-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

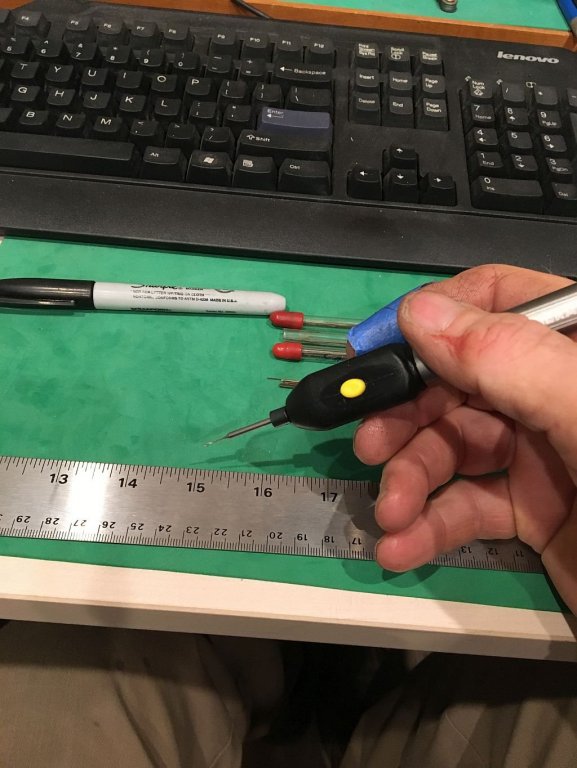

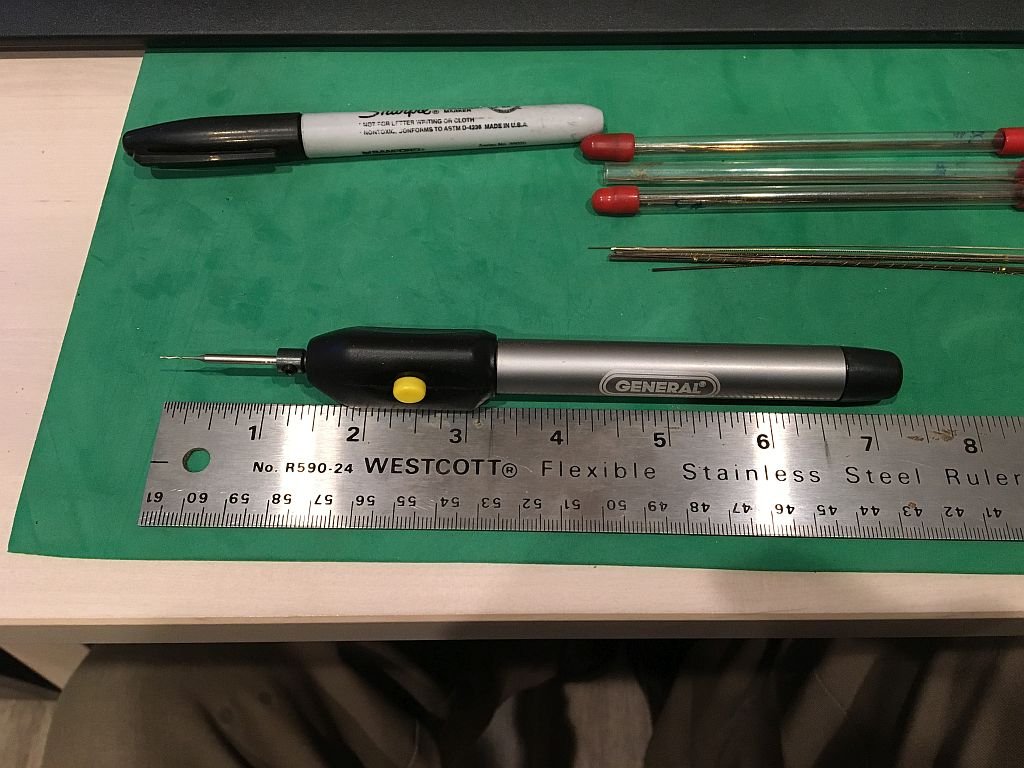

While on an obligatory trip to Home depot to pick up some caulking for the home reno, I took the opportunity to do a little grazing in the tool section, and came upon a small pencil engraver. this tool had a diamond burr for doing the engraving. Advertised as a standard 3/32 shank regular burr, with pictures for putting names on anything and everything. it was the 3/32 shank that piqued my interest, because I have a whole bunch of 3/32 shank miniature twist drills. It was also touted as 20,000 rpm, so fast. It was $39 so I purchased one as compensation for having to go back to get the second tube of caulking which i should have purchased the first time there. the yellow button is a momentary on switch. I drilled a few holes easily with a .022" drill it was true and smooth in its operation, and uses 2 AAA batteries. So it will be very useful for small hand held applications. Michael

-

Gerald, indeed enjoyable to read the information on you work anniversary, and the trials of replicating in model form the idiosyncrasies of full size subjects. The benefits of the building jigs are really apparent when it comes to the complex soldering sequences. Michael

- 281 replies

-

- falls of clyde

- tanker

-

(and 2 more)

Tagged with:

-

Isn't it amazing how many lines there are even in a simple rig. You are doing a super job Keith, although I think that you are being just bit skimpish with the pure white lines I would have thought with your attention to fidelity an' all you would have used some home spun unbleached linen for that final touch..... Oh these white lines are just placeholders for the real thing.

-

Hi Keith, I have not been on holiday, just working through the list of jobs after the big move. The wall renovation is nearly completed. Michael

-

Wonderful work Keith, your build is a gem to be sure. When you have finished this one you need to build a second one with a white hull now that you have had a little practice. Michael

-

Catching up again Ed, you continue to inspire me with your attention to detail, then the execution of those details. you do set a very high Bar sir. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Brazing vs soft soldering

michael mott replied to dvm27's topic in Metal Work, Soldering and Metal Fittings

Of course there are always exceptions to the rule, (he said smiling). Kurt; Thanks for your clear definition of the difference between hard and soft soldering, which in my view is a more clear way of describing the process rather than the visual colour of the solder. One other aspect of the differences is that when soft soldering the metal model parts, usually brass, copper, or nickle silver, the metal itself stays hard, whereas when silver soldering or hard soldering because of the higher heat involved, the metal model parts that are being soldered get annealed or softened. Michael -

My goodness Nils you don't hang about do you? September 13 start and now almost done the planking. looks like it will be another great looking ship from your yard. Michael

- 692 replies

-

- eagle of algier

- chebec

-

(and 2 more)

Tagged with:

-

Hi Mark Just to be clear I read that you are using 46/60 resin core solder. My understanding is that this would be called soft solder and not silver soldering or brazing. Silver solder is called hard soldering and uses a much higher temperature it also comes in a paste and is expensive. Looking at your brasswork which is nice and clean, it would appear to me that you are indeed soft soldering and not hard soldering. The reason for my comment is that in reading the comments I get the impression that some might think you are hard soldering. Michael

-

Hi Walter, I am sorry to hear of your loss, My deepest condolences. In time the great and fun memories of your life together will be the important ones that will make you smile. Michael

-

Just a bit of catching up Russ, that hull really does have sweet lines, Love the low shot from the stern. I hope the weather down your way hasn't been too much of a problem. Michael

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Ed the more that I look at the work you are doing the more I sit in awe. In the last picture there is what appears to be an open double hook that looks a bit delicate, is this just a temporary one or does it actually look that way? Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Cliff Your resawn lumber looks great, and a good solution for the sharing of tools. On Thursday last week we had some tree pruners come and do some serious thinning of some overgrown apple trees in the back yard. I took the time to share my affection for wood and let the pruners see my collection of wood. I gave the foreman a small piece of boxwood. Next thing he asks for my phone number and says that they get to cut stuff like Russian Olive, Cherry and Elm. He will call me when something good comes up. I will be re-sawing the apple and stickering it for future work. Michael

- 19 replies

-

- milling wood

- echo cross section

-

(and 1 more)

Tagged with:

-

ancre Le Fleuron 1729 by rekon54 - 1:24

michael mott replied to rekon54's topic in - Build logs for subjects built 1501 - 1750

Giorgio, it is great to see you back at the shipyard, I smiled seeing the curved part being worked with the gouge. Michael -

Ed it is funny that you mentioned these, as I was reading through doing a bit of catching up, I kept thinking that it must be an ever present worry catching or snagging something while focused on a small detail. Stunning work on the running rigging. It also occurs to me that the seamen on a ship of this nature would likely spend time in one specific area for a while to become very familiar with the lines and functions, at the rails. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I was very happy with my own progress, until now. At my age I though I was over being jealous of anything! Your organization of the wall storage of the tools speaks volumes about your mind and why your model is such a wonderful example of workmanship. Jeez....now I'm gonna haf ta rethink my whole shop..... Ed my fuse is already blown. Michael

-

Took the mast down this morning in preparation for the move to the new shop. The move is beginning to wear on me. Michael

- 2,215 replies

-

I have been whittling away on my billet of ebony now for about 40 years it was 36 x 7 x 6 with an adze finish when i purchased it cost me the (exorbitant sum of $70 at the time) very happy I spent the money then. I still have enough left to last the rest of my lifetime given the rate at which I have been using it. it is sitting on the cherry top for the new end tables. Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.