-

Posts

3,046 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Found this article from 1901 on the carvings used on ships. It was in 'The Connoisseur' magazine.

-

-

So, Brian, as the original poster I hope this helps see the ship in the correct light. There are other sources online selling what appears to be the same item, all with unrealistic versions of their quality and value. I can only assume that your family-owned piece was new at some time around the middle of the 20th century and the fact that these dealers are offering models with so much in common proves that they were mass-produced. Brian, ignore the prices in the advertisements: the ship is worth whatever your family feels it is worth. It is a decorative piece that celebrates Hanseatic Hamburg and may give a nod to some particular ship in an old print but it is not a true representation of an actual ship. Please also ignore the amusement we expressed at seeing how 'antique' dealers choose to describe these pieces as fabulous achievements in modelmaking and valuable. Actually, I kinda like it.

-

https://www.chairish.com/product/2443266/mid-20th-century-model-of-1541-german-hanseatic-league-warship

-

A couple of recent additions to US Naval History

bruce d replied to trippwj's topic in Nautical/Naval History

They sound good Wayne, but I can't get the links to work. -

Remember the 24 hour cafe at the top of Bethnal Green Road?

-

-

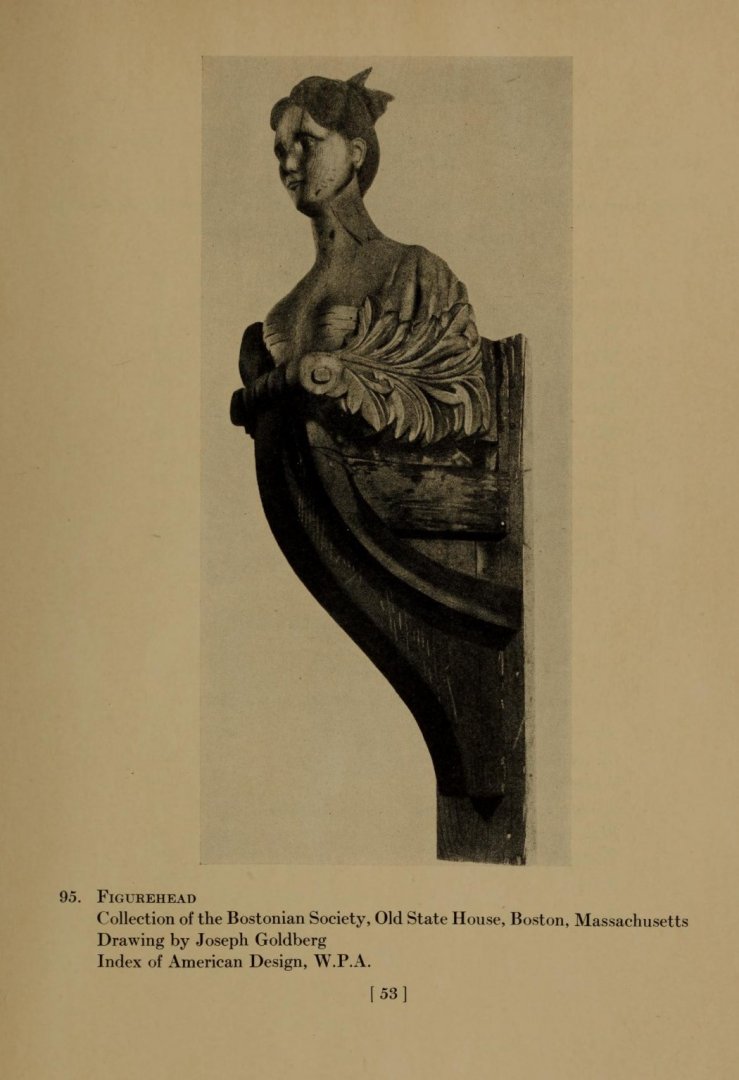

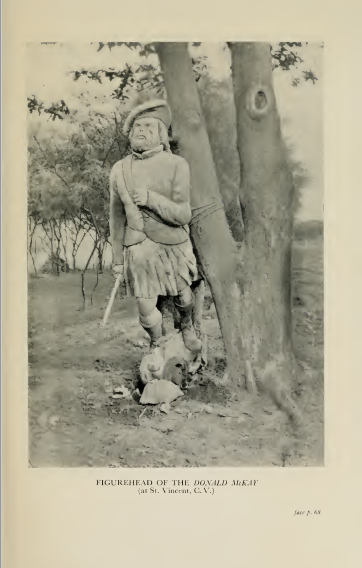

I especially liked the yarn on page 16. Ships' figureheads in and about New York.pdf

-

Ordered. Many thanks, I thought I knew a few things about pens but I never once found a pen that didn't bleed into wood to some degree. I just had a baaaaaad experience with my first laser-cut small boat kit. I used a pen to pre-colour some very thin ply that made the formers for a ships boat. Guess what? The ply started to delaminate. I look forward to some experiments.

-

Hello Jose and a warm welcome to MSW. This is a great place to get support and answers during a build. The 'stash' is something we all understand.

-

Ships at Trafalgar - what kits are available?

bruce d replied to bruce d's topic in Wood ship model kits

Just got it. I see what you mean, looking forward to reading this one. Thanks! -

"Stout, Sturdy and Strong: A typology for early nineteenth‐century American whalers" A thesis by Madeline McAllister Stout_Sturdy_and_Strong_A_typology_for_e.pdf

-

Anyone interested in how the wooden walls were built will know the humble saw must play a part. I was pleasantly surprised to find much of the contents of this work entitled 'Story of the Saw', produced for Spear & Jackson, relates to shipyards. Story of the Saw-compressed.pdf

-

Le Coureur by PC52 - Mamoli - 1:54

bruce d replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Looking good so far. Mind if I watch? -

To make sense of the above, I asked a question and then deleted the post as I found the answer myself. Thanks Jim, afraid I can't answer the original question. Regards, Bruce

-

Adrian, it is not often I would add to a warning from Druxey but ... Beech varies. Try your piece (if you have one already) with (A) a sanded surface, (B) a planed surface and (C) a sanded surface with a thin coat of WOP or sanding sealer. I tried these tests on a piece salvaged from an Ikea cabinet leg and there is a great difference between (A) and (C). (C) looked mirror smooth and had a scale effect grain that simply did not show up on the test pieces that were sanded but untreated. Other pieces of beech I had from a timber store always had a more prominent grain but I double checked and the Ikea wood was actually beech. You would not know it by comparing the two examples. Ignore if you don't have some beech already (or an Ikea donor 😉) HTH Bruce

-

That folding gizmo is called a 'linen tester'. Wonderful tools.

-

A paper on an amazingly complete 17th century Baltic craft. "Eriksson, N. & Rönnby, J. The Ghost Ship'. An Intact Fluyt from c.1650 in the Middle of the Baltic Sea" Eriksson_N_and_Ronnby_J_The_Ghost_Ship_A.pdf

-

Keith, I think the admin should add a 'mind-boggled' button in the reactions: 'like' just isn't sufficient. Bruce

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.