GrandpaPhil

NRG Member-

Posts

6,140 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

Is there any guide for scratchbuilding in card?

GrandpaPhil replied to ubjs's topic in Card and Paper Models

I used that tutorial to build my Prince de Neufchatel from card (my build log is one of the card builds mentioned). Ab Hoving does an amazing job of explaining how to go from plans to model in card. The part about translating line drawings to keel plate and bulkheads also applies to wood. -

Newbie just starting needing help

GrandpaPhil replied to NomaD7801's topic in New member Introductions

Welcome! That kit looks like fun! -

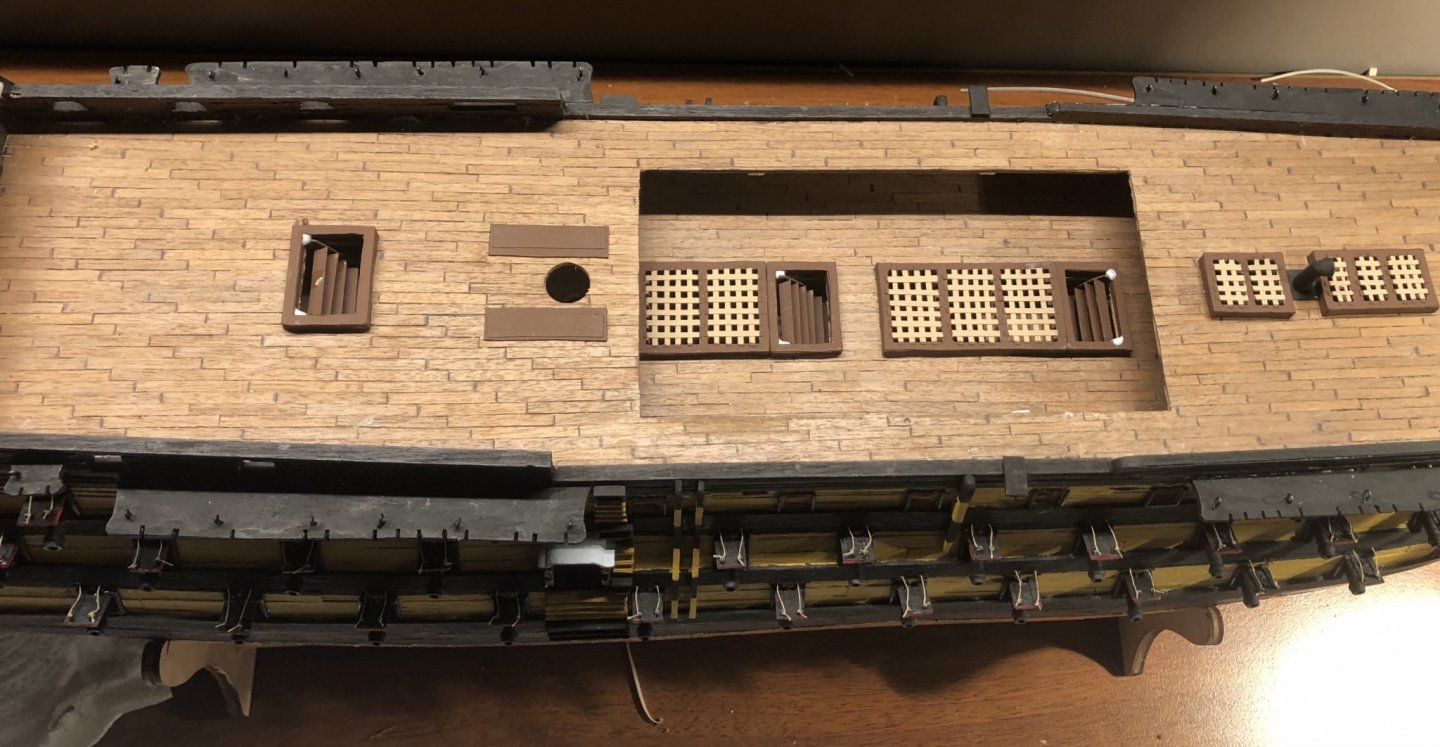

That looks like a good selection for the future. I am also trying to finish my Victory this year. I also have the Bellona and Granado planned for sometime in the future (although mine will be from the AOTS plans, probably in 1/72 scale). I look forward to seeing your progress on your various builds.

-

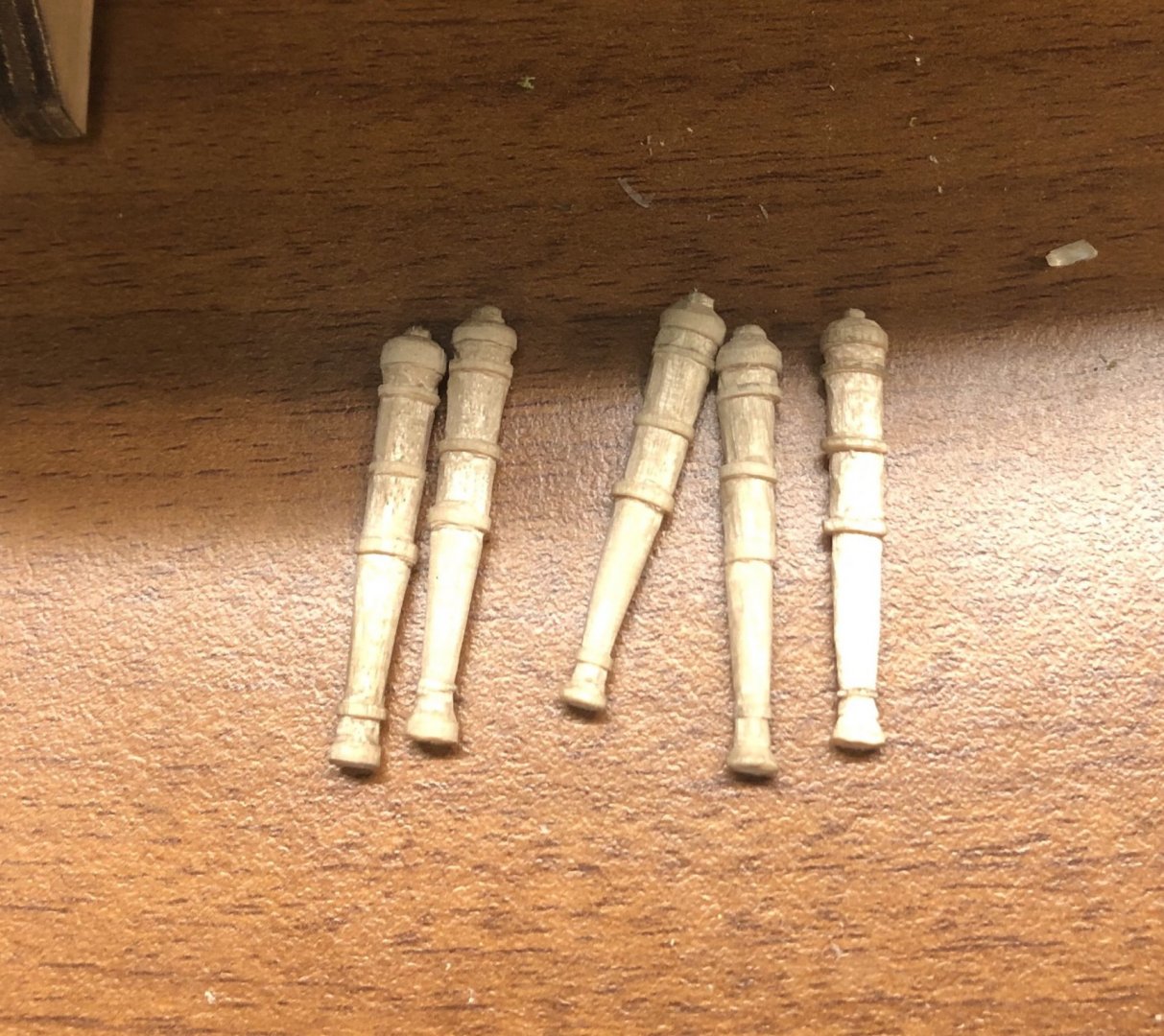

I made my fourth cannon. It’s actually the fifth, but I threw one away because I used a dull blade on it and it split out on me, beyond what I can repair. I put a scale next to them. I integrated the cascabels into these, unlike last time, where I glued a seed bead onto the back end of the cannons. Quick note: I am using a scalpel to carve dowel rods. These are not turned.

-

Just starting, in Boothbay Maine

GrandpaPhil replied to S Gottlieb's topic in New member Introductions

Welcome! -

Rafale by CDW - FINISHED - Hobby Boss - 1:48 Scale

GrandpaPhil replied to CDW's topic in Non-ship/categorised builds

Excellent! -

Welcome!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.