-

Posts

7,341 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Mirabell61

-

-

Oh Pete!

I do hope my input of the last post did not upset you too much....

Your "Bluenose" will for sure have more displacement capacity to carry a suitable ballast. I will be following your progress with great interest.

I wanted to show you what I meant with the lines of the "America" I built, but did not complete. You`ll see why it reminded me of your "Bluenose". Some years ago my PC broke down, and all the personell files, and hundreds of pics, also modeling pics went lost with it. Fortunately I posted to a thread here at MSW to my rememberance, where I found my only still existing pics after searching...

Have a nice weekend

Nils

Yacht America, hull closed and watertght, but not complete, deck and fitting out started....

The length of the hull was about 1380 mm, as long as the sideboard where its standing on

3 Kg extra internal lead-weight made the hull already reach the waterline

There were two large hatch plates, under grating and skylight, flush with the deck in order to give access to all RC equipment and winshes etc

- GrandpaPhil, G.L., Siggi52 and 1 other

-

4

4

-

Thank you very much for your kind words Pete,

I see were walking down the same lane, your suggestions for fuel tank, brass filling cap, shiny straps etc, many thanks I`ll see what I can do about it. I was also thinking of placing a steelbarrel with Shell / Mobil Oil,. or so... enblem on it aft, next to the motor. My wife suggested there should be some blue/white checkered pillow cases for the berths of the cabin

Nils

-

Good morning Pete,

Motor preference, certain make ? Actualy no, the engine I chose was a free chosen fictive engine that would comprise motor housing, gear- and clutch housing, cylinder, shaft, flywheel, front bearing shield, water pump, oil dip stick, starter, generator, mounting brackets, V-belts,cooling- and exhaust tubes, clutchlever and propshaft coupling. I know that some essentual devices will still be missing, such as tank, gasoil injection unit, ignition box, glow plug, etc....

Some time ago I saw a Zeesboat plan being offered at Ebay, It could perhaps be worth searching there or in the web (Google) from time to time.

Mathias was using pear wood for planking, and yes, same as you did, I was amazed that neither glue stains nor toolmarks were to be seen there, he is a genius (what a skilled work !! )

What spooks aroung in my mind is, how can I achieve the old fishing workboat character, seeing all the newdays leisure Zeesboot craft. Example the wonderful deck Mathias built would probably be too fine for the fishermens muddy and scratchy boots and scraping network and fishing equipment ....

I must admit that a strong criteria for me is also ( in lack of carving or clay modeing skills), to choose the scale for the boat due to the scale-true crew figurines. Here I found two figures from make "Pola" which are actualy forseen as driver and stoker ( now converted to fishermen father & son) on scale "G" steam locomotives scale 1: 25 resp. 1:24

Nils

-

Good morning Pete,

thanks for sharing your progress, I very much admire your large version of the "Bluenose" you are at,.....it reminds me a bit of the schooner yacht "America" I built for RC in about the same large size. I wated to build a boat that could be seen, out on the water. The hull was plank on ply frame from mahagony wood planking, and to get her 100% watertight, coated with glasfibre roving mesh and epoxyd resin. The hull had true shape, was very sharp cut and grazile, and I already during the build had doubts if later on I could get enough inboard lead ballast inside at the lowest possible point, stradeling the keel and the neighboured frames. When the first time in water, I was quite disappointed that although the hull itself was a lightweight,

the waterline was already reached with appr. only 3 KG inboard lead ballast, (which would have been far too light for the large sail area to compensate). So the ship without the ballast went to the shelf. I sold it many years later to a modeling enthusiast in Hamburg and never saw or heared about it after that.

Trust that an removeable exterior fin keel with lead bulb would have been the better choise

Wishing you good success with the "Bluenose". The Billing boats Bluenose, I still have, was one of the first models I made when I was much younger, because I fell in love with the lines of this beautiful "Glouster Fisher" of the Great Banks

Nils

-

Hi Pete,

looks like you caught fire !

I support your comments about Mathias`s incredible Zeesboot, (on the Wettringer Forum), the other models or kits on the web did neighter increase my blood pressure nor inspiration, when I was in search during the preparation phase...

Yes, stove and brown sails will be fitted to my boot.

Perhaps the tuc engines of this link my be of help for you..

Nils

-

Good morning Pete,

I shall be very pleased to see another Zeesboot to be laid on Keel here at MSW, and shall be pleased to help you in this evaluation period.....,

now to your questions...

Cheers, Nils

Model dimensions:

The model in scale 1:24 is 495 mm long between the posts, will be appr. 750 , mm aver all (bow- and aft spars)

Mainmasthight appr. 490 mm

Beam 155 mm

There are several books available, two of them I am using, and can recommend they are :

-Zeesboote Segler durch die Zeiten, by Hermann Winkler

- Erlebniswelt Zeesenboote, by Timm,Stütz

this one also contains the overview plan I am basicly using, as well as the overview from the web, both motorized, one with fish containment boxes placed left/right of the centerboard

.jpg.7b88533c3651710ed5c6a5dc73a20d4e.jpg)

.jpg.ee60c9406c90387fb6f72ef4e1144e82.jpg)

if I`m not mistaken this build is from the web page : https://www.modelships.de/Zeesenboot/Zeesenboot_dt.htm

-

-

- Captain Poison, FriedClams, rafine and 9 others

-

12

12

-

Thank you very much Pete,

You are right with the thoughts about the natural curve of planks. The moment when the bow and the stern area is "fuller and rounder" in shape, there definately would be more adjustment to be made especialy to the clinkered planks....

Nils

-

Good morning Kees,

Thanks very much for your nice comment.....

Nils

-

-

Wow Bob,

good looking longboat

Nils

-

Good morning Pete and thanks for your kind comment,

I always admired model builders who were able to fit contoured frames into a clinkered hull ( built over a plug or a preliminary skeleton)

this now is my first clinkered hull, and also planked with pear planks, so I`m experiencing and learning, hopefully to get it done as I aimed for..... The best result I achieved was like shown in my post # 95

I`m still hesitating a bit with the resembling of the horizontal rows of plank connecting,pins, nails, dowels, etc. because I fear, that if they do`nt get absolutely aligned, near to the plank edges, it would not look neat and perhaps could spoil the look above the waterline. The actual Zeesboot planks had glued-in wooden plugs over the connectors, that were sanded flush after setting....

Nils

-

-

Congrats Danny,

That guitar looks great !

How about doing a 12 string western Guitar ?

Nils

- popeye the sailor, Canute, mtaylor and 1 other

-

4

4

-

H Kier,

if you can make use of it, here is how I usualy do it. In this case the model, my Chebec Eagle of Algier, is foreseen to display in a glass cabinet when completed.

When using brass pedestals I look out for some hollow ones, for instance made from old candle holders. The connecting part is a threaded spindel, which is anchored in the ship (interlocked in a suitable threaded conterpart fastened above the keel.

The bottom side of the spindel goes through the pedestal and through the stand plate, and gets a washer and a nut as a counter part.

Please refer to the pics, trust they ars self explaining....

Cheers , Nils

.jpg.5986e2292ce36c4cd06638b28547b525.jpg)

- dvm27, JerseyCity Frankie, allanyed and 2 others

-

5

5

-

Tolles Modell Martin !

a very good looking model Martin, I like it

Nils

-

Wunderbar !

very neat work Peta, love it...

Nils

-

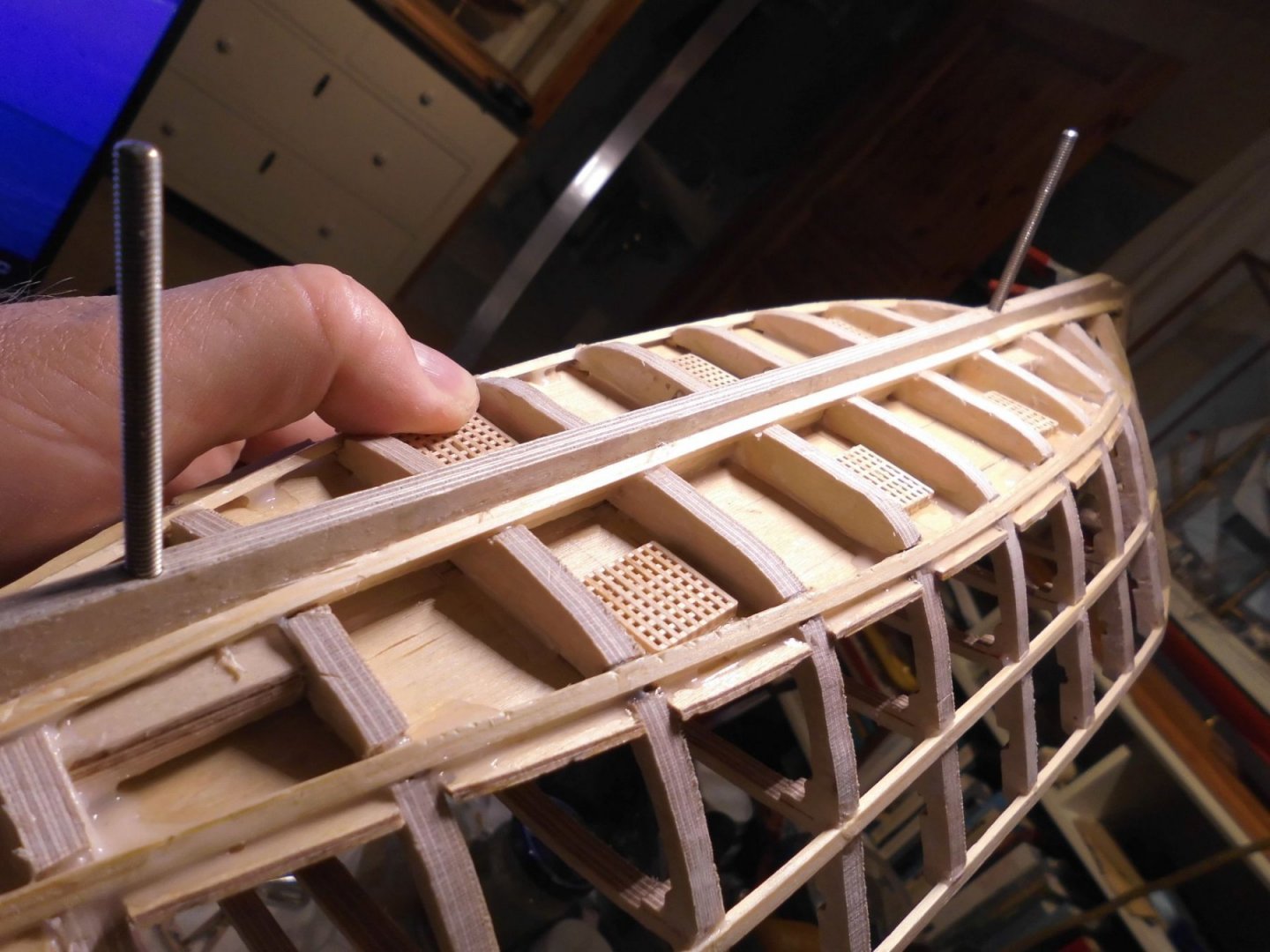

Status :

beginning the port side deck edge....

Nils

the brass strips (0,6 x 3 mm) are fastened to the short side deck beams with pins, before they are securely glued in

the side beams will be trimmed off on the inward side to the working cockpit later on

a "footrail" will be fastened to the brass stips

- popeye the sailor, cog, mtaylor and 14 others

-

17

17

-

Hi B.E.

I`ll be in for the same tricky task with my Zeesboot a little later on. I think I`ll give up the simulated rivet connection with 0,6 mm flat headed pinswhere I wanted to slip on miniatur discs from the inside to simulate the clenching discs.

Looking at lapstrake joints in actual the copper nails pins are not even flush th the planks but sunk in so far that towards the outside the holes are plaged off with small round wooden dowels and sanded flush. Although I``m working in scale 1:24, that would be impossible for me to do in that way, although the planks are 2 mm thick.

I went Web-looking for mini brass or copper flat head pins...., best suitable are mini nails I found at Krick (Article 473842). The great benefit is that the nails have only 0,6 mm diam. and a flat head with only 1 mm diam. !!. I think I will be using these... and set them flush with the outside. An alterative could be doing only dilling the holes and fitting in toothpick points ( like treenails)

Another task is to get the borings all to align properly in row. and distance, if this ca`nt be done utmost tidy it will "look at you" for ever after....

Am curious how you shall master this, and wish you luck and good success

Nils

-

Looking good so far B.E.

What will you be using for the horizontal inter connecting of the lapped planks ? (for optical matter only)

Nils

-

-

13 hours ago, Michel Bénard said:

Very nice and with this engine, no pollution !! 😄

Correct and thanks Michel,

no pollution, good idea, perhaps I can claim a technical Nobel prize for that

Nils

-

Good morning John and Eberhard,

Thanks for your comments, and also to all those who clicked the "likes"....

John,

I had a broad smile from ear to ear when I read your lines.....

Think its just that what we remember as the good old days, compared with the regulations all over, we have for everything today. The exhaust pipe should get a little plate fixed with warning "hot, do`nt touch, danger of being burnt, plasters, bandage and Asperin in the cabin"

Eberhard,

when I read asbestos the "red light" went on in my mind straight away, bearing all the facts you mentioned

Nils

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

in - Build logs for subjects built 1851 - 1900

Posted

Status :

transfering the waterline to the model, and beginning to put wooden (Bamboo toothpicks) into the horizontal, overlapping clinker planks. I did`nt do this before, so its a jump into the cold water.

I did my best to get the 1 mm toothpick holes in alignment, starting with the upper stb. plank. Check of the outcome will follow tomorrow, when the toothpicks are trimmed off and the plank sanded over.

Nils

the little jig for marking the waterline

thin bamboo toothpicks

a trial with 1 mm holes in the planks (Chose this one)

trial 1,5 mm holes ( found them too large)

picks glued in lightly with CA