-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Another version of the 'Third Hand'

michael mott replied to wefalck's topic in Modeling tools and Workshop Equipment

Wefalck, Wow! excellent work, it is great to see how ideas evolve and are transferred. I was just asking Johann about the screws with the hole for a bar or pin and see that you have one as well at the base. I really like the copy of the wood clamp to a steel version. Could you share the source of the small chucks, they look like they would be worth having a set? Michael -

There is an interesting parallel to this. It is falling into the rhythm of trying to do everything on the next piece with the same tools as we used for the last piece, ie the mill, or the sander ,or the scroll saw. so I smiled when reading about using both tools to accomplish the task, because sometimes we just miss the opportunity and don't switch out of the rhythm. Michael

-

One thing I noticed with the second one, is it has a small vibration in the shaft. so it will be used for polishing brass with the small wire wheels and mops. Michael

-

Mike an interesting point. I remember that Gerald Wingrove built himself a small micro drill years ago using a model train DC motor and if my memory serves me correctly it was pretty short as well. At the low cost of these on sale, as an experiment I might just chop it up and use a short flex power connection between the head and the battery part of the body. It might be more trouble than it's worth, but on the other hand it might just be the ticket. Michael

-

Ed your comments about the falls crossing is interesting, my first thoughts about this are regarding the topping lift, it is an important line on my sailboat because I can use it in a hurry to spill wind off the mainsail in a hurry (immediately) I am not sure about square riggers but there would not be any doubt that the first pins would be logical from a speed point of view there being no confusion in a panic. One obviously doesn't want panic on such complex sailing vessels, but nature can require very prompt action at times. Part of that old "form follows function" idea. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Stevenson's ER32 Collet Blocks

michael mott replied to KeithAug's topic in Modeling tools and Workshop Equipment

A collet block is on my Christmas list. Michael -

I saw an ad in the Canadian Tire Christmas flier today they have them on sale for $12:49 so tomorrow I am going to pick up a couple more. Michael

-

Congratulations Rusty your model looks very nice. Michael

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

As Mark stated, the clarity and explanation of the complexities is superb. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I can see that the detailing will only be finished when the obligatory splash stains of the champagne liquid are evident on the bow. What a superb piece of model shipbuilding you are producing Keith. Michael

-

Looking at your photographs is always engaging Geatan, please tell us about the 4 schooners. The last picture is most interesting, what a simple way to keep the mill table clean with slips of hardwood filling the T slots. it also creates a more useful work surface if the vice is basically in a permanent position. The scale of your work is really interesting to follow, and your comments about the thickness of the glue interface was revealing, something that I had not really considered but yes the accumulation adds a significant amount. i shall also have a go at some dark background photographs because the really are dramatic. Michael

-

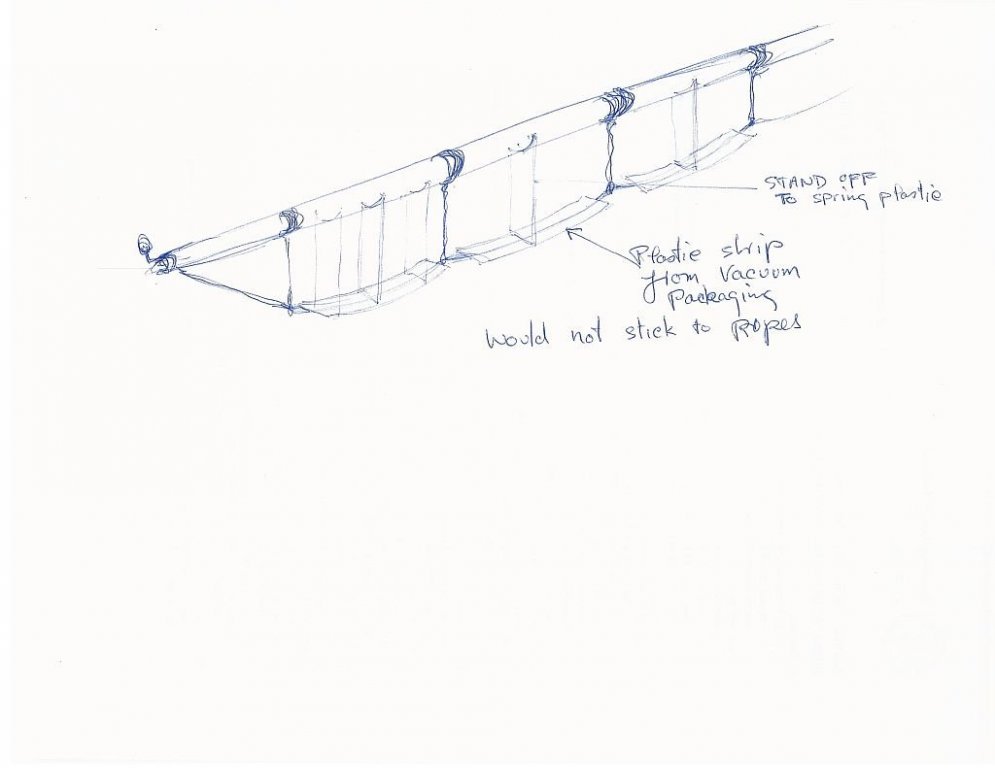

Hi Ed at risk of overworking the foot-rope issue of shape it occurred to me reading the comments about weights that a different approach might just prove to be useful. it involves shaping the rope by pushing gently on it with some clear vacuum packaging plastic. see the accompanying sketch I think it would be worth a trial on your jig. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Ah yes us folk who live on the outskirts of the civilized world eventually hear about these things, or stumble across them accidentally as I did. Michael

-

One of the issues with long lengths of naturally hanging rope, wire, or cable is that it tends to want to form naturally into a Catenary Arch which is the natural curve followed by anything hanging between two points. this curve is a result of gravity and the flexibility of the material hanging. To better understand this take a couple of blocks of wood with a pin in each place them about 6 inches apart and hang some model or jewellery chain between them, as the blocks are pushed closer together or pulled further apart the natural curve that occurs is a catenary arch. This is true for all curves hanging between two points. Therefore to get a clearer view of what the hanging foot rope would look like test the shape by using some small chain between the ends and hook the chain up at the various points, adjust the tension between the ends to get the required natural curves of the foot-ropes. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Fraid so John. Michael

-

One of the things that I do enjoy about following your work Ed, are the jigs and sequences that you use to accomplish this superb work. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I will be getting back to the ship by the end of this week. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.