-

Posts

945 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by mbp521

-

-

I am my own worst critic when it comes to pictures of my builds. My only saving grace is that I see other builders with the same concerns about their photos as well. So I trudge diligently on. Beautiful work Roger, I’m taking it all in to help learn the metalwork craft.

-Brian

- KeithAug, Canute, FriedClams and 4 others

-

7

7

-

Absolutely stunning work Keith!

-Brian

- mtaylor, FriedClams and Keith Black

-

3

3

-

2 hours ago, Roger Pellett said:

To look for welds to show on your model, see if you can find photos of Drydocked vessels built by JeffBoat.

Roger, that is actually what I have been doing to research this subject. I found a nice video on YouTube that shows a walk thru of the MV Mississippi IV and then a walk around of the hull. The video does show some good detail. In some of the shots you can see the weld lines, especially where the bottom of the hull meets the side of the hull. There are also some shots that show the sides of the hull and you can make out the welded panels, but they are fairly flat to avoid drag. I do take this walk thru with a grain of salt since this vessel was built in 1961 and the Caroline N was built in 1973, so the building methods might have been different.

-Brian

-

Now that is impressive, thank you for the link. What is even more impressive is that there is a building big enough to house a 345m (1132ft) cruise ship! The Admiral and I are going on a cruise in a couple of weeks so I will definitely be looking to see how the ship was put together and taking notes. 😁

-Brian

-

Thank you Eberhard & Roger for the useful information. I have seen videos of some of the modern day military ships going together, i.e. the Aircraft Carriers Gerald Ford & John F. Kennedy where the hulls are assembled with the modular concept. It is very impressive to watch and even more impressive that they can get all these modules lined up perfectly. I was a welder for several years, 25+ years ago, albeit on semi trailers and not ships, and I am all too familiar with the skip welding technique. This method is a prime example of less is more, where as at certain areas a solid line weld can actually cause more stress and breakage on the steel where the skip method allows for some flex removing the stress and minimizing breakage. I am not much on up on the engineering of ship hulls, but I would guess that even with the stiffening bulkheads there is always some flex. But I could be wrong.

-Brian

- Keith Black, mtaylor, Cathead and 1 other

-

4

4

-

21 hours ago, wefalck said:

- styrene sheet with seams engraved into which one lays fly-tying thread

I’m going to have to experiment with this method as well. Thank you.

19 hours ago, Roger Pellett said:With this type of modular construction heavy manual weld seams with heavy reinforcement on the outside of the hull were minimized.

Roger, so do I understand this correctly, through this process there were no welded seams on the outside of the hull. The plates were butted up against each other and welded from the inside? Just curious, and want to get this right and if this was the case, what prevents water from entering the seams? I can see the benefit of the welds being on the inside of the hull, in that it would make it more streamline with no drag on the welds.

-Brian

- Keith Black, mtaylor, Cathead and 1 other

-

4

4

-

On 2/24/2023 at 2:07 PM, KeithAug said:

I am never very sure about MDF but i suppose for display models it is both cost effective and stable.

Keith, MDF is a fairly stable wood for forming the frame. It is a tad bit heavier than plywood, but makes a nice solid, sturdy base. As Eberhard stated above, as long as it’s is kept dry there should be no issues with it.

4 hours ago, wefalck said:I gather the boat was welded? Perhaps covering the wooden planking with thin Bristol-board would save a lot of time in filling and sanding and the individual plates could be simulated that way. Otherwise, I used copper foil (as in copper-sheathing wooden ships) to simulate on-off riveted plates. Could be used for welded hulls as well.

Eberhard, I have a couple of experiments I am working on to simulate the welded hull. One of them uses aluminum foil tape over fine tread to show the weld lines. I am currently working on covering the bulkheads with basswood panels. Once the basswood is in place I’ll see which experiment works best.

I hope to have some pictures posted soon of the progress. Work has been crazy busy, so my time at the bench has been limited.

-Brian

- Cathead, Canute, Keith Black and 1 other

-

4

4

-

Eric, apologies for missing your last update (#96), not sure how I didn’t see the post, but thank you for the mention. The ridge beam looks great!

To help ease some the pain on the vent funnels, these were used to direct fresh air down to the gun deck for cooling and clearing smoke from the boilers. They could be rotated 360 degrees and could also be raised and lowered, or completely removed from their positions if needed. So in reality, there really is no right or wrong way to face them. As for the davits, I think you got this. I say go for it.

-Brian

- mtaylor, Canute and Keith Black

-

3

3

-

10 hours ago, Zetec said:

Hi Brain thanks for that info. I have found some resin ones in this country so not the cost of the postage. I cant find a picture of the paddel wheel that I can size the spokes and the rims what did you use and what size.

Happy to help out John, glad to see that you were able to find some local and avoid that international shipping. It definitely can get pricey.

If you are looking for my construction of the paddlewheel, take a look at post #129 on page 5 of this build. That is where it starts and runs for a few posts. As for the dimension of the paddlewheel, in 1:48 scale the outer (larger) rings have an outside diameter of 139mm while the inside (smaller) rings have an outside diameter of 91mm. If you also take a look at post #490 on page 17 of this build,, I have some close up pictures of the paddlewheel frame on the Cairo display that I took last year, you can use for a reference of it's construction.

-Brian

- Canute, Keith Black, mtaylor and 2 others

-

5

5

-

1 hour ago, KeithAug said:

I think I am well on the way to amassing enough information to attempt Cangarda. 1:48 or 1:36 scale would be sensible but I am wondering about the non sensible scale of 1:24.

I will definitely following along on that beauty! Looks like fun, can't wait.

1:24 *cough *cough....😁

-Brian

- KeithAug, Keith Black, druxey and 1 other

-

4

4

-

Absolutely amazing details Keith! What a fantastic journey it has been following along. Can’t wait to see what the future holds for your next project.

-Brian

- FriedClams, Retired guy, KeithAug and 2 others

-

5

5

-

-

8 hours ago, Zetec said:

Hi Brain glad to see you are back building again I like the look of the one you have just started. Could I please ask a couple of questions on items that you used on this model I am thinking ahead so I got them when I need them. What are the sizes of the rigging blocks or strapped blocks you used on the gun carriges and also the size of the ropes. I want to get the right size first time as the postage is more than the items. I got the bulbs and the lights you used the lights are very good.

Hi John, glad to finally be back at it and that you like the lights and led's. I used 4mm double sheaved blocks for the gun carriages, and for the ropes I used .025 (.63mm) rope for the training tackle and .045 (1.14mm) rope for the breaching ropes. I ordered these from Chuck at syrenshipmodelcompany.com and I do believe he ships to the UK, but you may be able to find somewhere more local, like Cornwall Model Boats to avoid international shipping fees. Hope this helps you out.

-Brian

-

Hello again everyone.

Made some progress this past weekend, not a lot, but some.

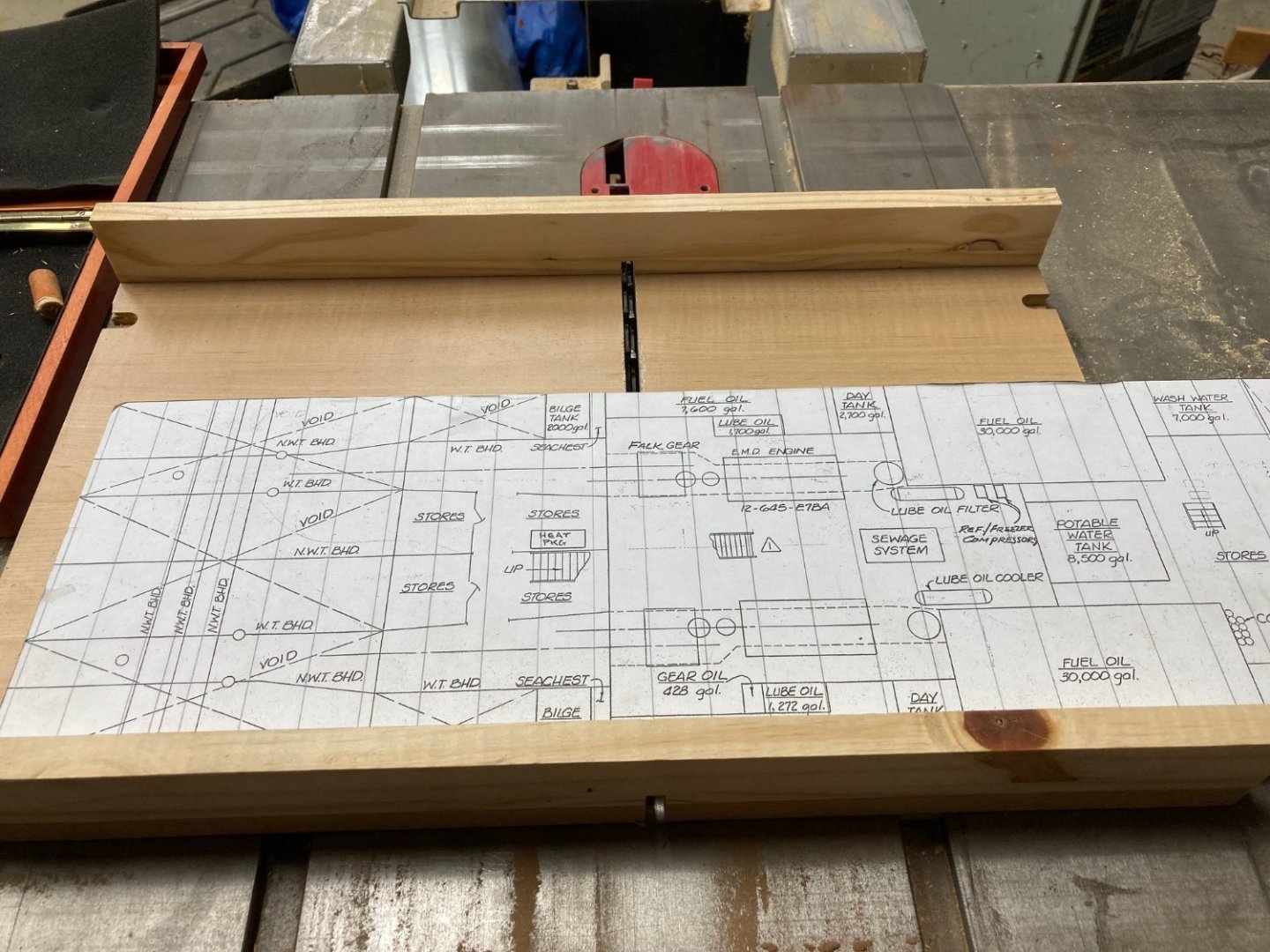

I managed to get the main deck cut out and sized to the plans.

I built up a table saw slide to cut the rabbets for the bulkheads.

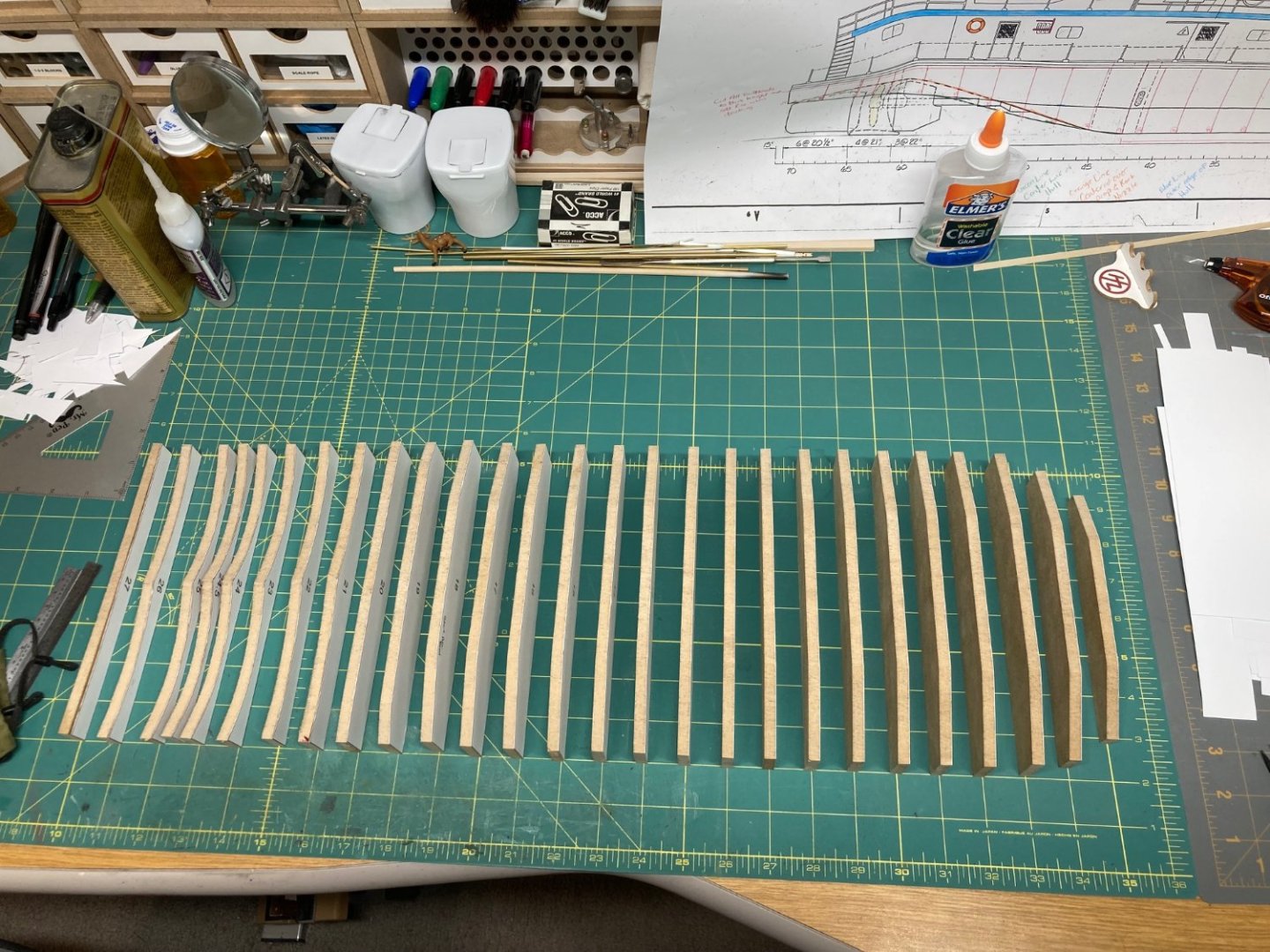

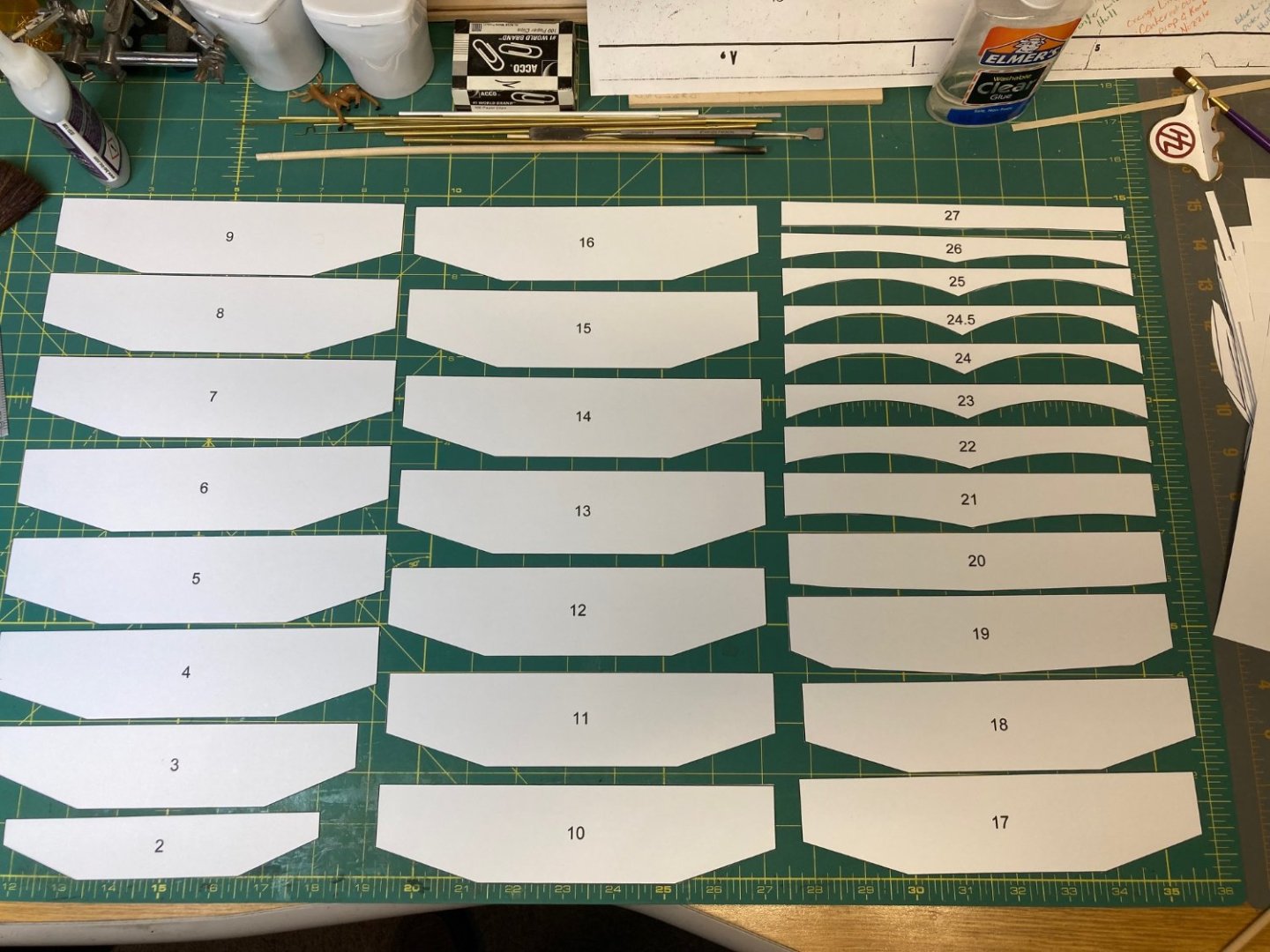

Next, I glued all the bulkhead templates to the 1/4" MDF and got them all cut out.

Here are all the bulkheads lined up on the deck template.

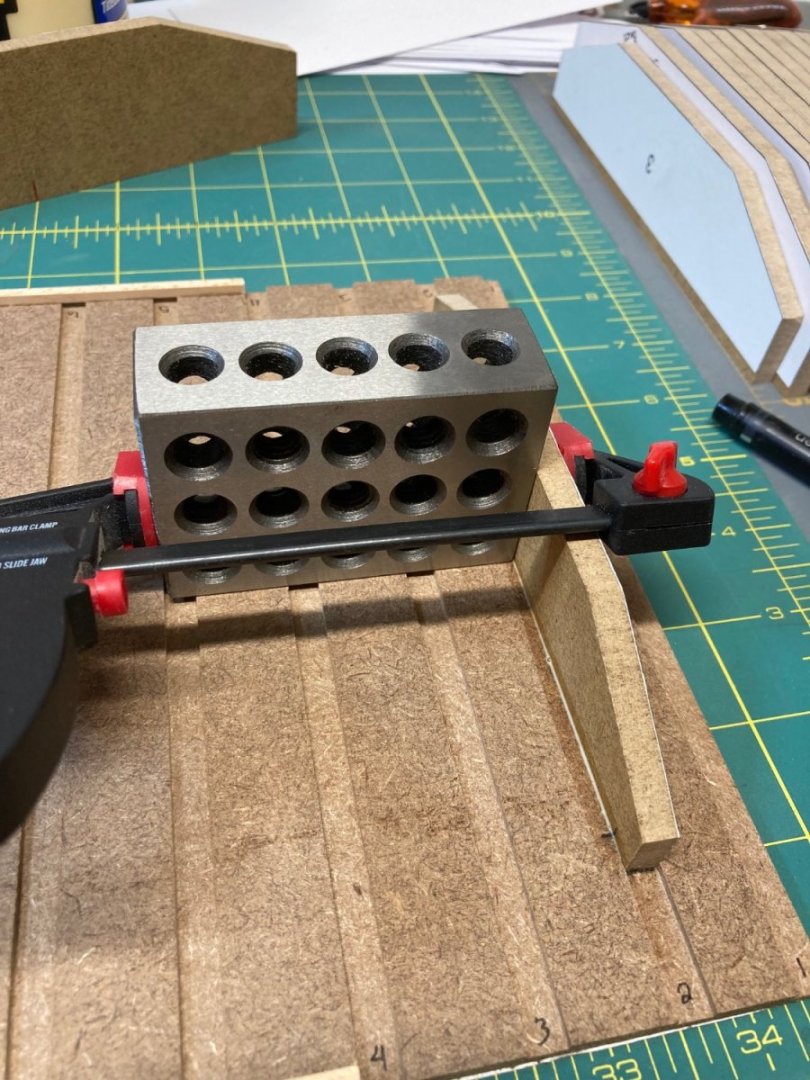

First bulkhead getting glued in place.

More bulkheads going in. Not sure why, but I couldn't get this particular picture to insert right side up.

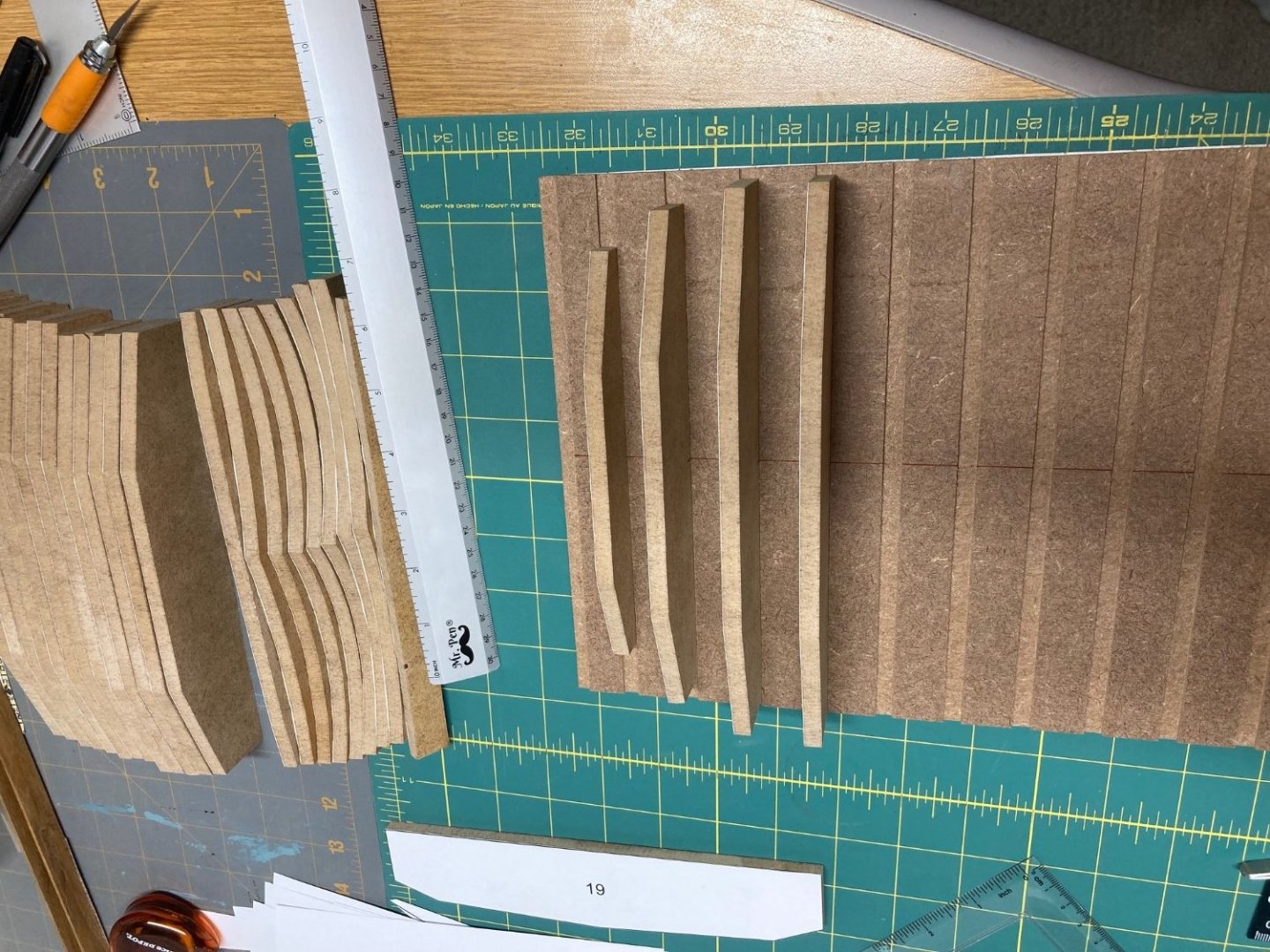

And more bulkheads getting glued down. Slow tedious process.

And all of the bulkheads in place.

That is as far as I have been able to get this week. Hopefully more progress next time. I'm going to work finish up with the #1 bulkhead then on to getting the bulkheads shaped and faired, then start working on the hull plate templates.

Thank you all for the like and stopping by.

-Brian

-

Beautiful micro details Eberhard! Glad to see you back at it.

-Brian

- mtaylor, FriedClams and Keith Black

-

3

3

-

On 2/9/2023 at 12:37 PM, Roger Pellett said:

Put the company in the barn🤣!

Not a bad idea. We’ve had some company before that belonged in a barn. 😁

On 2/9/2023 at 12:37 PM, Roger Pellett said:She was therefore something of a showboat.

That is somewhat the role of the current MV Mississippi V. Going off the stats, she is the biggest towboat on the Mississippi and is use by the Corps of Engineers as their flagship. I wouldn’t mind touring that one as well.

On 2/9/2023 at 7:07 PM, KeithAug said:You give them the best years of your life and they just toss you out with the trash. Chin up mate, maybe someone better will turn up.

Too funny Keith. We’ve been together for 34 years, I’ve got a feeling if she hasn’t got rid of me by now I’m in good shape. Either she a glutton for punishment or she’s just keeping me to protect other women from having to deal with me. 😁

-Brian

-

-

On 2/7/2023 at 3:06 PM, Cathead said:

Otherwise, great to see the build underway. Envious of your workspace setup, I'm still operating out of a small portable tray as we haven't been able to move forward on renovating the spare room that's intended for my workshop long-term.

Thank you Eric. My workspace isn't a whole lot to brag about. I just have a yard sale geek desk in the corner of one of our spare bedrooms with the Hobby Zone storage units. I share the room with my other desk I use for my home office. My plan is still to build out one corner of our barn to incorporate my office, shipyard and reloading room, some day (hopefully soon). I have been taking up the spare bedroom for the past few years and I am surprised the Admiral has not told me to pack it up and remove myself from the premises. I have a feeling it will be coming soon. Thankfully we have not had any company that would require the use of the room during this time.

-Brian

-

Something just for fun. I ran across this website while researching the Caroline N. It shows and tracks marine vessels by their ship ID. In this case, the Caroline N is currently on the Ohio River in Louisville, KY.

https://www.marinetraffic.com/en/ais/home/shipid:3566996/zoom:10

-Brian

-

1 hour ago, Keith Black said:

your workspace is way too neat

Give me a couple of days, I'll take care of that. 😁

1 hour ago, Keith Black said:I see Marquette Transportation has openings

One of the reasons I joined the Air Force was the main areas of industry back home were either work at the refineries or work the port docks. Neither sounded very appealing to me. Looking back though, it might have been interesting to work on these boats. Just the scenery alone would have been worth the hard work.

-Brian

- Cathead, Canute, Keith Black and 1 other

-

4

4

-

-

20 minutes ago, Keith Black said:

Tow size info and towboats in general.

Excellent info Keith, thank you. While I was reading the article I noticed that they discussed the M/V Mississippi and all of the previous boats to carry the name. When the Admiral and I took our trip to Vicksburg last year, we visited the Lower Mississippi River Museum. They have on display the fourth M/V Mississippi (the first diesel powered vessel to carry the name) and of course, we took a tour of it. Beautiful museum boat. These guys had very nice accommodations.

-Brian

- Canute, Keith Black, wefalck and 7 others

-

10

10

-

Alrighty, I figure it's time to get this thing started.

So I managed to get the bench cleaned off and ready to go.

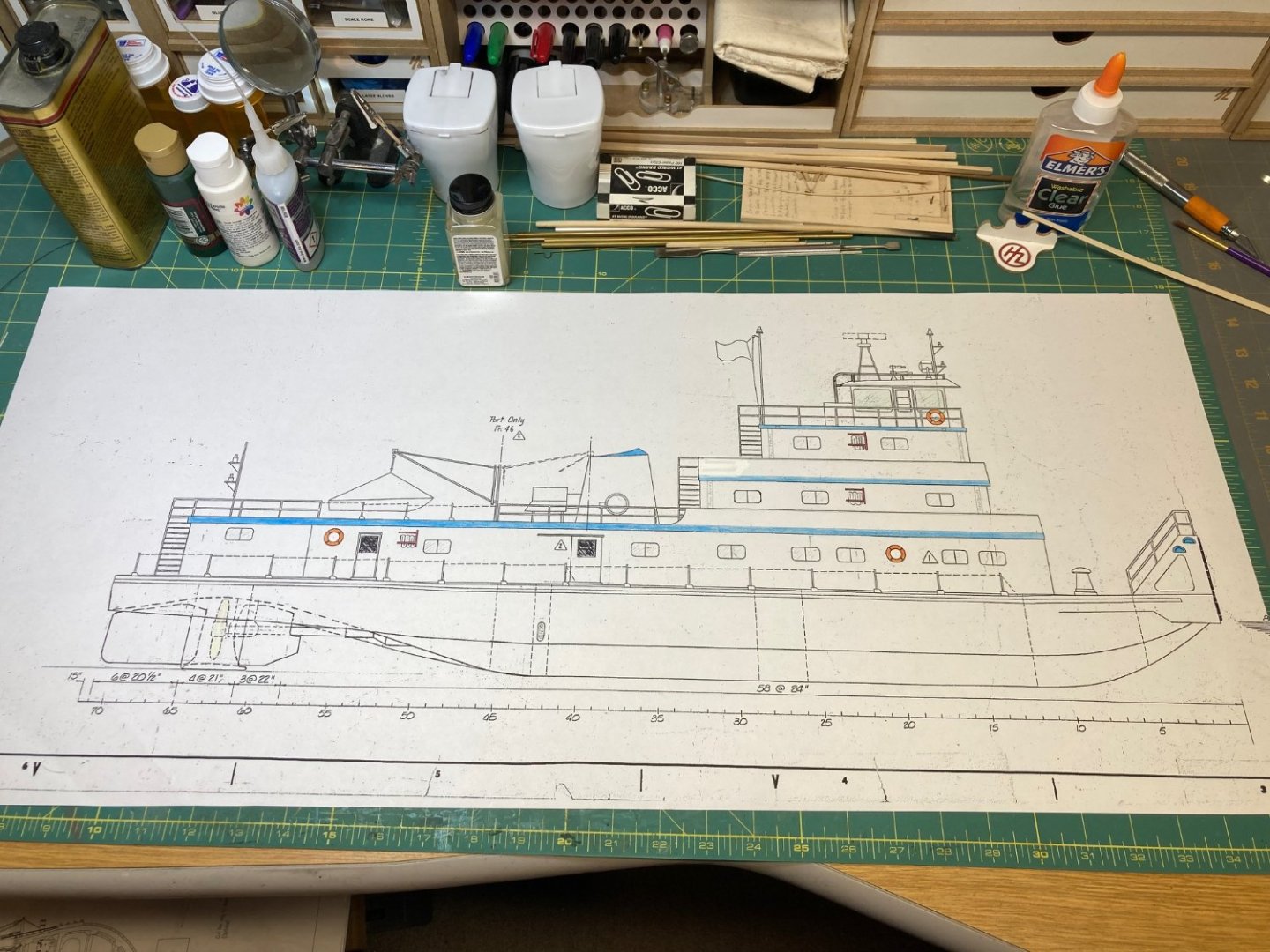

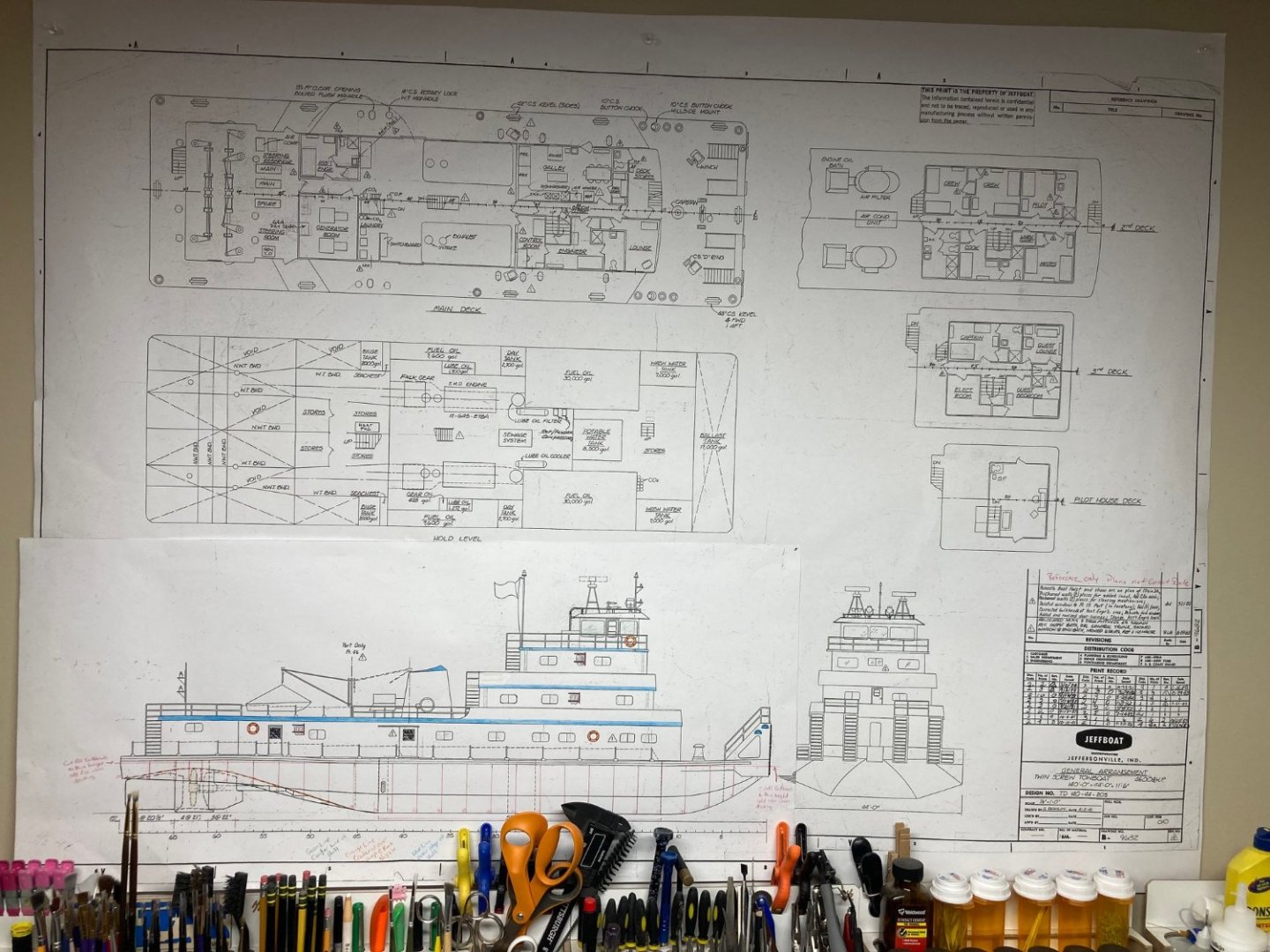

The plans have been scaled and marked up. I went through and got my measurements, divided up the hull bulkheads and made a few adjustments to the plans to reflect the differences between the actual boat and the drawings. Not too many adjustments were needed, just a few structure details that didn't match up.

The plans are on the wall. When I was at the printshop the first attempt at printing didn't come out to the right scale (they came out a bit too small). The clerk was nice enough to give me those drawings free of charge, so I will be using those as my wall reference and I can use the correct scale ones for my templates and other measurements. This worked out better since the smaller scaled ones fit better on the wall.

I got as far as printing out most of the bulkhead templates. These will be glued to some 1/4" MDF then cut out and shaped. No hold details will be done on this build, so the hull will be the basic POB. Still trying to decide on if I will plank the hull with basswood strips, then smooth out the lines with body filler, or just go ahead and cut out the hull shapes from 1/16" basswood boards and shape it from there. I would like to try and simulate some of the steel plates on the hull If possible, to give it a little more detail. I've got some time to figure it out.

Not too much more to report on this update. I have the main deck printout cut and ready to build, just need to make a run to the lumber yard for supplies. I thought I had enough MDF to get a good start, but I seem to have come up a bit short. In the mean time I am going to get the bulkhead templated glued down and cut out and hopefully next time I will have more progress.

Thanks for stopping by.

-Brian

- FlyingFish, kurtvd19, Keith Black and 10 others

-

13

13

-

16 hours ago, kurtvd19 said:

A lot more barges can be pushed with the current than against it. Much also depends on the speed of the current and the angles of the turns.

Kurt, that makes perfect sense. There are many twists and turns along the rivers and some of them fairly sharp. I can see where a long line of barges could be difficult to navigate as well as current speed being factored into the equation. I can't speak for other rivers, but I know for a fact that the Mississippi runs a whole lot swifter when the water levels are higher than when its low, and I'm sure it is a struggle to get those barges upriver fighting that swift current, or controlling the turns going downriver.

16 hours ago, Keith Black said:From earlier reading the Coast Guard is the governing body that places tow limits. I'm not sure if that is dependent on the stretch of river and river levels. At some point X number of barges in a tow is going to be potentially unmanageable and potentially dangerous.

To my untrained flatlander eye that last picture you posted in the above of the 48 barge tow looks like port side disaster is at hand.

Keith I totally agree. Too many barges can be a disaster waiting to happen, that may be what is going to transpire in that photo. From the looks of it the pilot does have the starboard engines running full speed or all rudders are hard to starboard. He definitely looks like he is trying to turn it around.😁

1 hour ago, Cathead said:In other words, there was a slow evolution from the powered river vessel being the primary means of carrying cargo (classical steamboat) to the powered vessel towing some of the cargo in independent loads, to the powered vessel being adapted to push those separate loads (the beginning of the modern towboat), to the powered vessel becoming nothing BUT the power source (more like a railroad locomotive) for independent barges. But the original terminology never changed. Just like how we still "dial" phones.

Eric, in my Cairo research I ran across many instances where the ironclads would have their coal barges lashed to the sides of the ship. This could be one of the transition periods where riverboat pilots were getting away from "towing" then and migrating towards "pushing" them. Although pushing the coal barges with the ironclads would not be the most safest thing to do, especially with an 8" and two 42lb cannons pointed in that direction. 😁 Also, Great point with the phone example. I hadn't thought about the transitioning from towing to pushing and just having the name remaining out of habit.

-Brian

- Keith Black, Canute, mtaylor and 1 other

-

4

4

SMS WESPE 1876 by wefalck – 1/160 scale - Armored Gunboat of the Imperial German Navy - as first commissioned

in - Build logs for subjects built 1851 - 1900

Posted

The miniature details of this build just keep getting better and better Eberhard.

-Brian