-

Posts

1,528 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by VTHokiEE

-

Really appreciate the commentary on this post. Especially how you adapted to allow the least amount of future impacts. It was relatively small, but quite eye-opening for me - thank you! PS - Beautiful work by the way

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Depending on how much you need to manipulate the cap rail while the glue is drying you might be able to get away with blue painter’s tape as a clamp, just a thought. Looking good so far! Keep at it!

- 44 replies

-

Awesome job! It looks great! Unfortunately I have no idea about the scale of the anchor and such

- 100 replies

-

- pauline

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Thank you, I appreciate that. I've found that it works pretty well for me, I tried a method or two similar to your plate and spring method but I wasn't very successful. It looks like your coils in the background are coming along quite nicely so if you have a method that works for you keep at it! Good work on the build so far, enjoying your updates.

-

Rigging the cannons can be really time consuming, but it is all part of the journey. I don’t know if this method will work for you or not but I make my coils on the sticky side of painter’s tape. I coil them by hand and then either use diluted white glue (if cotton rigging) - still trying to determine the best option for synthetic (maybe varnish?) to hold the coil. After they dry I pop them off with a small scrapper and attach them on the model. I think I have some pictures from my Alert build. Let me see if I can track them down… hope it’s useful in some form or fashion. Edit: Found a picture from the prior build:

-

@dvm27 and @iMustBeCrazy Thank you very much for the picture and the detailed explanation (apparently I learn better from pictures than words - once I saw the picture everything started aligning in my brain). I've been spending some time in TFFM Vol.1 as well to see these chocks. I don't have a tilting vice yet for my mill so I think I will have to take the chisel (or maybe even filing approach).

-

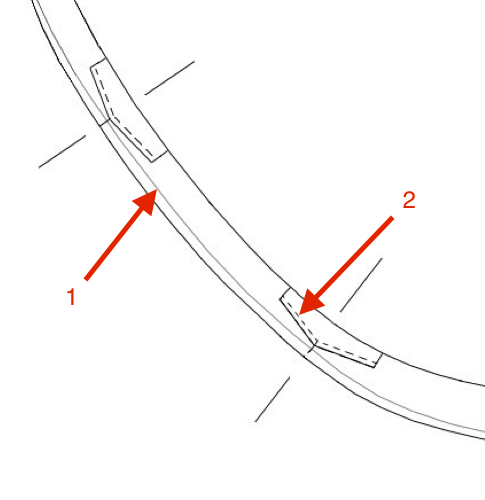

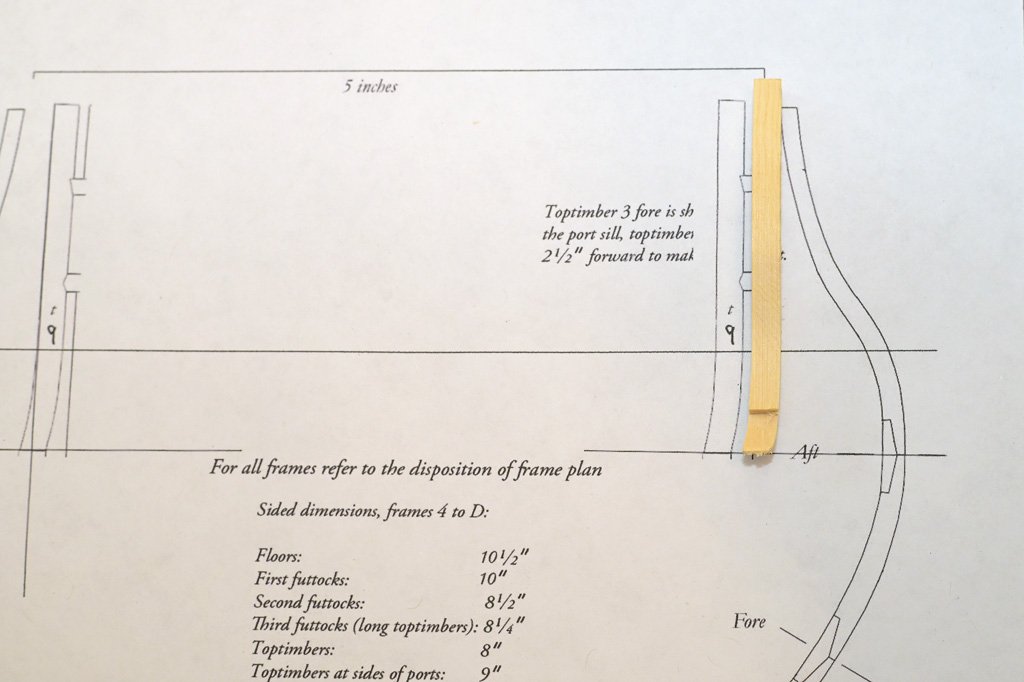

Frame 3 is done and dusted and as I move on to the next frame I was wondering if anyone could help me understand what the "extra" lines in frame plans 4 and 5 are (highlighted below on the plan for frame 4) : I read through the framing instructions, power point and several build longs and found the following explanation from Greg on a build log: "The chocked joints become angled as you progress towards the fore and aft hulls. Note the dashed lines in frames 4 & 5 on the plan. Otherwise the fairing process could break through the face of the chock. However, this angle is so slight on the cross-section section we have chosen it's not really an issue." Unfortunately I don't fully understand what I am supposed to do differently when building these 4 frames. I assume I have to do some angled fairing on the aft side? If so would this be more easily accomplished during fairing? Thank you for any help and insight.

-

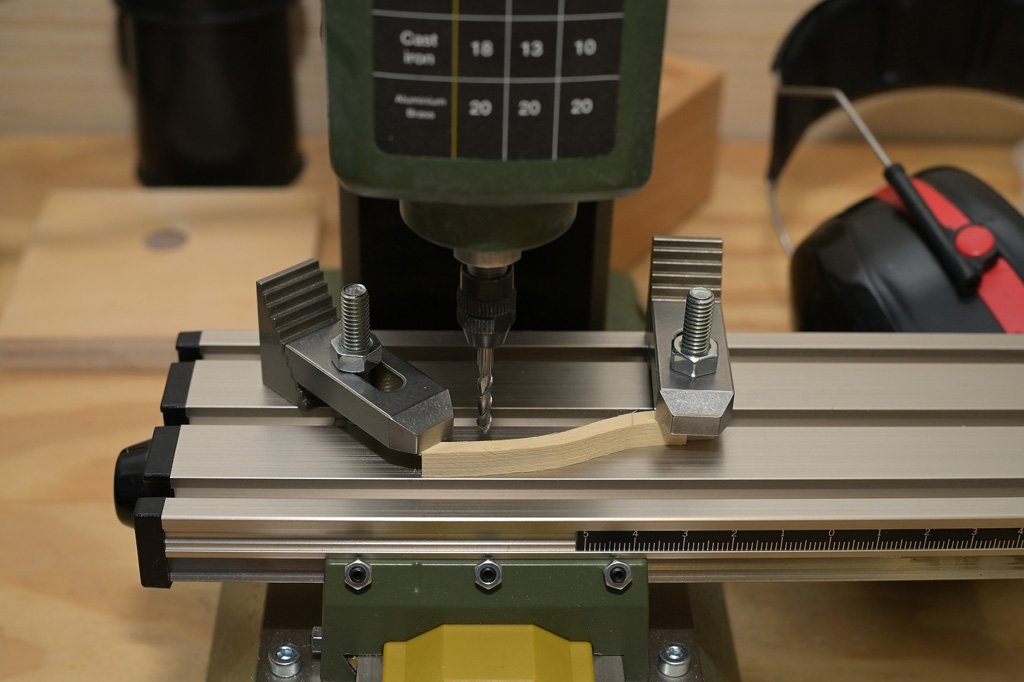

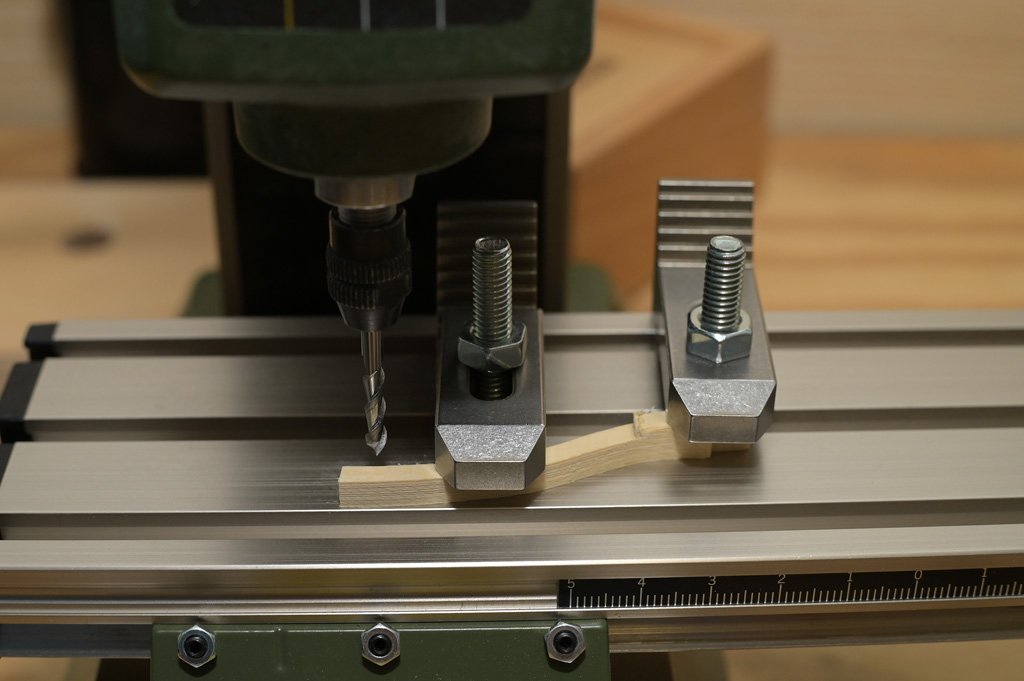

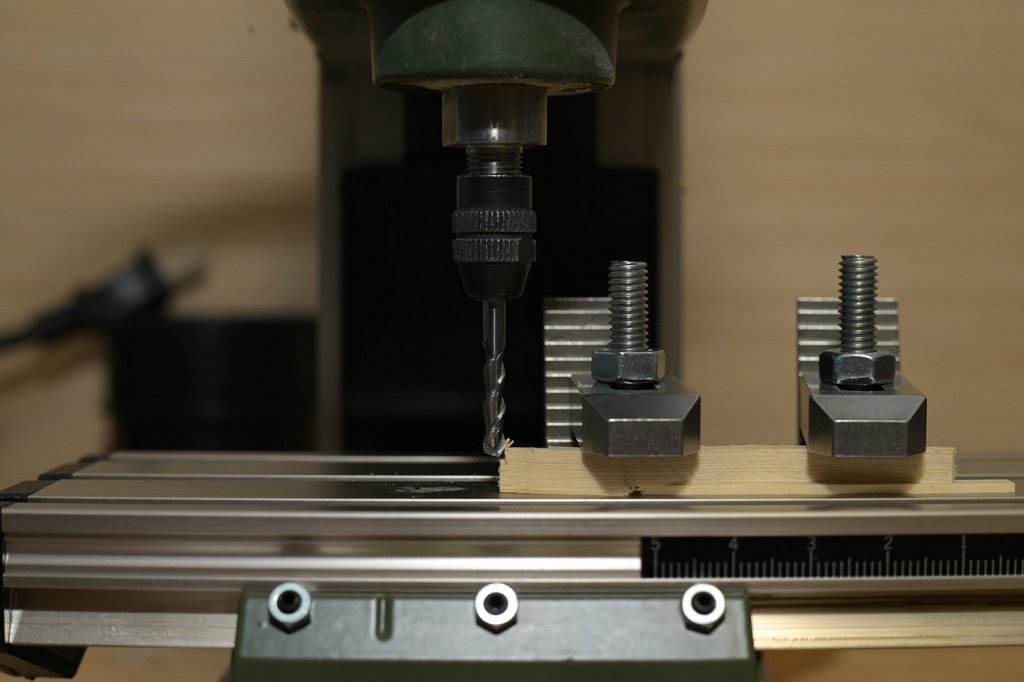

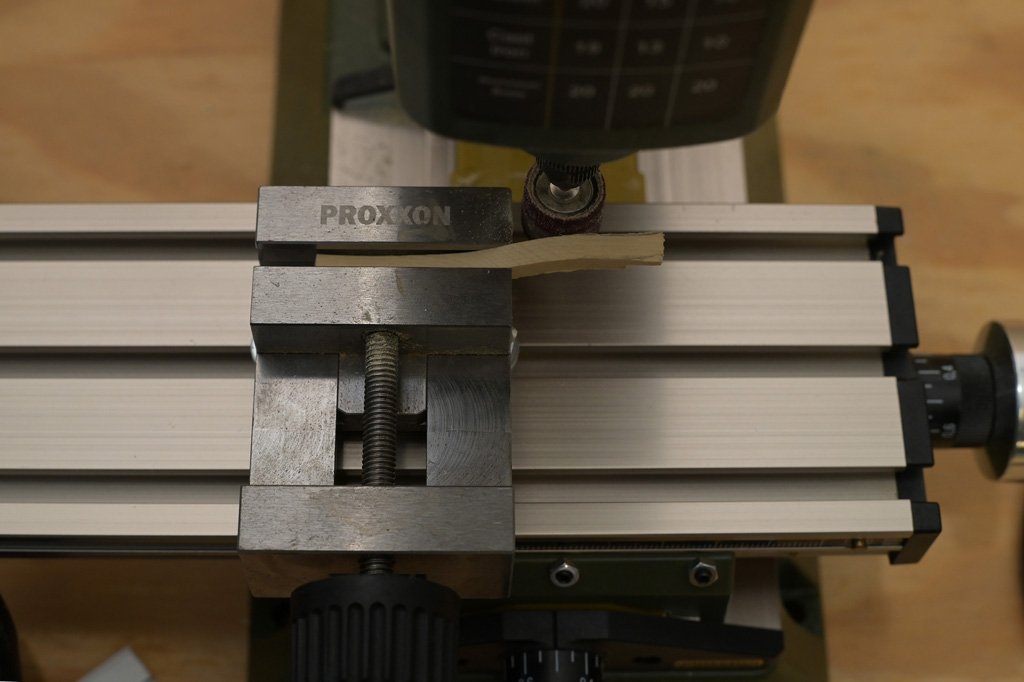

Thank you everyone that has helped me so far on this build I can't express my gratitude enough. Without it I would've certainly given up by now, but here I am with a touch of progress. I finally conquered my fear and tackled one of the top timbers on frame 3 aft. I'll go through my process in case it is of help to anyone (I can guarantee there are better ways but this made sense in my head. I first cut the piece out of a thicker piece of AYC to account for the cast (11.5" to account for the 2.5" cast on the 9" frame). I then used my micro mill to cut out the mostly straight portion of the forward cast (I did some editing of the frames and sided dimensions in photoshop to determine approximately where this line would be. I then flipped the piece over to create a notch at 8.5" to help with the curved section. As an aside I used my Byrnes table saw and NRG thin strip jig (still trying to figure out the best way to set this up, but I got there) to cut a strip at 2.5" to help hold everything in the right place when I'm working and eventually clamping and gluing the piece to the frame. Finally I drew the curve in, and rough sanded it out. It isn't perfect (I unfortunately took a little chip out where the timbers meet - see below) but I'm pretty happy and proud that I was able to get here. Of course now to do the second one but the garage is so hot I need to hydrate and eat lunch. Thanks for following along!

-

Beginner looking to start building, In the USA

VTHokiEE replied to lstmysock11's topic in Wood ship model kits

Unfortunately I don't know of a wooden kit (I think they are or were some plastic kits and maybe even a paper model kit), but there is a scratch build currently ongoing that I think you might enjoy looking through. -

What type of rope are you using? I found that moving to polyester rope for me helped solve this problem (there are disadvantages to it as well, some that I'm probably not even aware of), but polyester has a stretch to it so you can make it tighter. I never found a great way to keep all my cotton lines taunt and it bugs me a little bit on an earlier build of mine.

- 100 replies

-

- pauline

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Beginner looking to start building, In the USA

VTHokiEE replied to lstmysock11's topic in Wood ship model kits

Hi Andrew - Welcome to MSW! I see that you're considering the Columbu ships or WW2 but I would toss Vanguard models (https://vanguardmodels.co.uk/product-category/vanguard-model-kits/) into the mix. These are unfortunately a little more expensive than you probably were thinking for an initial kit, but makes some great kits (I built the Alert kit) and would heartily recommend them as a manufacturer. The fishing vessels would probably be a good first kit to start with. FYI - Ages of Sail (https://www.agesofsail.com/ecommerce/new-vanguard-models.html?limit=36) is a US distributor for them. I apologize for suggesting something that doesn't exactly meet your thread (inexpensive and Columbus/WWII) but I think there's a high chance of success with these kits which might be worth a peek. -

I really like your dioramas, would love to make one some day (it seems quite tricky to do well). Quite intrigued by your sail-making technique - do you have any idea how to get a copy of this article? I looked all through the NRG website but it appears that the purchasable digital archive stops around 60 and I didn't see it in the individual articles or available back issues.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.