-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Amazing Igor, the sail is a work of art all in itself. Michael

- 185 replies

-

- jolie brise

- pilot cutter

-

(and 2 more)

Tagged with:

-

Very nice work on the details Adrian. Michael

- 184 replies

-

- ruby & arthur reed

- lifeboat

-

(and 1 more)

Tagged with:

-

Thank you Doris for the information about the glues. Michael

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Doris I am curious about your use of different glues and where you would use them. Your work always looks so clean, could you say a little about your use of glues and your thoughts about them. Especially where you layer one thickness of card over another, as in the planking. Thank you Michael

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Hello Doris it is great to be able to see another one of your models take shape. Your skill at turning such a humble material into very elegant models is a joy to watch. Michael

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Hi Nils revisiting this section regarding the covers on the lifeboats. My question relates to the top surface, is the canvas cover supported along the centreline of the lifeboat by a spar or some other element, and would there be a slight sagging like a tent with the lacing pulling the cover tight to keep water from pooling on the top? If this is the case perhaps some fine fabric stiffened up with sizing or glue laid over a thin dowel (toothpick or brass rod) give the desired effect? Just a thought. Michael

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

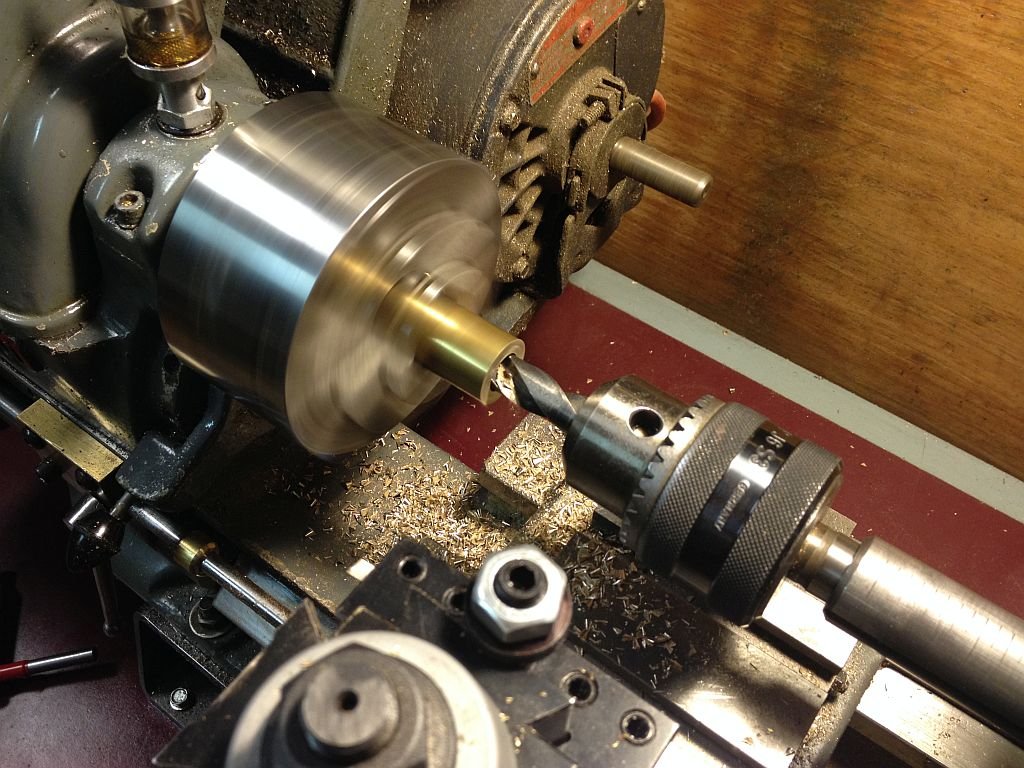

Hi Keith I have not had this problem in all the years I have worked with plex, perhaps it has something to do with the types of Plex, I prefer to use the Cell Cast type and not the extruded type. First I bored out a piece of 7/8ths with a half inch drill Then using a brand new tool bit which I ground from some 5/16 HSS steel, I was pleased that I was able to take a single depth of cut of .125" for a distance .312" which is the thicknes of the side walls of the cabin. The first three porthole shells still a lot of work to do but it feels good to make some progress. Michael

- 2,215 replies

-

Riccardo I think your idea has a lot of merit. The reason I say that is that the stitching is raised not cut ans sweat soldering a bit of brass etch onto the edge of the hoop would be a breeze for Keith. The ends that could be pulled together and squeezed to ensure that the stitching is tight to the hoop would also be where the fixing point could be to the sail. A little bit of work with a paint brush and nobody would know it is not stitched leather. There ya go Keith we have solved your Problem....... Michael

-

Thanks for the kind words Carl, thanks also to all of you who have been visiting. In between the hockey periods I did a little work on the companionway, and lowered the side walls by 1/2 inch 4 inches in scale which leaves them at 17 inches at the aft end and 13 1/2 inches at the forward end. I'm good with that. I will shorten the hatch about 3 inches shorten the sidewalls length by 4 inches to make them 48 long and add a couple of round ports in them. Michael

- 2,215 replies

-

Thanks for the information on the flag Chuck, I shall have to try this. Michael

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chris your fine workmanship shows so clearly with this latest addition with the bow details. Michael

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Mark she is looking very nice, your workmanship is reflected in the lovely clean lines and finishes. I like the sculptural shape of the rudder. Michael

-

Hi Pat, the card is 14mm or 35/64, the card rotates very nicely. I printed it up on photo paper and then coated it with CA glue. The Plexiglas was very old I had it left over from my Architectural model building days so since 1984, the trick with removing the protective paper on old Plexiglas is to warm it up with a hot air gun. The paper then comes off as if it were a new sheet. Michael

- 2,215 replies

-

Hi Mark To make the front edge of the drill a scraper similar to a bit for brass. Michael

- 2,215 replies

-

Denis , Elmer , and Piet thanks for the kind remarks. Did a bit more work cleaning up the compass and made the cover from some 1/32 plexiglass. The bolts are some modified 00x90 1/4 in long hex bolts. After cutting them to length and polishing the threaded end they were held in the pin chuck to reduce the hight of the head and to round it up a bit. All the gimbal rings were given a final sanding with some 1200 grit wet and dry. and fitted back into the copper dome. Michael

- 2,215 replies

-

Nice work on the lifeboats and Davits Nils, I like the look of the navigation hardware as well. Michael

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Ross I should think that boxwood would be fine, will you be applying it over a plywood substructure? Michael

- 10 replies

-

- africa

- passenger liner

-

(and 1 more)

Tagged with:

-

Andy this has crossed my mind, it would entail sorting a couple of things out, not the least of which would be testing the printed card for deterioration in the oil or spirit. also I would need to seal a few spots to prevent leakage, eliminating the air is not a problem. I shall consider my options on this one..... Michael

- 2,215 replies

-

Hi Dan thanks for the kind words. This evening I reduced the depth of the inner cup and machined a new insert it is drilled through with a .6mm hole at the top and threaded 1/4 inch deep x 8/32 thread on the bottom. This allows the needle to be adjusted up or down, the needle is in fact the end of the 8/32 screw machined down and honed to a point to hold the compass. The magnetic part placed on the pin I tested the pivoting by bringing a pair of metal tweezers up to the compass and the needle swung to them Next to find the print that I made for the compass and mount it on the metal magnetic part. Also the plexiglass cover. Michael

- 2,215 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.