-

Posts

429 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Richard44

-

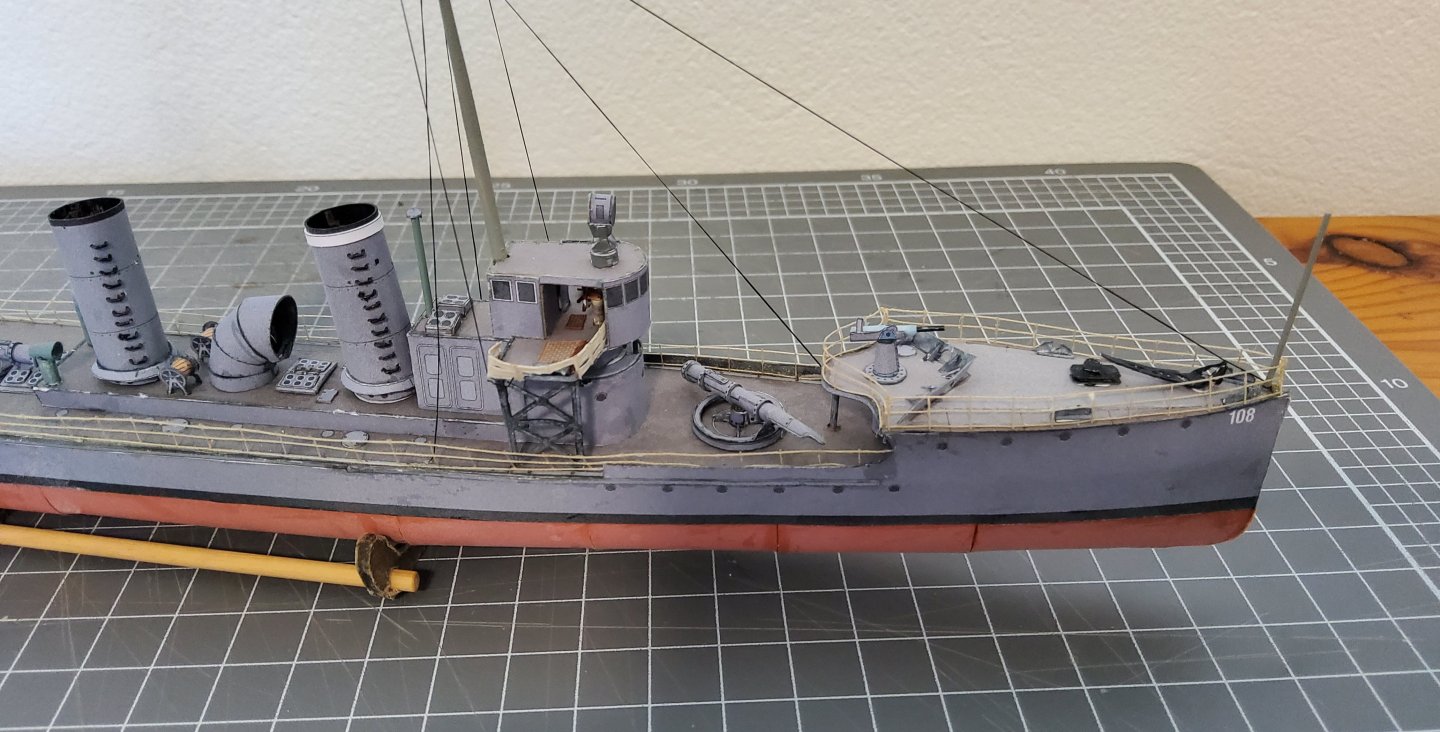

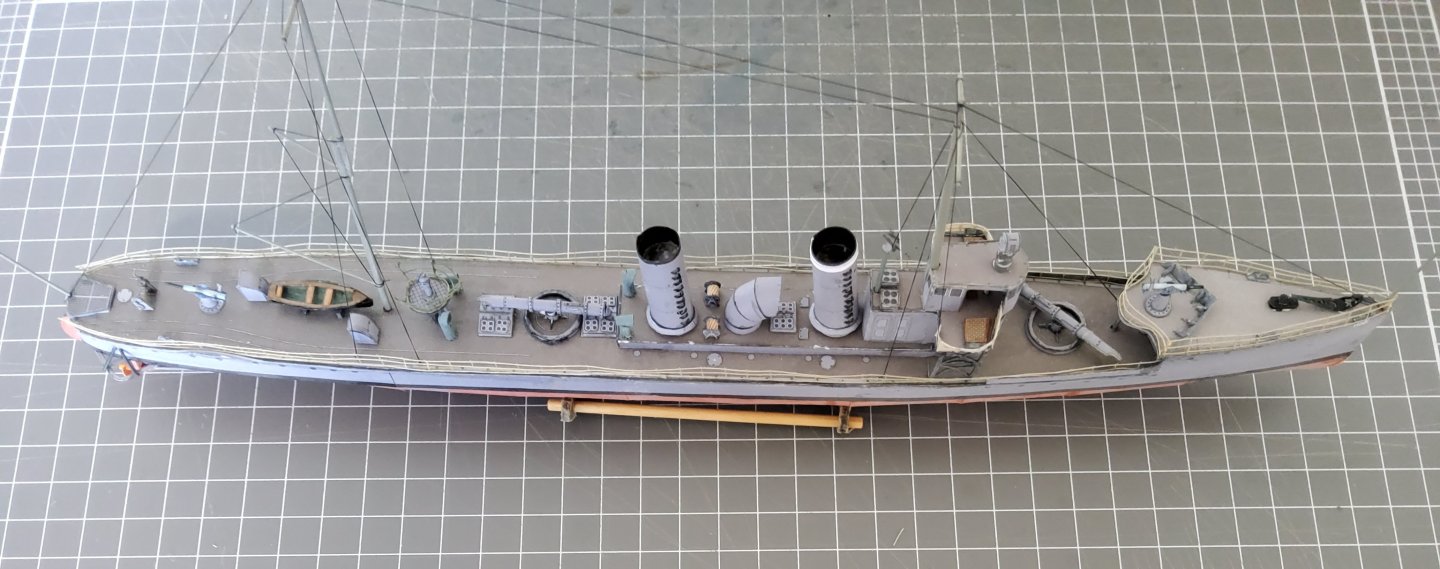

Intro to Card Models Part VIII: Building V108 - Miscellaneous Bits

Richard44 replied to ccoyle's topic in Card and Paper Models

Morning all. There's no build log for my model of the WW1 German torpedo boat, V108. Various factors conspired against me doing this so all I have is a few photos of the completed model. Chris Coyle presented a tutorial on card building using the V108 as the subject. The designer, Digital Navy, allowed the kit to be freely distributed to MSW members and though it is no longer available on the Digital Navy website it can still be downloaded here. I had built several card models but only waterline models, so I decided to try for a full hull, though Chris in his tutorial only builds a waterline V108. It's still a learning curve for me with card models, but my V108 turned out reasonably well with some new techniques being tried (eg thread railings). Cheers -

Probably referring to common white carpenter's glue, PVA, poly vinyl acetate.

-

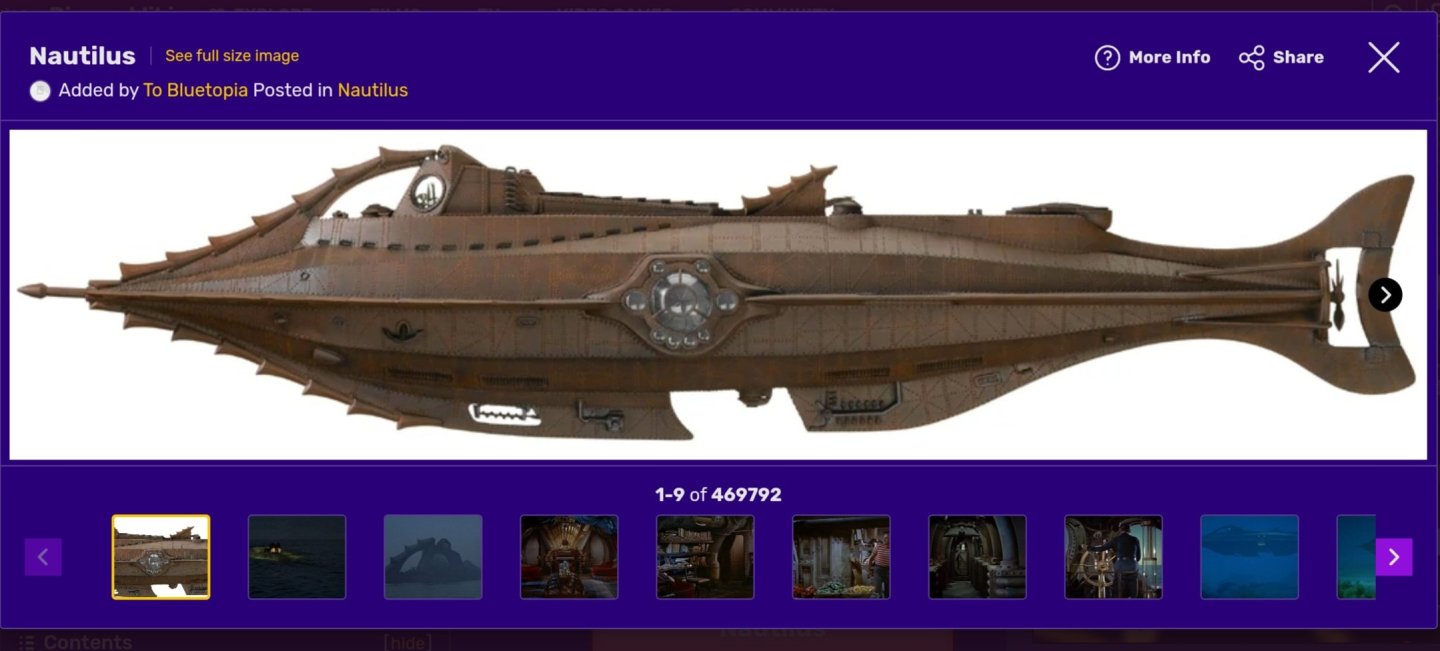

Wow. Very, very different to the Nautilus in the Walt Disney movie. Cheers Edit. Should have added this image.

- 40 replies

-

- Nautilus

- Heinkel Models

-

(and 2 more)

Tagged with:

-

I'm with Keith on this. Use the existing pieces, but before committing, check how much you need to remove where the pieces aren't quite in alignment - it looks to be about 1mm or so. Dry fit a couple of the frames to see if the reduced height of the keel (assuming you do sand the lower/upper edges of the keel) affects their fit. If it looks like everything will be more or less "off", then a new keel from ply would be the answer. Also, I've noticed that you wrapped everything in cling film while glueing and as you have found out, this can obscure what's happening with the glueing. You only need the cling film if there is a chance of accidentally glueing another piece to the two you are joining. You didn't need to use the cling film that shows in the following images. Cheers

- 146 replies

-

- Roar Ege

- Billing Boats

-

(and 2 more)

Tagged with:

-

Micha, For what it's worth, I used white PVA (the common one here in Aus is Aquadhere) almost exclusively when building the boat. I may have used CA occasionally. Most of the gluing is easy enough. For the planking, I ran a thin bead of glue along the top edge of a plank, clamped (pegs work well) the next plank to it and wiped off excess glue, moving the clamps as required to do this. Good luck with your build. Edit. I should have added this. The only joints on this boat that will be under any sort of stress are those associated with the planking. The planks are already spiled, and if you fit the planks before gluing, the stresses will be minimal. You do not need a super strong glue. Cheers

- 146 replies

-

- Roar Ege

- Billing Boats

-

(and 2 more)

Tagged with:

-

Hi Micha, I thought that I would show you a few photos of my Roar Ege. Unfortunately, there is no build log as I built it before joining MSW ☹️. Probably can't help much with questions either 🥴 as the build was quite a while ago. The kit does make into a nice model. Enjoy. Cheers

- 146 replies

-

- Roar Ege

- Billing Boats

-

(and 2 more)

Tagged with:

-

Chopper Lesson Learned

Richard44 replied to Todd Hart's topic in Modeling tools and Workshop Equipment

Hi Jaager, The screws are now metal, but it is fiddly trying to get that sweet spot. I had no trouble with stock moving around, but I was only ever cutting small sectioned wood. It's not perfect, but it worked for me. Cheers -

Chopper Lesson Learned

Richard44 replied to Todd Hart's topic in Modeling tools and Workshop Equipment

I fastened mine to a board, then fashioned a moveable stop from aluminium (aluminum 😁) angle so that I could cut multiple pieces all the same length. Cheers -

Hi Alex, I don't actually live in the Blue Mountains, I live at Gosford. I travel to the BlueM occasionally for bushwalks. That's a great looking model you've got. Cheers

-

Chopper Lesson Learned

Richard44 replied to Todd Hart's topic in Modeling tools and Workshop Equipment

You could look at this tool. I have one and it works very well. https://www.micromark.com/Miter-Rite Cheers -

After drinking a bottle of schnapps, I can well understand your confusion - clearly I meant along the bottle, not around it 😁😁 Cheers

- 63 replies

-

- card

- Revenue Cutter

-

(and 2 more)

Tagged with:

-

Wind the thread gently around a dowel 10 times, measure the length, divide by 10.🙂

- 63 replies

-

- card

- Revenue Cutter

-

(and 2 more)

Tagged with:

-

Hi Alex, welcome. What part of the Blue Mountains are you from? I've just done a bushwalk at Lawson. Cheers

-

Don't know if it would work, but you could try printing by stretching and fastening the silkspan onto a sheet of paper. Laser printer might work better than ink jet.

-

You could try moistening the frame first - the moisture triggers the CA. One problem may be the wood itself. Some woods are slightly oily and CA doesn't like it. Best of luck.

- 68 replies

-

- Sanson

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Hi Mike, I see that you've just looked at my build log, so you know that the outside of the hull was painted, but most of the rest of the boat was left natural. 🙂. I now have no idea where I got the colour scheme from - I think it is fairly typical of boats of that time. Cheers

- 62 replies

-

- lancia armata

- panart

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.