GrandpaPhil

NRG Member-

Posts

6,161 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

Help with tapering

GrandpaPhil replied to N1ckel's topic in Building, Framing, Planking and plating a ships hull and deck

Yes, and stealers. I used them on my Revenge and they looked really good. It seems really difficult, but after the first few, it gets easier. -

I typically use an overhand knot.

-

1/16 inch basswood makes excellent planking material. If you are in the United States, it can be found pretty cheaply in the woodcraft sections of Hobby Lobby or Michael’s, along with most hobby shops. I have seen it at hardware stores such as Menard’s and Lowes too.

-

I just got an email flyer from @OcCrediscussing the Great Eastern. Are they making a kit of the Great Eastern? That would be very cool if they did, since the Great Eastern is a popular topic.

-

Congratulations! Very nicely done!

- 87 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Ahoy from Southwest Arizona

GrandpaPhil replied to CaptainBlackbeard's topic in New member Introductions

Welcome! -

Bob, Gnomer is doing amazing work! Your King of the Mississippi is looking great!

- 87 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 2 more)

Tagged with:

-

The on the model paintwork is done: Next up, I am going to seal my work in and make some “decals”. I am hand painting the “decals” on regular paper and then sealing them, prior to cutting them out and installing them. I cut some 1/8” wide strips of paper to make the stripes from. I just need to paint them and seal them prior to installation. Card modeling has been very informative for me and has helped me develop my skills tremendously.

-

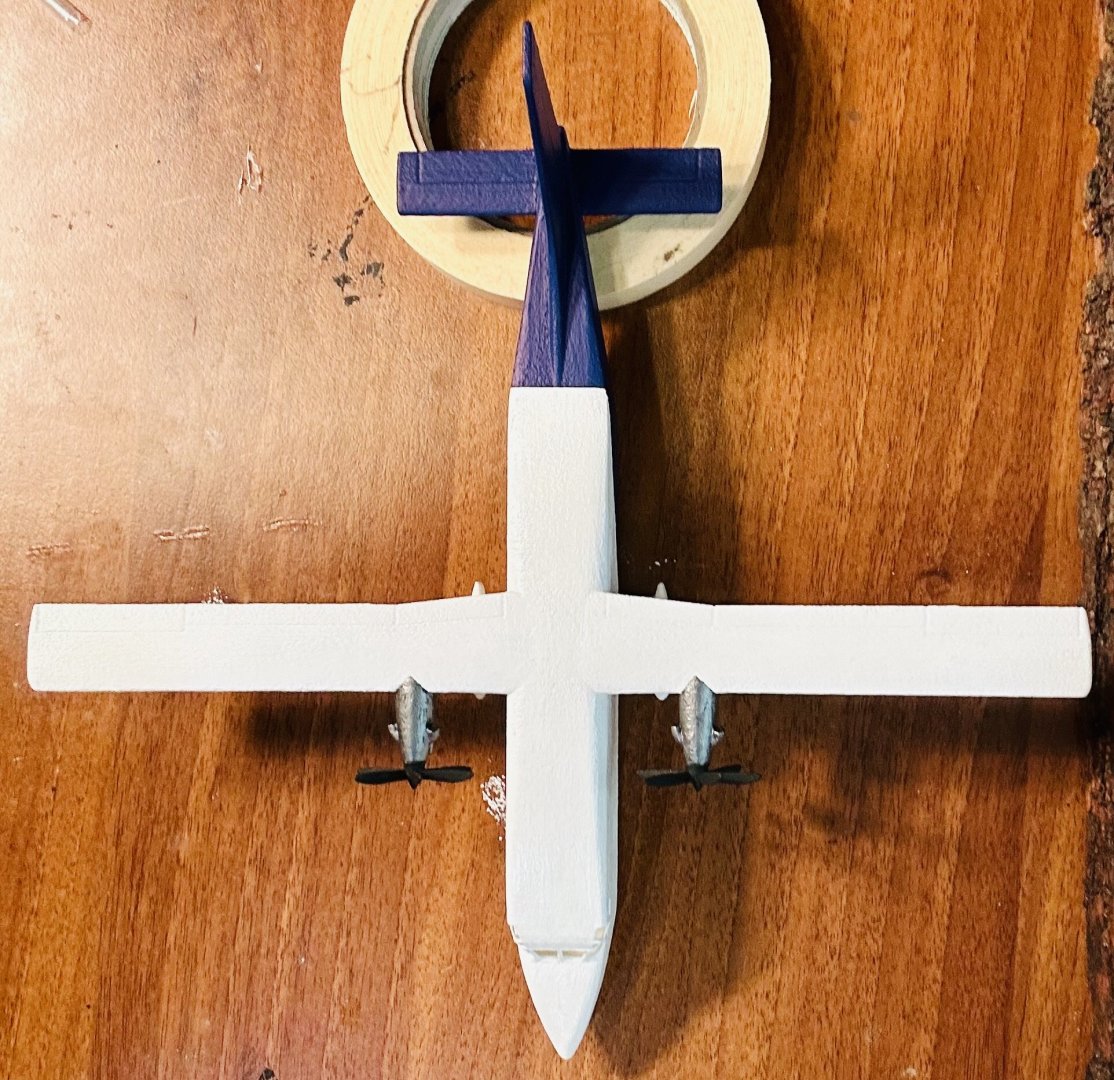

I haven’t gotten a lot of modeling done lately. I discovered the Uncharted games and have played through the first two games. I’m half way through the third one now. I picked back up on this one: The wing supports and props are painted. The engines are base coated and are awaiting drybrushing with a gunmetal color. I figured out how to do the light blue stripes. I’m going to precut strips out of paper and paint those. Then just glue them down. Painting civilian stuff (like aircraft) is like painting High Elves or Eldar (from the Warhammer franchise), it’s very clean cut and not roughed up like most of my models.

-

I remember the instructions in the Heller kit being quite excellent. They are (or were) in French though. Be careful, the French word pont means both deck and bridge. Google translate will translate it as bridge. That caused me some confusion back then.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

Aloha from North Carolina

GrandpaPhil replied to Charles Roseberry's topic in New member Introductions

Welcome! -

This model was one of my absolute favorite builds! You will enjoy it! From my building experience (granted from 2007-2008 time frame), I would recommend swapping the masts and yards out with wood. AAMM has the plans for La Reale: https://boutique.aamm.fr/plan-reale-de-france They are most excellent and ran me about $50 shipped. I bought them to build another La Reale, one of these days. I am looking forward to seeing this build!

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.