-

Posts

612 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Remcohe

-

Mayflower by SawdustDave - Finished

Remcohe replied to SawdustDave's topic in - Build logs for subjects built 1751 - 1800

I might join next spring, but forgive me for not bringing my KF along. The cutter and longboat will fit in my luggage though Remco -

Bob, For a long time I could not make a decent drawing of a person let alone make a sculpture of a face. Until I bought copy of this book and my results improved dramatically after I understood the concept of proportions. I still have to make the step from polymer clay to actually caving in wood but that is just a matter of time. Remco

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

I see they are really challenging shapes to make, but you make it look like a walk in the park My hands are itching to continue with my masts...... Remco

-

Yes do keep boring us Piet Popeye, I found a guy in North Dakota and he has an Alps printer and was willing to do a one of print job. It's a dye sublimation printer that has white ink, ideal to print decals with. Remco

-

Bold move Piet, the result looks great. There is a way to know what port and starboard is in Dutch too, I have to use that all the time. The first half of the dutch word stuurboord has an R in it just like right (or rechts in Dutch), bakboord (port in Dutch) does not have that. Remco

-

The antenna installation looks great. You might opt for not removing the decals but just repaint them? Remco

-

Mayflower by SawdustDave - Finished

Remcohe replied to SawdustDave's topic in - Build logs for subjects built 1751 - 1800

Impressive work Dave! Remco -

Piet, regarding the flags I've been thinking. I never tried it but what about really thin plastic card, <0.01", shape it into form and then stick some decals to it. With the decal paper you still have you could make some red and blue stripes (first paint then cut to size). Remco

-

Nice Danny. I hope you do find the mast plan from Admiralty models, it has all the details you need. Remco

-

Interesting Piet, I did not know the Royal Dutch Navy had a different flag than our national flag, learning something every time here in your build log. Remco

-

Danny I just realize it's been way too long you've show an overview picture of your Vulture. You always have been showing all the details but I was stunned (but not surprised ) to see how beautiful everything is in the overview shot above. I can only say 'please show me more!' re: the masts, you'll find that lots of fun. Remco

-

Mayflower by SawdustDave - Finished

Remcohe replied to SawdustDave's topic in - Build logs for subjects built 1751 - 1800

Nice looking pumps Dave! Remco -

Gaetan, at the slowest setting my dremel (cordless type) still turns very fast, and even with the flexible cord I find it to bulky to operate near my model. My other micromotor has no 3 jaw chuck. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Nice metalwork Danny, you fooled me into thinking the plates were forged together Remco

-

Thanks all for the kind comments. Alan,I use a pin vise to drill the holes, my dremel is much to aggressive for this type of drilling and the smaller drills do not fit in my other micro motor. Next to that I feel much more comfortable to do this precise work by hand, a powertool will not give the feedback a pin vice does. Ed, Mark, I draw the castello up to the .018 hole, getting at the smaller sizes you really need to be careful not to break the wood. I use 24" strips to get a better yield from the work involved drawing one strip. I also made a minor improvement to my Ed's style clamps as the treaded holes started to wear out pretty quickly in my case. I added square holes and inserted little nuts for strength. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

250 hanging knees....... and I'm going nuts over the 30 or so I need to make for my KF. I really admire your persistence to do it right. Remco

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Popeye, I used a white decal film and a color laser printer. I'm thinking of trying a different solution to fix the con numbers for Piet. Remco

-

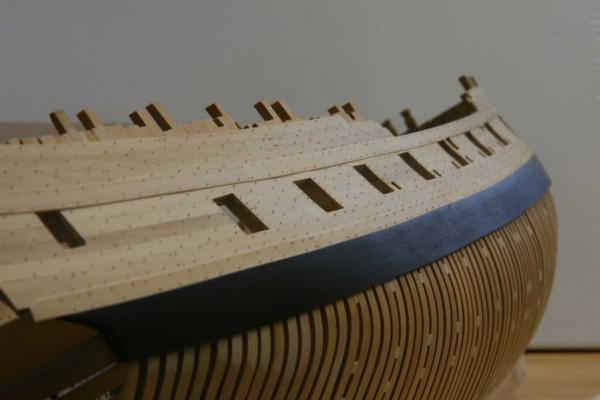

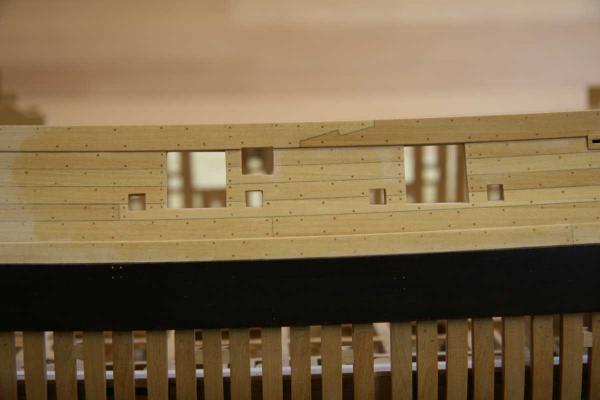

So after lots of holes and filling them up again ..... The hull ready to be sanded Close up of the end result Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.