-

Posts

1,368 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FriedClams

-

Thanks for the info, Paul. I'm going to give it try soon. Gary

- 201 replies

-

- Oyster Sharpie

- first scratch build

-

(and 1 more)

Tagged with:

-

Nice work on the cabin, Paul. I was wondering how you like working with the Alaskan cedar? Never tried it myself, but something a little harder than basswood would be nice. Gary

- 201 replies

-

- Oyster Sharpie

- first scratch build

-

(and 1 more)

Tagged with:

-

Keith, I must be experiencing the first stages of dementia. Back on page three, post #61, I explained how I repaired two recessed planks by adding on additional wood to the surface and then sanding it back to flush. I did this to a number of areas on the hull, but the planks I was using to demonstrate this process were these two very same planks. They are indeed repaired, and it was that repair that saturated the wood with CA. Good grief - this getting old business is not easy and at times downright troubling. Thank you, Mike, for the kind comment Gary

-

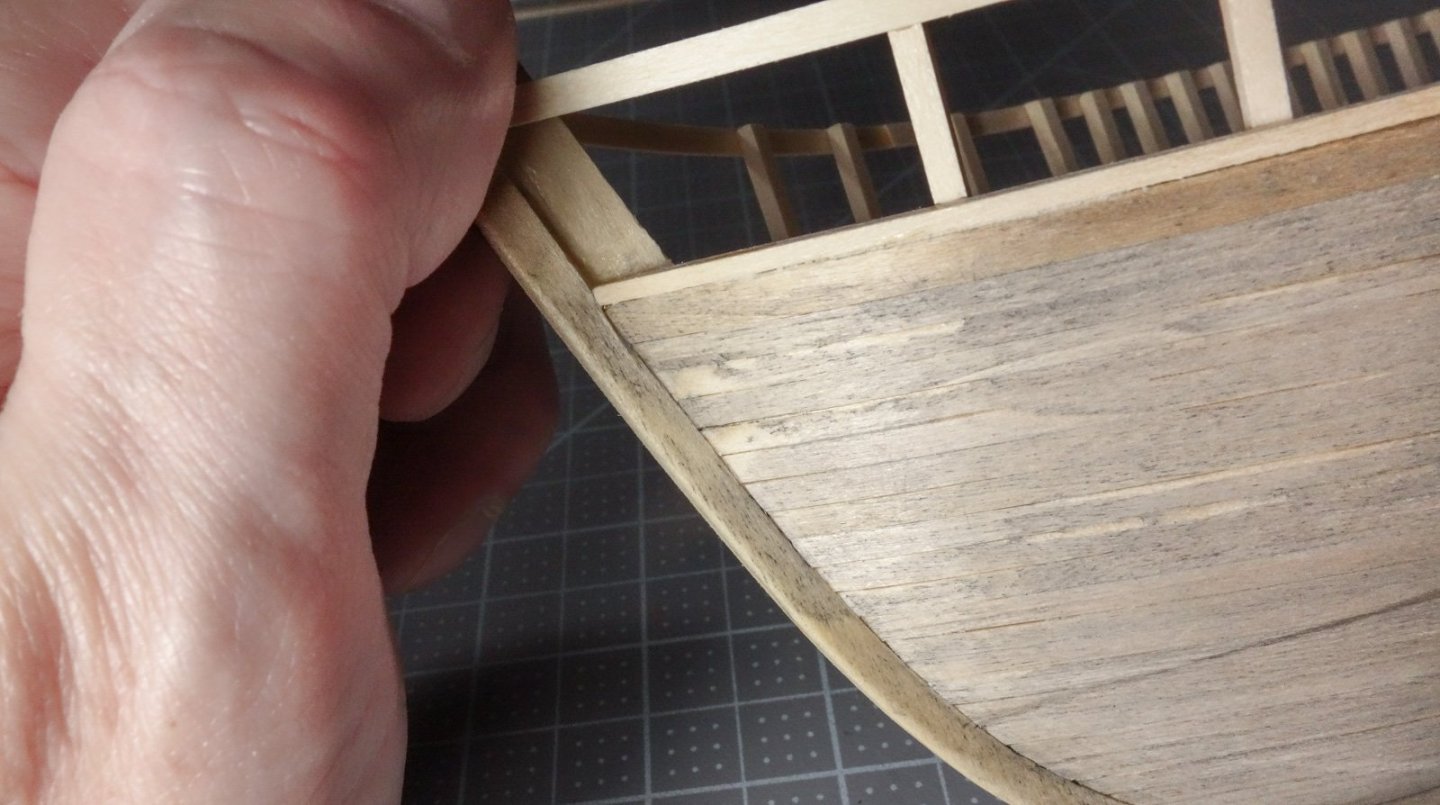

Thank you, Tom, Paul, Keith B, Keith A, Andy and Rick for the nice words! And thanks to all for the visits and the "thumbs up". Thanks! I have a Sony RX 100 that a bought about eleven years ago and use for all the posted photos. It's a fixed lens pocket camera that has features you would only expect to find on a DSLR, like RAW capture. It takes great images even in bad lighting and can focus inches away from the subject. It makes taking a decent photo easy. If you mean the third and fifth hull plank down where it is attached to the stem - no, that's a spot where I got CA smeared onto the surface when I was forcing those planks to submit to my will. After the hull was fully planked, I washed it with india ink/alcohol to give it little age, but the solution couldn't absorb into the wood where CA had penetrated. In fact, all the lighter colored splotched or streaked areas are due to this. In the end, the hull will be painted, weathered and I wouldn't be surprised if there is chipped and flaking paint here and there exposing some of that aged wood underneath. Not sure yet. Thanks for observing that, Keith, because if it had been recessed - now would be the time to fix it. I agree, Andy. A utilitarian design for sure, but I think the designer had an aesthetic eye just the same. Gary

-

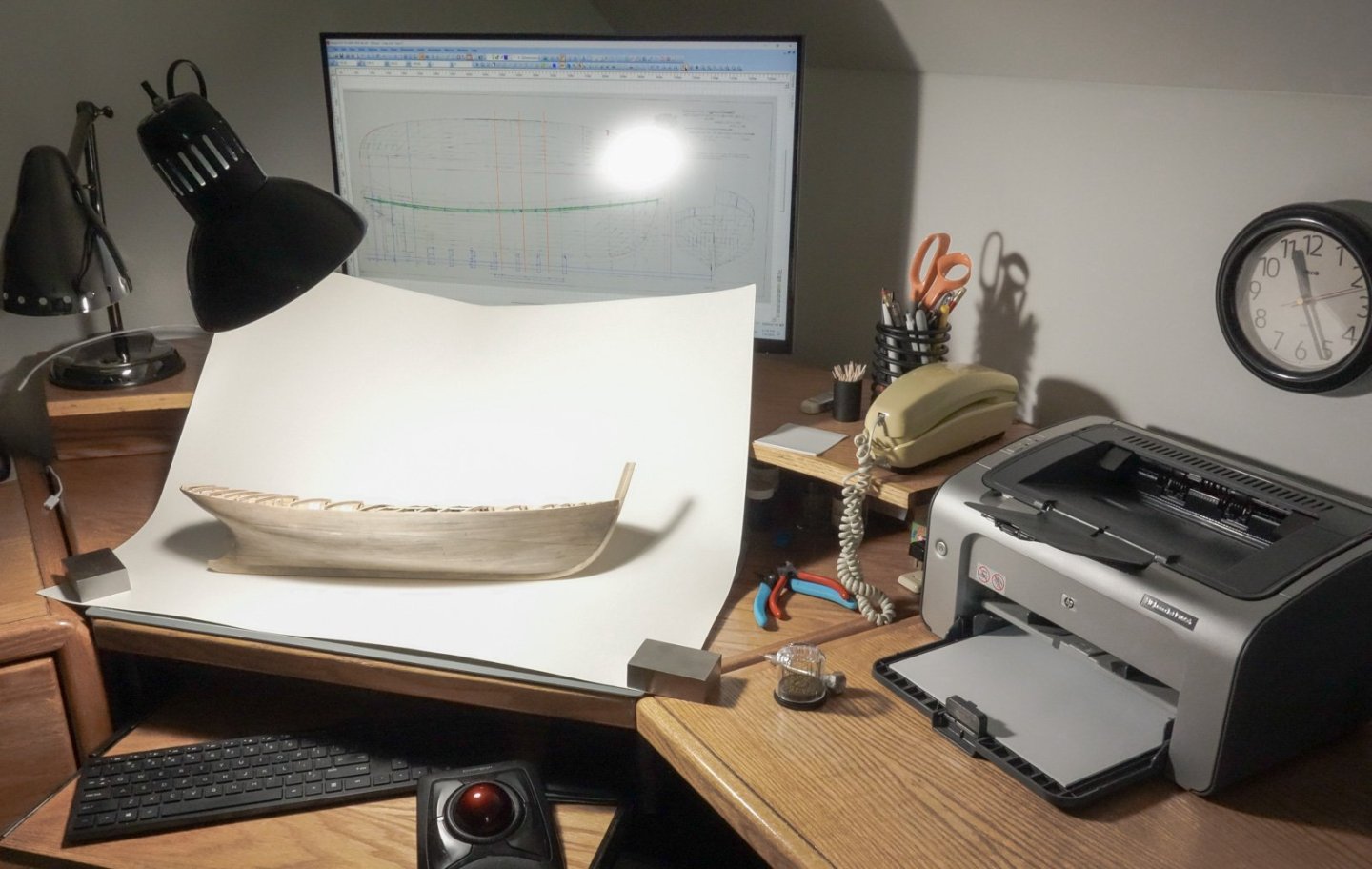

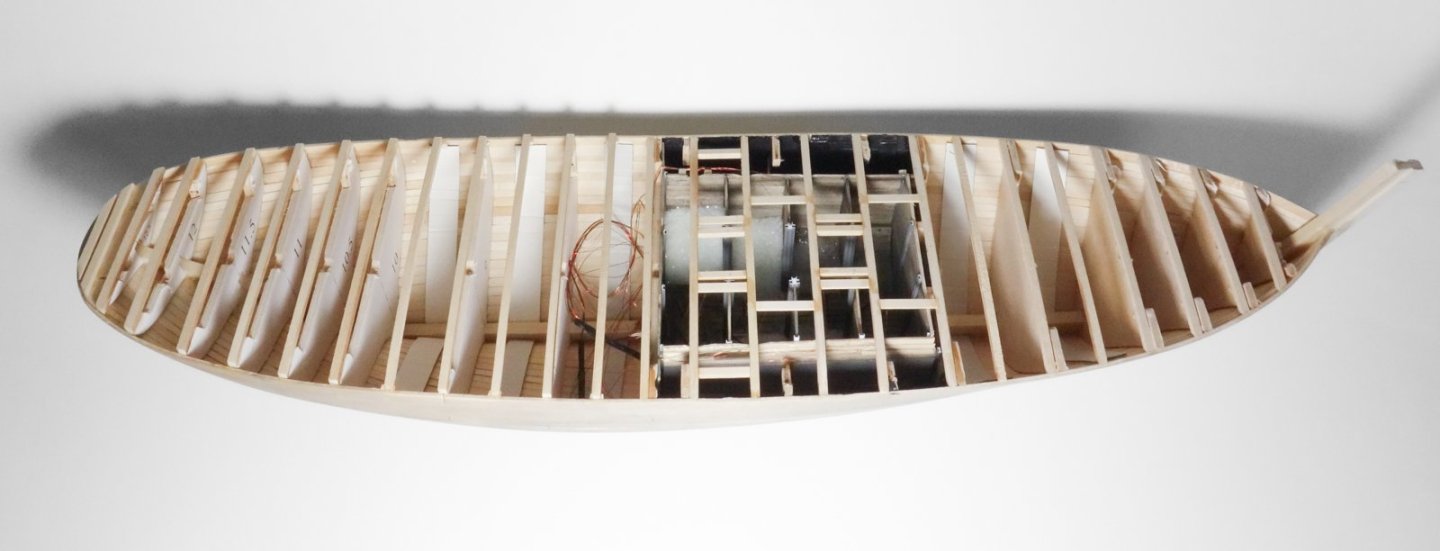

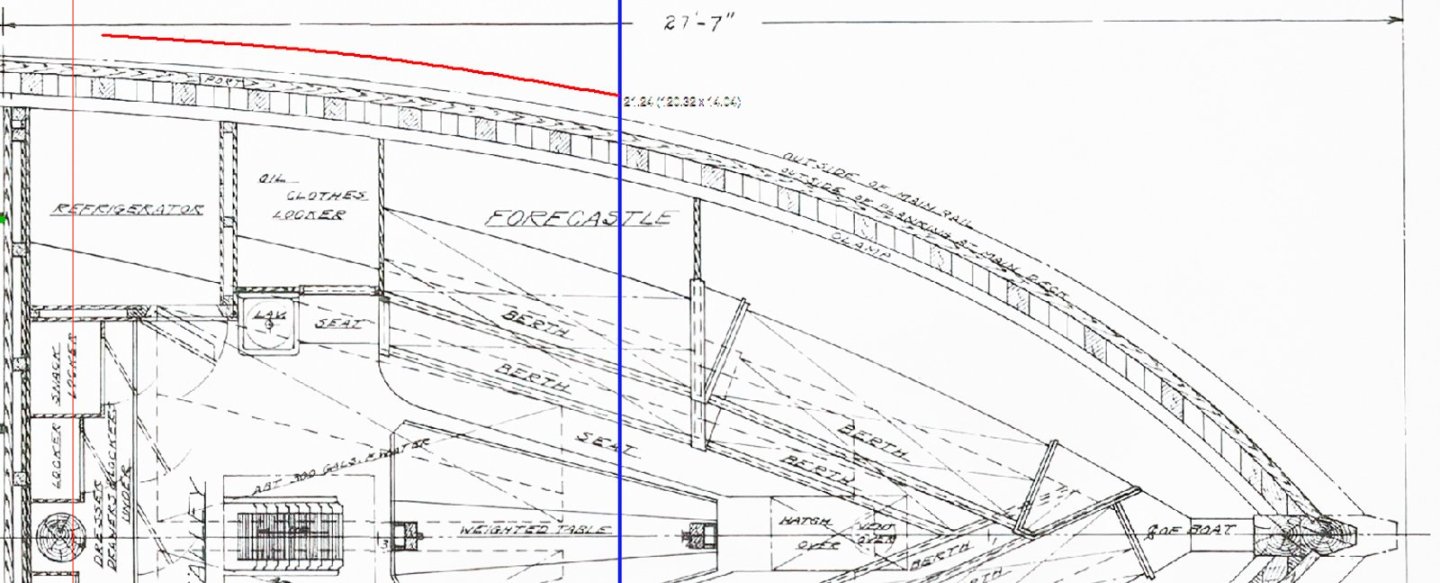

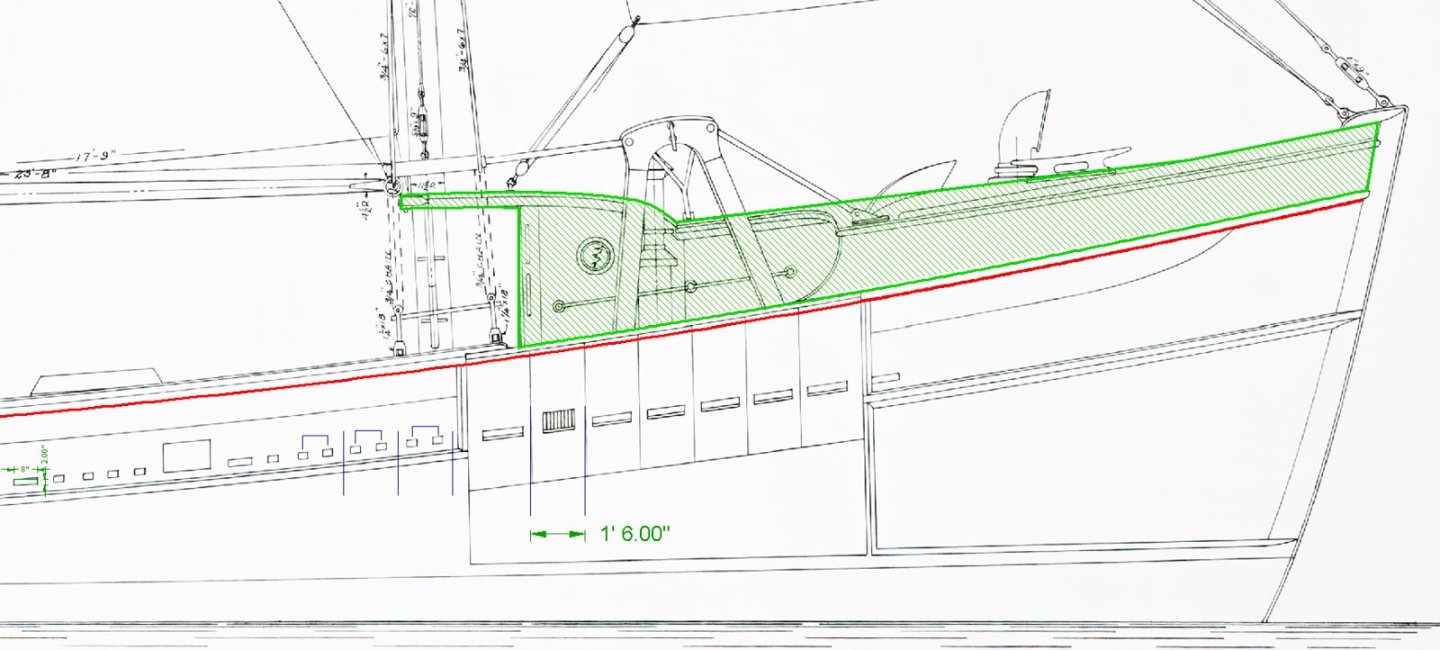

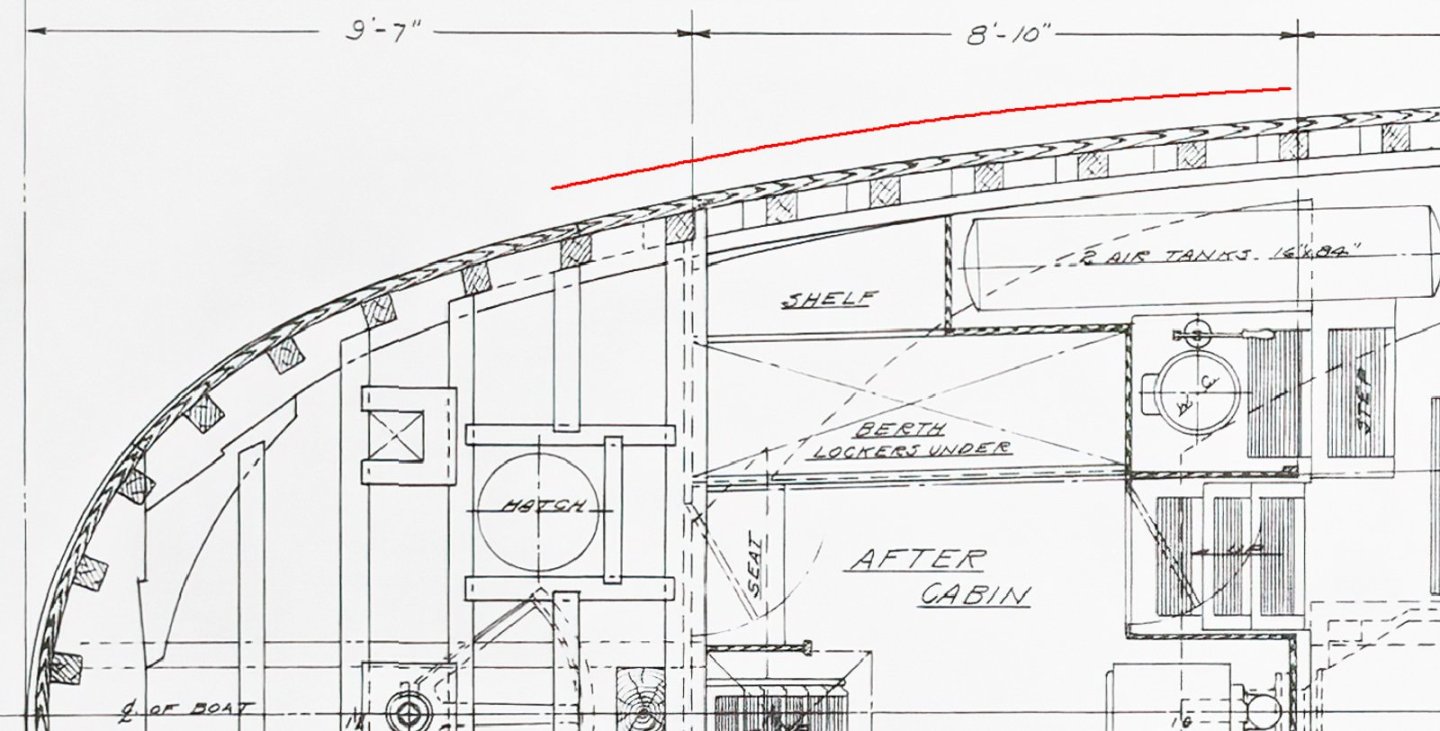

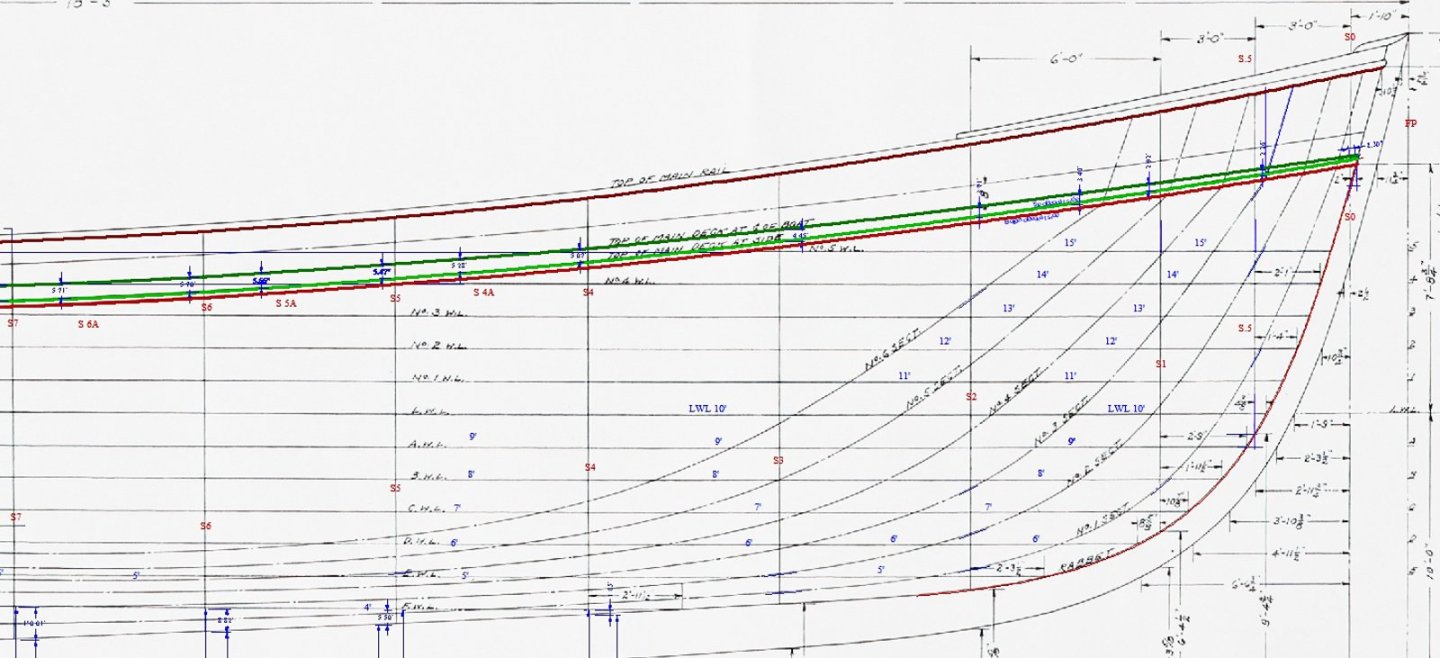

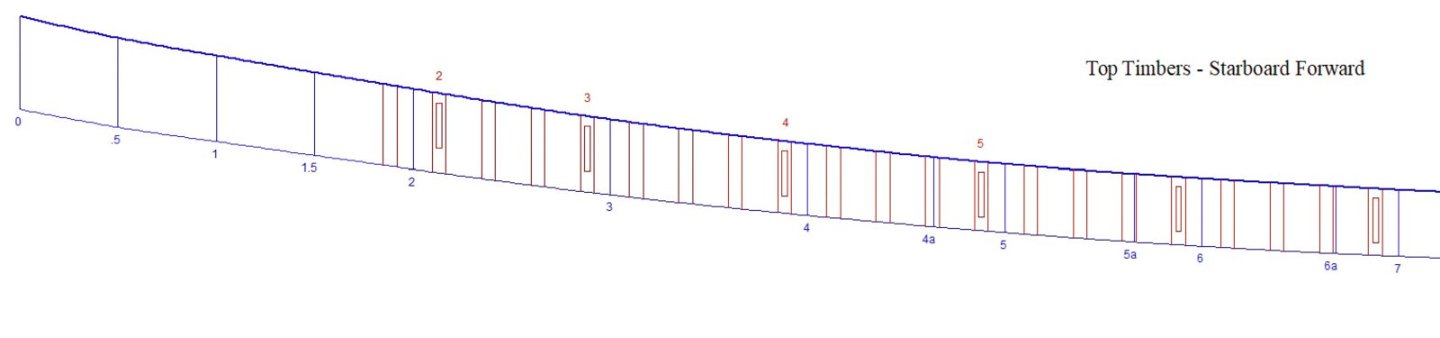

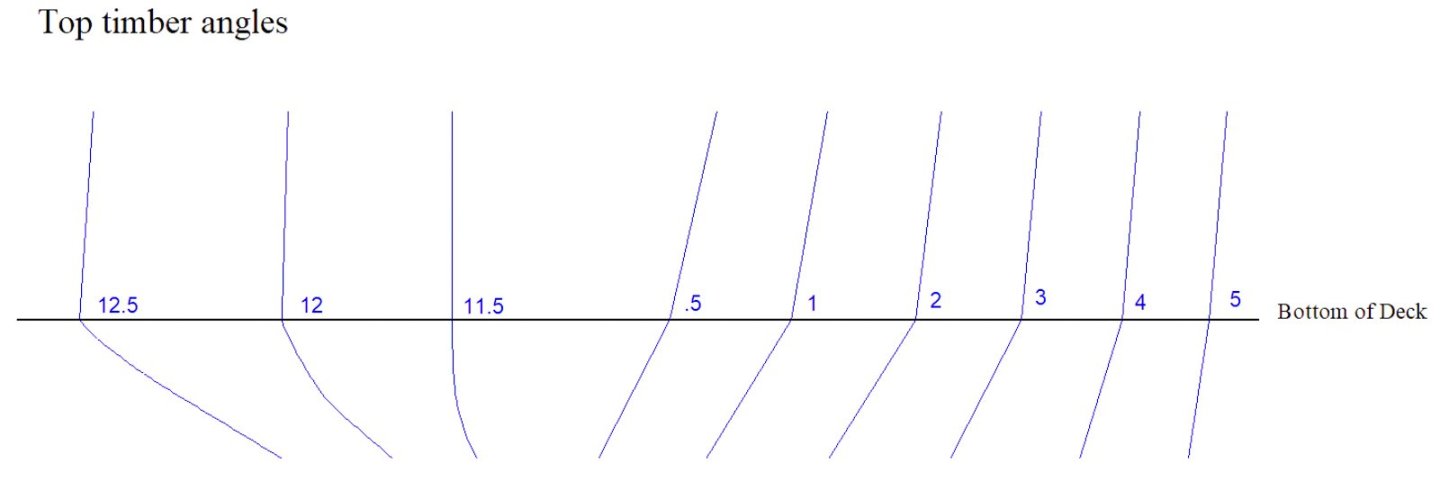

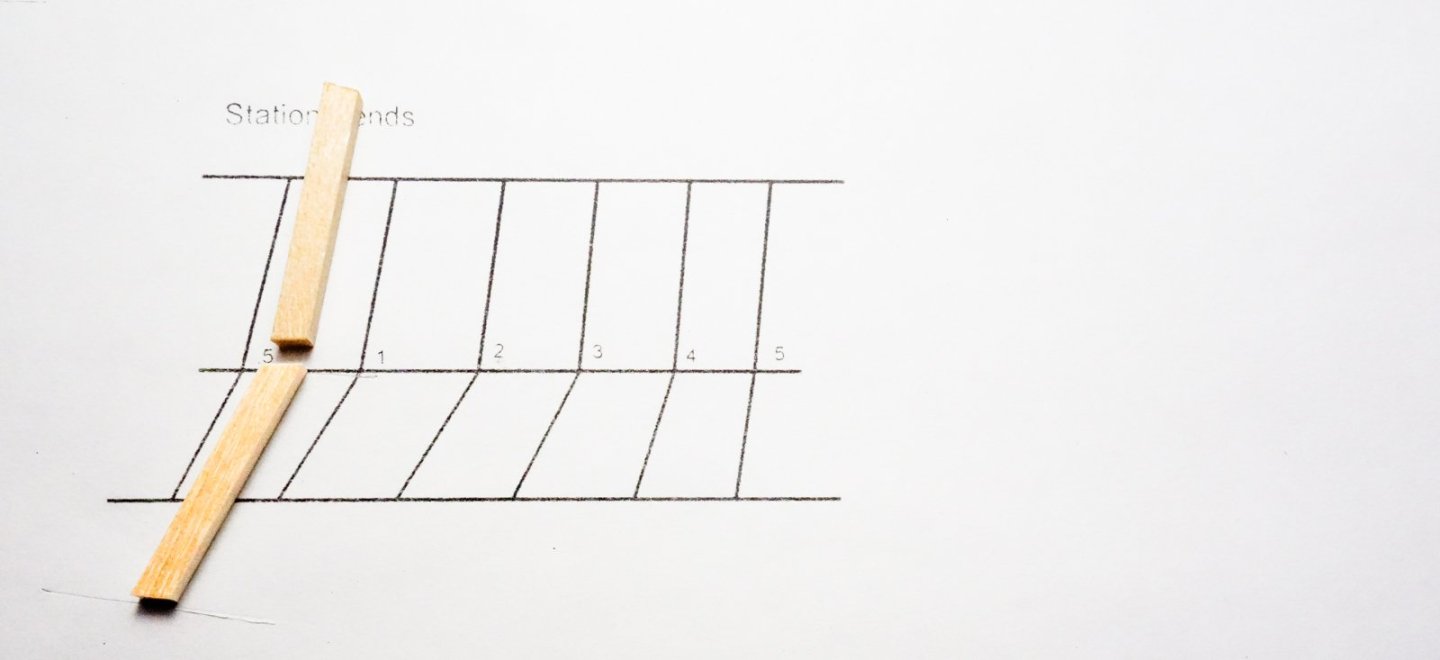

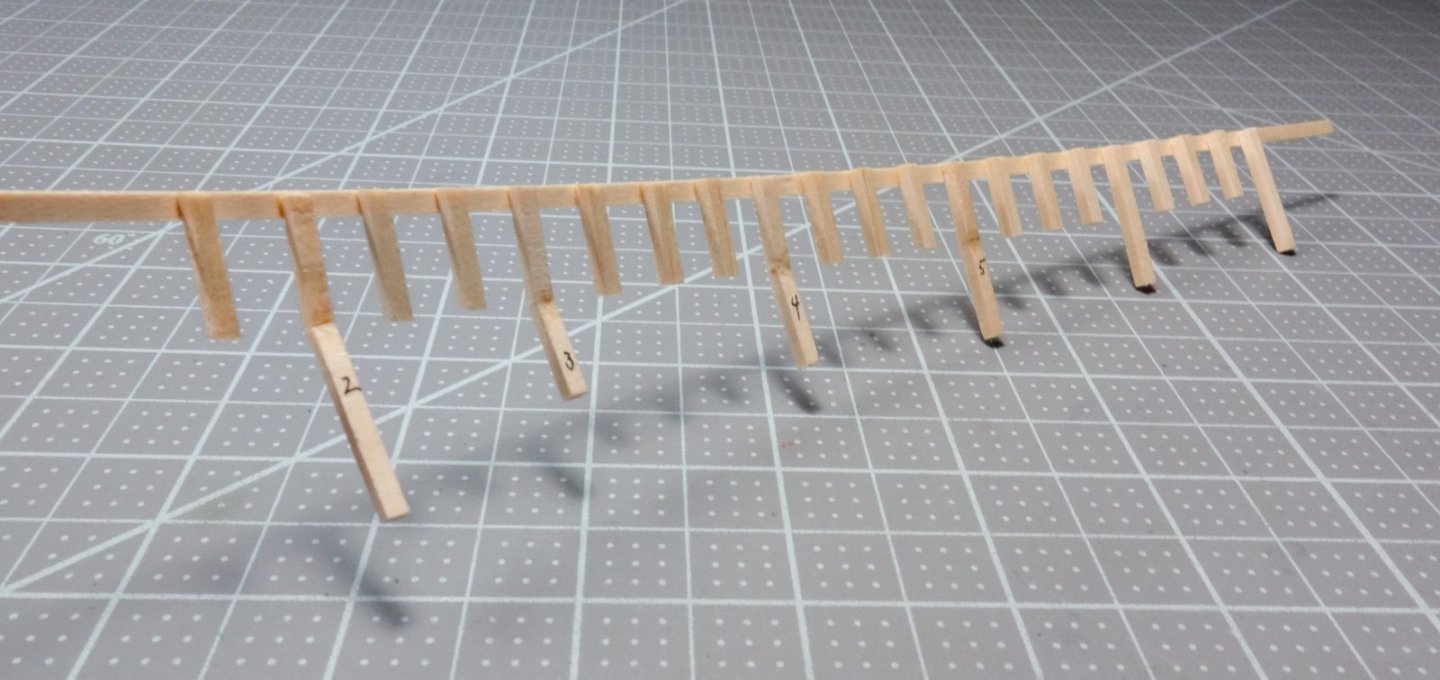

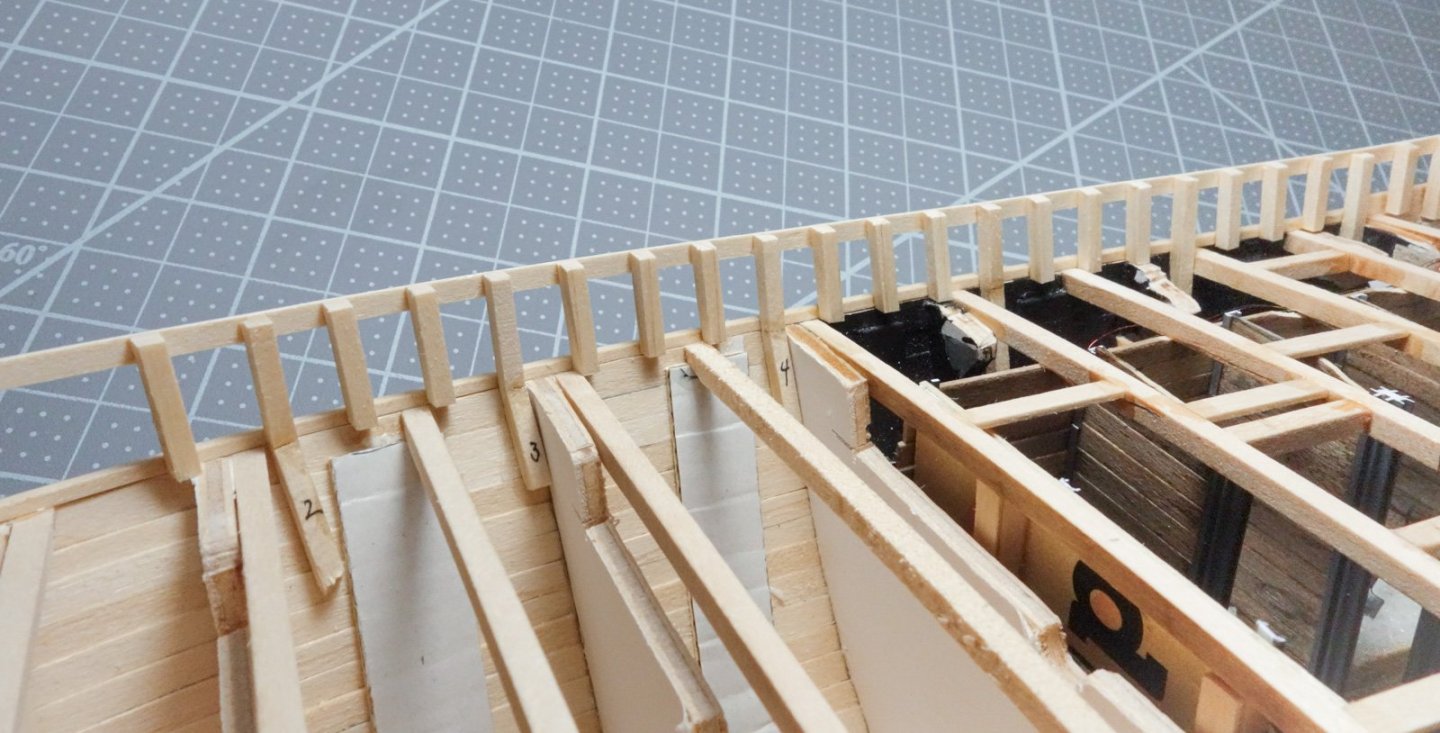

Greetings all, Thanks so much for the wonderful comments, the thumbs-ups and for finding the time to visit this build. Bulwark Stanchions Before work could begin on the stanchions for the bulwark, I first had to finish up from the last post by adding five more deck beams where the span between existing beams was too great. With that done, I started on the stanchions which the drawings refer to as the “top timbers.” This boat has 106 top timbers and are spaced about every 18” (45.7cm). In full disclosure, there are several details of these timbers that I didn't model because I felt there would be little return on the effort invested. First of these details is a taper of the timbers from 4.75” (12cm) at the deck to 4” (10cm) at the underside of the rail. In 1:48 that's a difference of .016” (.39mm), so I used wood that doesn't taper and scales to 4.5” square instead. Also, the drawings call for chamfered edges on the inside facing corners - very nice, but no. The most glaring omission is that I didn't bevel the outside and inside faces as they approached the stem and stern. In the image below, the top timbers below the red line are obvious enough that I should have beveled them, but I didn't. Forward of the blue line will be a raised “whaleback”, so those extremely beveled timbers are all hidden. This is the profile of the whaleback (green) visible above the main rail (red). And the same thing aft, but there are no beveled timbers as they round the stern and there is little discernible bevel moving forward through midships. If it sounds like I'm constructing a justification for not beveling any of the top timbers, you're onto something. I made four off-model stanchion bulwark assemblies. One each for the port and starboard bulwarks forward of station #7 and two more for P/S aft of station #7. I created a template for each assembly based on the distance between bottom of deck at side and bottom of main rail. The top timbers are at a right angle to the waterline, not the rail. The angle of bend at each body plan station is found. The upper waist strake for the bulwark section is bent to the proper arc and then attached to the template with double-sided tape. The top timbers are then glued to it. The section of top timbers is affixed to the hull. Note that a strip of wood equal to the deck thickness has been glued to the upper most hull strake. The bottoms of all the top timbers are glued to its inside edge. The final eight timbers at the stern were placed individually. The scant number of timbers in the bow area were placed willy-nilly to temporarily hold the waist strake in its proper orientation until the bulwark is complete and the whaleback structure starts taking shape. Next up – finish planking the bulwark, installing the inside rail stringer and fitting the covering boards (oh boy!). Be safe and stay well. Gary

-

Excellent progress on the base, Glen. I particularly like the front row of pilings, those sticks really look fantastic! Gary

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

Gunboat Philadelphia 1776 by tmj

FriedClams replied to tmj's topic in - Build logs for subjects built 1751 - 1800

I enjoy unusual build subjects, so your Philadelphia gunboat caught my eye. Best of luck on this interesting model. Gary -

Excellent job coloring the sacks, crates and other accessories, Eric - they look great. I particularly like the coal bin and the fact that it's the real thing from your property is an added plus. Your model has a nice organic rustic feel to it - very realistic. It suggests the rough service these working boats performed without over doing it. Looking forward to the final display. Gary

- 393 replies

-

What he said! Beautiful work, Paul. Gary

- 201 replies

-

- Oyster Sharpie

- first scratch build

-

(and 1 more)

Tagged with:

-

Congratulations on setting her in the bottle, Glen. Interesting process and your videos make it understandable. Terrific work! Smoke, eh? Gary

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

Congratulations on finishing this wonderful model masterpiece! This log has been a real tour de force in miniature modeling techniques, so thanks for demonstrating these and the unique materials that you used such papers, etc. A beautiful model display and I look forward to the "glamor shots." Gary

-

This is complex model building, Andy, and what a great job you're doing. Your detailed CAD work really illustrates what is going on in the stern and of course the on-site images of the full-scale reconstruction are always a treat. "The good news is that the Trust have been successful in getting a further National Heritage grant to complete the replacement of the deck, which means Vigilance will now have a fighting chance of another 100 years afloat! Excellent! Gary

- 174 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

Nice progress, Marc! Terrific work as always. Gary

- 2,669 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Your paddle wheel turned out great as well as the connecting rods and cams. I think caving to peer-pressure on the connecting rods turned out to be a good call. Beautiful work, Eric - especially for being such a young lad! Gary

- 393 replies

-

I haven't read all of your earlier SIB logs yet, but I've seen a few of them now and as great as they all are, Banshee II is fast becoming my favorite. You mentioned that one of your goals is to get better with each build and in my humble opinion this model is elevated work - bravo Glen! Can't wait to see it surrounded by glass. Gary

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.