-

Posts

699 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JpR62

-

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Small progress. The hawse plates were cut from a 1/32" sheet of boxwood and put in place. The holes for the bowsprit and for the hawse cable were drilled in the sheet before cutting the shape to avoid any breakage. Once the cap rail is in place, the model will really start to look like a cutter. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Thanks to the people who follow my work. It's always motivating and reassuring to know that you can count on the support of others. I like to try new techniques. I really liked the result of ebonizing to get a nice natural black color. In his excellent log on the 'Fifie' produced by Amati, Tim Moore had shared his technique (see link below). Fifie by Tim Moore - #19 - April 4, 2021 I decided to use this technique to stain the cap rail before installation to make it easier to color. After a week of soaking, the iron acetate preparation is ready. The tannin preparation is quicker to prepare, it is simply 12 tea bags in a cup of hot water. I made a first test on a piece of Alaskan Yellow Cedar and miracle it works perfectly. It's quite magical... and simple. Just apply the process described by Tim. I cross my fingers and do the treatment on the front part of the cap rail. And the chemical reaction works again. The result seems to me correct and I will be able to apply it for the other segments. Again a great proof of the richness of this site and the wonderful sharing of techniques 👍. -

Stunning work, Mike. It's perfection. Work that inspires and motivates us. Thank you !

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Before installing the hawse plates, I glued the front part of the cap rail. I cut it out of a 1/16" sheet of Alaskan Yellow Cedar with a cutter (I don't have a scroll saw at the moment and boxwood of this thickness is really too hard for a cutter). Alaskan Yellow Cedar is ideal for this job and since the cap rail will be painted black, the wood species used is of little importance. The cap rail has been intentionally cut out leaving a margin on each side. It is then sanded to the correct width after gluing to the model. Protective tape was applied to the inner bulwarks to protect the red paint as much as possible. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

The small "ear" was cut out of a sheet of boxwood. I first cut its shape out of a sheet of cardboard and after several adjustments I was able to use this template to reproduce its shape on the boxwood. The last segment of molding was glued on after the 'ear' was in place. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

The fancy moldings were made using the scraping technique. I used 2 different profiles and the 1/16" x 1/32" boxwood strips were then shaped by making many light passes across the strips. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Thanks guys for your kind comments and Thank you for all the 'Likes' I started by working on the boarding ladder. It seemed like a better idea to do this task before I put the molding in place because it saved me from having to cut and peel the molding segment at the ladder location afterwards (thanks to Stuntflyer for bringing this to my attention in his excellent build log). The boarding ladder steps were constructed from a 3/32" x 3/32" boxwood strip.I used my proxxon MF70 micro milling machine for this. Once the different levels were milled, they were rounded with emery paper. For a precise cutting of the angles a small jig was built in order to be able to reproduce regularly the angles. Once the steps were cut, I used a needle point and the blade of my cutter to continue the profile on each side. The bottom step is painted black since it will be positioned on the wales. Next step is the moldings. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Over the past few days, I have been finalizing the internal planking. I first applied the first layer of planks having decided not to cut them between the gun ports in order to obtain a very regular curvature. The gun ports are then opened with a cutter and sanded. I had to add some wood filler on the 2 bottom rows because I must have been a bit heavy handed when sanding the bulwarks. It doesn't matter because a second layer of planking will cover them. The second layer of planking was added below the ports in order to simulate the spirketing. The whole is sanded to prepare the coloring that will be applied first with an airbrush. The gun ports are closed again to prevent paint drift during airbrush application. A liquid masking film is applied in the joints. And the whole hull is protected. We often spend more time protecting what should remain color free than the coloring itself. Rather satisfactory result. No trace of color on the hull. I will be able to finalize the part of the hull above the wales by adding the fancy moldings then add the cap rail. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Thanks to all those who follow my work. @Glenn, I had a lot of fun detailing the interior of the 2 rooms and adjusting the opening visible from the deck. And I am fortunate to be able to refer on this site to excellent reference models every time. Thanks again for your excellent log on the Cheerful. @Will, it's true that the addition of the false deck marks an important step. All the internal structure is hidden and we will be able to detail all the fittings that will take place on the deck. It is indeed starting to look like a ship. @Johann, thanks for the kind words. Your work on the Creole is one of my references and I think many of us admire the quality and precision of your work. As for me, I still have a long way to go... -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Thanks to all the people who are following this build and giving me precious advice. This week I put in place the false deck. I followed the instructions precisely, so I started by adding multiples thin strips of protective tape on each side of the cut plan to adjust the false deck. The final shape is transferred to two 1/16" cherry wood sheets that are temporarily joined with tape. I didn't have a large enough sheet and it also saves me from having to cut through the middle. On Scrubbyjj427's advice, I painted the reverse side of the false deck in the areas above the two rooms to keep the light from coming through the wood. I glued the false deck in 2 steps so I could put the access ladder in place before gluing the second part. I was afraid to drop the ladder in the room if I proceeded to put it in place once all the false deck was glued.I know myself 😅 The false deck has been reinforced with small nails that will be removed once the glue has hardened. This ensures that the false deck adheres precisely to the bulkheads. Once the nails are removed, the gaps and marks left by the nails or their extraction are filled with wood filler and sanded. I also take the opportunity to finish the 2 openings located on the false deck. A final blank test of the various fittings. I will now finish the internal planking of the bulwarks. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Thank you Bob, Glenn and Mike for your kind comments and thank you to all the 'Likes'. I finished the assembly of the electric Evans Designs leds. I will then be able to prepare and glue the false deck of the ship. A small test once the assembly is completed. It works 😃. A big thank you to scrubbyj427 who made me discover these great little leds from Evan Designs in his beautiful build log of the Winchelsea frigate. The last details have been added: the open door between the 2 rooms and the small ladder that gives access to the door to the bread room. Next step: installation of the false deck. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

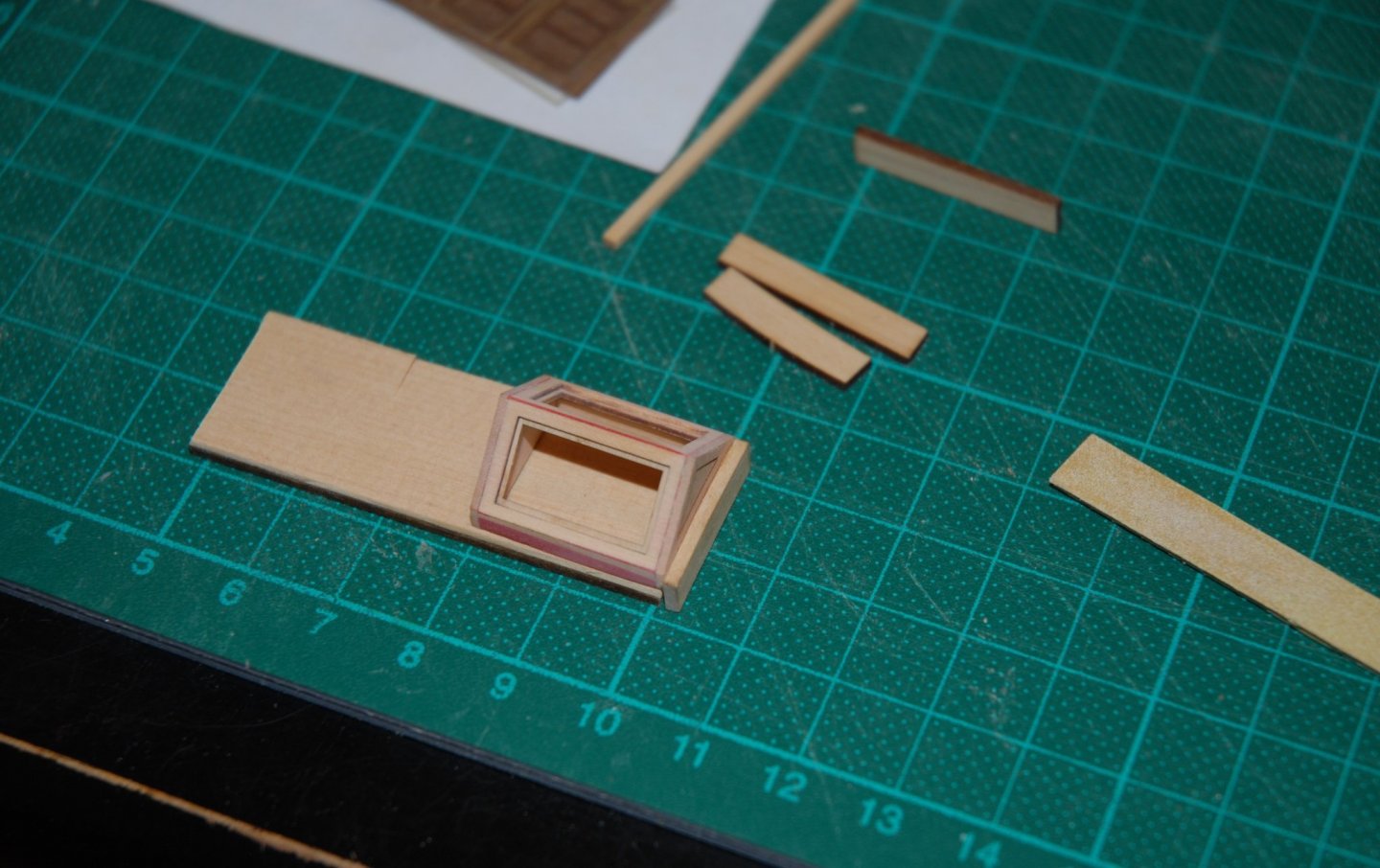

Thank you Glenn, Ron and Allan for your great advice and thanks to everyone who is following this build. I will definitely be testing for hull treenailing. I've already prepared a reproduction of the planking and I'm still waiting for my order for the drill bits (Covid has slowed down package deliveries again...) In the meantime, I am making progress on the preparation of the cutter deck. I glued a copy of the deck plan onto card stock and cut out the elements that will allow the two rooms I detailed to be seen. I still need to add tape around the edge to get the final shape of my false deck so I can cut it out of a 1/16" cherry sheet. I continued the assembly of the various fittings that will be on the deck. The gratings come from Syren and it is again a pleasure to assemble them. And finally, I started the assembly of the companionway. Since I'm going to leave the doors open, I have to be quite precise in the assembly. I quickly realized that it's not a simple cube that needs to be assembled, because I have to take into account the slope ('tonture' in French) of the deck. Reading the excellent log of glbarlow confirmed me on this question. So I quickly developed a jig to facilitate the assembly and especially to have precise angular cuts. A photocopy of the plan was made on a clear self-adhesive film. The two side pieces were mounted at right angles. They are made of 6 planks of 1/32" but are higher than the plan. I can use my jig to make the various cuts. For the height, I simply added again 2 pieces of wood at the top of the companionway that follow the slope of the deck. The result respects the plans quite well. I am trying to work cleanly because I am thinking of not painting the companionway and leaving it in natural wood. I still have to finalize the companionway by adding the open doors. -

Great job! These modified hatches are really beautiful and the choice of the black color is perfect. Happy New Year!

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Wonderful! It is always so precise and perfect!

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

A promising new project. No doubt it will be fantastic! Merry Christmas.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

As I am still waiting for a package of #78 drills for the treenailing, I decided to assemble the different fittings of the deck. They are mini projects in themselves. Again, we can only thank Chuck for the quality of these mini kits and for the precision of the assembly instructions. It's a real pleasure. Just take your time and follow the instructions precisely. What a pleasure! The windless will definitely be mounted once it has been painted. I will wait until the internal planking of the bulwarks is finished to paint all the elements at once. For the moment nothing is glued. I started to mount the skylight. Again a lot of fun to work on this element. And with the extra parts provided, no worries in case of mistakes (I had to redo one of the top frames because I managed to sand on the wrong side...) I filled all the gaps and sanded the skylight thoroughly before mounting the coaming. As usual, I tint the woodfiller in the final color of the element, which allows me to control my sanding more finely. For the coaming assembly, I put the skylight on a wooden board to simulate the thickness of the deck planking. Once this fitting is complete, I will mount the gratings. Merry Christmas to everyone 🎄 -

A beautiful model for your birthday 😃. Congratulations! This is really a great model with lots of personal details. This Fifie is absolutely a little gem. I look forward to your next model. Any ideas yet?

- 79 replies

-

- Fifie

- Victory Models

-

(and 1 more)

Tagged with:

-

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Thank you to all the 'Likes' and thank you for your kind words. Bob, I agree with your opinion on cherry wood. It is a warm colored wood. I still have to find the right color of wood filler for the treenailing. I will proceed with testing as soon as my #78 drill bits arrive. -

HM Cutter Cheerful 1806 by JpR62 - 1:48 scale

JpR62 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Thank you to all the 'Likes'. With the critical period finally over at my job, I was able to devote some time to my hobby again and finally finish planking the hull. A good step passed. 🙂 I decided to proceed to the treenailing of the hull. But I unfortunately broke the only drill bit of size #78. While waiting for a new batch of drills to be delivered, I decided to proceed with the last task producing a large amount of sawdust: to thin down the bulwarks inboard. I started by roughing it all up with my Proxxon rotary tool. Then I finished the process using various home-made tools on which sandpaper was glued. You will notice that to consolidate the planking of the hull, I coated the inside with a thin layer of woodfiller. I can now proceed to the installation of the false deck. -

What great news! A 1/4 scale POF model of a reasonably sized ship and what's more by one of the most innovative designers. I think there are many of us waiting for this moment! I'm getting ready for some great hours in my future retirement 😄

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wonderful! What care taken in the quality of the details! It is always more beautiful.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.