-

Posts

3,046 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Thanks to all who have replied. Craig has found what I was looking for, a specific reference in scantlings to thwarts being described as 'fixed' etc. This did not appear in my sources. It would be interesting, if possible, to date those scantlings. It makes sense of the drawings I have been pondering of launches and other boats adapted to mount cannons or carronades. Mark, I believe we have been looking at the same model. I was thinking of doing something similar for the boat on the deck of my Mediator. Looking at this model and also trawling through images of cannon armed boats the thought occured to me: how did they stack the boats if the centre thwart was fixed? The boats were in many cases capable of carrying guns when required. The slides for these guns varied but looking at the full length versions, the slides were on top of the thwarts. It seems certain that the slides required solid fixings and removable thwarts don't fit in with that idea. Some mountings were shorter and allowed for lowering the gun to improve stability of the boat. These slides all seem to be either side of the centre thwart. I may be chasing my tail here but the two requirements, ie stacking boats and having solid thwarts, seem to contradict one another. If the answer is obvious, I ain't seen it so before I spend a lot of time re-reading every practicum I thought I would ask. Thanks, Bruce

-

Hello Tom and enjoy the year of the ox. Regards, Bruce

- 67 replies

-

- granado

- cross-section

-

(and 1 more)

Tagged with:

-

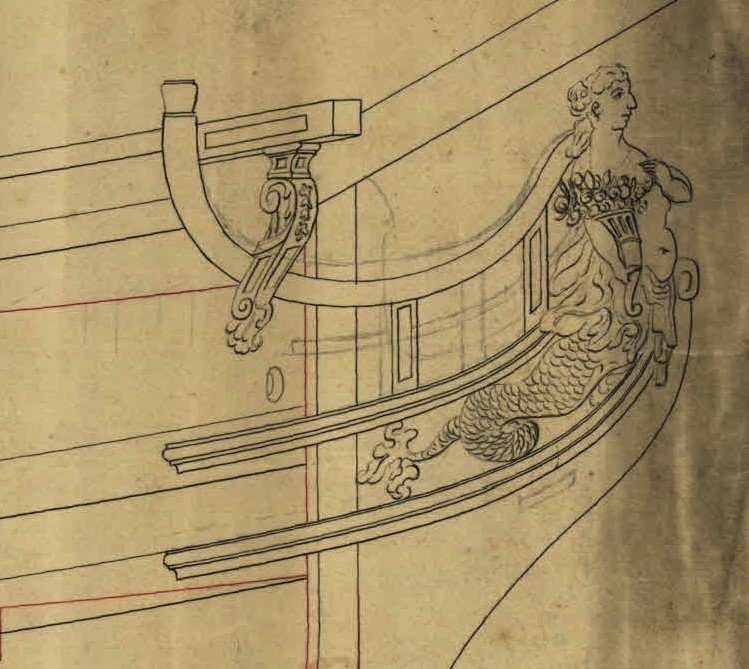

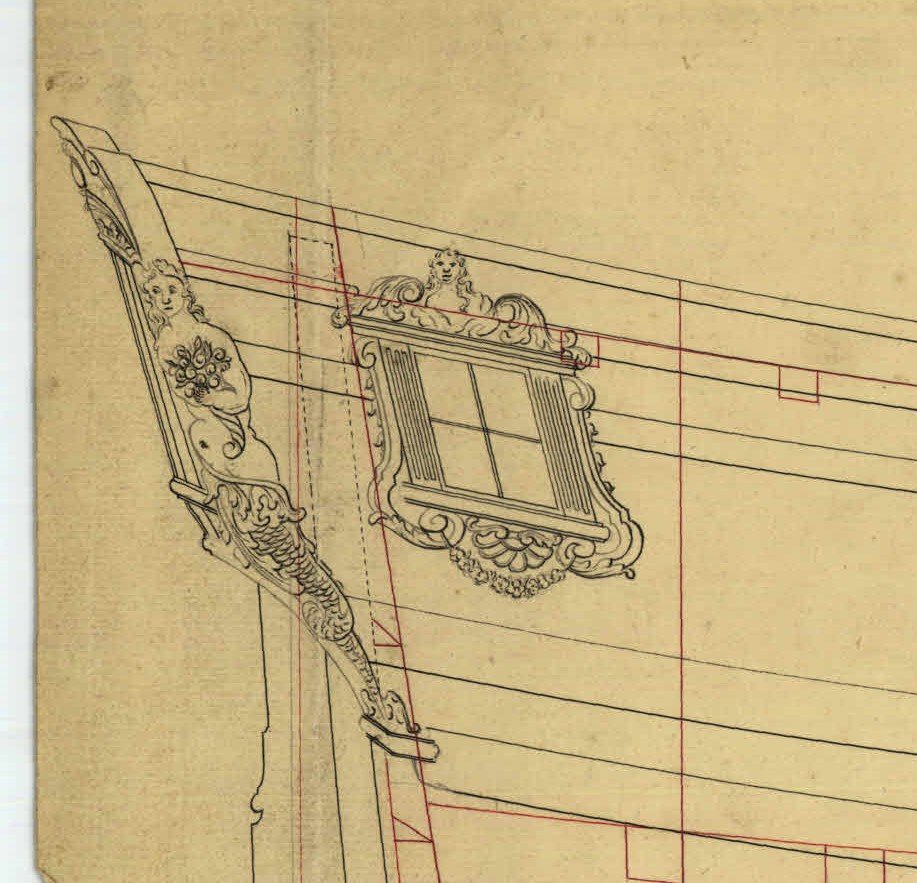

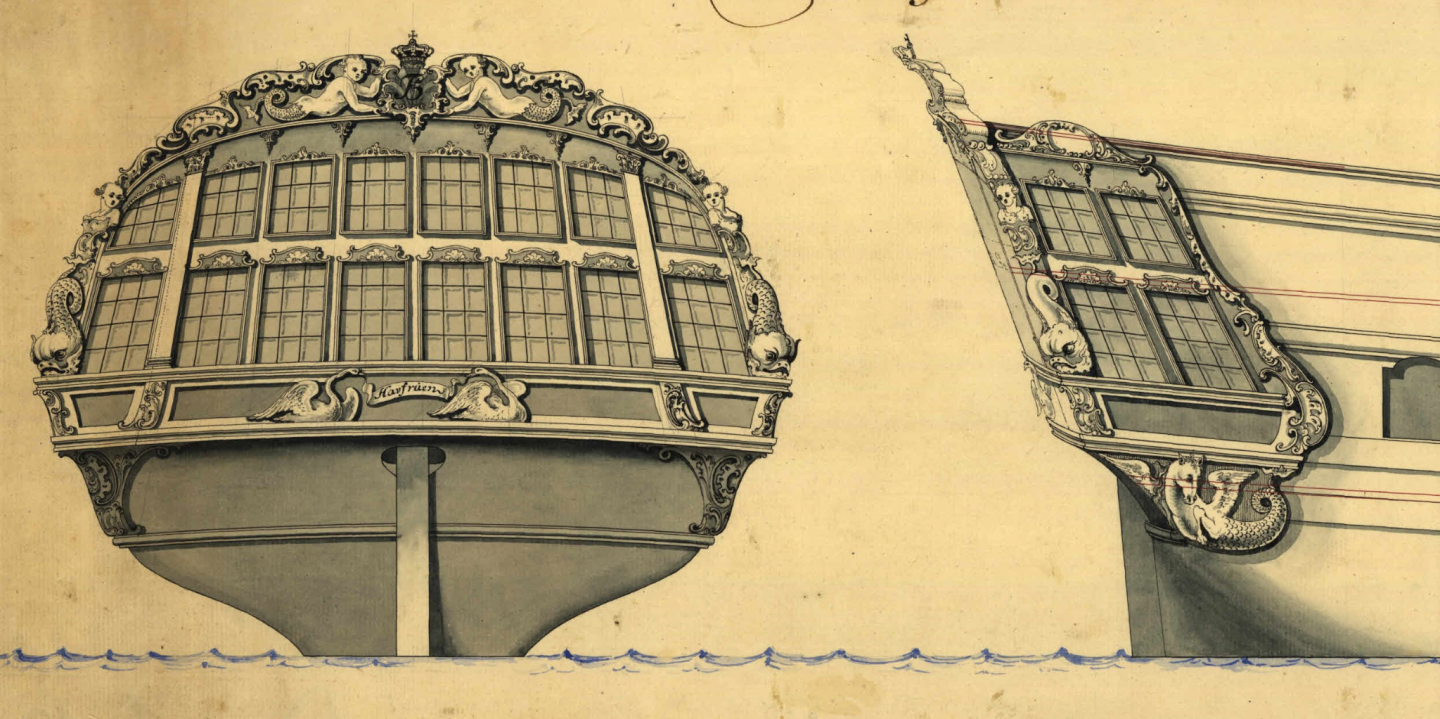

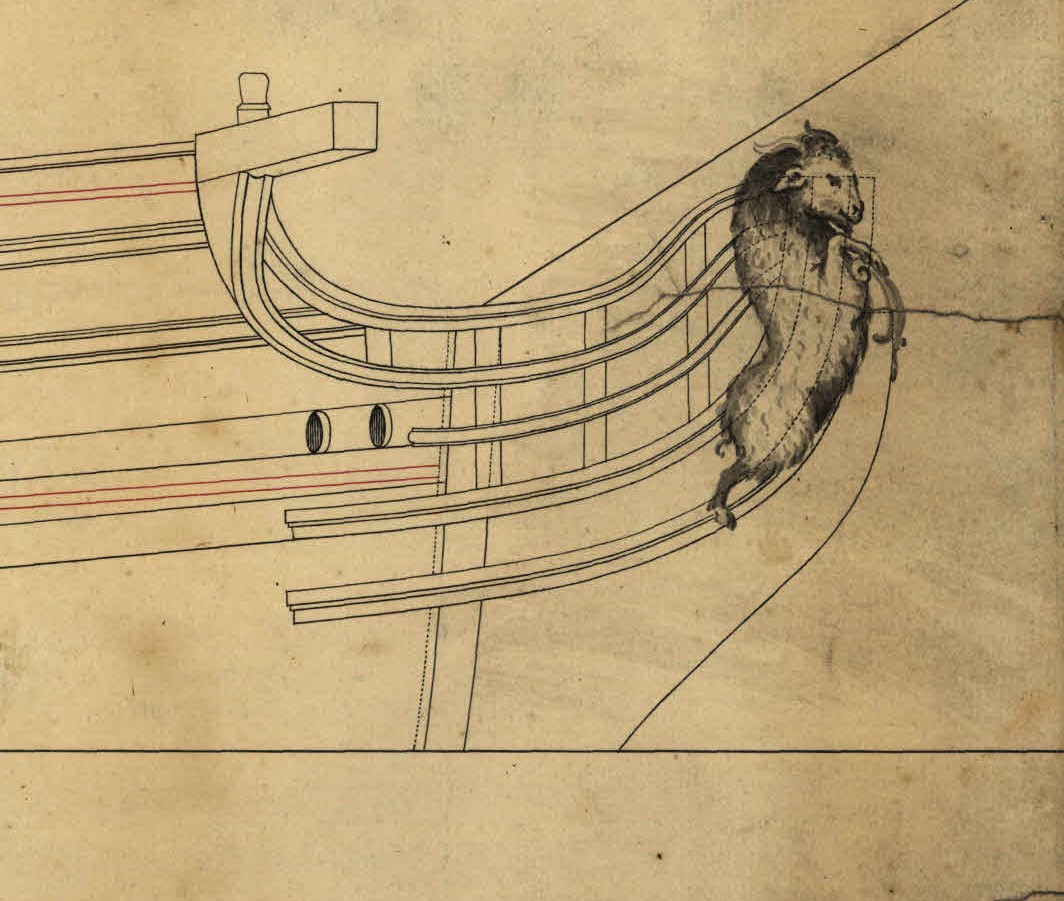

Another 18th century Danish ship, name unknown, with stern decoration reflecting the figurehead features. (Please note I have corrected a dumb mistake in the previous post, correct image is displayed now)

-

I want a good modelers saw

bruce d replied to Roberts Orca's topic in Modeling tools and Workshop Equipment

The advice is overwhelming that the Byrnes is the best. Having finally got one, I agree. I previously had a Proxxon FET and it cannot be faulted it if it is used for the light jobs it was designed for. It is a very good modellers hobby saw but the Byrnes is a precision tool. If you can justify the expense, no contest. -

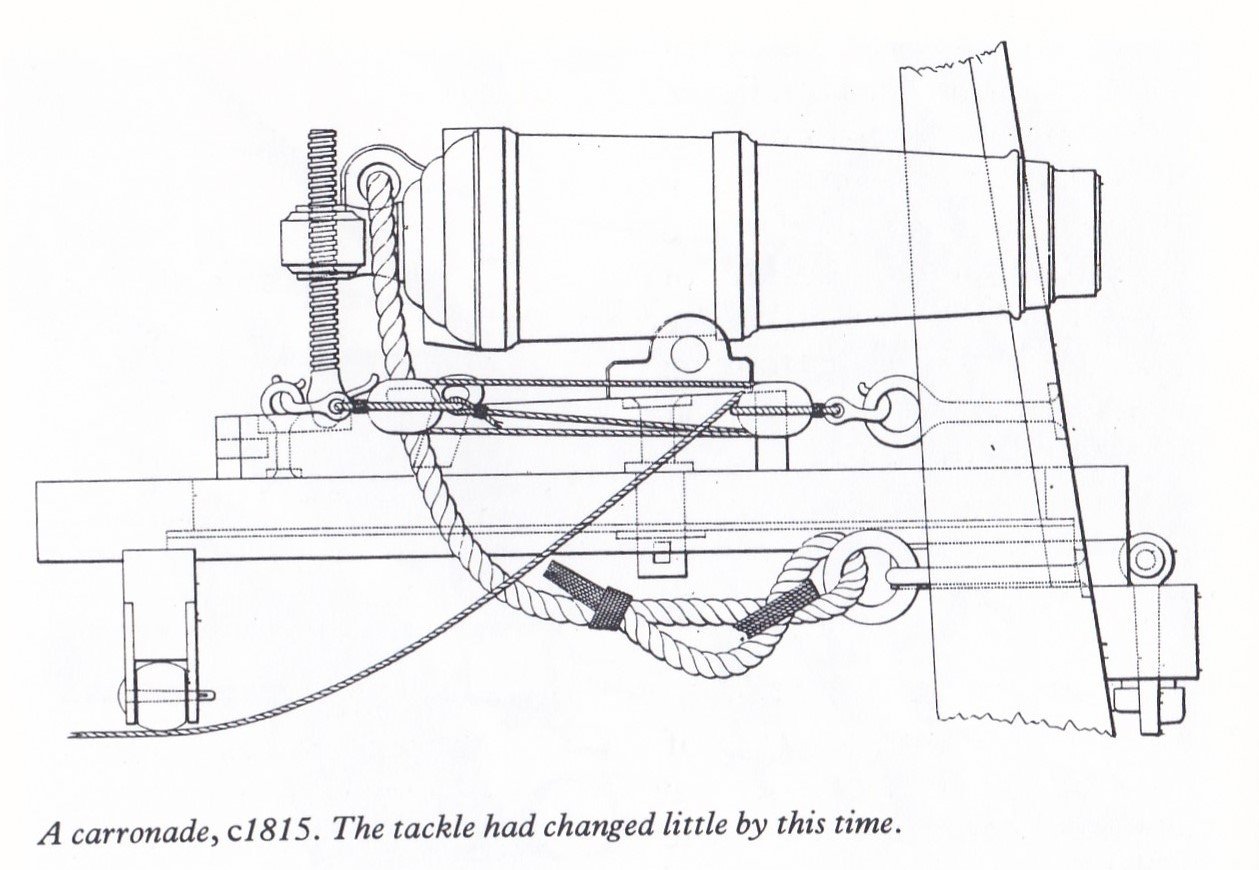

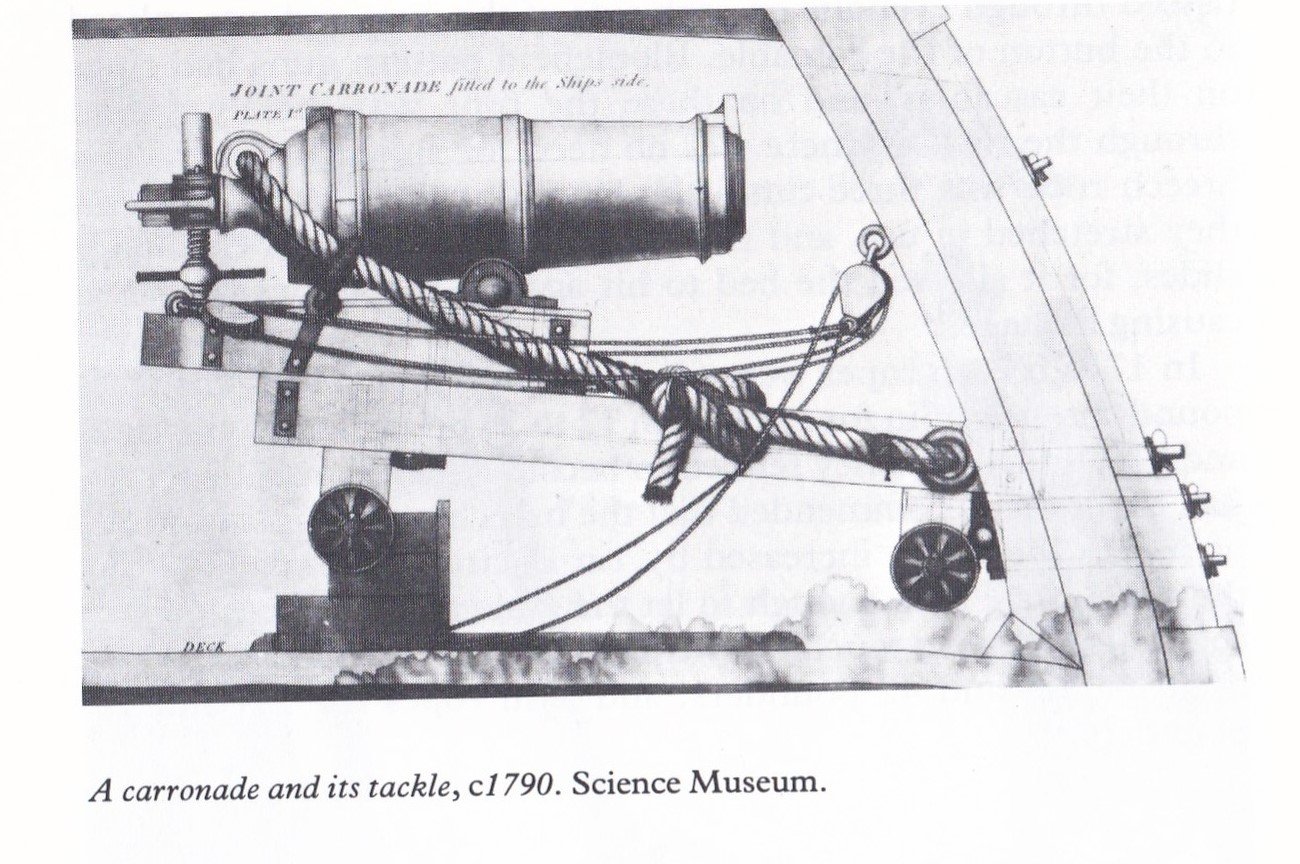

Visited the bookshelf and found 'The Arming and Fitting of English Ships of War 1600-1815' by Brian Lavery. He doesn't specify the inner and outer fixings in the text, just describing the gun tackle and eyebolt arrangement that is common knowledge. However, the two illustrations accompanying this passage show the through bolts and the outer fitting. The earlier has a clench proud of the surface, the later example is flush. It is worth noting that the earlier carronade has several through fittings. His photographs of the gun ports on Victory do not reveal any sign of the outer clench of the bolts we are discussing but that ship is probably not the best example. Bruce

-

Hello Gary, thanks. I had a couple of questions in the back of my mind when I wrote the question. Number one was : planking gets replaced, is that why we don't see evidence of this practice? Now that I am looking closer, it makes no sense that the recoiling cannons would be anchored to anything just screwed into the wood. It needed a through-fixing of some sort.

-

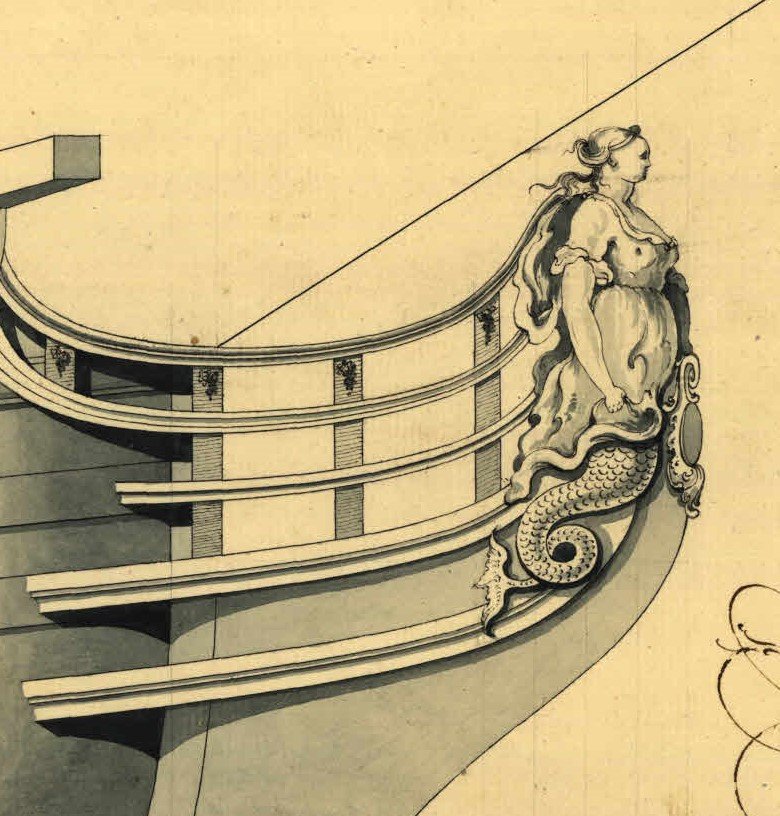

Danish frigate Havruen 1760. Stern decoration uses same 'fish tail' as on female figurehead: EDIT: Correct photo number #1 now, my boo-boo earlier.

-

-

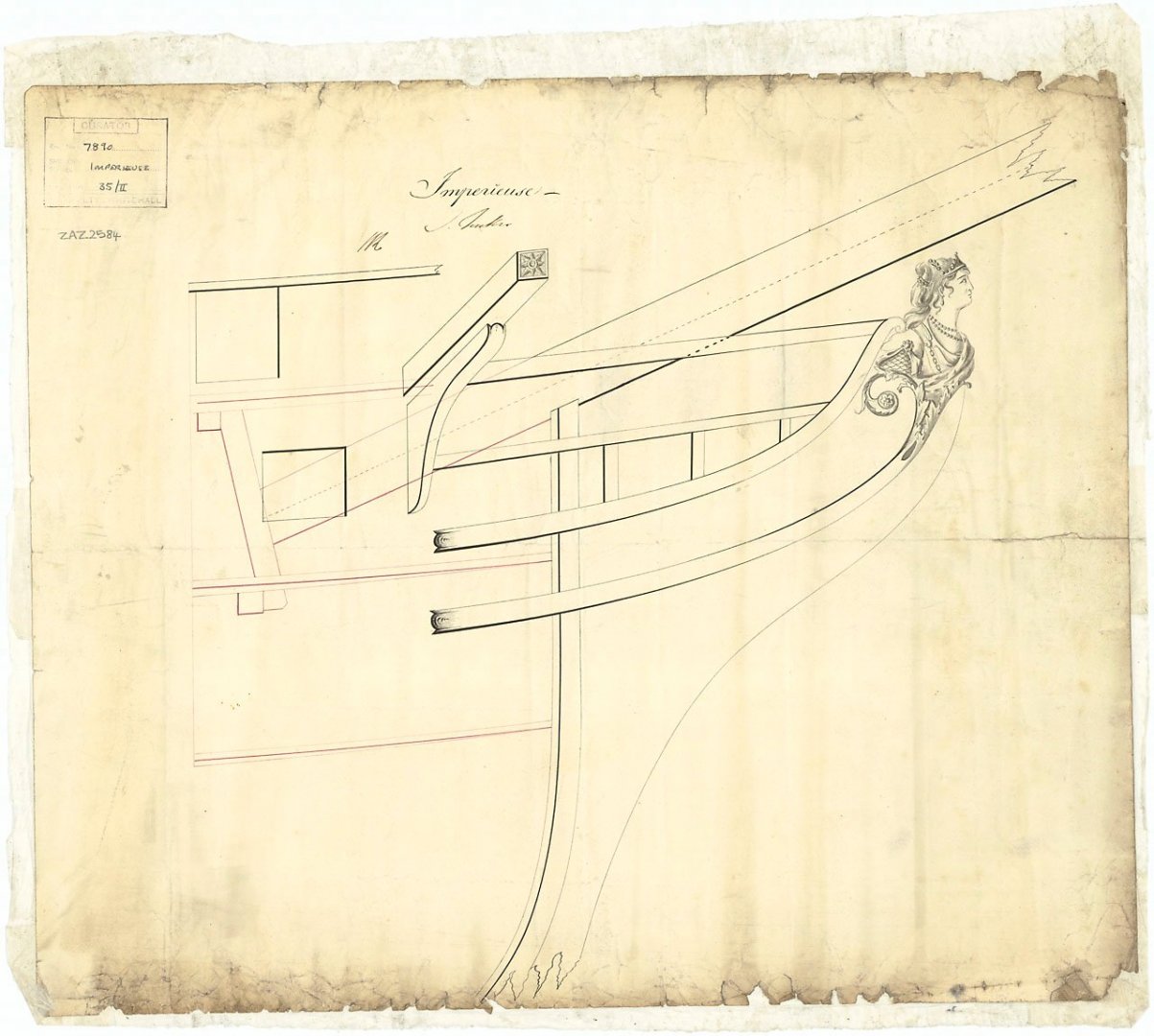

From NMM Collections, cropped: "... figurehead for Imperieuse (captured 1804), a captured Spanish 40-gun frigate. The bust figurehead is a female facing forward wearing a tiara and pearls in her long hair. A double pearl necklace sits around her neck above the top-line of a flowing gown. ..." NMM id = J5366 As HMS Imperieuse she was Cochrane's ship during the attack on Basque Roads.

-

Introducing Colin. Currently living in South East England.

bruce d replied to colpatben's topic in New member Introductions

Hello Colin and welcome to MSW from another Sussex resident. Nice models and nice to see that some of them even got wet. (I am sure mods will answer question about 'morals') Regards, Bruce -

The joker in the deck is the carrier's admin charges on top. If it is sent via post, the RM Post Office will collect any duty + a couple of £ 'admin'. However, if the package is sent via a commercial carrir you will almost certainly get charged the duty + their admin fees, usually £20 to £40. There is little hope of arguing the point with the carrier, it just goes to a collection agency and gets nasty. So, from experience, ask before placing the order.

-

Remain optomistic. You are not alone. I was two years into a 5-inch gauge live steam loco build (a Sweet Pea) when Ibegan to realise that I was having too much trouble just manhandling the rolling frame and cylinder assembly and would never be able to deal with the finished loco. I decided to think again and only after a decent interval came off the fence. Whatever you decide, don't rush into it. Just take care of yourself and see what fits best.

-

Hello Paul and welcome to MSW. Those models look good, you know what you are doing. The weathering and toning on the subs is excellent, I hope you will talk us through your processes sometime. Bruce

-

Sutcliffe 1/72 vac form Coronado

bruce d replied to Lucius Molchany's topic in Non-ship/categorised builds

You are fearless! -

Hello, Henry Wombat, welcome aboard MSW. It sounds like your interests are spread across all the key subjects here, I am sure you will find a lot of interest if you decide to add a build log (or two or three...) especially as you are a 'proper sailor'. Bruce

-

Perhaps post #16 here will help. If Jolly roger isn't based on a real original then you have a free hand.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.