-

Posts

3,047 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Edwardkenway

-

Having seen your dark option and the natural one, my preference would be the natural shingles.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Mark, I found making them from wood a lot easier than from metal, I was never very good with soldering. I used 1mm x 1mm walnut, I'm not sure what your equivalent imperial size is. I'll be sure to check La Belle Poule out, thanks for looking in. Hope you've not got too much snow? Cheers

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

Brig Eagle 1814 by ChadB

Edwardkenway replied to ChadB's topic in - Build logs for subjects built 1801 - 1850

Ditto Chad, I'm in awe of you getting that much detail into something so small. 😲😲 -

@SpyGlass Dont care what all you neat workers say - I keep a damp cloth to hand and I can wipe off white glue when I spread it everywhere . CA just attachs itself to me and everything else - but never just where I want it ! I know what you mean😲😤 @Vane great start !! As soon as I've got enough pennies saved I will get Speedy

-

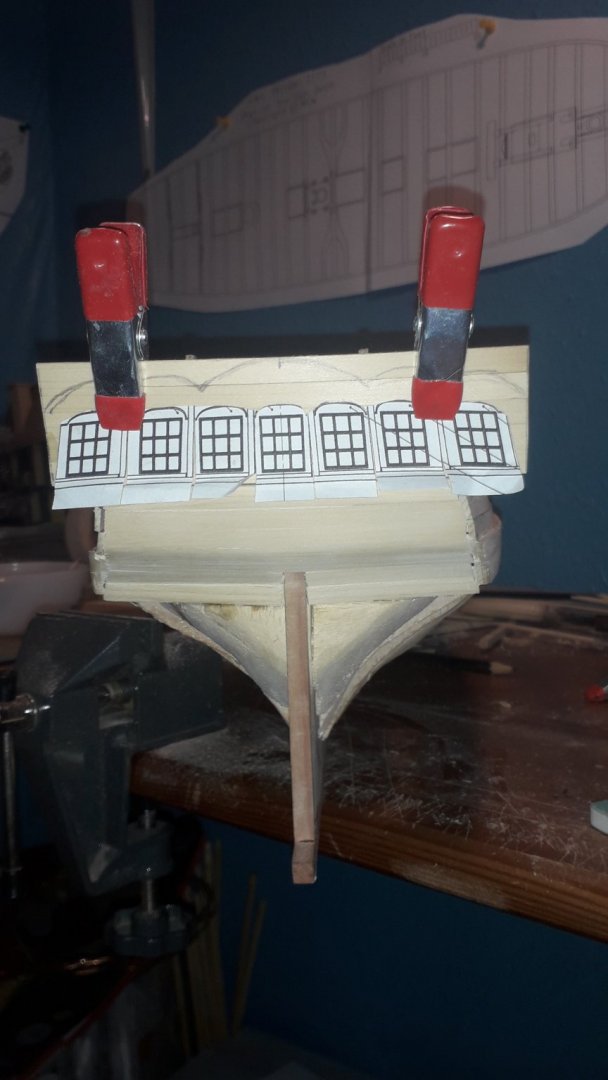

Hi, I've cut the top of the stern to shape, and dry fitted it, not completely sure about it!! There be some remodeling yet. The internal bulwarks have been faired, lots of dust and very awkward to do, and the first planks have been glued. Once the bulwarks are planked I will carry on with the deck planking. Cheers 👍😀 Thanks for the likes.

-

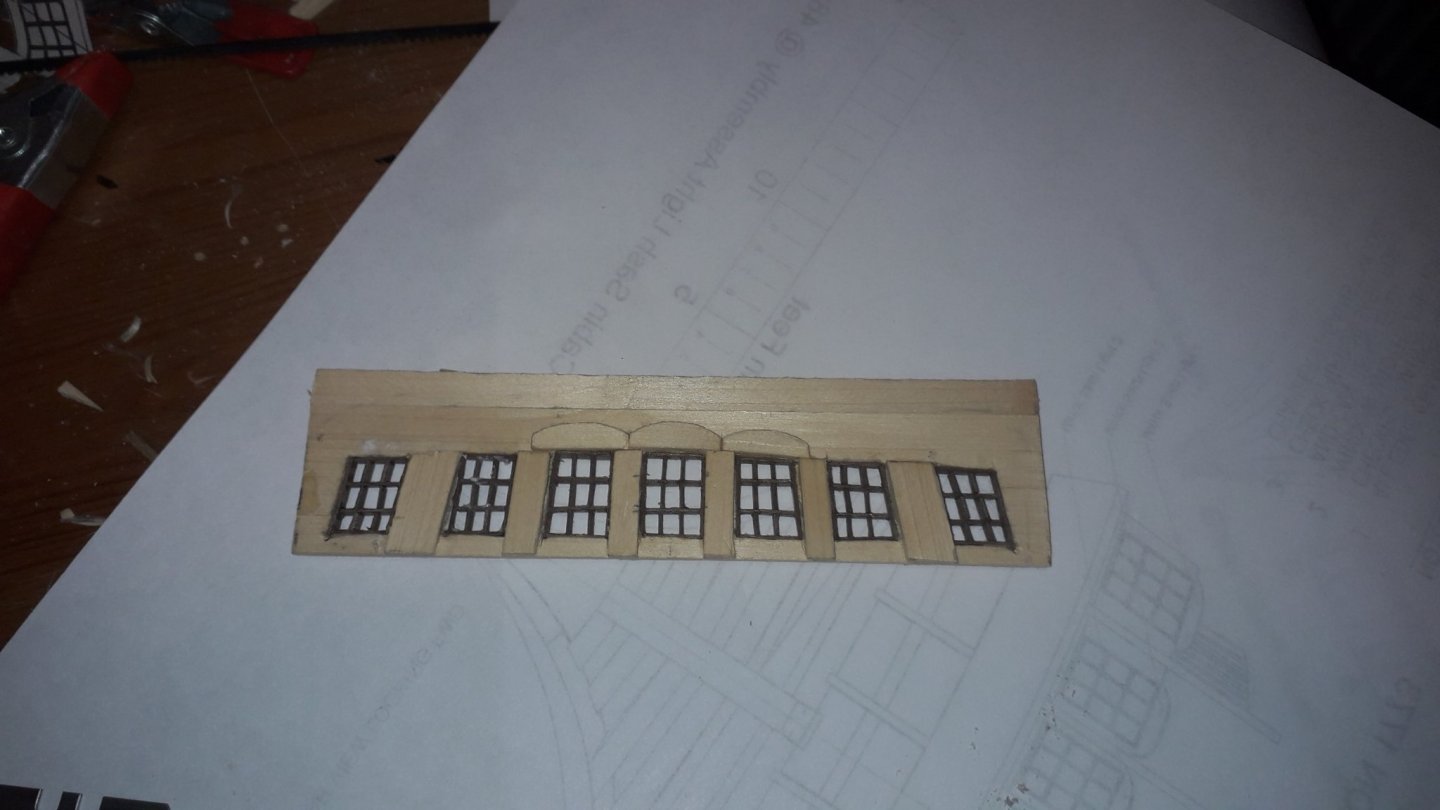

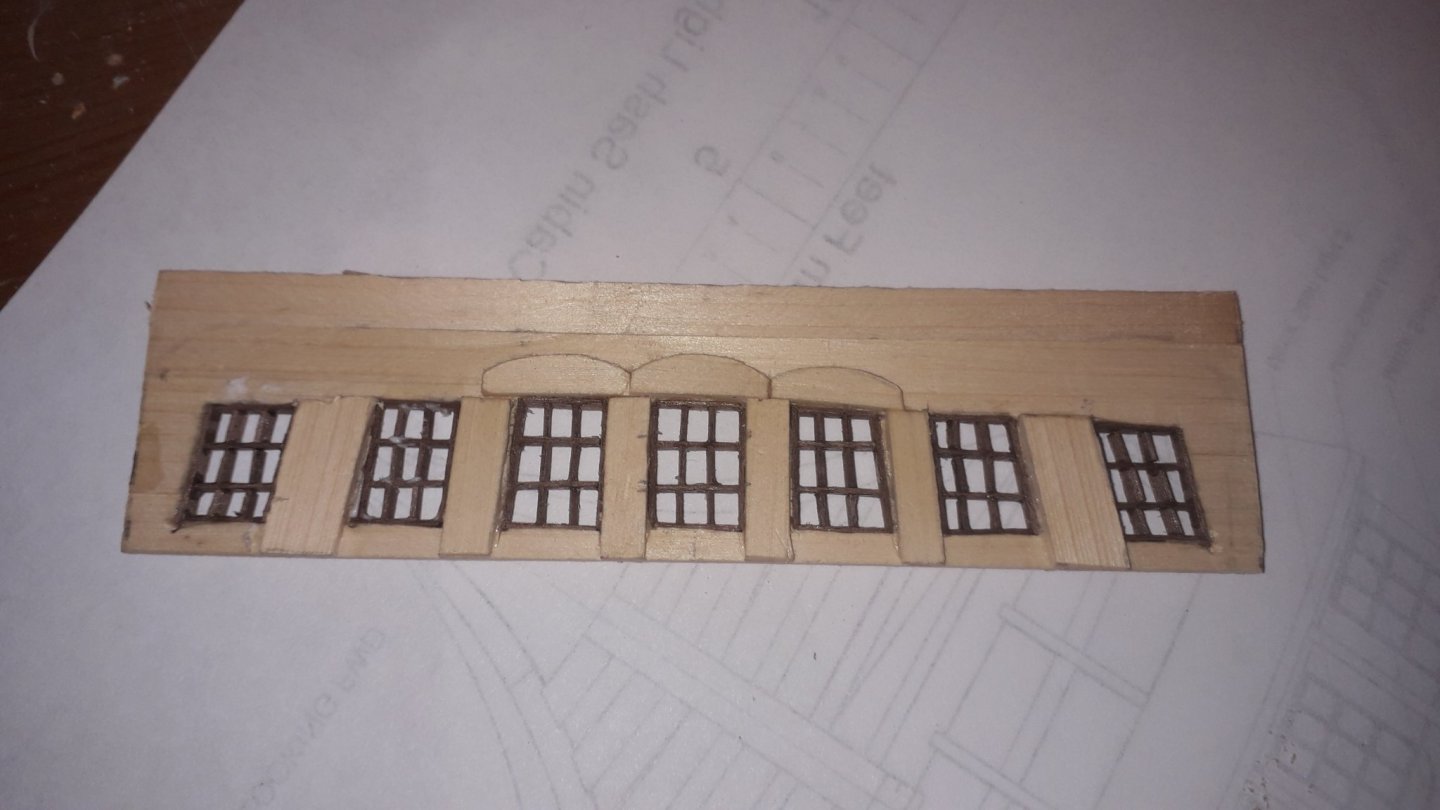

Ok, so this post sees the window openings cut and the sashes made. I don't mind admitting that they have definitely tested me (and my old eyes). Hopefully they'll look better when the details of the stern are done, although I not sure whether I can do detailed carvings. I'm just waiting for the glue to dry, so till next time, Cheers 👍😀 Thanks for the likes.

-

Thanks for that Chad!!😀. I have to admit that I have not spent as much time on this as I have on the full build. But it does keep calling me back when I'm waiting for some glue to dry. There's still quite a few bits and pieces that still need making and fitting, but there's no rush. Till next time Cheers 👍😀

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

-

As usual your tutorial is great and will help no end with my own build when I get to doing the quarter galleries. Thankyou 👍 PS wouldn't it be handy now and again to be small enough to get on board and do some of the fiddly stuff 😆

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

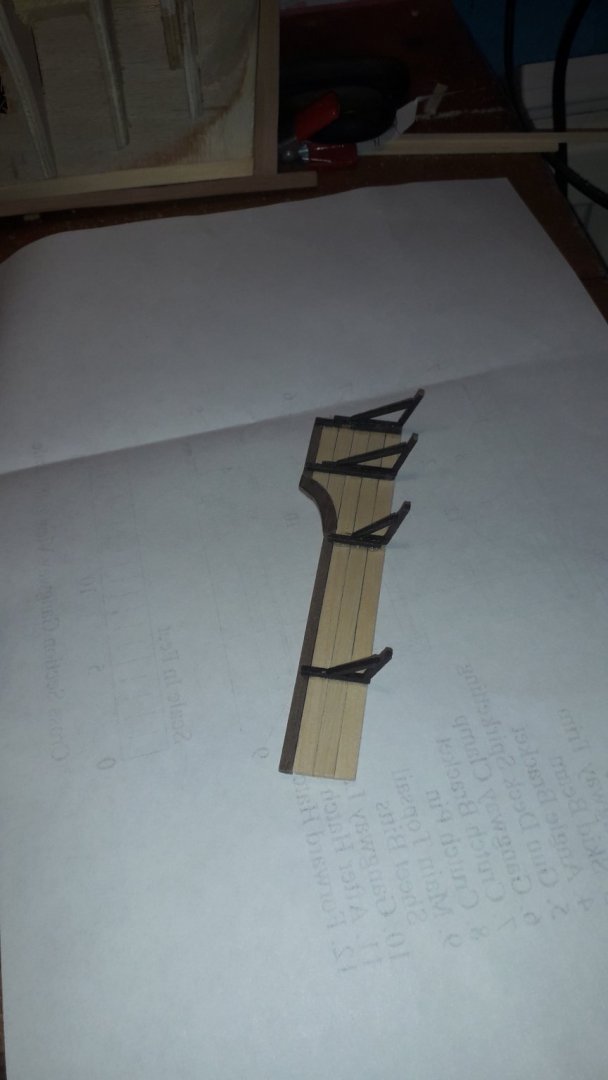

Hi, it's been a while since I've been on the Xsection, but had extra couple of hours in the workroom so made up one of the gangways. The brackets are wood and not metal but I don't think it matters to much. I can't fit it til I've rigged the cannon. Still got the other one to make. That's next time though. Cheers. Thanks to all for the likes and looking in 👍😀

- 94 replies

-

- Triton

- first attempt

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.