-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

Is that the planer by Proxxon? I saw a demo a few years ago but I have a thickness sander for my thickening. What are the advantages and disadvantages to a sander? David B

- 144 replies

-

- corsair

- bermuda boat

-

(and 1 more)

Tagged with:

-

Hemostats always come in handy finding away to hold small parts is always a challenge. Exacto has several good items but you have to know what you are getting, Their plane is garbage it is difficult to work with and I was not impressed. When I was back in my apt. I packed a coupe of mini planes and brought them back with me. My Lie Neilson 102 and what I thought was a small stanley with a bigger throat for larger cuts. However I found out that I had grabbed the exacto instead. No matter what I did I could not get a decent saving. Now I have to find a decent stanley low angle block plane. Any suggestions on what I can use without breaking the bank I would go with a veritas or another Lie Neilson but I am on a limited budget at the moment. David B

-

Nice planking job Brian The reason I use an airbrush is because I am heavy handed and usually get a bad looking job using a brush. I do have decent brushes too. David B

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

I have always been amazed every time McCann brings a model. It usually is something old and based on nautical archeology. I would love to get a crack at his sources. If I posted every model he has brought you would be amazed at what he comes up with along with the build log log with sources listed along with photos and plans. I sat next to him at the Sat. banquet one year and it took a massive amount of self control not to quiz him for the rest of the evening. I think maritime archeology is a hobby for him and he transfers that hobby to model building. David B

-

Congratulations on a job well done. Do you plan to put a finish on her. I think it would add to the look? David B

- 120 replies

-

- mystic

- motor yacht

-

(and 2 more)

Tagged with:

-

Magnificent work on your Lettie. I can admire the lines and the sleek look of her. Question for you. What is the difference between a cod bot and a seiner? David B

- 420 replies

-

One of our club members picked up a unit and sid it was the cats meow. He bought it to a club meeting and gave a hands on demonstration. I found it to work great. No heat sinks just make sure the part is clean and properly fluxed. apply the solder touch the probes and hit the switch. The solder elted and flowed with the flux. First part was very small. and the next part was huge. But the unit had a dial to control the wattage. My only reason for not getting a unt is cost versus how much I would actually need it. David B

-

I generally use StaySilv solder with a liguid flux. I have a regular iron and one that can be increased up to 20 watts. I also have a Smith's Little torch when I hard solder. David B

-

One of our club members built a model without taking into account the finished size. His workshop is in the den of his house when finished and cased he could not get it out of the den. Outside of the case he was stuck as well. I remember seeing a photo of the build. It was massive. The last time he brought it to a meeting for ships on deck I almost had a hernia trying to move it safely without masts and rigging. We barely got it through the door and the stairs. And I was used to lifting large and awkward items! Plenty of exercise doing the stairs. I was younger and stupid but I volunteered. That is why I build at the smaller scales. Nothing larger than 16" at the most. David B

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

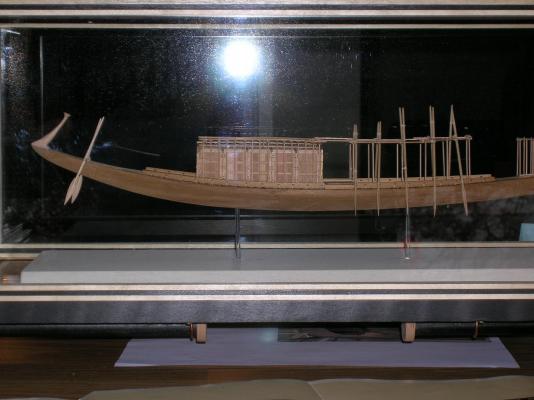

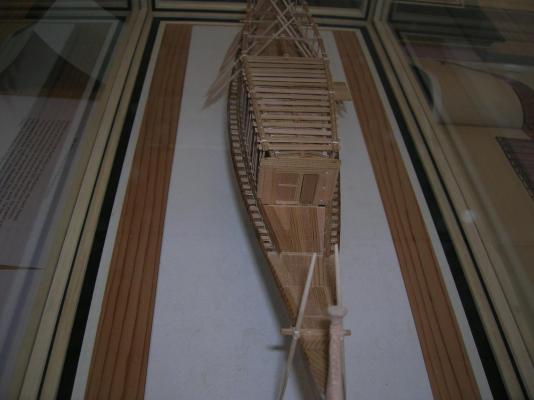

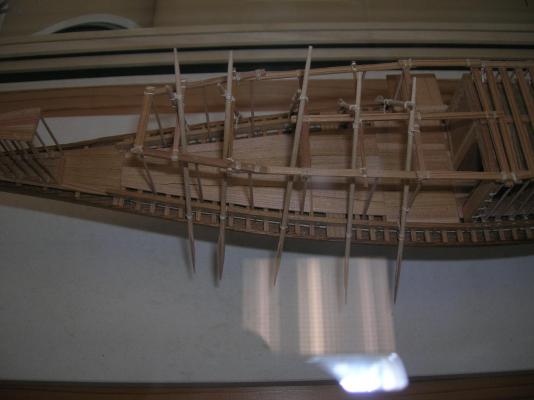

That is one of the reasons I go to Manitowoc every year and help out. The modelers know me as I act as a gofer giving everyone a hand. I take pleasure trying to second guess the judges. And asking questions on techniques and putting people together who can help each. A couple of years ago John McCann from the Rocky Mountain Shipwrights brought in an exquisite model of the burial barge of Kufu. A real work of art and skill if I can locate it I will post it, One of the visitors so loved it and asked me to hook him up with John. The end result was it was donated to the Oriental Institute in Chicago. John was thrilled because of the hassle of bringing it from Colo. to Chicago. I took one look at it and fell in love. So did the judges. Found it!! John Fox III was in town and blew mind mind when he said he had a Constitution in his pocket. He is my go to for SIB models. This is why the show is unique, everyone is having a good time and learning new things at the same time. Even those who did not place were happy and learned new things. The perpetual student and learner.David B

-

I am surprised you did not take aa few drinks doing those shrouds. Nicely done and very neat. David B

-

Interesting video that is why I have the smiths little torch. From one nozzle to the next. The disappointing thing about it was doing soft soldering and the wattage of the iron depending on the size. David B

-

There is a link on this forum about prepping a plane for use But I do remember part of it. I had a stanly as well. After resharpening the blade it worked okay. I bought a Lie Nielson violin plane that is the cat's meow. That is the one I turn to. L-N 100. David B

- 71 replies

-

- benjamin w latham

- model shipways

-

(and 1 more)

Tagged with:

-

Omega you are a glutton for punishment. Are you by chance intoBDSM? Good luck and fortune to your build. I hope to learn many things from this log so I will pull up a chair. David B

- 120 replies

-

- mystic

- motor yacht

-

(and 2 more)

Tagged with:

-

Make things easier for yourself. If you planking is smooth and symmetrical, use that as a base and replank using 0.5 strips. They will be flexible and you will not have to use nails to hold them to the hull. Before doing this make sure your base is the look you like. Think solid hull approach. David B

-

Mark, The NRMSS meets in Westmont IL on the 2nd Sat. of the month. Kurt Van Dahm is the Pres. and wrote some articles on building the Philly. If you are interested he is a member of MSW send him a PM and find out the contact info. He knows the kit pretty good and his Philly is nice. I am from Chicago and I petty those friends I know who got hit by that arctic blast. Though it is chilly here as well. I feel it because of my ongoing medical problems. Hic 70 F and I am wearing a sweater. David B

-

Your build log should be edited and taken to a publisher as an addenum to the Swan books. Bravo. David B

-

A couple of years back I was able to attend the Mariner's Contest in Newport News. I went buy the miniatures area and saw a sis of a Royal Louis that took a gold. I was able to track down the builder and ask him a few questions on his build. He informed me that he used Plastene for the sea and acrylics to give the proper shading and color. Then a top coat of Future Floor Wax. This gave a sheen that highlighted the shading and added to the realism. A fellow modeller I knew said the it was knocked down from gold because the blocks were to to scale. That was a conceit I did not agree with. One of the judges from Manitowoc told me he would have given it gold. The reason was basic. He was measuring the proportions by eye. And he was not going to risk damage and take the case off and use a micrometer to get the exact dimensions. I think he did the right thing. Some may disagree with me but I am used to illusion to get a part correct looking at the smaller scales. David B

-

This can be very deceiving. Silver solder can also be called hard solder. It comes in sheets and wire. I buy the wire according to the melting temp. I flatten the end paper this and with a clipper nip off a piece the size of a pepper flake. Once I apply the flux I use the same tool to pick up and place the solder in position. Then I sneak the flame to the flux and solder and the second the solder flows I pull back. The reason silver solder is called hard solder is because the wire is very hard. You need nippers or wire cutters to cut it. Silver bearing solder is called a soft solder. All you need is a pair of scissors to cut a wire. My supplier is Sante fe Jewelers Supply www.sfjssantafe.com/ They are easy to do busines with. They also have a list of what they have and the applications it can be used for. David B

-

Is that a hull or a work of art? I would put that in a museum the way it is. I am surprised your hands did not cramp up during the installation. David B

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Clear Shellac Sanding Sealer

dgbot replied to grsjax's topic in Painting, finishing and weathering products and techniques

I have Always used Poly cut with thinner. Works great at taking care of the fuzzies. The thinner helps open the pores so everything sinks in. I usually do this before I went to work. When I got home time to buff it out will steel wool. Then a wipe down with some cheese cloth and a terry cloth towel. The last two procedures were used to get the finer particles off so no rust marks. The wood is now ready for anything I throw at it. I have never tried shellac so I have no opinion on it. Several club members have used it with good results. Experiment with some scrap from your bin and note what you did. This sample will give you a good idea for how to use it. David B -

If you did that photo with a background I would have bet even money that it was real. Good job. David B

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.