-

Posts

3,047 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Edwardkenway

-

Welcome

- 6 replies

-

- fairing

- hull fairing

-

(and 2 more)

Tagged with:

-

welcome aboard

-

Thanks for the compliment Phil, hopefully the cross section will be done and dusted by the new year, and then I'll have Triton full hull do and Winchelsea to start.😆 Yes that's the better way, I've put the first attempt in the bin, I will try again😁👍 Merry Christmas and happy new year to you and your family 🎄🎁😁

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

Just found this log after seeing it on snapshot page. What an absolutely amazing 'kit bash' , please more!!

-

welcome

-

Welcome, good to see you here😁

-

Thanks Mark, have a merry Christmas and a happy new year .

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

Have a great Christmas holiday and new year and I look forward to the next chapters. 😁 Thanks Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome and good luck with what sounds like an awesome build👍!!!

-

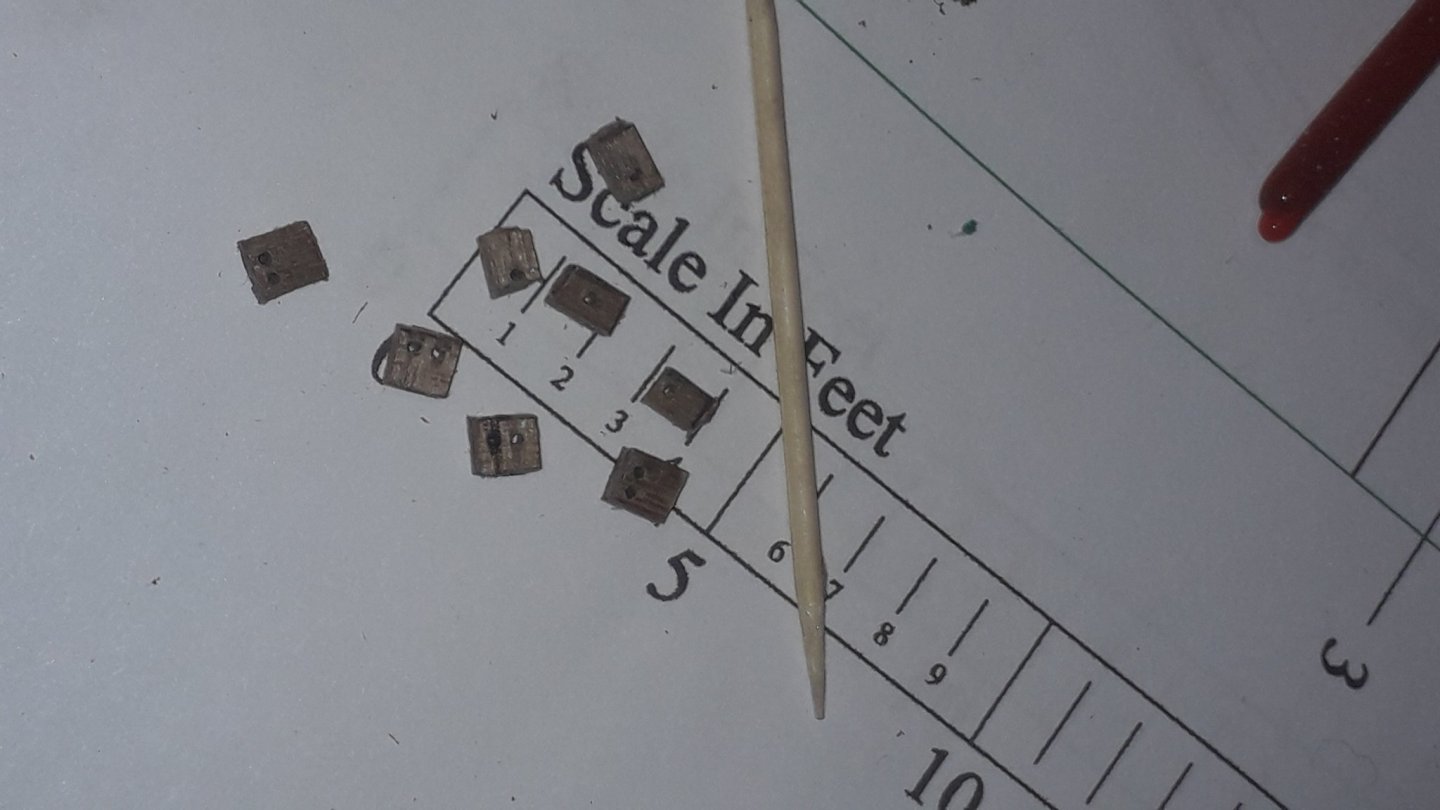

Hi all, another small update, I decide to fit the access ladder to the gangway on the unplanked side, therefore I had to put a small area of deck for the ladder to stand on. Also made the second gun barrel, it still needs painting. To rig the cannon I need blocks but looking through my bits and pieces I have not got enough so I'm attempting to make my own. I've used a piece of 4x3mm walnut and made 4 single and 4 double blocks. I need to get them to look less "blocky" if you get my meaning. I thought if I put them in a small pot with coarse sand it might work a bit like a tumbler, I'll let you know how I get on next time. I appreciate all the likes, comments and advice 😁 Cheers 👍👍

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

Welcome Harv

-

@Peta_V when I have looked a while back apart from he bulkheads all Winchelsea packages shipping was between $16 and $27

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome Dean have fun with whatever ship you decide to build, you'll be sure to find help and advice here at MSW👍😁

-

Thankyou Chad, I welcome your input and advice. Hopefully I shall keep getting better but at the moment I still look at what I've done and see where I could have done it differently or better and neater. I still make plenty of errors and most things get made or done more than once. It all helps the learning curve though 😁 Eamonn and Phil thanks for your continued support I really appreciate it👍 Cheers

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

Hi, just a quick update, I've repositioned the entry steps and adding one more as per plans. Also made the gangway ladder which will go on the side with the deck planking when I finally fit that gangway. My thanks to everyone who has looked in, liked and for comments. Cheers 👍😁

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

Thankyou Mark, no I've got to change a couple of steps as one should be set where the moulding is! Just a small error on my part😖 Thanks for looking in and your advice 👍

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

Hello, managed to get a couple or three hours at the workbench, and made a scraper to form the entry steps, I've also fitted them and the fenders to one side of the cross section, the gangway to the same side has been fitted as there are no guns going that side. Thanks for the likes. 😁 Cheers for now 👍

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

I'm back, I think that the cross section needs a bit of attention as I've been concentrating on the Triton full hull and getting the plans for Winchelsea printed and sourcing the materials for the bulkheads. Anyway the second gangway has been made, (twice because I forgot to make it as a mirror image and ended up with two starboard side gangways 😖) Also fitted the capping rail and made the fenders, not fitted. Next I'll make the entry steps. Sorry no photos but will post some next time. Thanks for the likes😁 Cheers 👍

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.