Jim Rogers

NRG Member-

Posts

1,381 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Rogers

-

How to sew ratlines help needed please.

Jim Rogers replied to Peter Cane's topic in Masting, rigging and sails

All clove hitches from beginning to end secured with diluted white glue (PVA). -

Make sure you post about the new Airport.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

This is just me but I think that Fruitwood Gel Stain would make it all pop.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks beautiful Chuck, you Sir are a true craftsman. Wish I had a tenth of your talent. Will the frieze and these two figures be available when this chapter is issued?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Really. Never saw that before. Learn something new everyday.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You gonna lose the period?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome Tom. I use Titebond thick set and CA dependent on the situation. Those little brass nails are a large PITA as they bend very easy and you usually need to predrill a hole. You also need to lay a pretty uniform pattern or it can look terrible, ask me how I know. What you need is a vast assortment of various types and sizes of clamps to hold your planks whilst the glue sets. You also need to learn how to bend planks

-

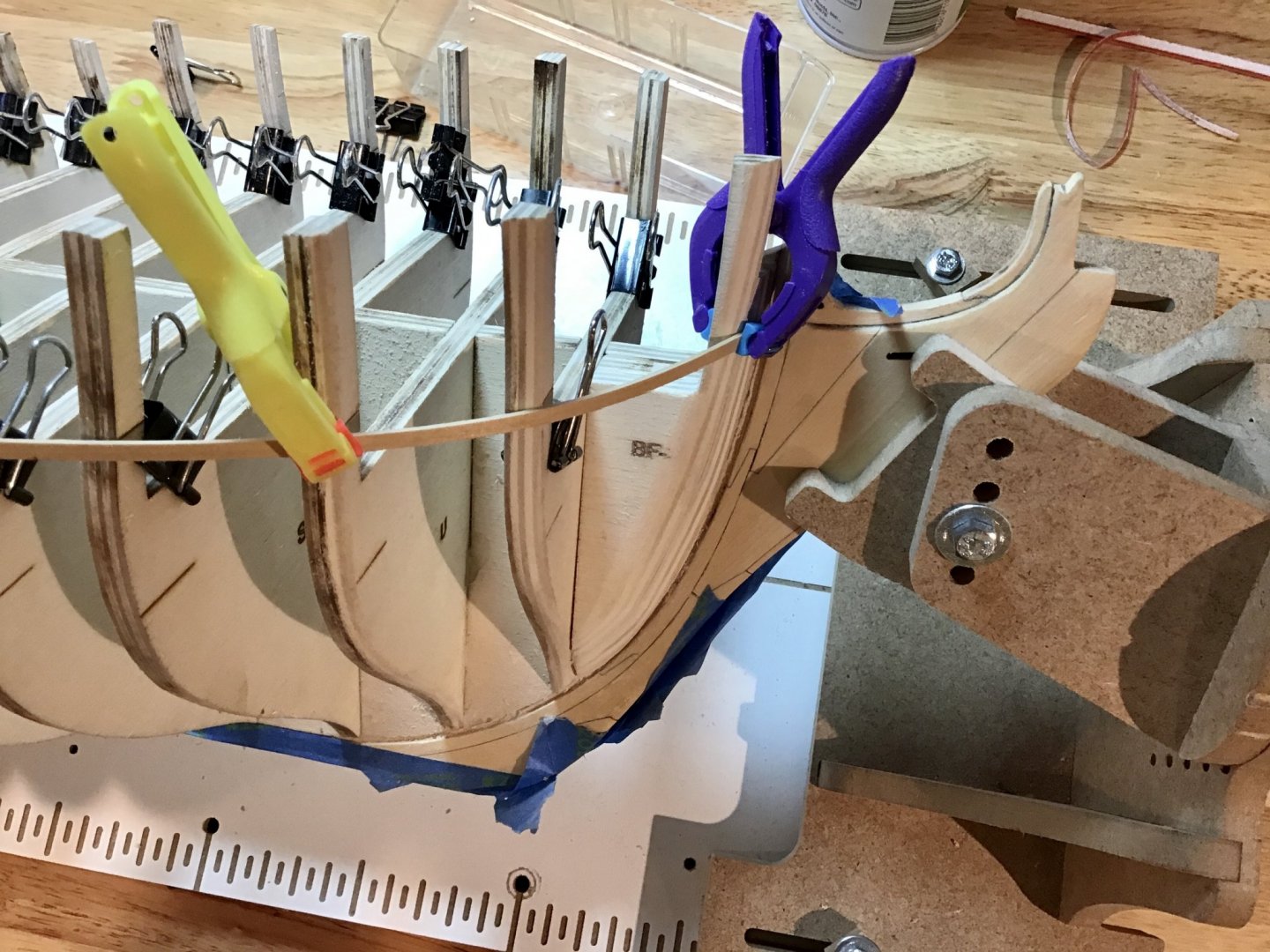

Reg, I LOVE it. I have used the Amati Keel holder for all my builds and the Hobby Zone slip is magnitudes above. The Winnie is a beast, it fits very well with room to spare. Your ship locks solid and you can rotate 360 degrees if you have it mounted high enough. The screws that came with it were a tad short and would not tap into the secure nuts. You will have to get creative with attaching your ship after the stern is built all I did was remove the clamp, slide the base up to the stern, slipped in a piece of scrap and tightened her done worked great. The Hobbyzone Slip is a solid and very useful piece of kit. After cutting several strips with a band saw I just dropped the hammer on a Byrnes Saw as I did not like the blade marks on the strips and cutting those 1/64 strips for the Black Strake was a PITA. You can almost read a newspaper through those they are so thin so I am going to replace those with 1/32

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Model Shipways Fair American vs Syren US Brig

Jim Rogers replied to WalrusGuy's topic in Wood ship model kits

The Syren instructions are a tutorial on model ship building. -

Proxxon Planer DH40 Issue

Jim Rogers replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Need new blades or sharpen old ones. -

My cedar billets arrived today. Thank you Chuck! Quite the surprise.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

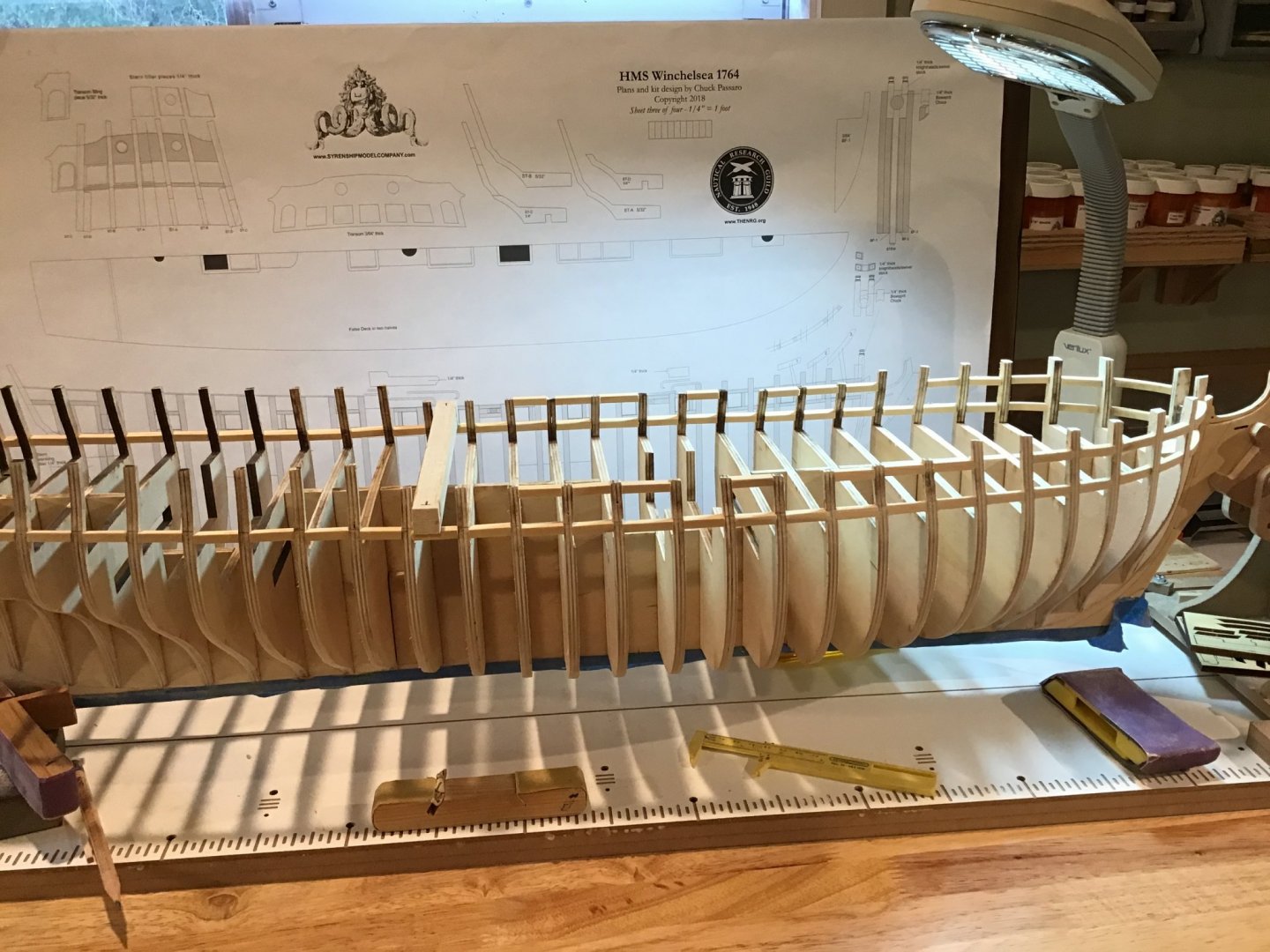

Looks great Steve. I am just adding the battens on mine.

- 99 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Anyone use a bandsaw for cutting strips? Seems it would be easier and more accurate than a mini table saw and having to move the fence for each cut.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I hear ya Jack. I wrote technical documentation for the Navy for ten years and bad documentation drives me nuts. I have gotten so frustrated on occasions I have actually rewritten instructions and sent them back to the companies. A major issue is they assume WRONGLY that everybody building their kits understands nautical terminology. Another issue is they provide terrible visual references with no identification in the written instructions which visual references apply to a step.

- 52 replies

-

- artesania latina

- titanic

-

(and 1 more)

Tagged with:

-

Chuck is there a reason bulkhead 29 is not added before fairing the hull?

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

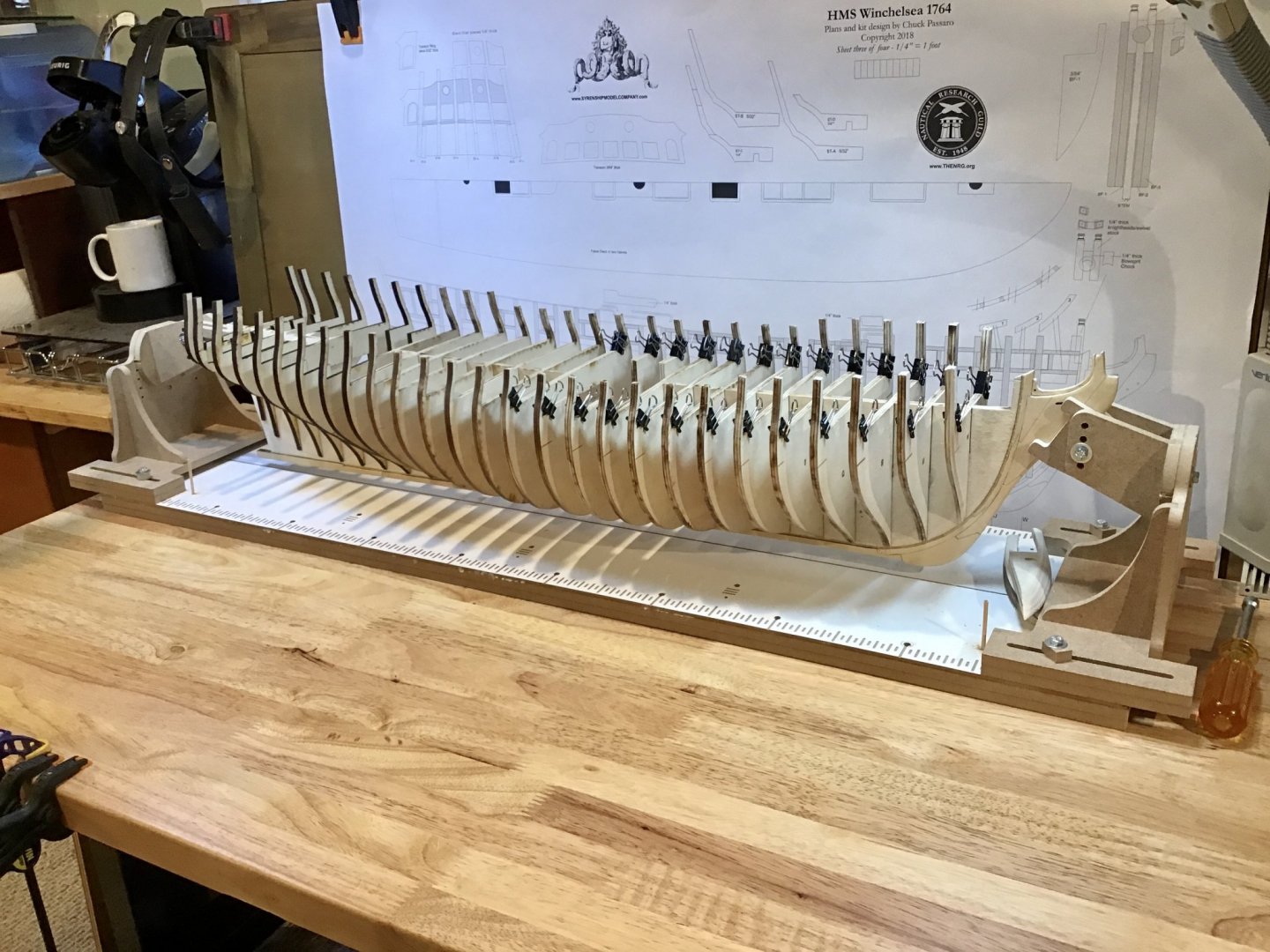

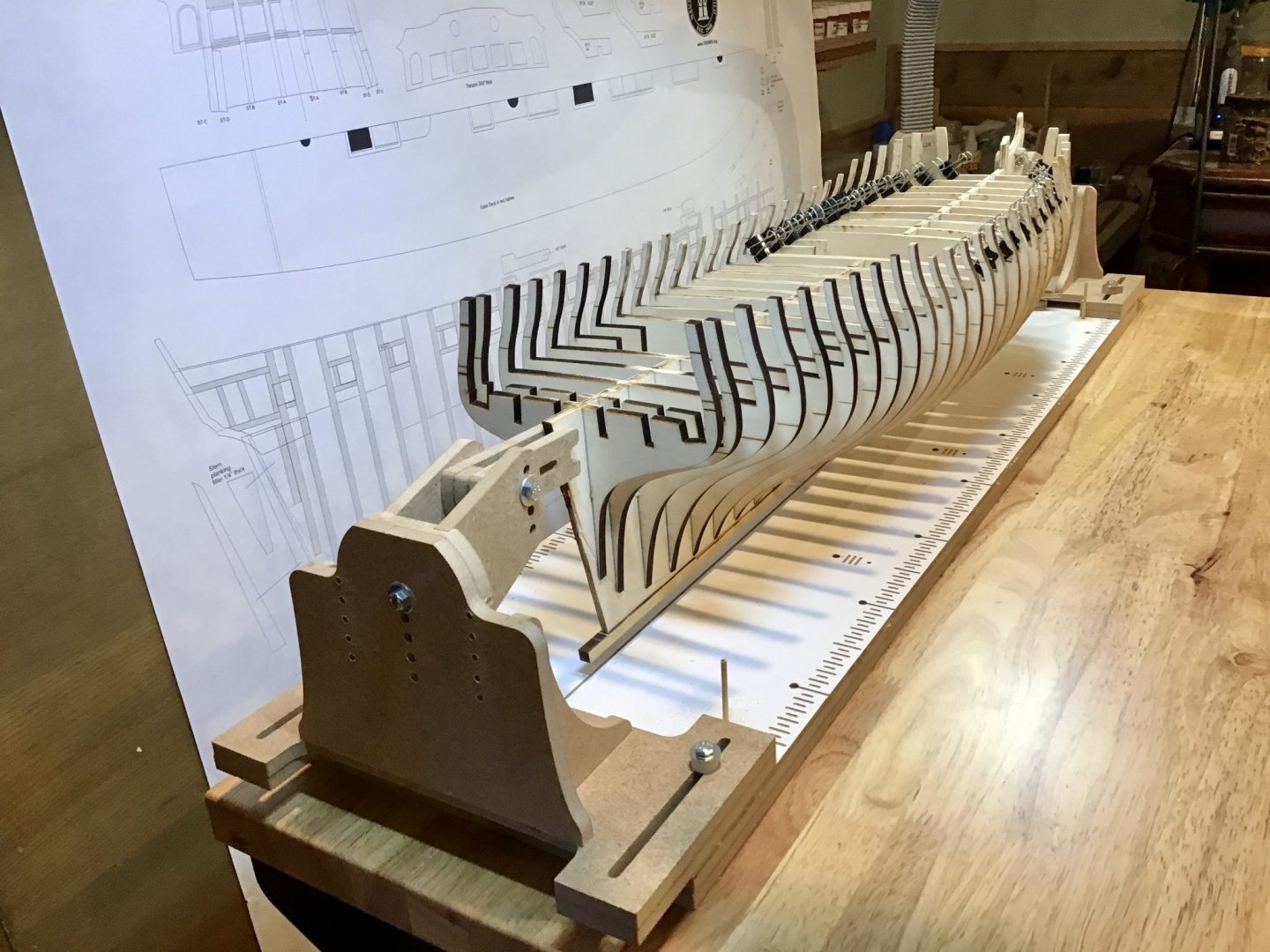

Finished the bulkhead installation yesterday evening. Took three days. Started the fairing process expect an easy five to six days.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck are you going to add color?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Will swap homemade bacon for information in Tacoma WA

Jim Rogers replied to Paul Gardner's topic in New member Introductions

Paul, I am located in Bremerton drop me a PM if you are interested in dropping by......bacon not required.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.