-

Posts

989 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by mbp521

-

-

9 hours ago, bruce d said:Any complaints, I will claim to have been hacked. And I was out of town.

I’m sure glad the Admiral doesn’t have access to this forum. She’d swear that I posted this under a different name.

…as I type this nervously looking over my shoulder.

-Brian

- thibaultron, Canute, bruce d and 2 others

-

5

5

-

All of those battens were indeed a tedious process, but it looks like you managed your way through it very nicely while keeping your sanity. 😁

Sure look like someone was having an off day when they cut the hurricane deck piece out. It was probably a Friday and they were ready to go take in the South Florida night life, or maybe it was Monday after too much of the South Florida night life. 🙃 Either way ME is usually pretty good about getting replacement parts out quick.

Looking good!

-Brian

-

Glad to see that I was able to spark an interest in this magnificent boat. I will be following along intently! Best of luck.

-Brian

- Keith Black, mtaylor and Canute

-

3

3

-

Alrighty folks, the brace is finally off and the new build has begun. Come on over and take a look.

-Brian

- mtaylor, Keith Black, Paul Le Wol and 2 others

-

4

4

-

1

1

-

Greetings everyone, I am finally ready to get going on my next build. This time I am going a bit more modern and taking a step into the 20th Century.

A friend of mine asked if I minded building him a model of the Caroline N, a Mississippi River Towboat that his father-in-law named after his daughter. This sounded like nice challenge, and an excellent chance to hone my scratch building skills, not to mention I have never built any boat newer than the late 19th Century, so I accepted.

The Caroline N was built by the Jeffboat Company out of Jefferson, IN. She is 134' long with a weight of 946gt. She was originally laid down in 1973 as the Louis H. Meece for the American Commercial Barge Line. She was later purchased by the Triple M Transportation Company and renamed the Caroline N in 2004. She was sold to SCF Marine in 2012 and in 2018 she was leased by Marquette Transportation and renamed Titletown USA. As of the start of this build, she is still being operated by Marquette Transportation. She is powered by two GM Diesel engines, a 4.192:1 reduction gear box, turning two fixed pitch screws in kort nozzles and rated at 6,140hp.

I will be building this model at 1:64 scale which will put the model at just over 25" long. The hull will be POB and most of the construction will be basswood & MDF. I'm sure there will be other materials thrown in for good measure as I go along. Her paint scheme will be the blue and white from her Triple M Transportation days, as pictured below. I am currently working on getting the plans scaled to size and will be using reference photos from the actual Caroline N, as well as her sister boats the Charles Lehman (now Limestone Lady) and Richard C. Young (now Miss. Kris) for additional details.

The plans that I will be using are the original Jeffboat General Arrangement plans of her configuration in 1981 for sizing. These match up best with the photos as far as placement of critical features such as windows, doors, stacks and other details.

With all that being said, it's about time to get this build started. I'll hopefully be back shortly with the scaled plans and ready to start making some sawdust.

So pull up a chair and stay tuned.

-Brian

- Cathead, Keith Black, FriedClams and 9 others

-

12

12

-

2 hours ago, KeithAug said:

Brian, Your 2 weeks shore leave is over. How are you doing?

I am still around, just a couple of more days and I should get this contraption off my arm and start physical therapy (torture). With the brace gone I should be able to at least get things ramped up on my next build, At the very least I can get the build log started. Stay tuned. 😁

-Brian

-

1 hour ago, Cathead said:

Somehow I managed to throw out the rudders. At least that's the only explanation I have since they had vanished when I'd finished straightening up.

I’m not really surprised that these would have gotten lost, at the small scale I would’ve had a hard time keeping up with those as well. Nice job on the scratch built ones though. Yours are probably better than the kit provided ones anyway.

1 hour ago, Cathead said:deck protectors (or whatever they're called).

These were the races that the tiller rollers rolled along. I can just imagine the fits you would have if the rollers were included with this kit. They would probably be the size of a pin point. 😁

1 hour ago, Cathead said:I know that others have argued for the lower hull being a dull red, and that's the sort of upgrade

One of the issues that I had in research was trying to find if the hull was red or black. There is no information available that I was able to dig up that showed either way. When I was discussing this with Ray Hamel at Vicksburg NMP he said that tests had been run on pieces of the wood fabric but the results of paint color were inconclusive. So I just went with personal preference to break up the coloring a bit. To be honest though, the all black scheme looks pretty good too.

-Brian

-

Just squeaked that one in there! Beautiful mount, I love the idea of using reclaimed drawer pulls.

One thing of concern that comes to mind, would the sulphur in the rubber o-rings cause a reaction with the poly coating of the hull? Just curious. I’d hate for something to damage the beautiful work you’ve done.

-Brian

- mtaylor, Retired guy, Keith Black and 3 others

-

6

6

-

Eric, I admire your tenacity with sticking with this build. I for one would have shelved (or trashed) it a long time ago given your frustrations with it. I have a couple of builds that have been shelved for years, due to frustrations with the instructions and the kit itself. I, like you, didn’t just pitch them due to the fact that I have a few hundred dollars tied up in the kits and felt it was a waste of my hard earned money to just toss them. I figure one day that I will dust them off, and give them another go, but for now I have plenty of other projects in the works to keep me busy for a while.

Stay strong my friend, you will persevere!

-Brian

- mtaylor, Cathead, Ryland Craze and 2 others

-

5

5

-

-

Greg you are cranking out these boats faster than I can get through your build logs. Almost hard to keep up.

Beautiful work on fleet! The grunginess and weathering is all too realistic looking. Just amazing!

-Brian

- Old Collingwood, king derelict, RGL and 2 others

-

5

5

-

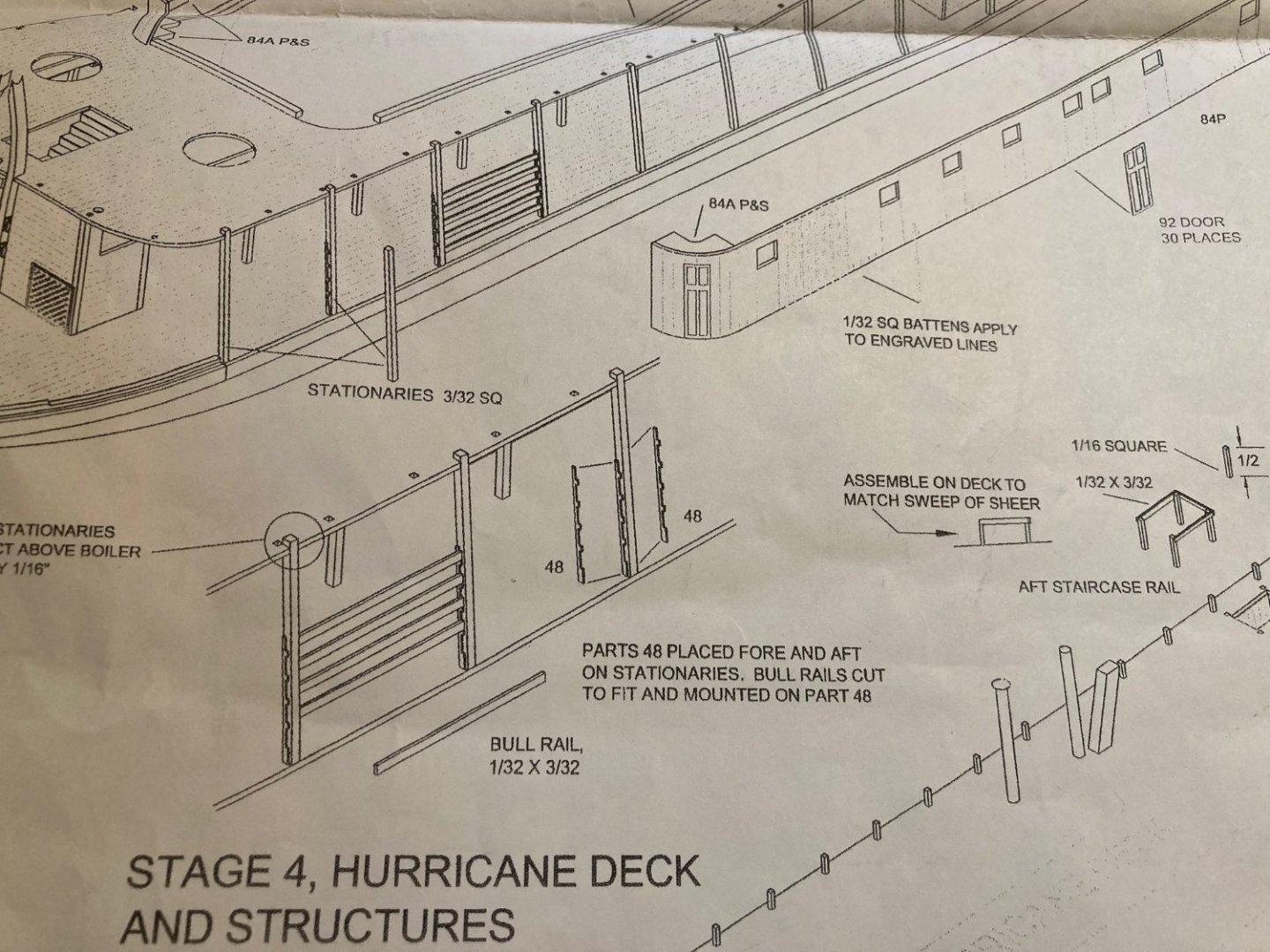

Speaking of following instructions, this conversation reminded me of another area of where the instructions are wrong and I didn't realize it until it was too late. When you get to Stage 4, the instructions show to mount the bull rail braces, part 48, to the stationaries with the opening outboard and placing the bull rails from the outboard side..

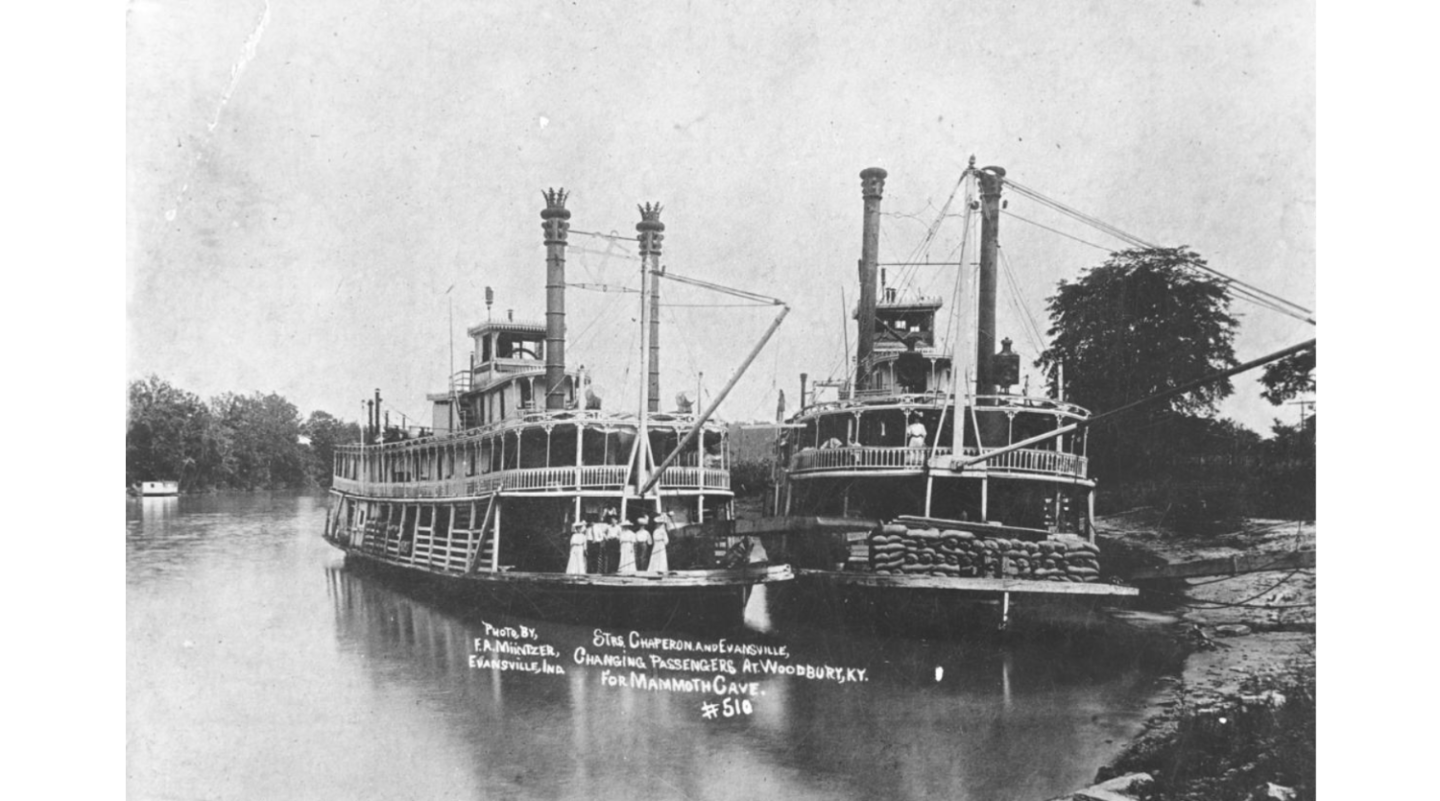

To be historically accurate, they were actually mounted the other way around to where the bull rails could be installed from the inboard side. I found this out later on when I was studying some of the contemporary photos of the boat. In the below photo, the Chaperon is on the left. If you zoom in to the starboard side where the bull rails are mounted you can just make out the framework of the braces that show them mounted this way (I thought I had a better picture of this, but I can't seem to find it right now). It would also make sense that they be installed from the inboard side, due to the fact that if a person or livestock were to lean against, or run into them they could knock the rails out of place and fall overboard.

-Brian

-

Beautiful work Tom, and congratulations! So sad to see the build come to an end but can't wait to see what's next. Thank you for putting this log together, I have it bookmarked for when I finally get around to building my kit.

-Brian

-

17 minutes ago, wefalck said:

I prefer the creative aspect of 'making' things over 'fixing' things ...

It's that fine line that we dance on with the Admiral between work and play.

A couple of years ago I bought the Admiral a Cricut for Christmas. She had said she wanted one and I thought, why not, it would keep her busy enough that she would leave me alone with my shipbuilding. Well so far, I think I have used the Cricut just as much as she has. And the honey-do list continues to grow.

-Brian

- KeithAug, mtaylor, FlyingFish and 4 others

-

7

7

-

2 hours ago, Cathead said:

That's cheating, you didn't even have to shape the pieces yourself!

Yeah, I guess it is cheating a bit. But the rigging sure was easy. 😁

-Brian

- Keith Black, GrandpaPhil, BANYAN and 5 others

-

2

2

-

6

6

-

On 1/15/2023 at 5:06 PM, John Gummersall said:

Instructions call to mount the bull rails on the first two support posts in the boiler room. Problem is, even though the boiler support structure is inside the support structure, the smoke stack protrudes outside the structure. So bull rails need to be attached to the 2nd/3rd supports posts.

John, you absolutely got it right. I ran into the same issue with my build and placed them on the 2nd & 3rd posts for that same reason.

Also good thinking on reinforcing the boiler deck, a decision you will not regret. I went as far as using scrap pieces inside of the walls as well to keep them even at the tops and bottoms since the walls were so long and flexible. It added a lot of stability to the structure.

She is really coming along nicely.

-Brian

-

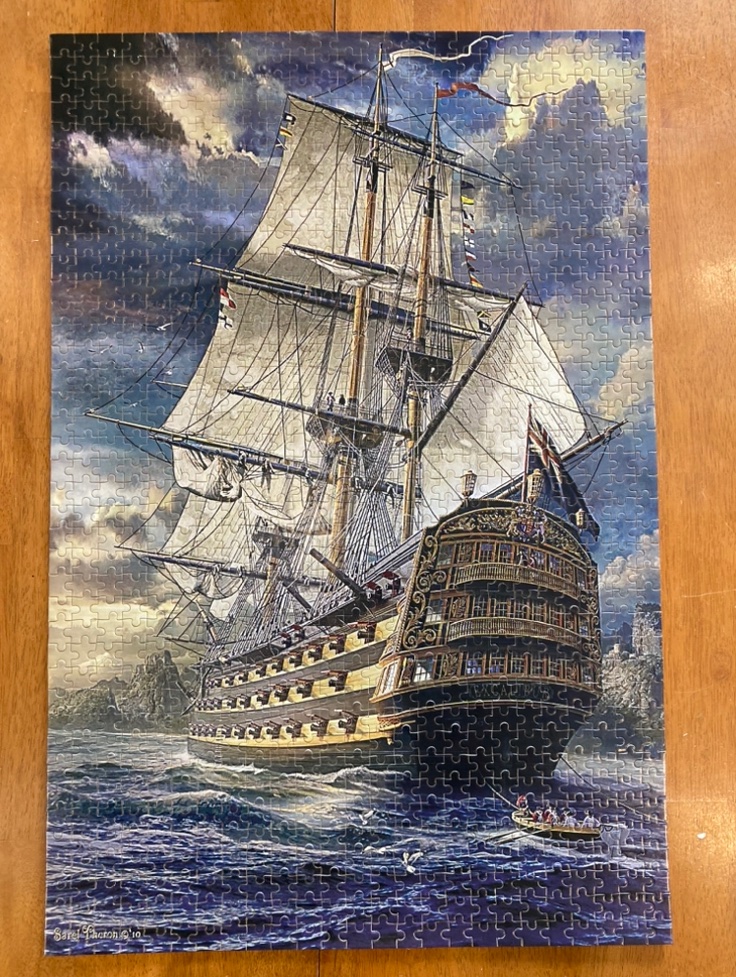

Thank you all for the well wishes. Even though I am not able to work on an actual wooden model ship build, I am able to work on wooden puzzle of a ship. 😁

While entertaining, still nothing like making some sawdust. Hopefully only a couple of more weeks in this contraption and I can get back to it.

-Brian

- Keith Black, GrandpaPhil, mtaylor and 3 others

-

6

6

-

So glad to see you back at the bench again Keith! I can’t wait to delve into the upcoming updates.

Kind of the opposite with the sunny days, I tend to find myself wanting to work on a build more on the cloudy days and wanting to be outside on the sunny ones. Of course wintertime sunny days can be a bit deceiving sometimes here in Texas, I can only imagine a sunny day in Michigan in the winter. I’m sure that would change my thinking in a hurry.

-Brian

- FriedClams, Keith Black, Dave_E and 5 others

-

7

7

-

1

1

-

I have a whole box of unused drawer pulls sitting in my barn collecting dust. Now I have a prospective use for them. What a unique idea Keith!

-Brian

- FriedClams, mtaylor, Keith Black and 2 others

-

5

5

-

Man that structure is tiny! I don’t think there is any way that I could do a full build at that scale. Even the tiny bits on my boat gave me fits. Definitely like the added details.

-Brian

- mtaylor, Keith Black, Canute and 2 others

-

5

5

-

Looking good Tom. I’ve never been a fan of the Britannia parts MS uses in their kits, and I often replace them with scratch built pieces when I can. Needless to say though, you did a great job on straightening and cleaning up the kit pieces and the bird cage looks wonderful. It will be a bittersweet day when “Finished” is added to the title of this build log.

-Brian

-

Playing catchup on the build log entries. There seems to be a lot of information posted lately,

On 12/31/2022 at 11:27 PM, Roger Pellett said:Absent documentary or archeological evidence, I would tend to believe then that these boats did use rope anchor cables instead of chains.

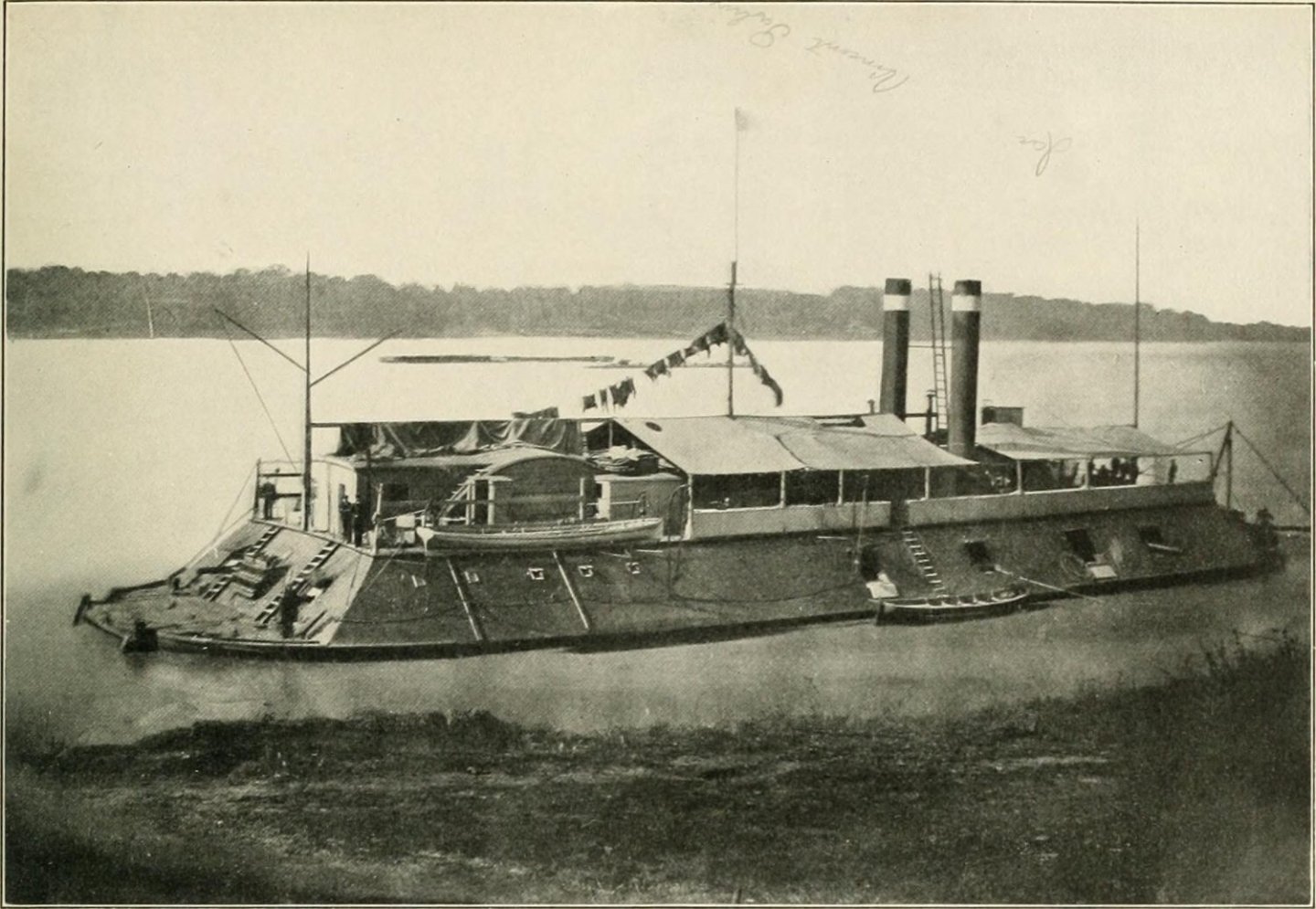

Roger, to answer your question about whether the Cairo use rope or chain to attach the anchors, I would say that it was chain. The below pictures were screenshots that I took from a conference Edwin Bearss gave just before he passed away. In his presentation he had these photographs taken during the recovery efforts up on the screen. I searched in vain to find the actual photos and finally settled on just taking a picture of my computer monitor (hence their graininess). One picture shows the starboard chain going through the hawse pipe and the other shows the chain draped across the foredeck. The port hawse pipe empty so it would somewhat be hard to tell if there was a chain or rope attached to the portside anchor.

There is documentation from journal entries of sailors aboard the Cairo and the other boats in the flotilla, at the time she struck the torpedo that tell when the explosion occurred the port anchor was launched from the deck. If I remember correctly, one of the flukes from this anchor is on display in the Cairo museum. So the possibility of the port chain being broken and with the force of the explosion could have cause it to recede through the hawse pipe and would not have been visible during salvage. Or this hawse pipe could have simply been strictly used for rope to tie the boats off to the shore.

During my build, I struggled with the same question, how did they haul in the anchor with a capstan that was designed for rope. I came up with one possibility that they would use a length of rope attached to a hook or a loop. They would secure the hook through the chain loop and run the rope through the hawse pipe and around the capstan and haul the chain up a little at a time. This by no means would have been an efficient method of doing it, but as with John Howard and the rest of the St. Louis team have stated, documentation is scarce. So with the limited information on this subject, this is the way I incorporated it into my build. As also stated previously, most of the time these boats were tied up to the shores of the rivers, but there were times that they were at anchor. Given that many of the Western Rivers were not known for their great depths at the time, there was the possibility that there would not have been much anchor chain to haul in.

Just my two cents.

-Brian

- Keith Black, wefalck, Montaigne and 6 others

-

9

9

-

1 hour ago, Cathead said:

It's interesting that your photos (and I believe your model) show a gently curved roof on the structure aft of the wheel, while both the BlueJacket plans and the more detailed digital plans you sent me show that to be flat. I went with flat because it's how the kit was designed and it was easier. You probably covered this in your log but I was lazy and didn't go looking for it

This was a real noggin scratcher when researching how to build the roof on the forward and aft structures of the paddlewheel house, and to be honest I can't remember if I covered it or not. Since there is only one known existing photograph of the Cairo it is really hard to tell how this was constructed. I stared at the picture for hours on end trying to figure it out. The HSR plans show the roof to be flat and I think they were drawn that way going off the Cairo photograph. But the more I researched and studied the picture I came to the conclusion that what it looks like in the Cairo picture that makes the roof look flat is the loading booms that were sometimes attached to the aft mast pole were stored on top of the forward roof when not in use. These booms can be seen in the Cincinnati photo in my previous post, and I added them as a deck detail on my build.

Since the Cairo, Mound City and Cincinnati were all built at the Mound City shipyard, I took it upon myself that they would have all been built the same way. The contemporary photos of the Cincinnati and Mound City, show that the rooftops on these two structures do have a curve to them as well as the four other boats built in the Carondelet shipyard, so why would the Cairo be the only one with flat rooftops. This was my reasoning for building my version with the curved roofs. I may have gotten it wrong, but I think it will definitely be hard to disprove my theory that the Cairo had round rooftops as well. 😁 In the back of my mind I would sure like to know for sure, but there is just not enough information out there on it. I'm sure the guys in St. Louis have run into the same issue, but since there is a photograph of they aft end of the St. Louis, they had an easier time with this part.

-Brian

- mtaylor, Canute, Keith Black and 1 other

-

4

4

-

On 1/7/2023 at 8:53 AM, Cathead said:

The most specific question I have, and it's the one least answered by the kit, is whether I'm bending a plywood roof over the curved part of the wheelhouse. No drawing shows this one way or another. I think it would make sense for visual consistency, but I'm curious what Brian and others think.

Eric, your solution to your pilot house conundrum worked out great. This was indeed an unusual shape to get correct and I struggle with it a lot. I ended up making several mock-ups with card stock for the sides trying to get the angles correct, and the forward three panels with their added thickness just made it that much more difficult. At least the kit provided a resin mold to somewhat ease the pain of getting the shape correct.

For your comment above, I know I am a little late in responding, my apologies but my arm was giving me fits this past weekend and my pain medicine tends to make me a little loopy. However, the curved section over the paddlewheel was not "roofed" like the rest of the structures built around it. From the contemporary photos of the City-Class boats I was able to discern that this area was planked with much thicker timbers (much like the deck material) and the rest of the structures were thinner planks and tarpapered. This can be seen in the photos of the Cincinnati and St. Louis.

On 1/7/2023 at 8:53 AM, Cathead said:Second, and related, the little side buildings aren't supposed to have flat roofs, but angled ones

The pitch of these roofs was minimal. Basically just enough to shed the rainwater off. I believe is set my pitch at about 3-4 degrees.

Hope this helps.

-Brian

- Keith Black, GrandpaPhil, Canute and 1 other

-

4

4

Caroline N by mbp521 - Scale 1:64 - Mississippi River Towboat

in - Build logs for subjects built 1901 - Present Day

Posted

Growing up on the Mississippi River as a kid I used to love going to the old ferry landing and watching the ships go by. Baton Rouge was the final stop for some of the really big cargo ships and there were always towboats headed upriver with their cargos. I would sit in amazement that one tiny boat could push so many barges, sometimes with 50 or more strung together.

As I grew up my buddies and I would always see how high we could jump our flat bottom boat on the wake of the barges in the Intracoastal Canal. This was a lock controlled tributary off the Mississippi that we frequently fished, swam and knee boarded in. These boats sure could churn up the waters in their wake.

Bob you should definitely give it a go. I have a keen interest in some of the more obscure builds, and would love to follow along on that voyage.

I’m also right there with you, I have seven kits that I’ve purchased over the years that need to be built. Hopefully some day I’ll get to them. Right now I’m having too much fun with the scratch builds though.

-Brian