-

Posts

986 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by EricWilliamMarshall

-

-

On 12/9/2019 at 12:33 PM, ccoyle said:Quote

described as ‘near fool proof’

Don't prove me wrong here!

Hopefully, that wasn’t too painful.

-

- ccoyle, thibaultron, Retired guy and 3 others

-

6

6

-

-

-

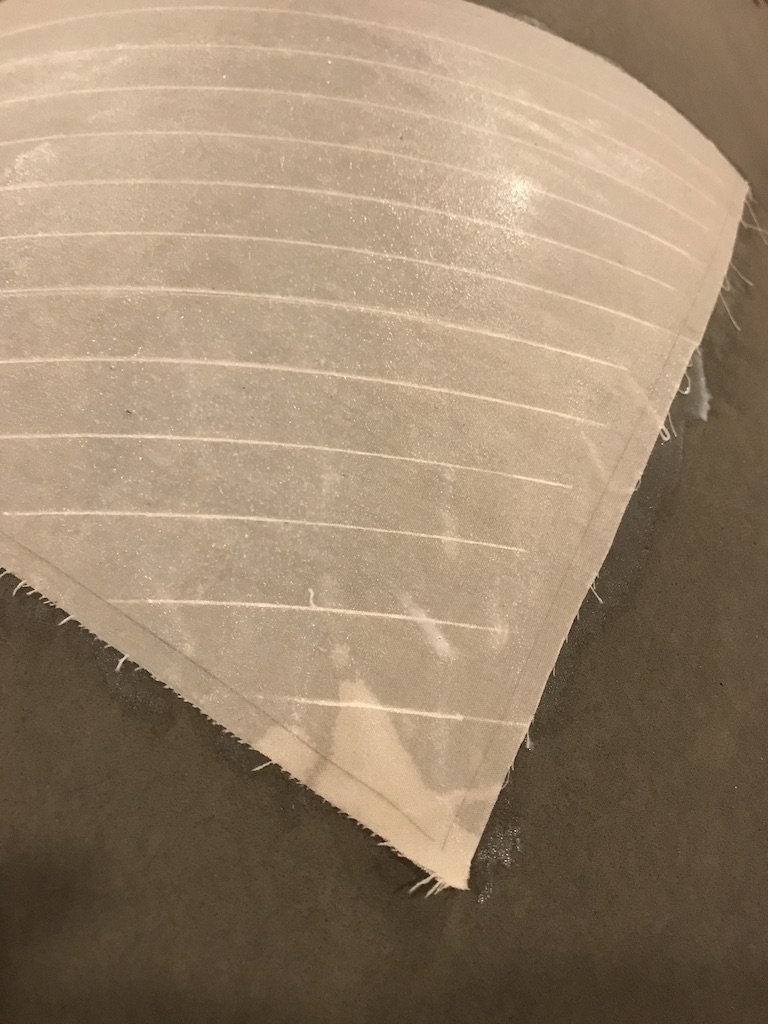

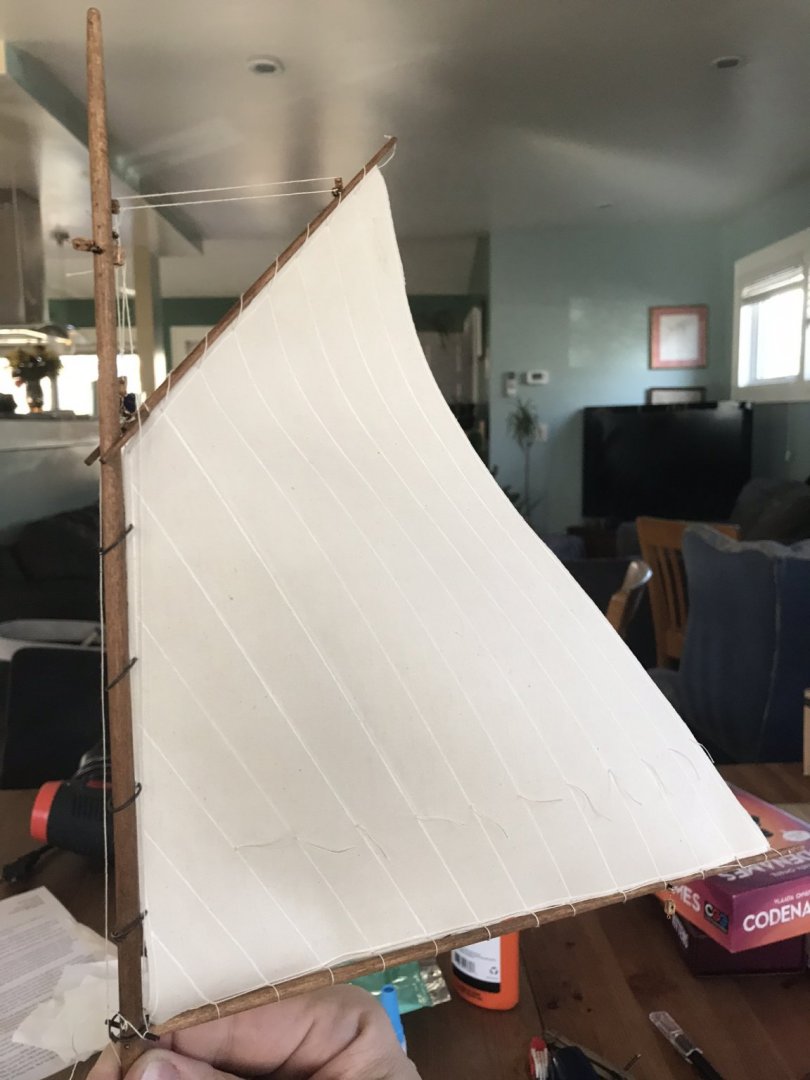

DonInAZ, white Gelly Roll was the pen I used. The is nothing particularly special about that choice. It happened to be the first one on came across. I did notice, as did JerseyCity Frankie, that the gel pen needed a little coaxing on the untreated fabric. It worked fine on the fabric coated in polyurethane. There wasn’t bleed in either case for me (the ink is on the thick side and “coats” more than “soaks”) but there was a slight difference in how sharp the edge of edge of the lines were. Play with a scrap and see what you like.

-

- ccoyle, GrandpaPhil, VTHokiEE and 4 others

-

7

7

-

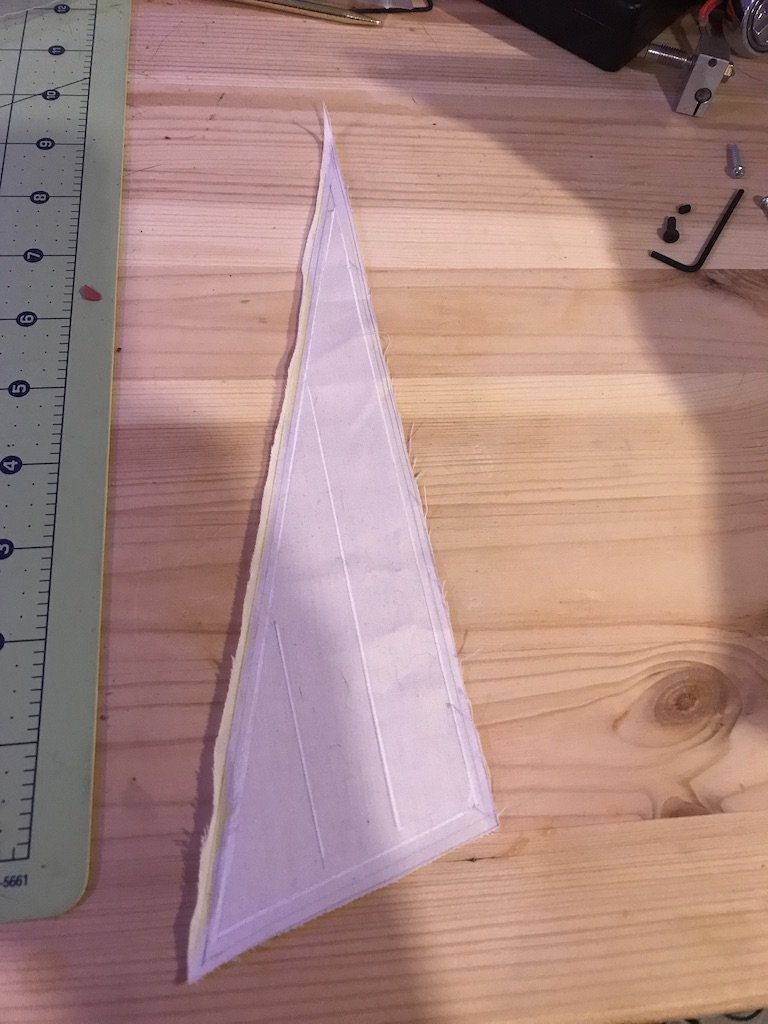

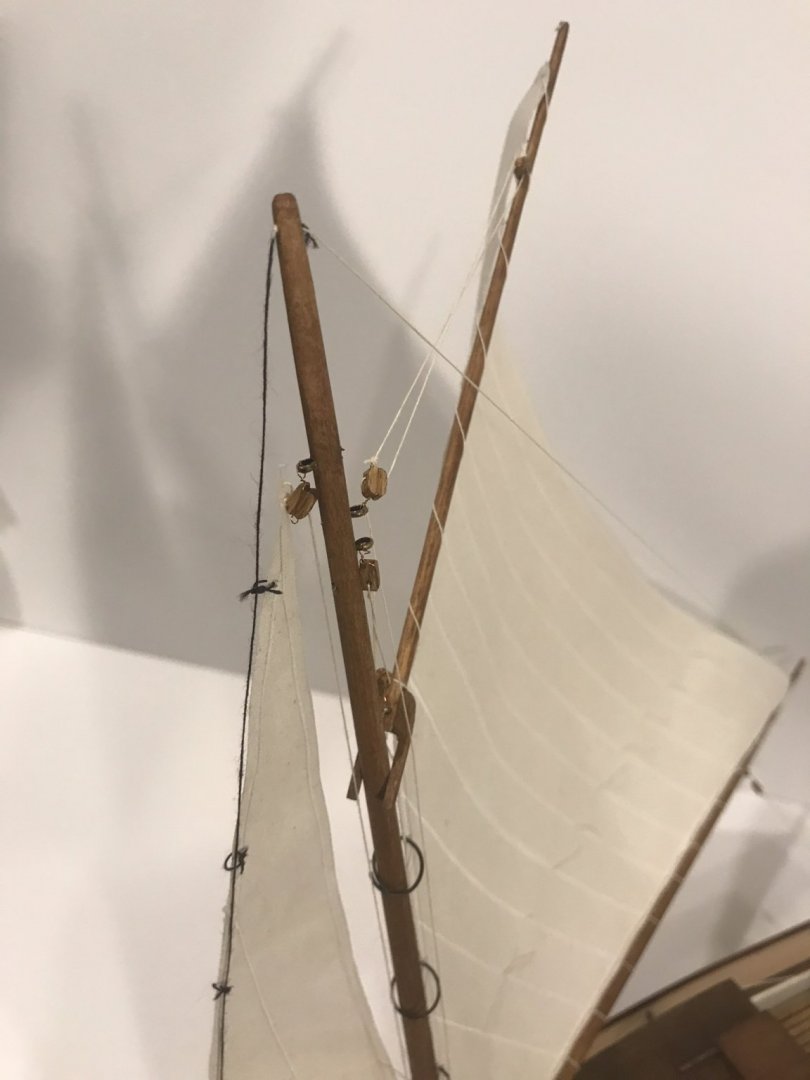

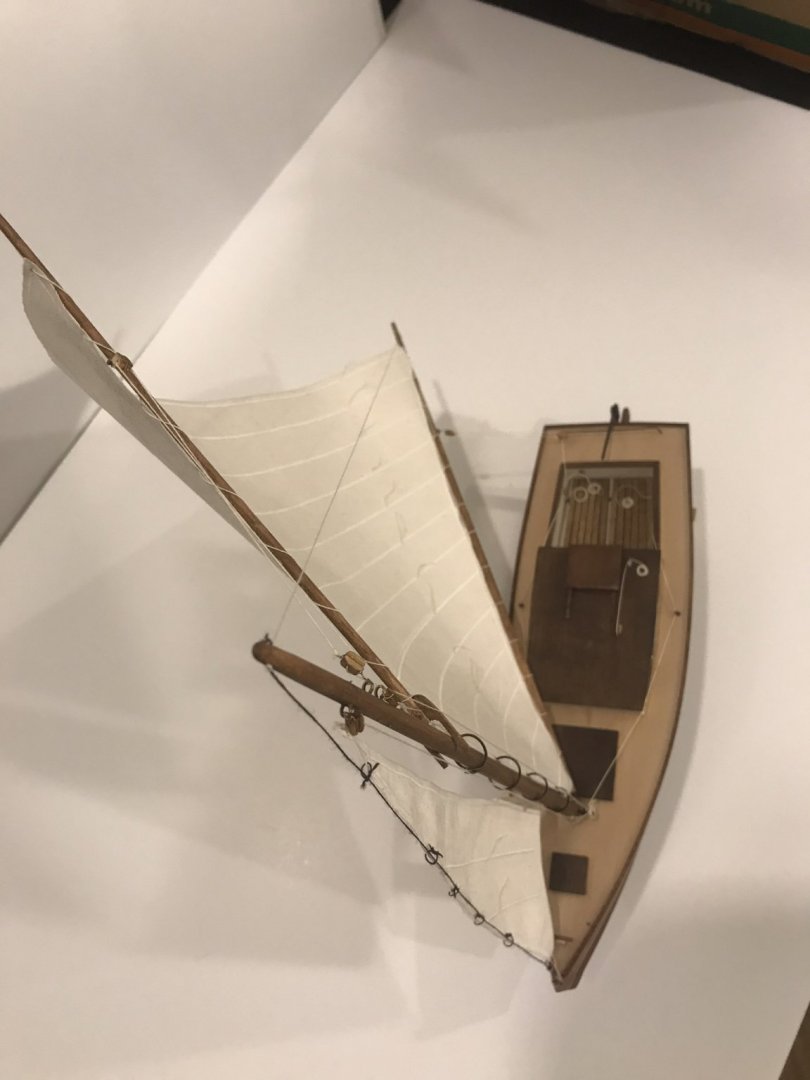

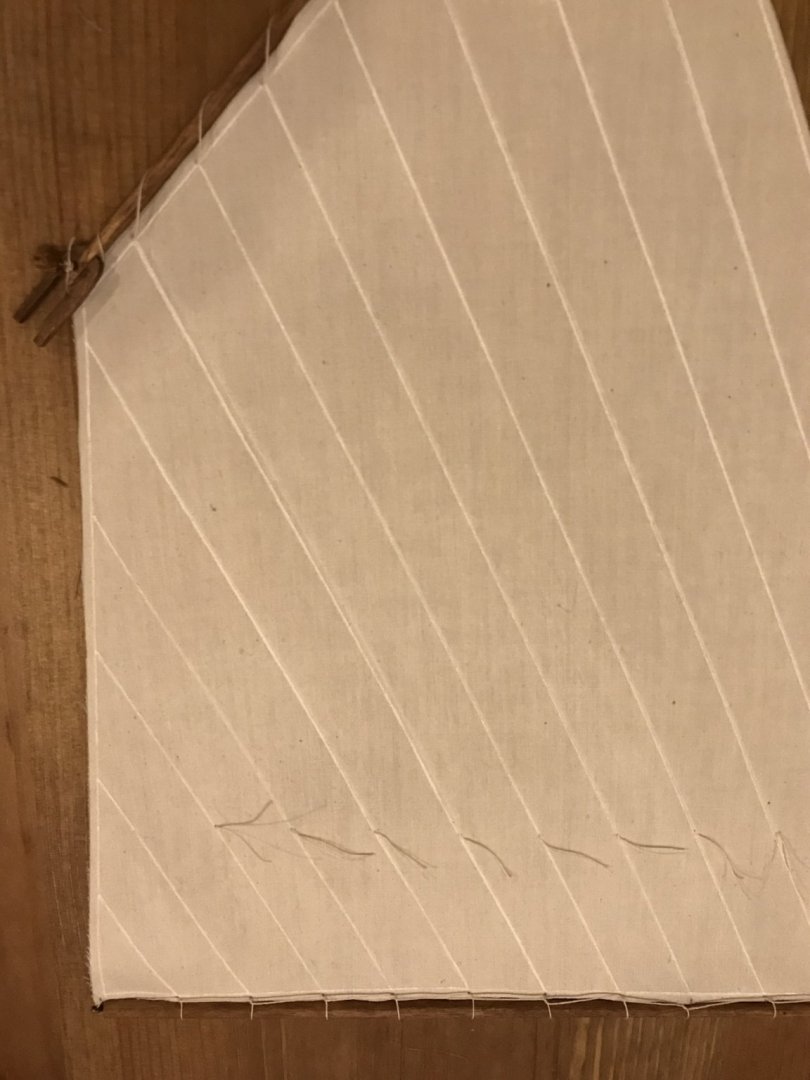

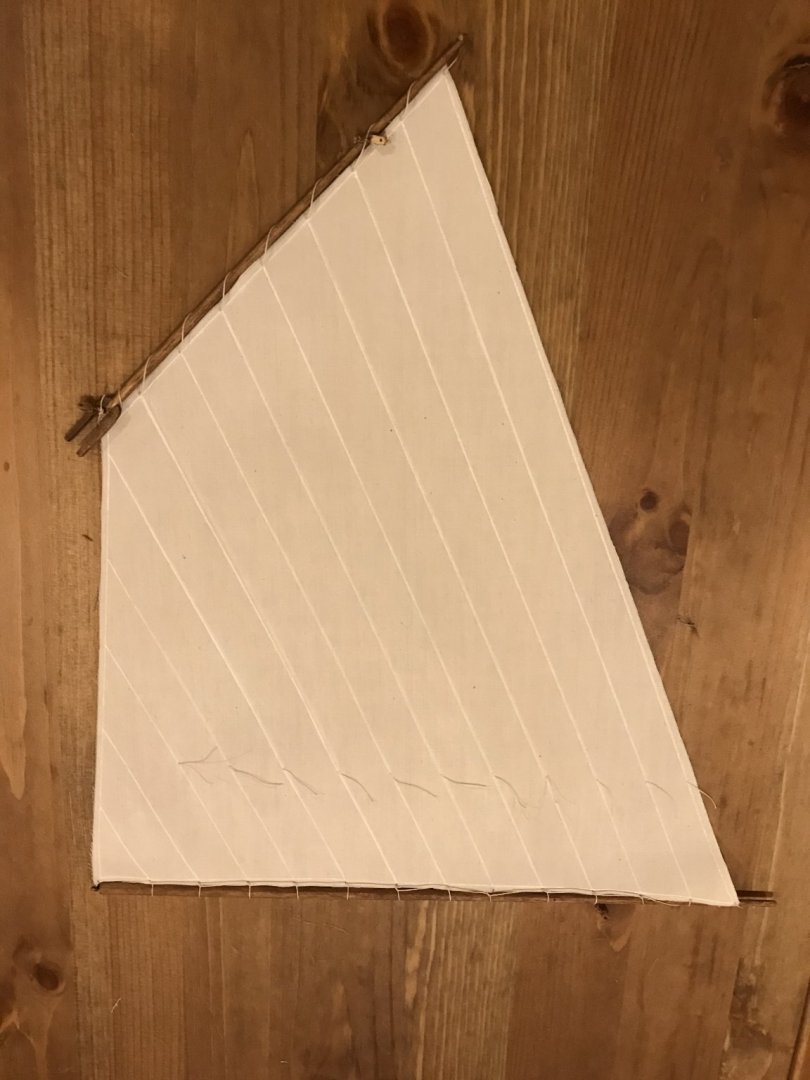

I’m inexperienced at the all the stages! These are my first cloth sails. I cheated and used a white gel pen and a ruler. If you look closely you can also see some pencil lines as well. I’ll post which one I used when I’m next in the workshop. The lines were simply drawn with a ruler. You might enjoy taking a peak at

That’s where in picked up the white gel pen idea. JerseyCity Frankie has a number of interesting ideas. Thanks for asking. Your skiff is looking a very neat and clean.

-

-

The learned wefalck is correct - his seat should be lower, the bench pin needs to flat if he cuts curved work, etc. I do like that the fellow in the video talks about tensioning the saw, possible use of wax, oil, etc., teeth to thickness, binding, breaking of blades and replacement, and so on. Stuff that leads to success for the first time user. Is it perfect, no. He does address some of those issues in the second video. I didn’t watch any other of his videos past that point.

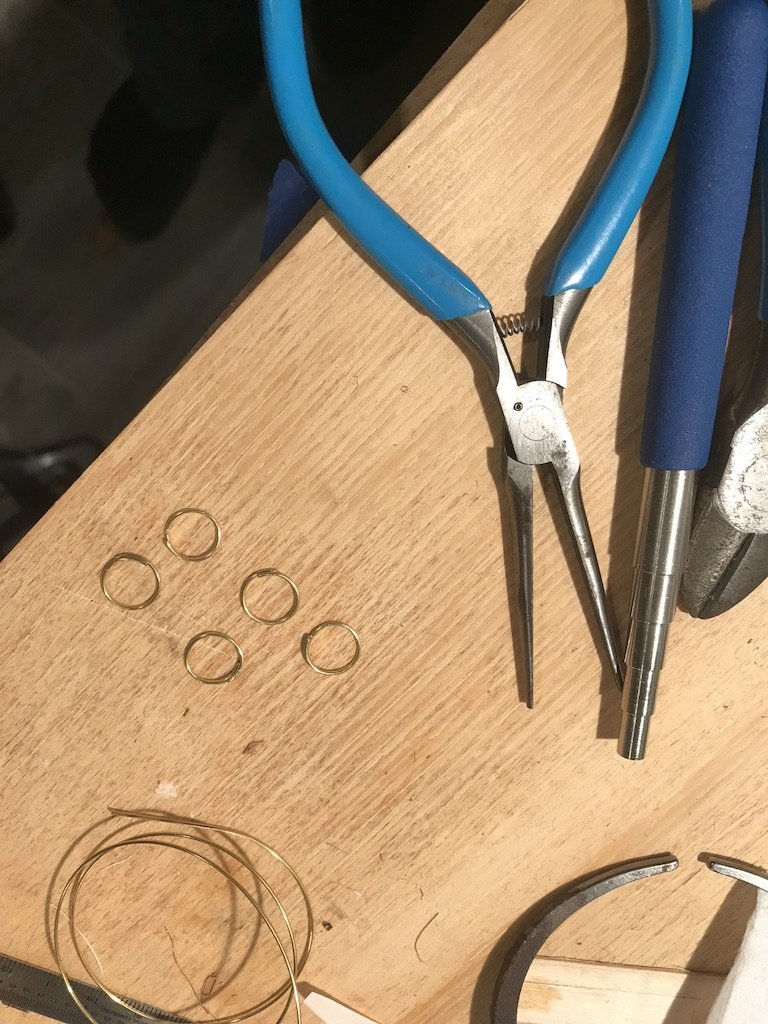

My goal was to simply point out there is a low cost, low tech proven set of methods for cutting brass that leads to successful outcomes that has a lot of instructional videos (created by the related field of jewelry making) pre-existing.

I love that there zillions of video these days. <Insert statement about it being harder learn ‘when I was young’>

-

While time has passed, I thought I would add a link to this video, it covers a cheap, time-honored and effective set of techniques (used by jewelers):

While I didn't learn technique from this video, it covers much of the basics for using a coping/jeweler's saw for working with brass and copper (there are lots of similar videos as well, and this fellow has more including one on cutting curves). When used with files (for light clean up), it is quicker than folks think and gives great control. I believe it is an easy skill to acquire if you give yourself some practice. -

-

- thibaultron, ccoyle, Duanelaker and 2 others

-

5

5

-

-

-

-

-

On 1/8/2020 at 5:45 PM, VTHokiEE said:

When you tried to fold over and iron the seams at scale did you use any pins?

Nope, but I will. I should have thought of that! Thanks!

- thibaultron and VTHokiEE

-

2

2

-

2 hours ago, Bob Cleek said:

I impulsively bought one of these on sale at the local Horror Fright store years ago, just for grins. (I think it set me back $25 or so.) I should have read the reviews on line. It's sitting in a cupboard in my shop, unused. I took it out of the box once when I bought it to see what it would do. Fuggedaboudit! Totally gutless. Very under-powered. It'll cut balsa if it's not too thick. Maybe it'll cut 1/8"basswood if you take it really slow. That's about it. The miter gauge has no degree ruling marks on it. It doesn't have a fence at all. The blade height is adjusted by raising the table and keeping it in place with a set-knob. It's made of metal and looks fairly substantial, but it's a toy, really. Push a piece of wood into it and it'll slow and stall in a hot minute. It saws what can otherwise be cut with a drywall knife and a straightedge. One of these days, I'll give it to my grandson to play with if he ever has any interest in such things. Mounting a circular plate with some sandpaper glued on it on the arbor might turn it into a very light duty disk sander. The blades are non-standard and unobtainable on the aftermarket, AFAIK, so good luck trying to put anything else on it but the stock ones. Given the competition, it's probably worth what they are charging for them, if anybody has a use for something within its very limited usefulness parameters.

Agreed, the saw is missing a fence or crosscut guide or any accessories which allow more efficient cuts. It looks like a similar set of issues for the Amazon saw as well. Oh well.

-

http://www.jans-sajt.se/contents/Navigation/Modelling/Patterns_Rigg_Viking.htm seems to call it a wantenbefestigung which Google translation believes to be a 'shroud attachment'. But I wouldn't put much faith is such a translation.

http://www.jans-sajt.se/contents/Navigation/Modelling/VikingRigging.jpg- thibaultron and mtaylor

-

2

2

-

And similar to https://www.harborfreight.com/4-in-mighty-mite-table-saw-with-blade-61608.html also $37.99

-

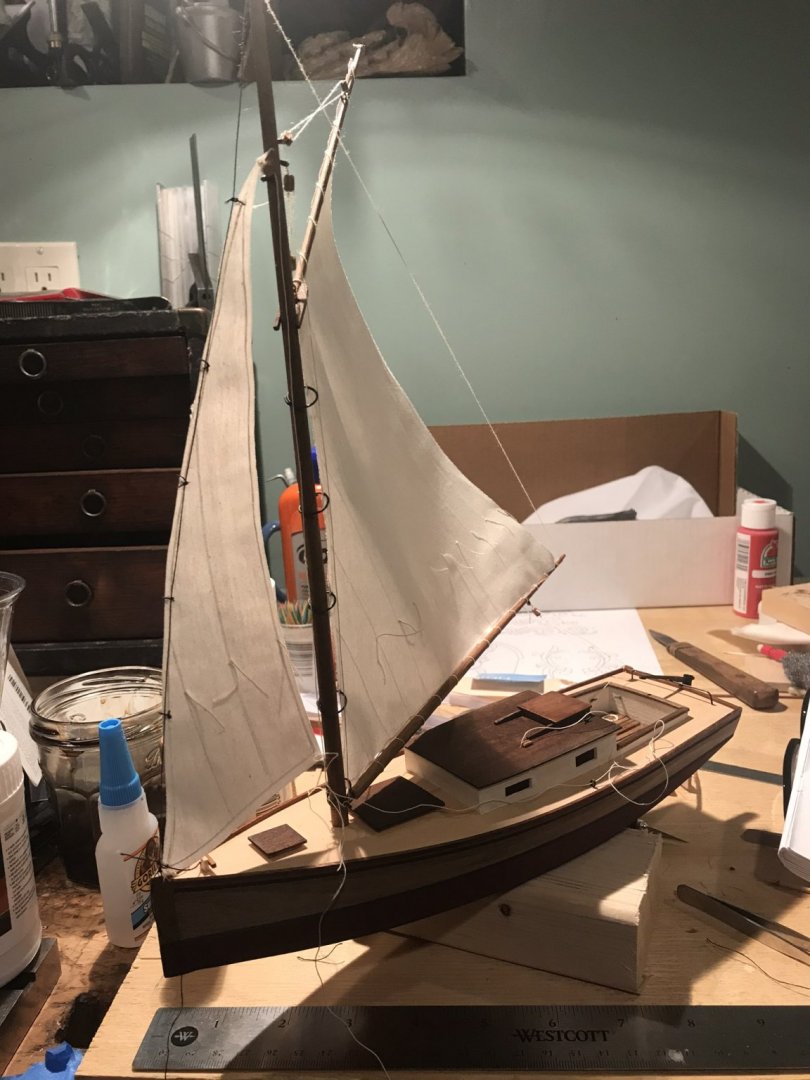

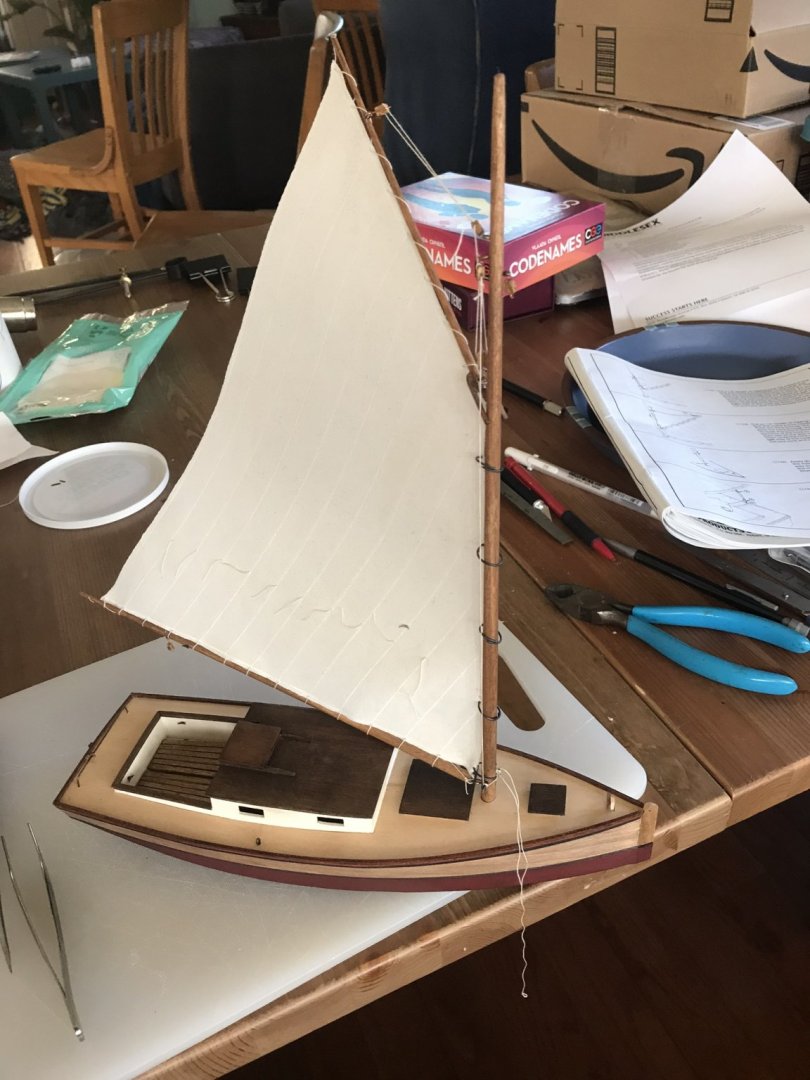

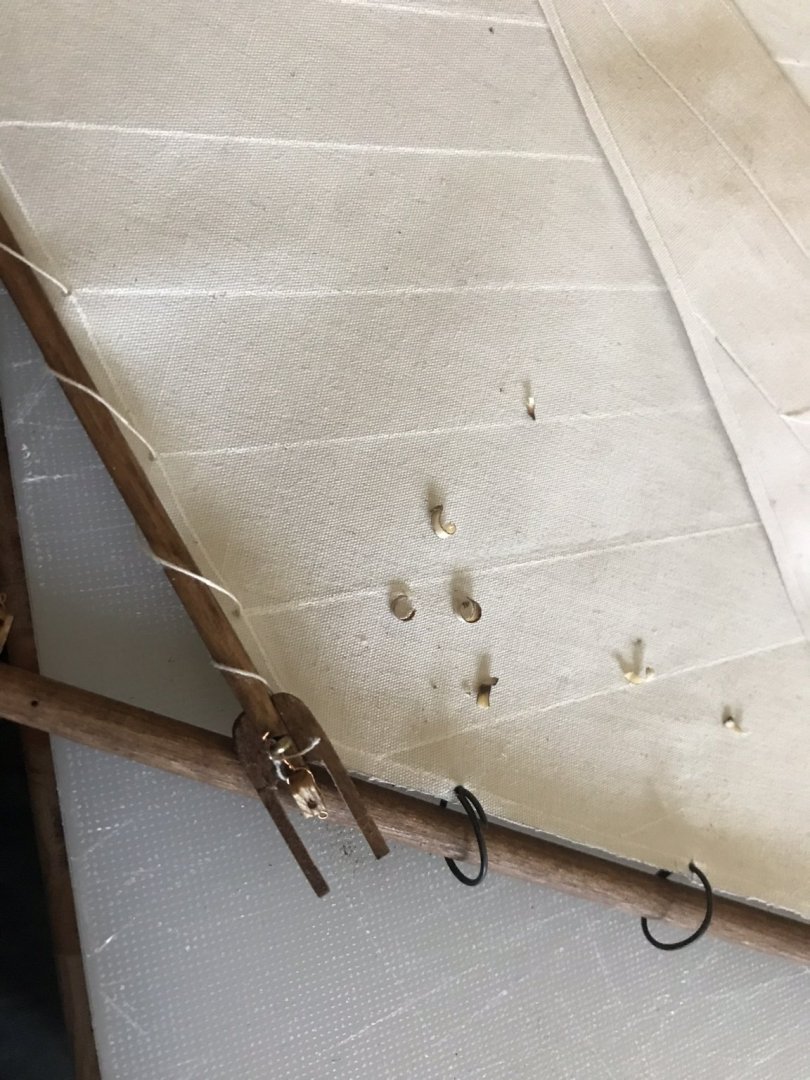

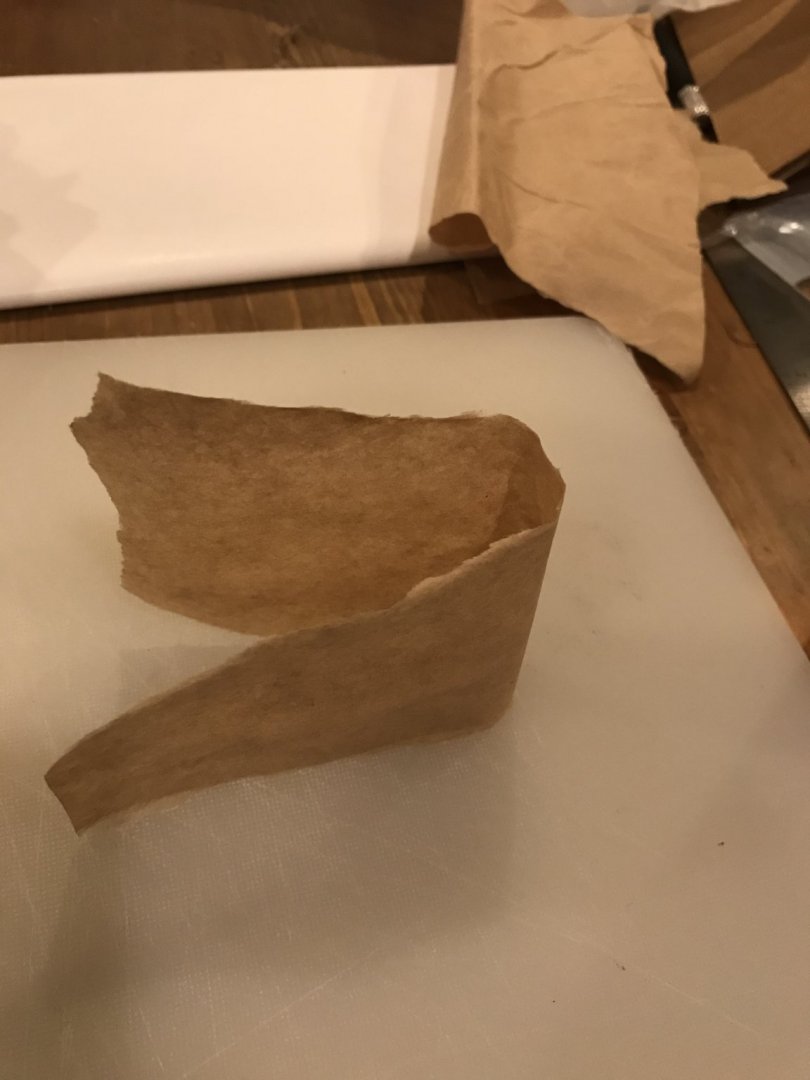

I also attempted: to sew a set of sail, I tried paper, cloth, spray stiffener, etc. I found I couldn't use the iron "at scale" to fold over the edges of a sail. Both sewing and paper are worth more work but are slightly out of reach due to skill and resource constraints.

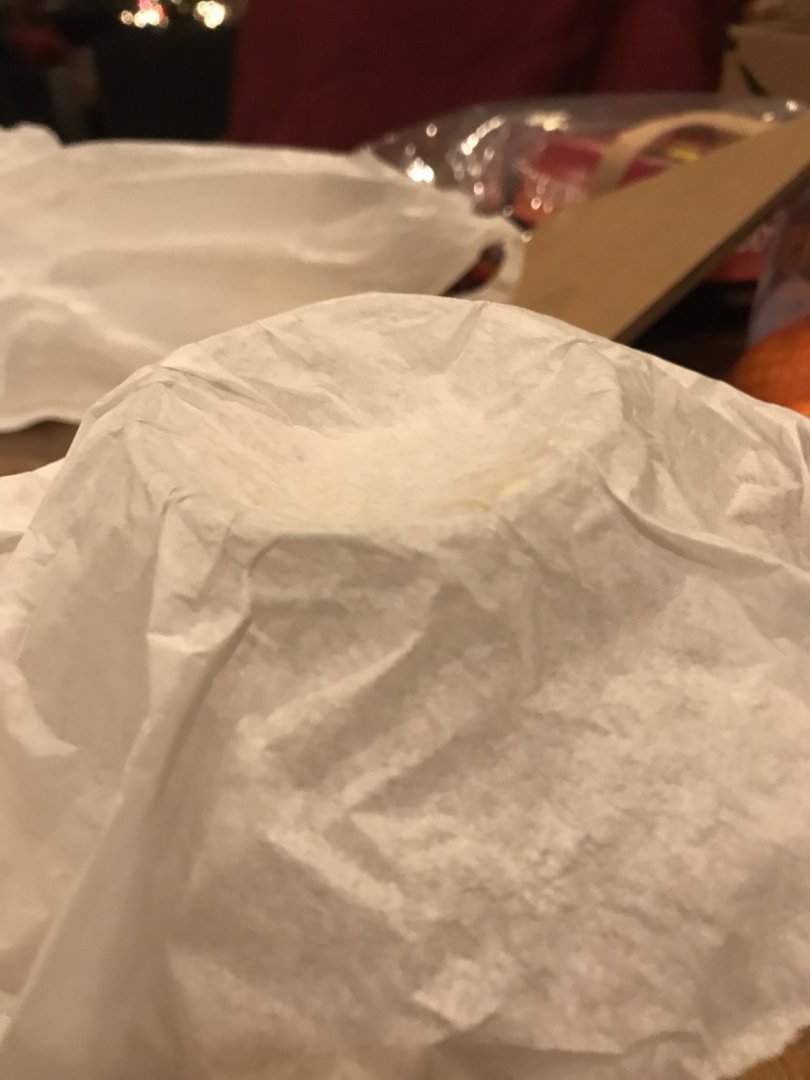

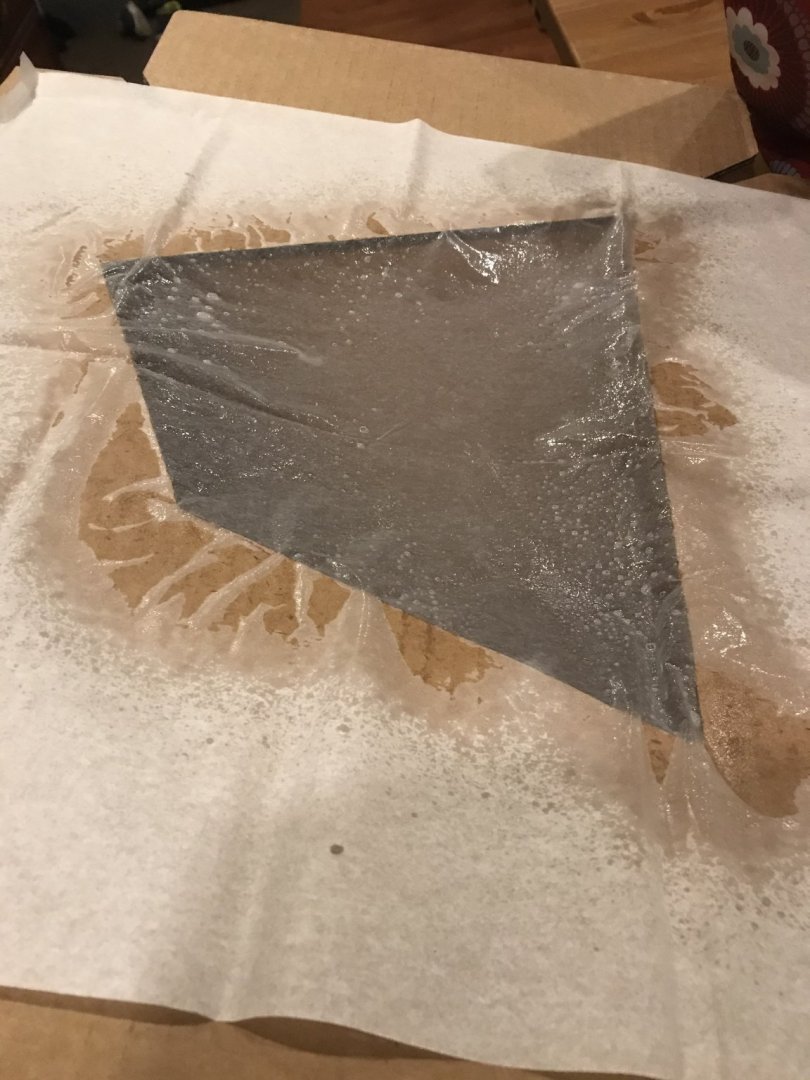

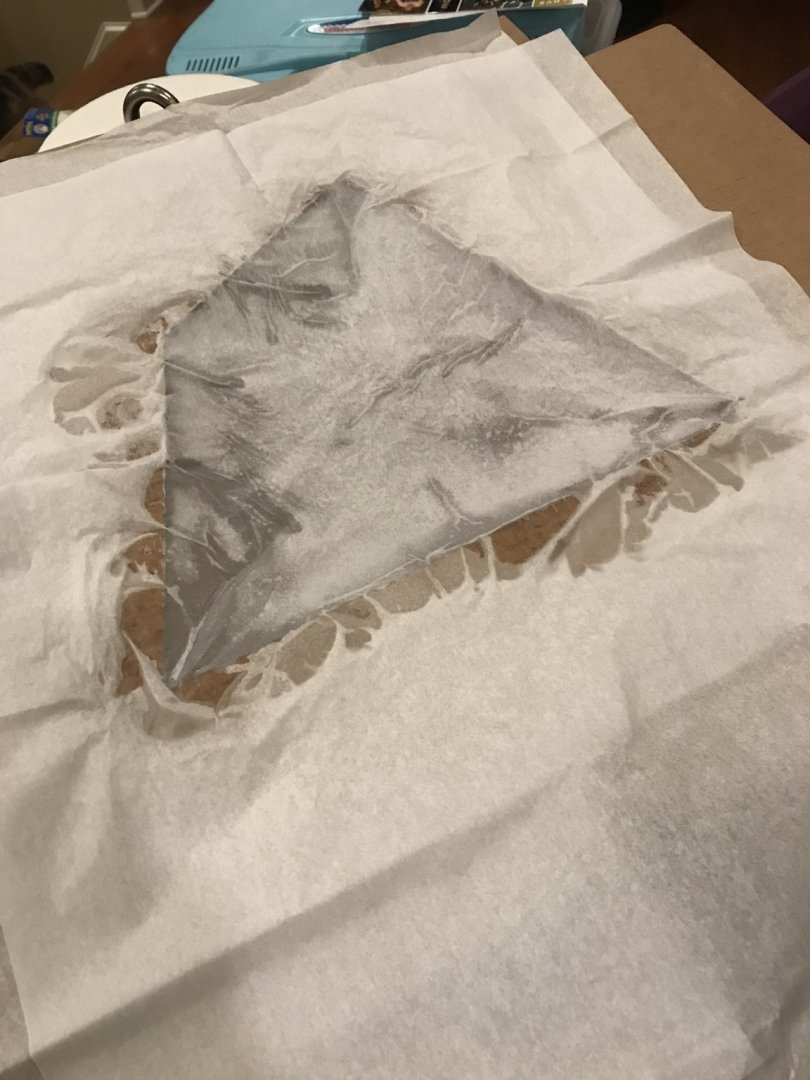

I tried using an acrylic paste over plastic wrap over a mold.

When drying the whole arrangement, I (re)discovered the principle behind shrink-wrap, which led to wrinkles in the sail. There is potential for the paste but I need to play around a bit more for it to be presentable.

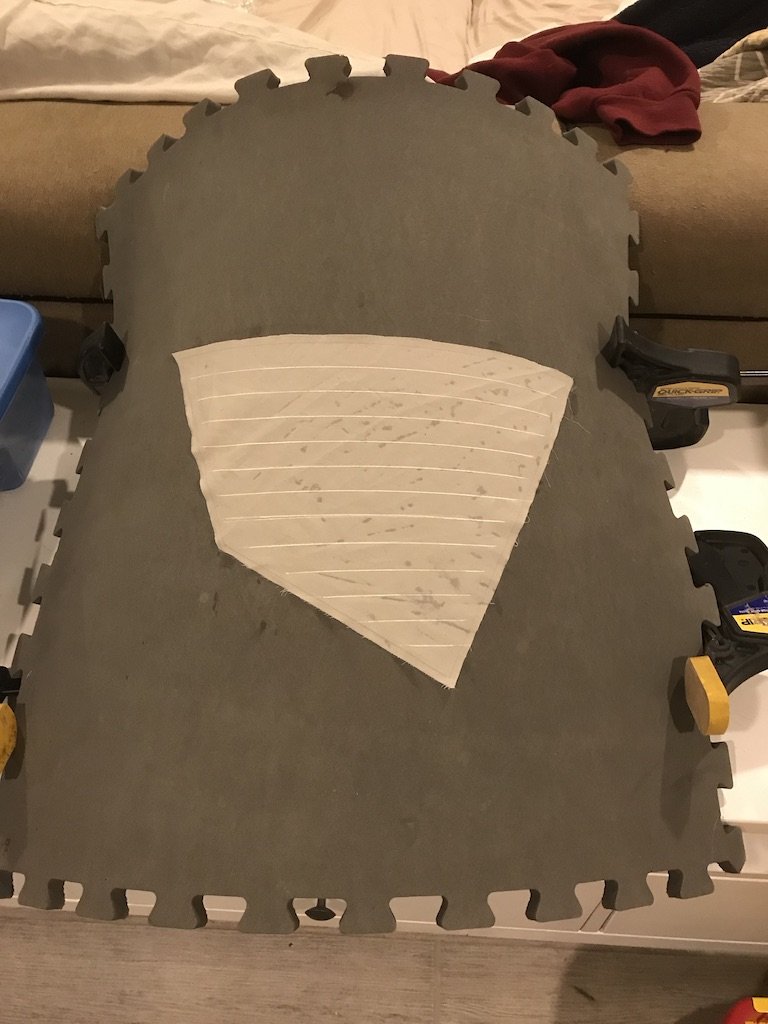

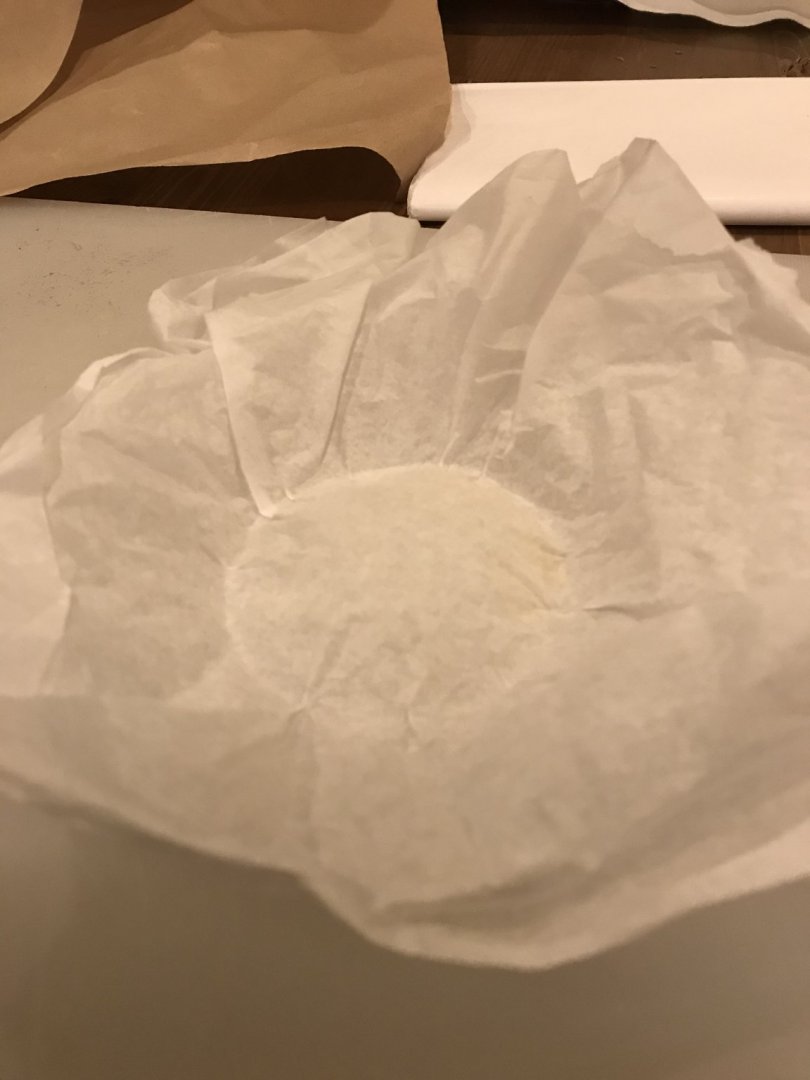

I tried using a foam tile as a possible mold:

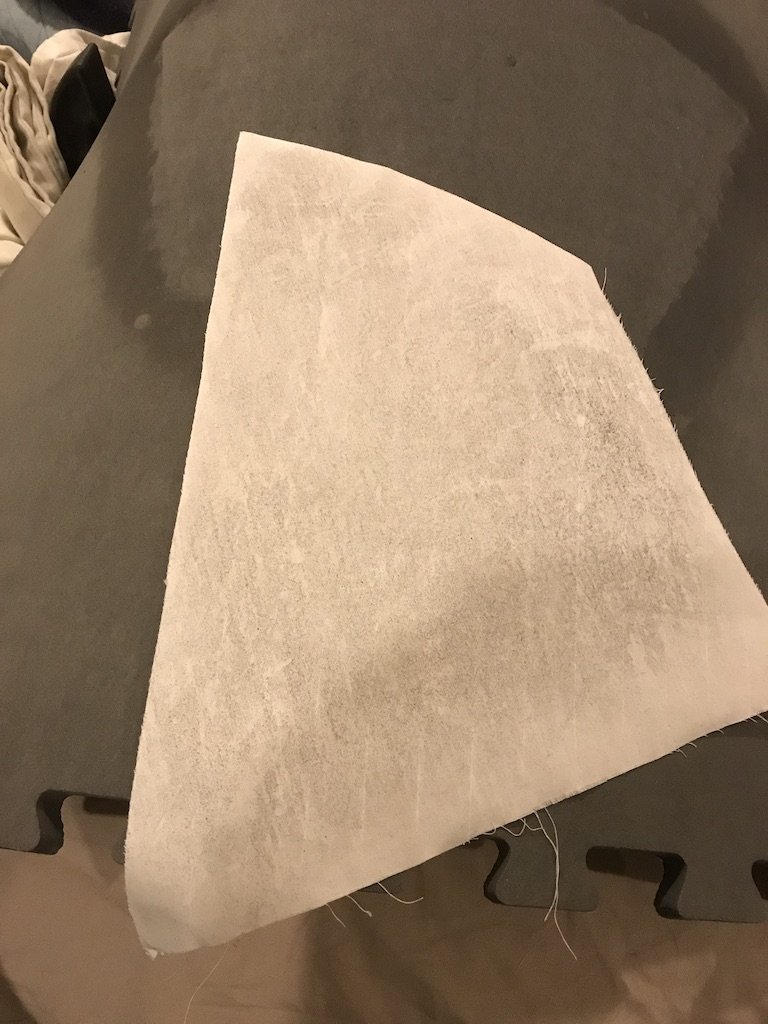

That worked well seemingly so until I saw the back:

At the moment, just paint the sail with polyurethane has proved best so far. That allows me to skip trying to iron over the seams without have too many loose ends.

Little by little...

-

-

56 minutes ago, ccoyle said:

I glue the hems instead of sew them.

Ah, I hadn't thought about that. Excellent thoughts!

42 minutes ago, VTHokiEE said:trace the pattern on both sides of the sheet

Thanks - simple but smart!

43 minutes ago, VTHokiEE said:You can get cheap white cotton fabric from Walmart for a few dollars and have plenty to experiment with.

That is what I did! (Well, at JoAnn's instead of Walmart.) I now have yards and yards to play with (I over-shot on the amount but I don't get to that part of the world often.) I'll soon post some of my successes and failures!

-

I was hesitating working on the sails; unsure how to proceed. I didn't want to waste or wreck the small piece of cloth that came with the kit. It occured to me to buy some more fabric, experiment and fail a few times until I am more comfy. I now have access to a sewing machine, although I may not use it. While hemming and hawing regarding the sails, I finished fixing up a old tool chest. I had fixed the broken drawers and cleaned and shellacked the drawer fronts. And relined the drawers.

I had a little plastic tool box that was overflowing and this is much nicer.- Retired guy, thibaultron, ccoyle and 2 others

-

5

5

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)

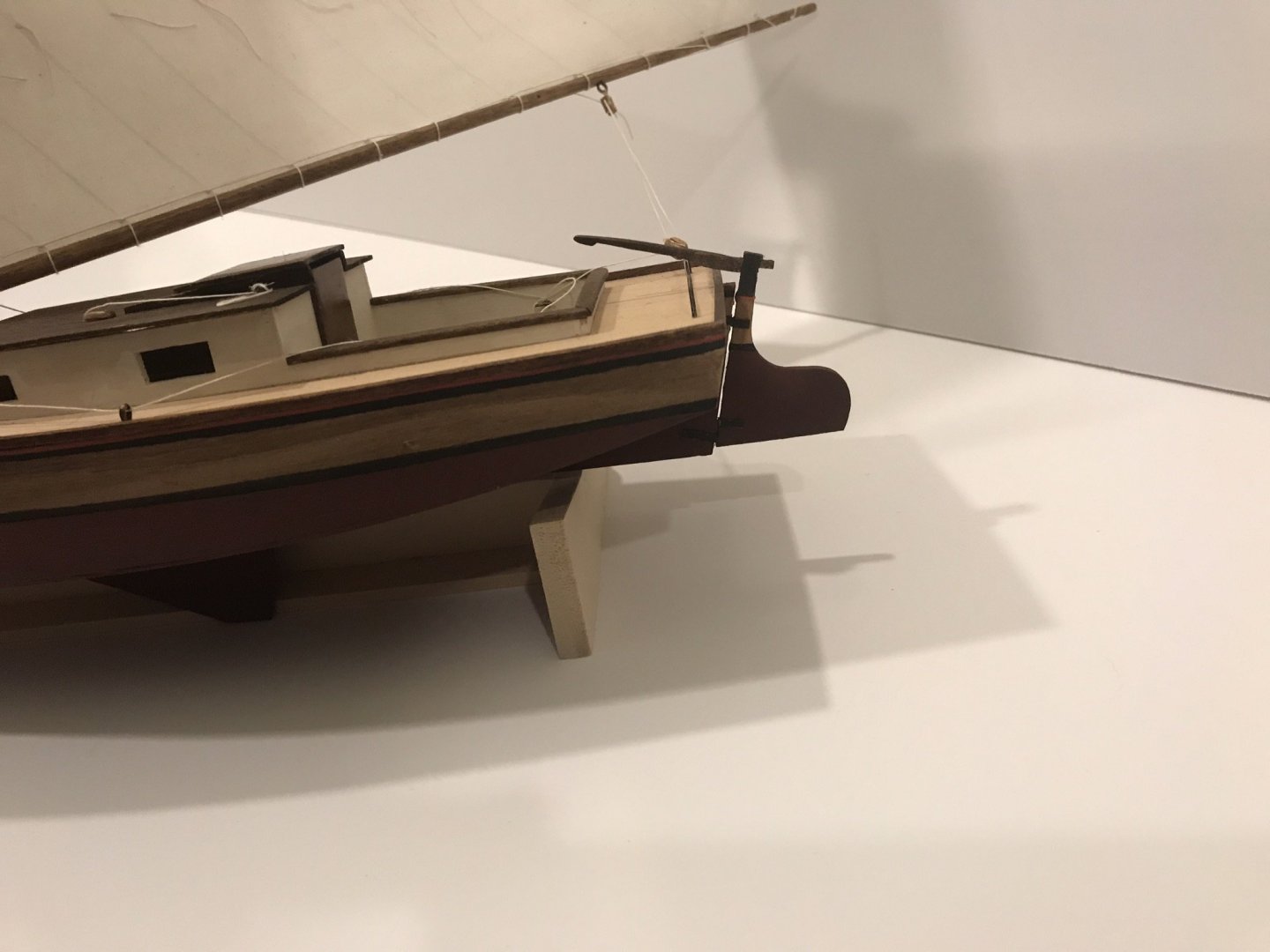

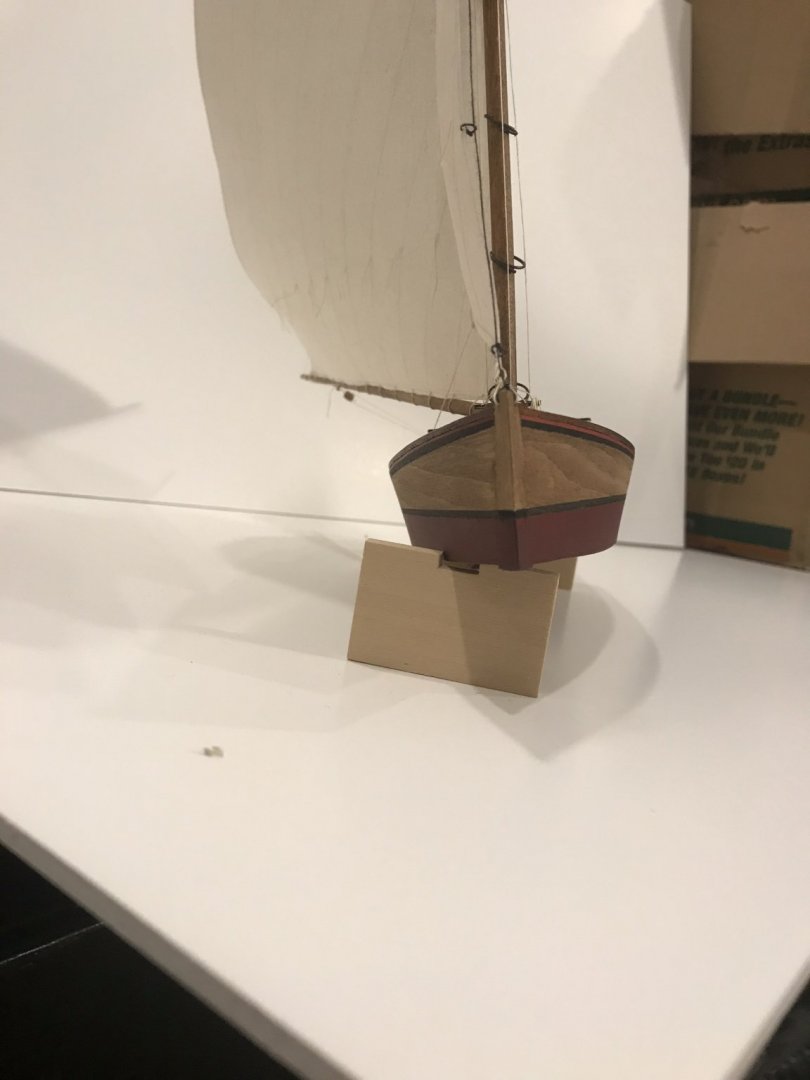

Opium Smuggler 1806 by EricWilliamMarshall - FINISHED - Authentic Models - Scale 1:75 - Schooner

in - Kit build logs for subjects built from 1801 - 1850

Posted

Having survived my first wooden ship model build, I’m going to push my luck again! I bought this model in NYC in the mid-90s and never built it. (My sole purchase of wooden ship models in the twentieth century!) It survived fire and flood. I cut one piece and chickened out. Apparently, I was waiting for the Internet and this community to be created so I could soldier on.

The ship in question seems to match a ship mentioned by Chapelle as a 1806 design by Samuel Humphreys called “Yacht for Canton.” (Thanks to trippwj and Roger Pellett for finding that!). The drawing in ‘The Search For Speed Under Sail.‘ is spot on. It’s not clear that this ship was ever built and I’m not aware of any other info regarding this ship.