed the fairing process beforehand. thanks for looking in. Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

It’s hard to turn away once you are hooked. Best Regards, Ian

-

Beautiful work Robert and ingenious solutions, methods that I am sure to employ myself. Ian

- 527 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

-

Terrific job Steve! Such nice crisp work. regards, Ian

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

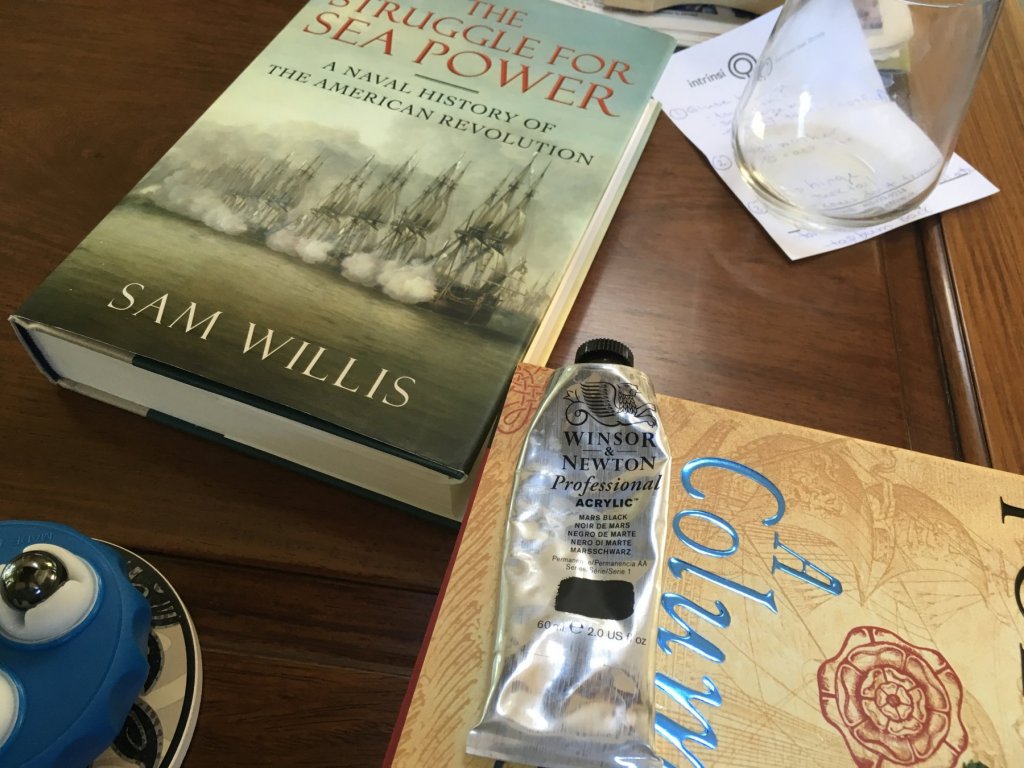

Thanks a lot Jim. I used a flat black acrylic. I think, but not positive it is what Chuck originally recommended. However I painted over it with satin wipe on poly which makes it shine a bit more than I like. Regards, Ian

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks B.E., honestly your build is absolutely beautiful and there has been more than one occasion where I had wished I was behind you so that I could have followed your lead. I have said to myself many times that I have to build another Cheerful so that I can do a better job next time. Al thanks for the compliment. I know your work and you will do a splendid job on it. You will also enjoy it as much as I do. Chuck has put together a beauty. Ian

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

DIY Workbench Mini Vac Cleaner with Trap

Seventynet replied to Tecko's topic in Modeling tools and Workshop Equipment

Very clever, nicely done! -

Thanks for the encouragement Kurt and Don. I really would like to see more of your build Kurt. Don I wonder what you’ve been cooking up in that shipyard of yours? Any undocumented projects you’ve been holding back? I cleared the Cheerful deck for action this morning . It feels good to be back at it. Best Regards, Ian

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That is so sweet looking Rusty! ian

- 120 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nice work B.E. I actually miss the hull planking part. It reminds me how much I liked working with boxwood. Cheers

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks so much for the (overly) kind words and for hitting the like button. Jim: Thanks for the encouragement. I am intrigued by the picture of your yellow cedar deck. Where can I find your beautiful model? Antony: Thank you. I have come up with a pretty reliable approach to removing planks by first treating the area with rubbing alcohol and then heating up the area with a heat gun (after the fumes have cleared!). The planks come off with ease. And clean up is easier too. Much appreciated Joe. I found your Atlantis restoration project the other day. Wow is all I can say! Thanks so much for following Niles. Love your work! Regards, Ian

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Atlantis by Thistle17 - FINISHED - Robbe

Seventynet replied to Thistle17's topic in RC Kits & Scratch building

Beautiful model and exceptional work Joe. It is going to be hard to part with this. I am sure the client must be happy! regards, ian -

Decking 1. I used Alaskan yellow cedar for the deck. I’d also used it for the deck on my Brazzera. It is perfect for this application. 2. Decking layout. I would do it slightly different next time. I would let some of the bow planks close to the center plank taper so that I could end up with all of the planks except the center plank being the same width at the bow. I could have been more careful to achieve the same objective at the stern as well. This is where I am at today. It may be a few weeks before I have any updates. I hope these are of some interest and value to those starting out. Best Regards, Ian

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

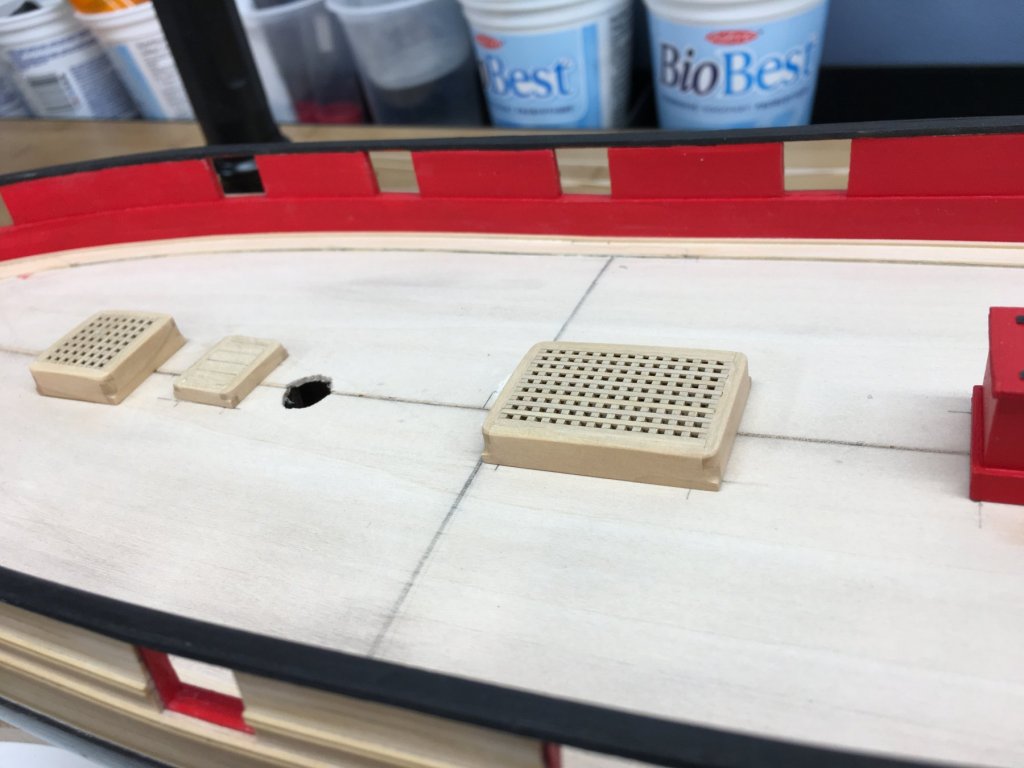

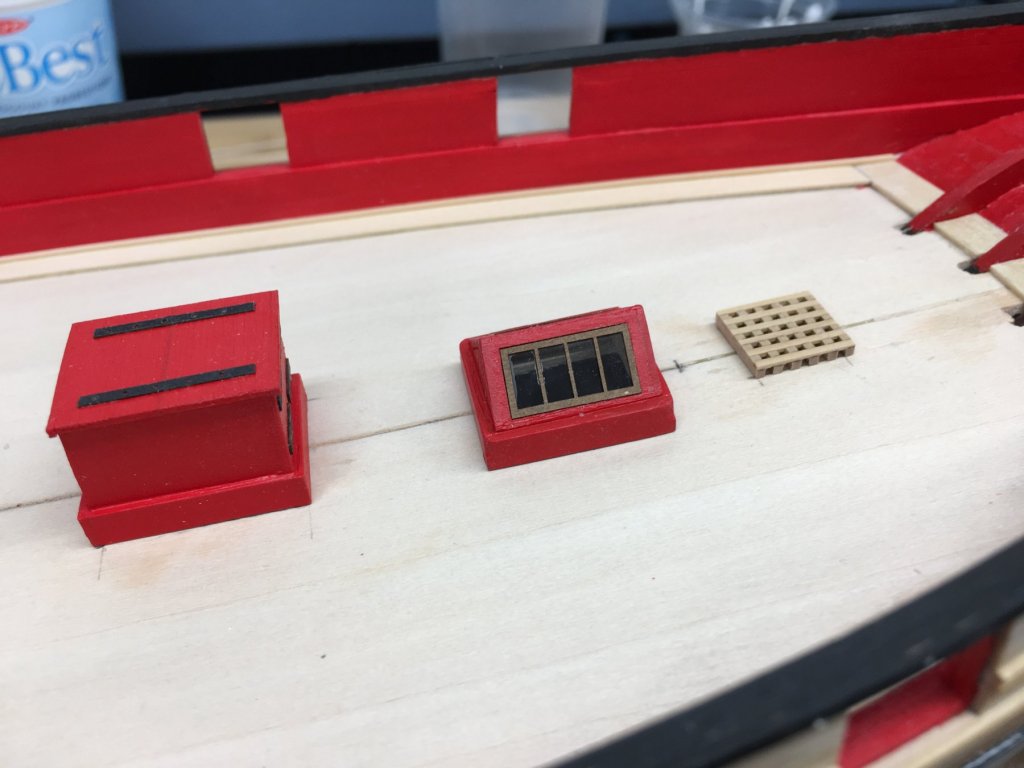

Deck Structures I bought and assembled all of Chuck’s kits. They are well worth it. Even the windlass which I built but can only conclude was eaten by my shop vac and dumped in the garbage after my semi-annual filter clean. Sigh, I guess I’ll have to order another one from Chuck.

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.