-

Posts

1,509 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Vladimir_Wairoa

-

-

...to add to confusion ---- im definitely not drawing any conclusion. using linux so i installed adobe acrobat there to compare ubuntu simple reader there and measures at 100per cent were even more off some 17 cm ?.? :/// woohoo. I just hope i am not making some trivial mistake omg... I think i will wait for Chuck to provide center block sternpost measure as i pictured...shoul i watch it in some vector program as corel or... im not that engineering able though... so I know what program is ok LOL....

i think i figured it out though

its not usual to get 6.3 or 6.5 mm ply here so i settled on 6 mm thickness ( which they are) and i guess he set up measures exactly for 6 mm so it shrinked the plan ratio accordingly littel bit which resulted those 96 percent. makes sense to me cant imagine how else it could have happened...im on verge to continue anyway with the hope windows will fit and with sigh i will have to extra rasp off the parts here and there. i will have dificulty to find out even 6.5 ply which can be on other hand even bigger which is trouble. at the point of skeleton the crucial part is gallery and stern side so well...i cant imagine making mine bulkheads after cutty in 1.24 its auch relief to follow nice guidance anyway...

-

On 11/21/2020 at 4:20 AM, Greg M said:

Appreciate the likes as always.

I finished the 3rd 1/4" strake and it was a lot tougher than I thought it would be. I just couldn't find a reproducible technique that kept working for cutting each plank due to every angle being slightly different. Every time I thought I had a breakthrough, the next plank would prove it wrong. In the end, side cutters worked and a sanding stick worked best, as well as taking frequent breaks. I also found a simple jig of a binder clip and scrap piece of wood as an upright went a long way towards making sure the plank was perfectly aligned.

I started on the 4th 1/4" strake up through the 4th gunport which is where the first tab will need to be created. Now that the first three gunports are fully enclosed, I gave everything a good sanding to remove any rough edges so I could make sure I didn't mess ups any gunports.

I'm pretty happy with the results, although I found the first problem that I can't really fix. I don't know how or why this happened, but on some planks the glue I used caused some paint to transfer. You can see this on the lower left plank of the 1st gunport. I've never known acrylic paint to transfer once cured, but something in the glue must have softened it to allow it to bleed into the wood.

Next step is to install the fixed blocks and finish up the 4th strake.

very nice Greg.

-

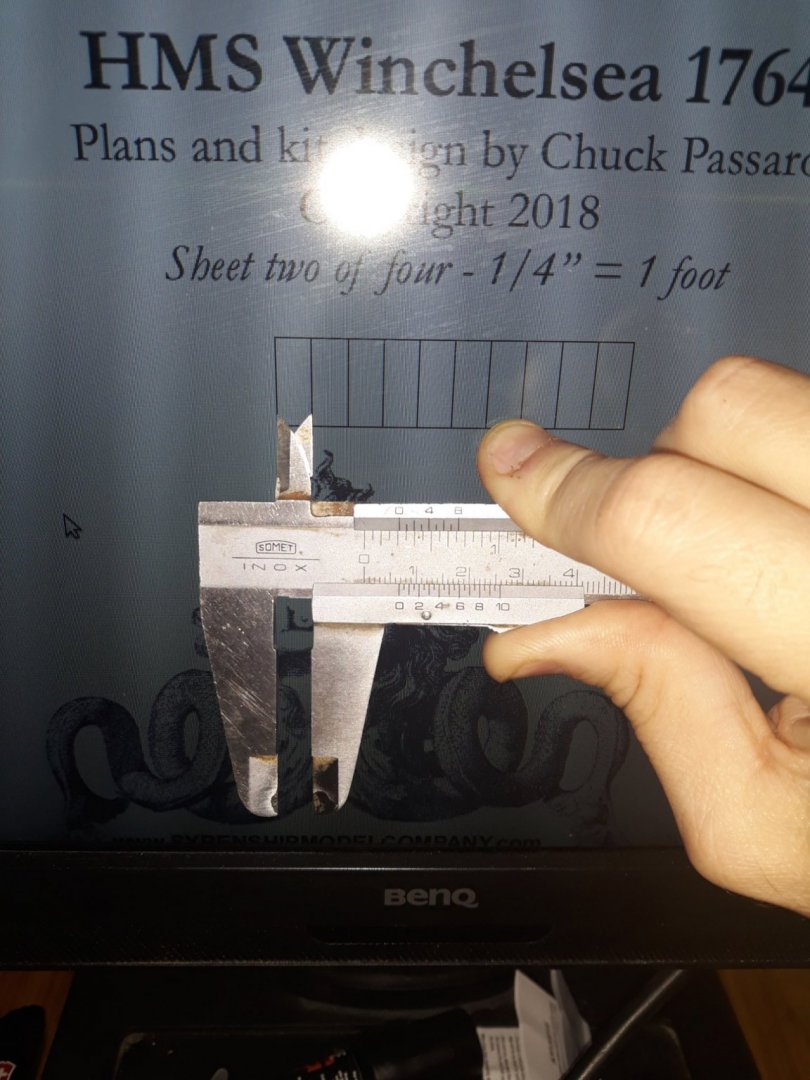

Well I cooled down a bit i remember there is stuff with enlargening of plans in softwares etc... I measured quarter inch on not sure it might be calibration staff or what, but 1/4" looks 0.68 in 100 % not 0.63 as should so im a bit relieved i can have it ok. . Stem length as on picture is 14.4 cm = 5.7 inch. So if that measure is correct is all good.:) If should be longer than i know i am off...

so far hope lasts

so far hope lasts

- FrankWouts, Ron Burns and Matt D

-

3

3

-

4 minutes ago, Ron Burns said:

Vlad, I feel for you! I'm not all that experienced but if it were me, I would do it again. I don't say it lightly as money is always tight for me it seems. If you were to make the entire kit from scratch, I would say 'who cares' as its like you said..a couple mm less all around won't matter. Since you have parts coming at full scale, I wouldn't want to have to sand them down as they are just perfect coming from Syren. Perhaps you could save the bulkheads for another frigate or a wee bit smaller, second Winchelsea

thanks for opinion Ron im on that side of decision too so far, but i will maybe wait untill parts arrived so...well..arrrgh:)

-

Hello all, alreadyvRun into first deadlock folks. :(((seems i enjoyed it prematurely, as i measured center board and bulkhears and all is cut smaller than original exactly 96 % of 100 size:( . im in despair as i see no window here than just to get it cut again , ican manage part 1 ( but curvature of stern would be problem i guess) and i ordered onl part one and three i intend to make part 2 and 4 myself. but that would be always struggle and i am affraid windows would not fit there , maybe ornametation wouldnt be a problem.

as boat progresses I guess there wont be much hassle as its few per cent so it makes 3 mm on 15 mm lenght which is quite a lot i guess...i would have to rub down even laster parts which does not make a sense to me to star this wrong...what do you think?

-

6 hours ago, MartinB said:

On board for your new build Vlad.

Cheers. Martin.

pleasure is mine Martin.

-

-

beautiful job. congratulations!

-

On 10/26/2020 at 2:37 PM, ObviousNewbie said:

Hi all,

It's been a while, but Teror is finally where she should be:

There are probably hundreds of mistakes in there, but I can't help but feeling proud for my first build. The Admiral was equally impressed, so the display case has taken up a central space in our home 🙂

Thanks again to all of you for all the help, advice and support. Without you, I'd probably still be figuring out which rope goes where 🙂

Stay safe and take care!

congratulations. you should be proud for this accomplishment as first build. well done! beautiful . v.

-

congratulations Mike. fabulous indeed. this boat is my desire in future build and i will look for this one and to your meticulous craftsmaship for inspiration.

-

14 hours ago, Ron Burns said:

Oh how I wish I had used lighter plywood! You will congratulate yourself when it comes time to fair the 27 bulkheads and bow formers! It looks like you are off to a great start! Wait until your chapter parts arrive...you'll see the quality and care that went into this project.

good point about sanding Ron, thank you.

-

45 minutes ago, Edwardkenway said:

You have a good friend there, to do those parts for you!

Good luck and happy modelling!😉

Thanks Edward & folks, well that friendship involved money too

as there is no free lunch obviously :)) but part of the decision were many leftovers from previous work. also one packge of planking suff that was lost in shipping and arrived half a year later

as there is no free lunch obviously :)) but part of the decision were many leftovers from previous work. also one packge of planking suff that was lost in shipping and arrived half a year later

- Edwardkenway and FrankWouts

-

2

2

-

56 minutes ago, Chuck said:

Well that is a great start. Hopefully you will get those parts soon. Shipping is a mess right now just about everywhere.

Welcome to the group.

Thank you also for all amazing effort.

-

Hi folks,

Im trying to catch up with rest of the bunch throughout winterly snowy evenings on this magnificent project, hopefully learn soke new skills and back myself up of Chucks and yours guidances photos etc. Still nervously awaiting package with 1234 parts from overseas but already started as friend made for me the bulkheads on cnc. He was so nice even marked letters and so on...And thats a ton of pressure he put off my chest. Its poplar, extremely light and so im pretty nervous how it be around those tiny wooden walls...i have big build behind me from scratch without any guidance nor buildijg lan now trying to learn propper stuff if up to it. Thanks for any comment like etc so ...i cant go on further at this point :)) . Central frame glued. ! So i wish her luck! hope everyone healthy and already arranging christmas tree with taking sips of favorite drinks. I do though

V.

V.

- FrankWouts, VTHokiEE, Edwardkenway and 6 others

-

9

9

-

joy to watch Bradley. thanks for showing.

-

I hope/wish for speedy recovery @Clipperfun

-

-

7 hours ago, rwiederrich said:

wow it looks very nice and of course Rob R. style - out of the box

her deep body starts popping up. clearly nothing like flying fish. cant wait to see it further.

her deep body starts popping up. clearly nothing like flying fish. cant wait to see it further.

-

Happy to see the progress Rob. Nice idea with separate wood for deck curvature and subdeck for strength. You could also glue up some pieces of wood around centerline and bulkheads joint, to fix bulkhead firms apart of subdeck, but you will do it later probably.

she starts to emerge....

happy continuation

V.

-

-

8 minutes ago, svein erik said:

hi

congrats, you are duing a fantastick job , the model is big but its also looking beautiful....

with rigging it wil be a master peace .

i hope i can build a cutty from scrath but not so big then😉 i love to see it rigged sometime in the future.

have a grait day☺

svein erik

Hi Erik thanks for nice words.

Well, if I was to start now, I would think differently in this direction. if going with full rig definitely go smaller at least 1:48 would do beautifuly. If going 1:24 - BOF without masts at all would be astohisnig but being frame not wooden - that would be a unimaginable challenge. also it woudl be long long work.

my piece of advice now is if someone desires to build larger than rest - be prepared for long route i mean long route - even longer than long

thats for sure

thats for sure

another piece of lesson i learnt was - it does not matter how big is ship - rather choose smaller boat dor intricate details - can be obtained in smaller vessel ( according scale) but some boats are too big in life that for detail they need to be built bigger to have those details appear.

i encountered a small piece of big deadeyes or eyebolts etc rigging there - and I struggled.

i encountered a small piece of big deadeyes or eyebolts etc rigging there - and I struggled.

but trying big rigging can be tricky because you will soon run into other problems that small scales omit - splicing and other nightmares:)

so it realy doesnot matter at the end each scale have its own advantages and disadvantages - for example - in big scales you have t omael own deadeyes - impossible to buy - and mostly everything that comes with ironwork -

rudder hinges? not existent .

most suppliers have things commercialy sold up to 1:65 i would say.

that itself would have shortened my timework approximately to the half!

so building smaller has numerous asvantages over building big -

but that is obvious i guess

but that is obvious i guess

for that I take hat off every smaller scale builders who rig their boats fully. that is unimaginable for me to achieve. i would rather make 10 boats hulls and cabins than one small 1 masted rig. :))

- svein erik and mtaylor

-

1

1

-

1

1

-

19 minutes ago, Mark P said:

Congratulations on completing her, Vladimir;

A very lovely model, and built with remarkable speed. There is a lot of good detailing on her, and I agree with the others above: it has been a pleasure to watch her taking shape under your hands. I hope that whatever well-earned rest you take now will not last too long, and you will be back in the workshop on your next project; which I look forward very much to following.

All the best,

Mark P

Thanks Mark for kind worlds and valuable support on this journey.

Truth is I will not have granted such time as I had building cutty ever. Due to work it will take linger to post. hovewer I have paln in my head established , as usually winter is my workshop time. i have violin and cello half built but not touched over 1.5 year now but i dont want to leave ships abandoned so i have to figure it out. - im eyeing some small models 1 or 2 - whaleboat or historical lognboat cutter and scottish fishing vessel. but my main project will be McKays glory of the seas as I have merchant clippers in my heart:)Now i can establish quite fast route with hull ( being way smaller im not scared that much - and having build cutty without any building instructions apart of campbel plan i had to follow try and continue route -

for glory i have i intend to use model shipways detailed building plan with step by step insteuctinos which would be breeze i suppose if i nail main things. but at the same time i want to make hull filled with balsa maybe for filled up hull - two layers of planking and I wish to make bow glorious so i would have to probably search for ways where to purchase a figurehead. that that would be later. - so i wish i can get hands on glory this winter and complete hull. fingers crossed.

oh by the way - i worked carelessly with chemicals and glue on cutty with bare hands and unfortunateyl ideveloped kind of

alergy on hands. so i will prefer to use wood glue from now on. its agressive chemical bastard that fastglue..meanwhile i will sit , watch and enjoy and like projecs of others...V.

alergy on hands. so i will prefer to use wood glue from now on. its agressive chemical bastard that fastglue..meanwhile i will sit , watch and enjoy and like projecs of others...V.

-

On 9/25/2020 at 9:32 AM, Bruma said:

Why? Because she will be too long or too complex?

Anyway, you did a great job, and she looks fantastic even now! And... Who knows, maybe in the future you will come back to her and complete the rigging!

Thank you for sharing your journey!good point Bruma , thanks!

- Paul Jarman and mtaylor

-

2

2

-

23 hours ago, Paul Jarman said:

Great job Vladimir,

I personaly think she looks Good without all the rigging. You get to see all the details better.

I have a few sailing ships in my stash. But I find my hands shake far to much when attaching small parts, and especially when tieing knots.

I will take inspiration from this and build one without the rigging.

Paul

Thats true as well Paul

thanks

thanks

- Paul Jarman and mtaylor

-

2

2

HMS Winchelsea 1:48 by Vlad

in Member Build logs for the HMS Winchelsea

Posted

@Chuck Chuck, could I ask please if you can confirm if this measure is correct or should be more? . many thanks its 5.7 inch which gives me 96 percent of plan im affraid thats the trouble. Vlad