-

Posts

1,528 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by VTHokiEE

-

Echo by tlevine - FINISHED - Cross-Section

VTHokiEE replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

Great work! I'm glad to see you back at this build (mainly because I started it recently and hope mine comes out somewhere close). I appreciate you listing what wood you used where; I think the combination looks very nice.- 52 replies

-

That’s good news it sounds like! Glad to hear that you’re taking another swing at it. For me everything seems a little more bright in the morning. Looking forward to round 2.

- 79 replies

-

- SD 14

- Marcle Models

-

(and 1 more)

Tagged with:

-

Looks very nice. I'm starting to think I need a more efficient printer as my next tool given all the templates I've been using and seeing how many others are using.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Closing in on the finish line for the dead flat. So treenails, using a Bynres draw plate I was able to get a bamboo BBQ skewer down to a 0.018". This took me a little while to figure out. After several failed attempts I built a jig (see here) to slice down the skewer to small sections to get through the largest hole (remember to pull through the flat side - found that out after an attempt or two). Then pulling several times (at different angles) through each hole I slowly stepped through the plate down to 0.018". Then I made a few treenails to see what it looked like in a test piece (old scrap version). This picture is right after I applied some WOP and the side on the right lightened up after drying (but showed the difference in grain for each piece). The left side is the better side (the right was my first attempt and had too much glue). My question is what is an appropriate spacing or placement for the treenails? How close to the top of the piece should they be? or how close the side? I'll look through some other builds so see if I can find some good pictures, but they can be a little hard to see. Thanks for any advice!

-

Dave - have you seen my Alert build? Specifically this post: My planking was a mess, so I ripped it off and re-faired (if you need to add material you can its wood and fair again). I don't think you are that far away and as someone who was there before I got very disheartened, thought I'd never complete the kit (all the woe is my things I could think), etc. Everyone here helped me through and I know you can get there as well.

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

I did this and can confirm that I was much happier in the end.

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

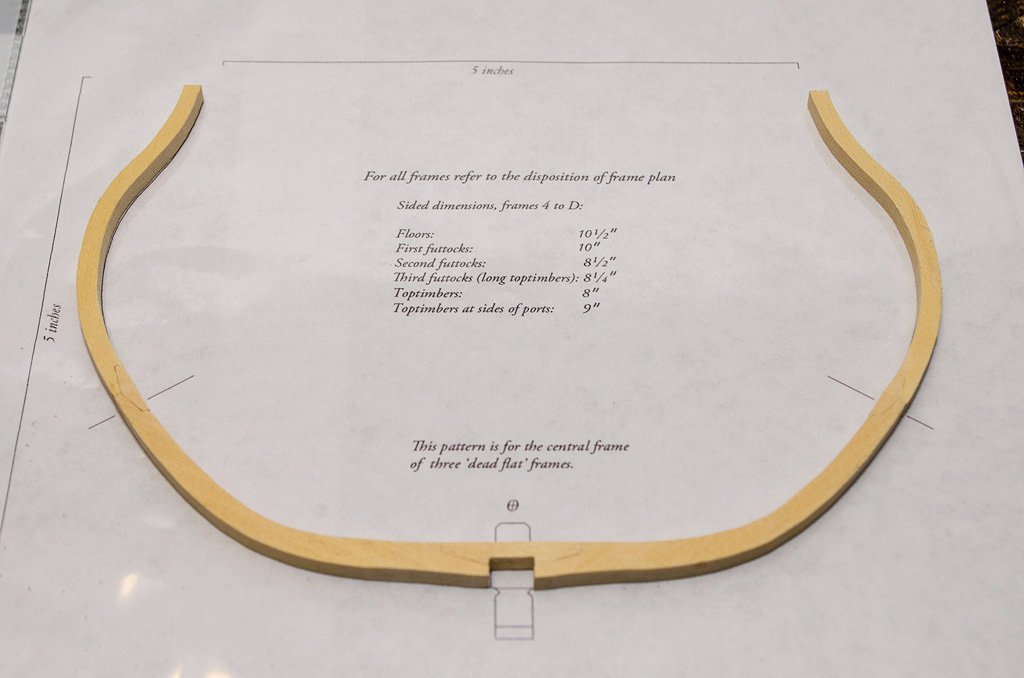

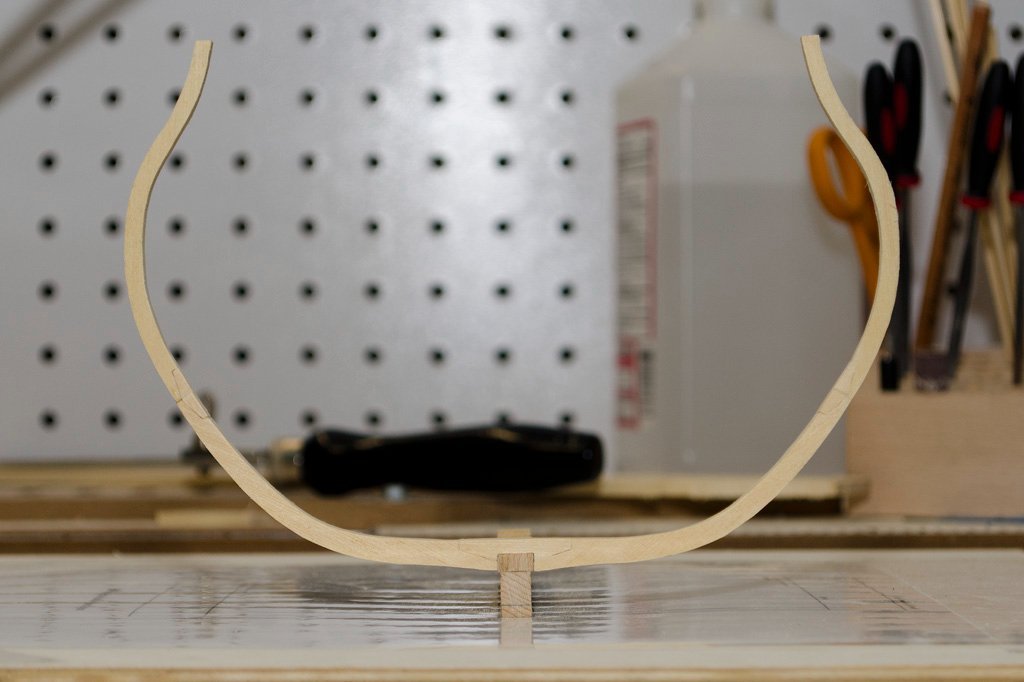

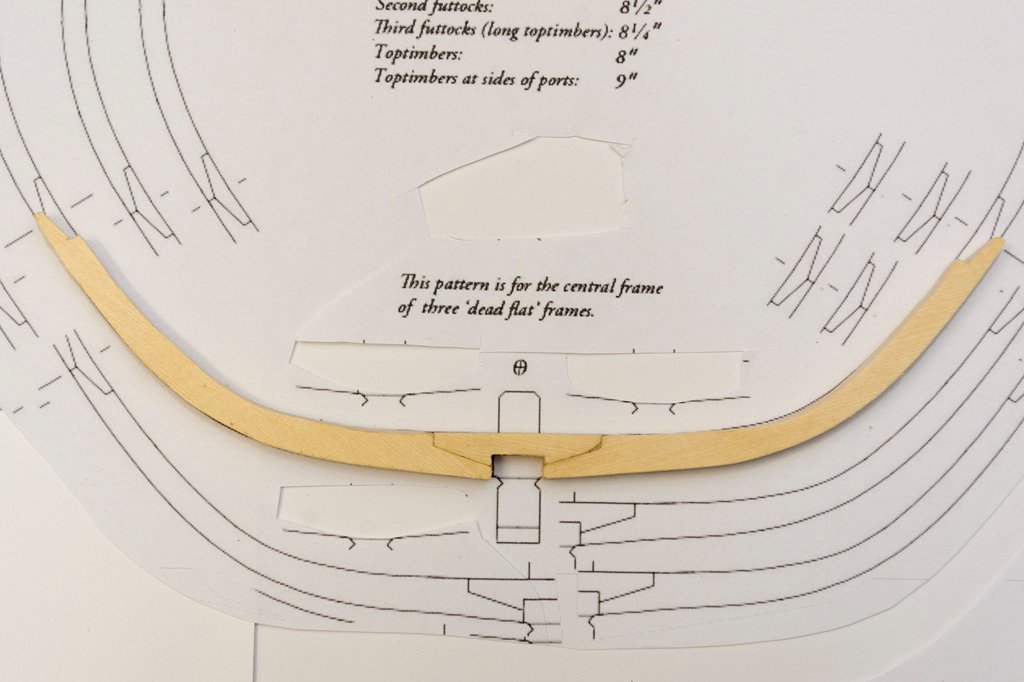

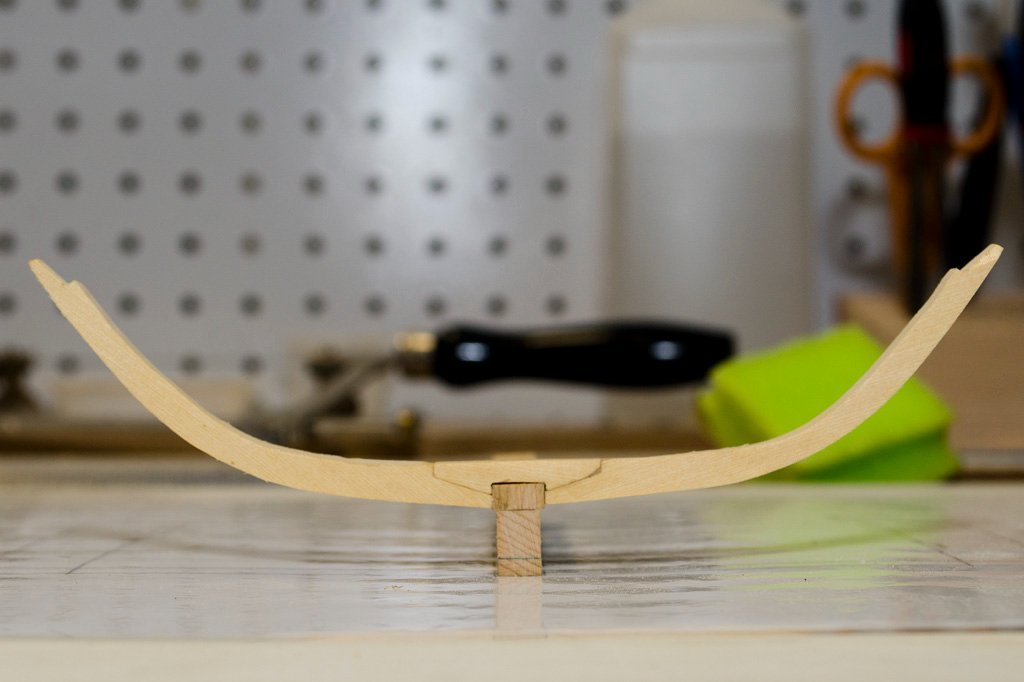

A belated Happy New Year to everyone following along! Santa was generous this year and I found myself with a Proxxon MF70 under the tree. With any tool (at least for me) there is a learning curve and I have spent some time becoming acquainted with my new toy (before this is all said and done I imagine I'll be making another order for cedar from Joe). I finally was able to get a (slightlyt) improved start on the dead flat and I think I'm ready to continue on. The mill is nice, it certainly is helping speed along sanding the internal curves of the frames, but my first attempt (in post 91) wasn't that much worse than where I'm currently at (but it certainly is a fun toy and I'm excited to have it).

-

Nice work the stern (and love all the colors in your pictures - I think I need some neon tape). Happy New Year!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I unfortunately don’t know but try sending him a PM on here directly @jimbyr he’s typically been responsive on here.

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Have you given any consideration to painting the coppered area white? You’re doing well so far; keep up the good work!

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Do you have any recommendations on this? Anytime I consider a lathe I spin out of control on what if’s.

-

Great looking model so far! I agree with dvm27, they jump out too much for my personal taste but if you like them then by all means keep them.

- 475 replies

-

Finished up very nicely; I like the mounting and label. Can’t wait to follow your capstan build!

-

I also have significant interest in a POF model - it's a goal that I thought I would have to scratch build my way into honestly (hence my current path).

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

According to the site it goes from 0-1 inch (http://richardkell.co.uk/honingECom.htm) Thanks @EricWilliamMarshall I ended up ordering the kell guide - I don't trust my freehand at all. I'd love to know about the books; I have a ton of stuff to work through as my supplies start arriving but more information can't hurt (hopefully).

-

Thanks @druxey and @dvm27, all great advice (I had been trying to take too much wood off at once and having a better stop under should help). I was about to purchase a sharpening setup based up the beginning of TFFM Vol 1 - with the veratis water pond, two grit stones, etc. Would you suggest your method to someone with minimal sharpening experience? Or do you recommend that I stick with the water stone method?

-

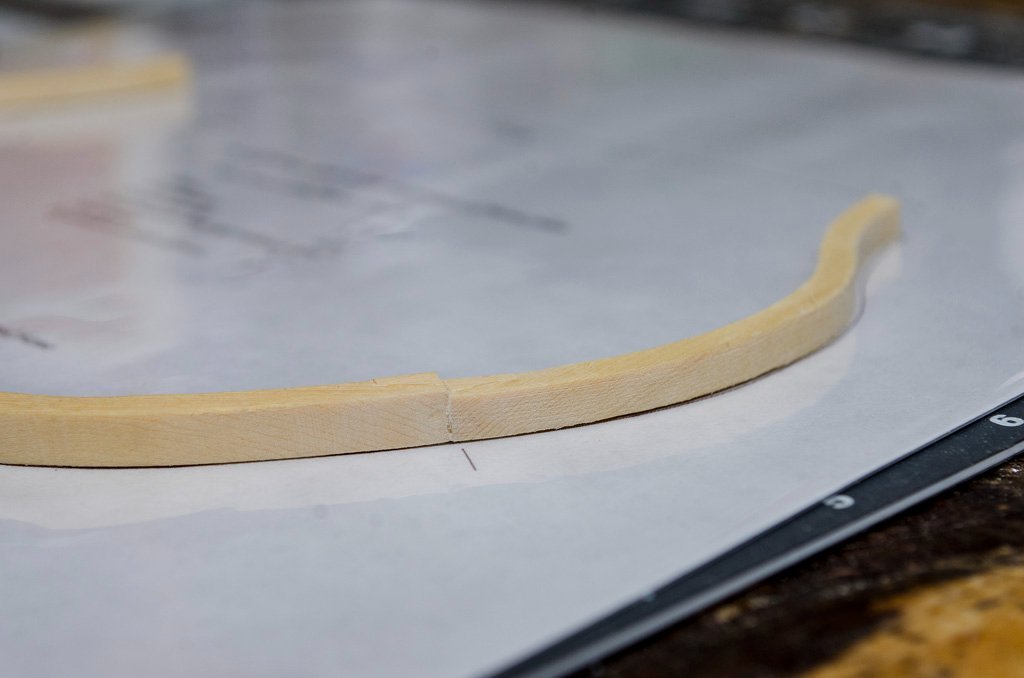

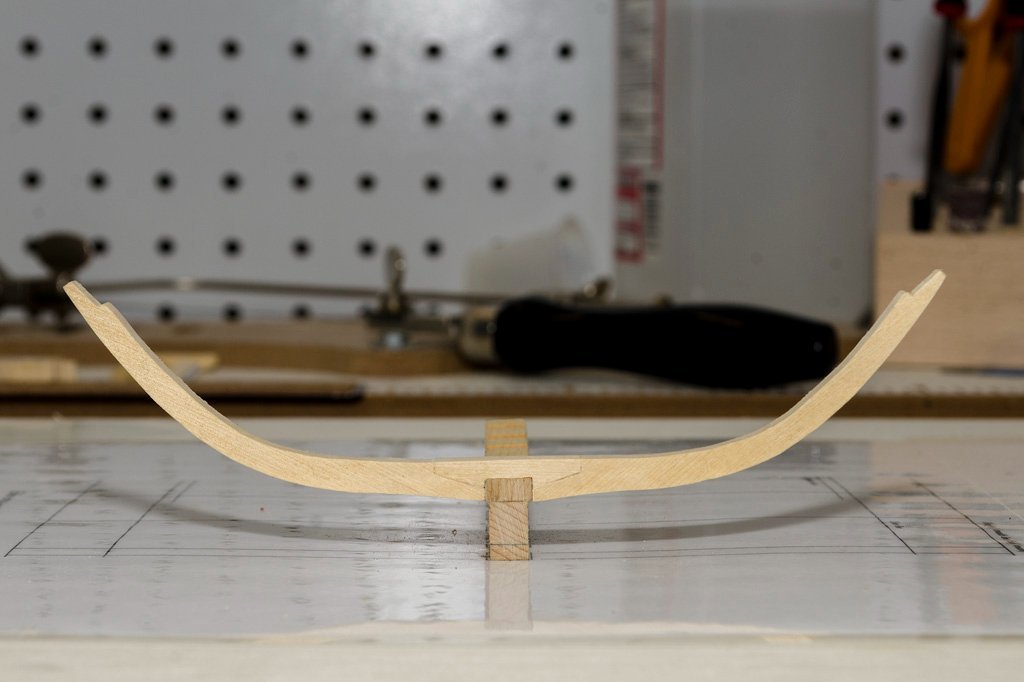

Mill shopping was a fun diversion and thanks for the tips - I'll be certain to do some reading and probably keep a look out for the vice - I think the dividing head will wait until I need it (given the price tag). Any other tooling that would be useful right out of the gate? Back to the build - I'm not the type to sit so I have been working on cutting out frames and finally glued up a portion of the dead flat (fyi - these are scrap parts but I wanted to see how things looked put together to see how I needed to improve). I already knew they wouldn't make the cut, but I am a little encouraged by what I see (I currently feel in over my head). My take away is that this was close (but no cigar) and hopefully I can close the gap without wasting too much more wood (but I'll be doing my part to keep the lights on at the sawmill 🙂. Without enough sharpening my chisels are breaking the other side on the wood instead of cutting it which is causing me issues (I will probably resort to files until I get a sharpening setup). I'm also struggling to get a nice sanding in on the frames - hopefully practice will improve that.

-

That stern decoration looks very nicely done.

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks @bartley not a bad suggestion. I broke down and picked up the MF70 though - I can’t quite justify the larger price tag for a bigger mill yet (and space is unfortunately a bit of a constraint). Of course it is a Christmas present so I still have a month to see what I can do by hand before trying to learn the mill. I misunderstood specs (I thought it would be significantly smaller) and picked up a 3.25 tilting angle vice that I think will be way too big for the MF70 so I may still keep an eye on a drill press if I need to drill some angled holes (or if I really enjoy the mill I’ll need to figure out how to get a larger one that the vice could sit on).

-

Is this it: https://cafmodel.com/products/hms-barge-40

-

@glbarlow and @Rustyj You guys are killing me and breaking down my resolve. How am I going to sand my frames with the mill 😂? Sigh decisions decisions maybe if I do the drill second hand but that seems to fill a more immediate need. I do have two of those files actually (had forgotten about them at the moment though 😬).

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.