-

Posts

1,528 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by VTHokiEE

-

Thanks Rusty. I purchased a sheet of 1/4" AYC from Syren ages ago but ended up not using it. I decided to mill all the pieces for the first version of the keel from that stock - so I have plenty of wood at the moment. I'm currently thinking that I will build a second one and then decide which I prefer before moving forward. I don't have my building board yet, nor the screw/tap set for the keel so I'm doing a little waiting either way. I appreciate the tip druxey. I'm going to have to ponder this and do some experimenting - it is sound advice but I'm concerned about my ability to execute 🙂

-

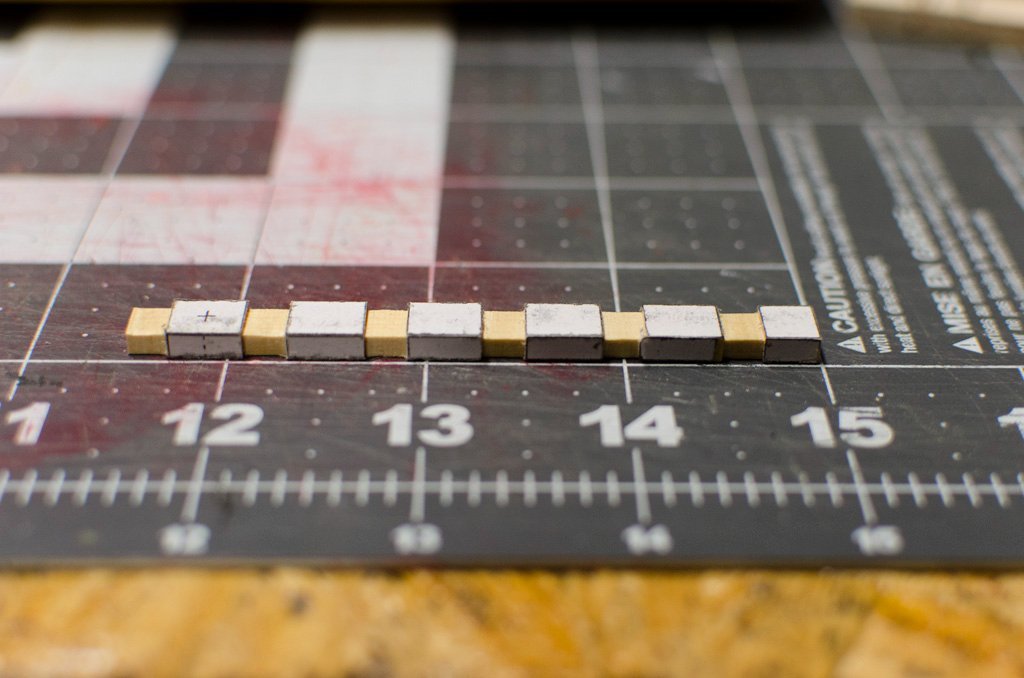

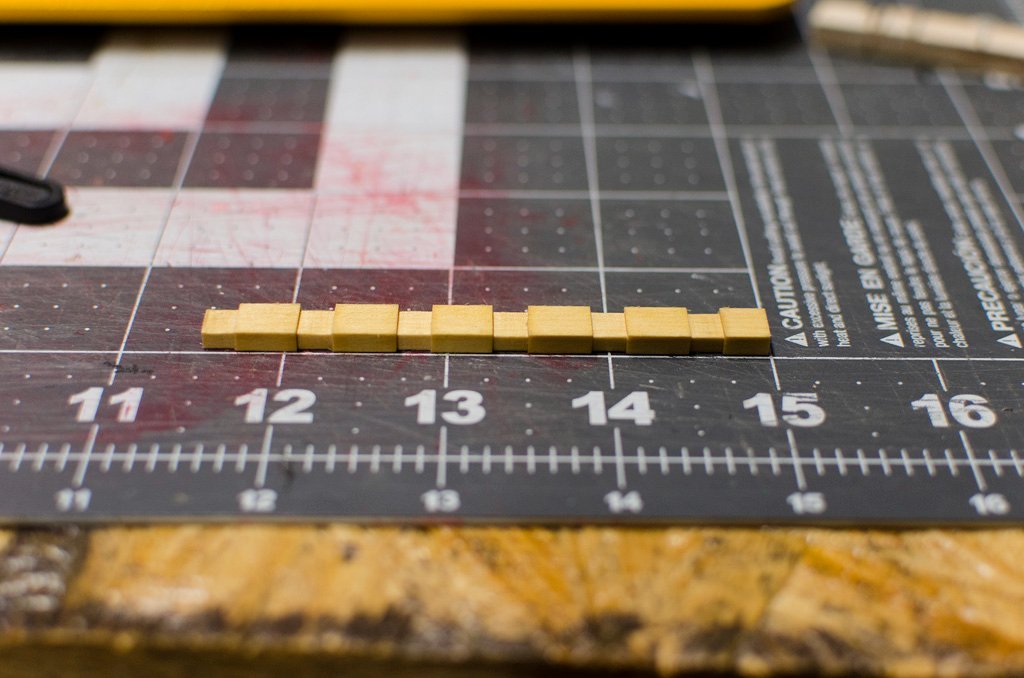

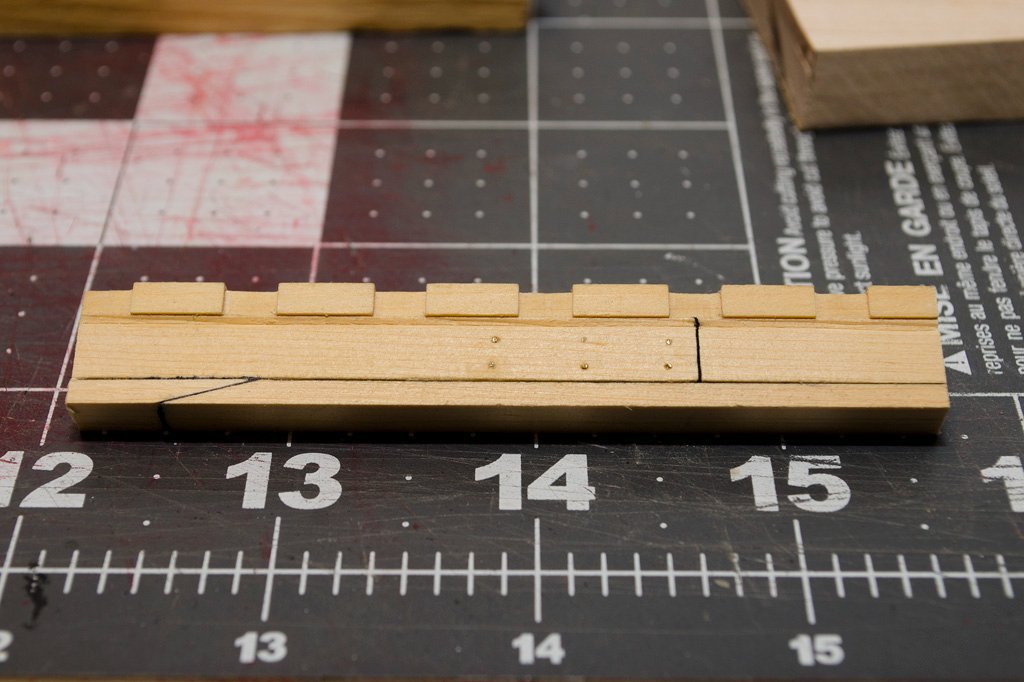

Keel V1 is complete (and I apologize in advance for all these photos, my flash is fighting the overhead florescent tubes and it is very difficult to balance). I decided to cut out the optional rising wood - mainly because I thought it looked cool and I wanted to play with my saw more. I think I'm most proud of this piece. The few things that could be improved upon are The Harris cut joint is entirely the wrong place according to the plans. I'm not entirely certain how I moved it too far back, but I did. I'm also not certain that the location of this joint is really a critical detail (for me at the moment). The bolts aren't exactly aligned. I don't have a drill press and did the best I could with a small 3D printed station that I had tinkered with awhile ago. Sadly the drill for that is not really aligned and it shows. I think to improve upon this I need to buy a drill press and I'm simply not certain that is in the cards right now. The tarred flannel - I used black tissue paper and in one area, by the Harris cut joint it is rough (maybe I can sand a little bit there to clean it up). All in all I'm happy with what I've accomplished, but I'm not certain if I should try to salvage the rising wood and try again. Any thoughts?

-

Did you use wood glue? If so isopropyl alcohol will allow you to remove the planks. Be care to apply it where you want though so you don’t break down the glue holding other areas. It can be a slow process but it gets the job done.

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

This reminds me of a Calvin and Hobbes comic, from their Yukon Ho adventure. Calvin and Hobbes are looking at a globe trying to decide how far away from the Yukon they are. After Calvin finds the Yukon on the globe Hobbes remarks: "Look how close it is! This won't take any time at all!"

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I love the boxes! We have a chess set that I would like to find (ideally build, but who knows) a box for the pieces. I may have to send you a PM to see if you can get me pointed in the right direction. Back to the model, I can see why you'd be frustrated with what you have. If you added a false deck you'd want to also buy some thinner planking stock to account for it as well. If you're willing to redo you might want to contact Joe at http://www.modelerssawmill.com/ he put together a custom wood package for me and might be able to help you out as well. It's very tricky to get in the right mindset for a redo on something so substantial but I would consider it. I've never done this (and I don't think it cane fully flatten that deck), but have you tried scraping the deck as an other option? Keep your head up though!

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

You're doing a great job so far! I'm always impressed with solid wood hulls - for whatever reason trying to shape it seems quite daunting but you've done an excellent job. I had to laugh about the sanding tips, solely because so often someone else mentions an improvement on my technique and I can only go "Hmm, I can't believe I didn't think of that simple change that makes this so much easier/better/etc - I'm an [fill in the blank]." At least your experience with 1:1 woodworking hopefully means you know how to use your tools unlike myself 😂. Keep up the good work and have fun!

-

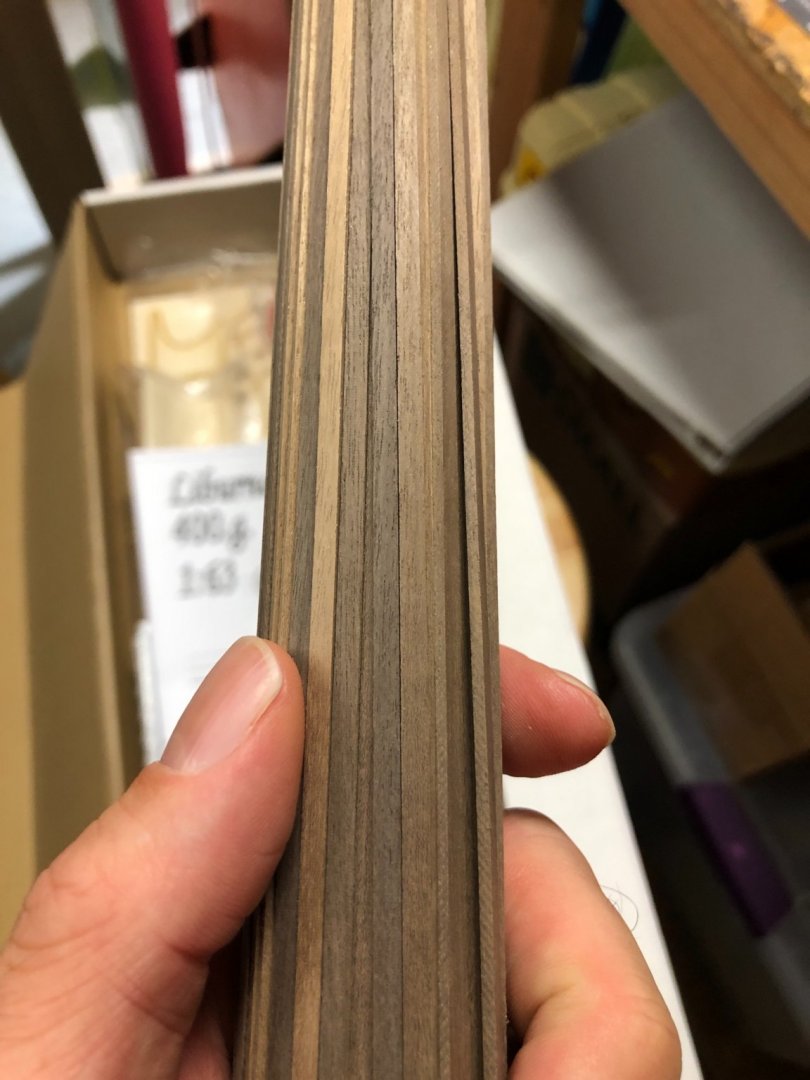

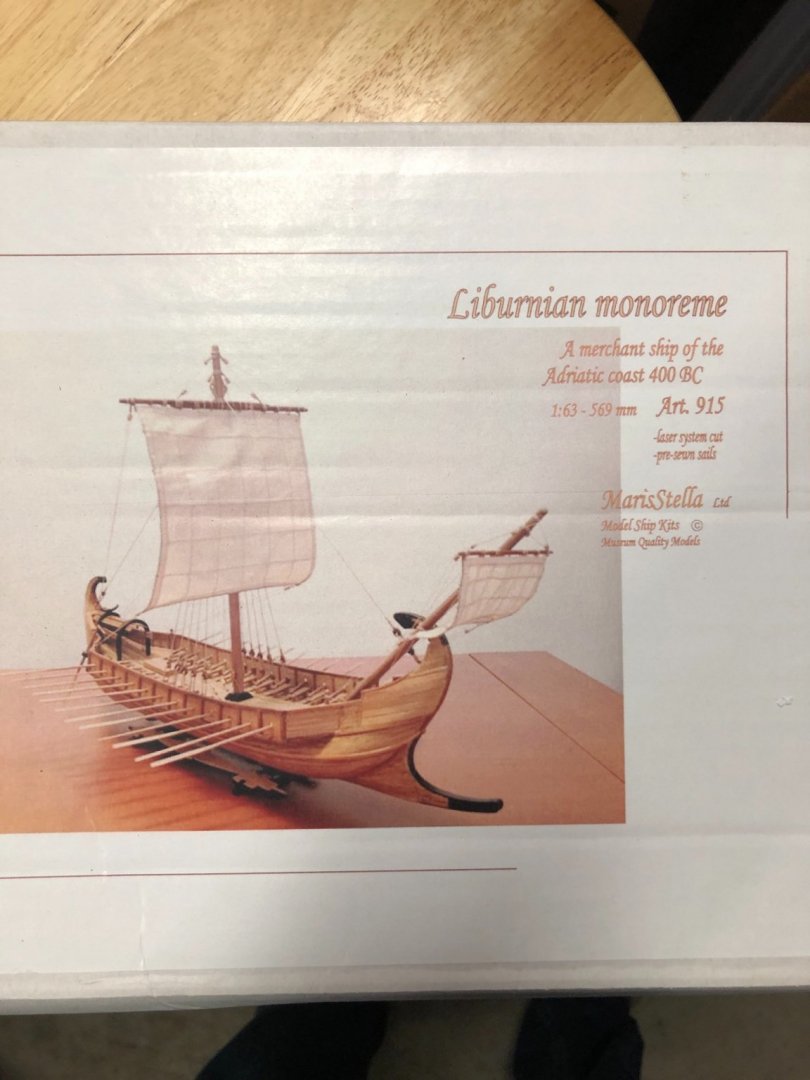

It’s the Liburnian Monoreme (I was supposed to be building it now, but the siren’s call is unavoidable). Unfortunately I can’t be of service for Britania pieces as this kit has none. I do suggest taking care when ordering (from wherever) as Maris Stella has upgraded many (all?) of their offerings. They were very responsive to my emails when I ordered this. The laser cut bulkheads are done in a nice plywood and the strip wood is all walnut. The walnut seems okay, but I’ve never worked with it before and have no good comparison. My kit also comes with some balsa filler blocks that may also be laser cut (or at least outlined). Here are a few pictures if they help at all. Feel free to send me a PM is you have any real detailed questions that I might be able to help with.

-

I have a Maris Stella kit in my stash, that I can take a peek at for you - main interest quality of wood and fittings?

-

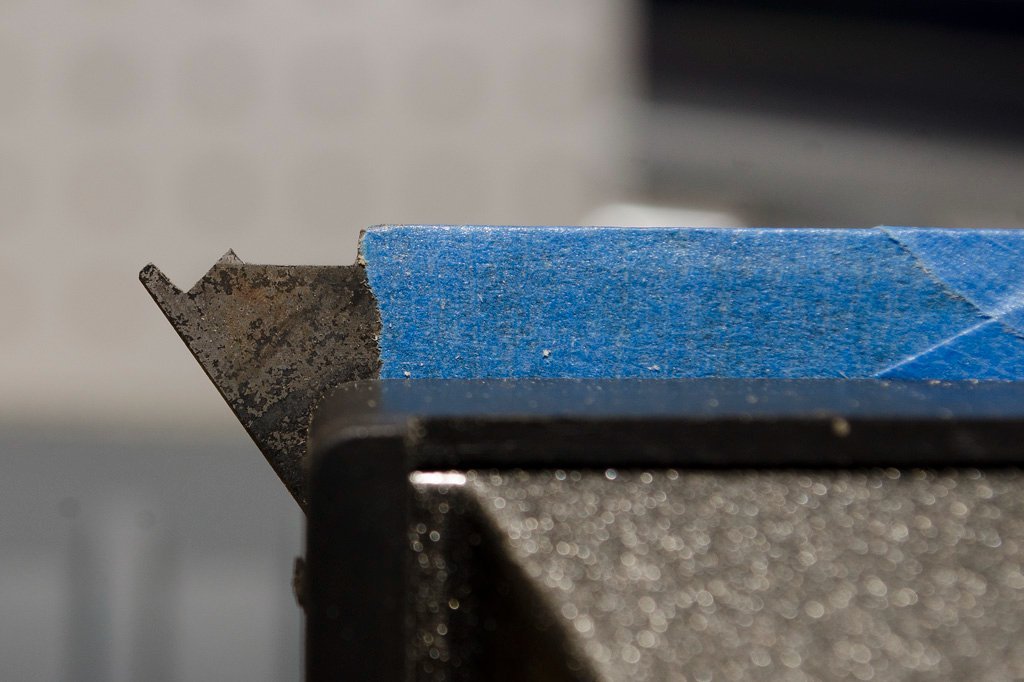

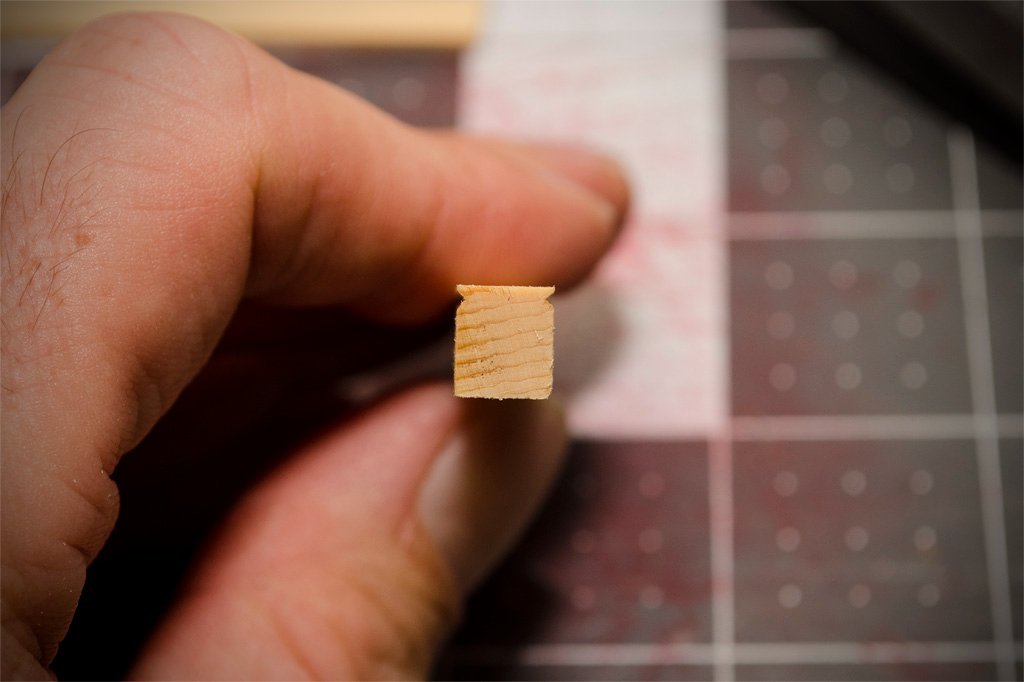

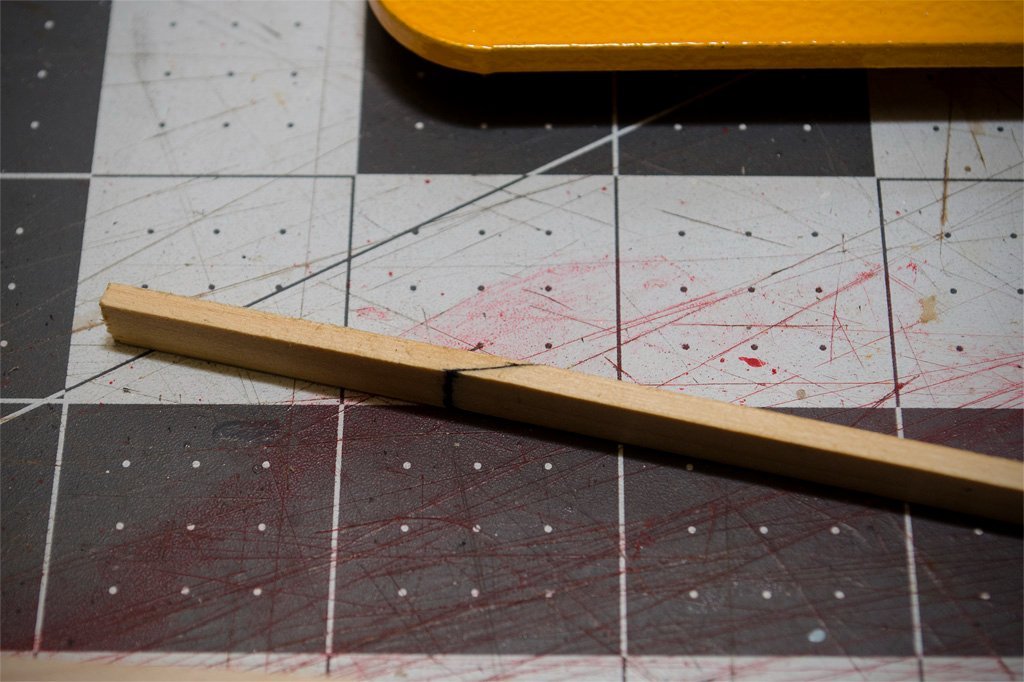

I'm quickly learning how little I know about using the tools I have. I have to greatly thanks @Rustyj for telling me how he cuts these joints. Long story short - use a higher tooth blade. I bought a 90T slitting blade with my byrnes saw and it sat happily in its box until I learned this (which then meant I had to learn how to change a saw blade... slightly embarrassed to admit that I needed to learn how to do that). After changing the blade I had a much easier time making the keel joint. That lead me to my tool that caused me heartache - the dreaded v gouge to create the keel rabbet. I'm pretty certain I have enough scrap wood from trying to learn how to freehand gouge a rabbet that I can heat my house this winter with it. At the end I came to the conclusion that I'm not great at making a straight line freehand, so I decided to try another method - making a scraper. This scraed me because I had never done such a thing, but in the end it really wasn't that difficult. I heated an only utility knife blade to red hot and let it cool, taped the pattern to the bladed and filed away. After I heated the bladed back up and cooled it quickly (I believe I saw that hardens it again?). You can see the corner isn't quite as 90 degree as it should be, but I was happy. After a few practice runs I was able to scrape out a rabbet much easier than using a gouge. If anyone is having an issue with carving and a scraper could work I highly suggest trying to make a scraper. Now to figure out how to do the false keel - a seemingly easy task, but back to learning my tools. I didn't properly set my wood making the cut so it as at a slight angle and then gluing paper in this joint failed to make a bond. I'm contemplating trying paint or maybe even sharpie marker 😬 to simulate the tarring here (we'll see how it goes). The image below is untrimmed paper that I couldn't fully remove with sharpie on a few edges - it needs to be cleaned up and won't be the final piece, simply a test. Please don't hesitate to point out any issues you see. I think I got it right, but I'm all ears if you see something that I missed.

-

Good luck and enjoy it!

-

I understand that sentiment; what are your expectations on how long you would like a project to take? I'm somewhat of a slow builder and it took me just over a year to complete the Alert. If you're looking for a smaller project than I would certainly consider the working boats for a first go.

-

I realize it is more expensive, but in this situation I would consider building the Alert. It can help your drive to continue and correct if you're building something that you really want. I do like his working ships and they would be a great choice as well, but if you want cannons you want cannons 🙂

-

Nicely done B.E. I will say that one of my short term goals is to acquire as many small clamps as I see in your build log - you simply can never have enough.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Glad to have you along! I think that you’re probably right in this regard (especially regarding the framing). I’m really enjoying your build btw - great work. I’ve been casually researching this option (I say casually because I frequently end up staring at the proxxon MF70 working if I could press that into service for a lot of things as well). I may have to pick your brain about what exactly you ended up with (especially if my 3D printed mini drill press doesn’t cut it when I try to add the bolts to the keel).

-

I recall a build log, but the owner is escaping me, who added a cutout frame section (similar to the confederacy kit maybe?) that looked really cool. Anyhow, I’ve got my eye on your log when it kicks off in earnest. Ha! It truly isn’t that clever but you may live on the wrong side of the country to figure it out. Great suggestion, I currently am overflowing the tabs in my browser with cross sections logs 🙃. Your log is a great one that I hope to use extensively and since you offered be warned the chances of me taking you up on that are quite high.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.