-

Posts

5,951 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Hi Jay, yep, I have the same understanding of zeroising (the readout) not the tool itself. However, as I said the unusual thing is that if I measure the same article/item, all three give a different result. I understand that if I zero the readout, the amount of movement is relative to the starting point (zero) and therefore all readings should be the same. The micrometer (which has been tested/calibrated and certified) I trust to be the most accurate. The readout given by the Imperial (fractional) digital readout calipers is not far off, but the cheaper (version/type most folk seem to be using) are out a bit. I have noticed that when the jaws are fully closed on the metric calipers and I 'zero' the readout, the etched vernier scale on the main slide (?) is out (not registering on the 0 line) and it is very close to the difference in accuracy of the measurement between the micrometer and the caliper also. This is the enigma - if the readout measures the relative movement to calculate the 'measurement', it should be accurate no matter what? Essentially, I believe that after a while the caliper readout of the measurement may become suspect, possibly wear on the internal parts? I am not sure how the distance reading is converted to the digital readout value, but I am beginning to think that the mechanical component of the sensor (or however it is done) may wear over time and that is why I am getting the slight error in measurement. This became evident after having to remeasure my micro-drills on several occasions as one caliper gave me one reading, and the other a different. A couple of hundreths (when rounded) makes a difference in determining whether to use the drill as say a 0.9 or 0.85mm drill. I double checked these sizings with a gauge plate (not the most accurate means) but the results using the micrometer were much better than using the metric calipers. I have reverted to using my micrometer until I get a better quality caliper (with digital readout) and I will be sure to check how accurate they are first this time cheers Pat

-

Hi, I have two sets, one metric the other Imperial (Fractions) and until recently I used them all the time until I became aware of a small problem I have yet to resolve. I was wondering why some of my measurements were very slightly out and finally recognised that the calipers were not truely zeroed (they differed from each other and from a "engineer" certified quality miocrometer). We are only talking a few hundredths here so it is not critical for many jobs; but I would love to know how to truely zero these? (I can reset the readout to zero, but the inscribed vernier scale is not zero when the jaws are fully closed (this is verified by the micrometer which indicates / measures a difference in size equivelant to the difference shown on that scale.) CraigB@ thanks for the reminder in your earlier post which alerted me to this possibility; I think I may have to invest in a better quality metric version; the Imperial measurement version is slightly out, but much better and I can live with it. cheers Pat

-

And a belated from me also John, I have been a tad distracted lately and hadn't caught up. This little beauty is up there with your previous builds mate. a right little lady of the sea! cheers pat

-

Very nice work work work on those sails even if you are not completely happy with them. They look quite good and amazing to think it is paper. A nice collection of small rigging tools also; the micro crochet needle is a surprise. Where did you find that? (don't tell me watchmakers use it ) cheers Pat

-

Rowan failing that, there is a shop over there called DCC Concepts. He carries Carrs Brass Black (well used to anyway). No affiliation etc...... cheers Pat

-

Hi again folks, this is more a push than a new question. Another area of research for the Club's build I am trying to clarify is around the Contract specification for a "Lang's emergency tiller". The only information I have found is by the Editor of the Nautical Magazine, Original Papers, January 1836, page 272, makes comment on the Lang ‘Emergency Tiller’ as follows: We understand that Mr. Lang has proposed a plan, which has been adopted, for a tiller, in case of the original one being carried away. A temporary iron tiller is supplied, being fitted to ship in the after part of the rudder above the water, and to be worked by guys leading up to each quarter. To the point: 1. Is anyone aware of an emergency tiller (physical) drawing of this tiller designed by Lang? 2. Has anyone seen an emergency tiller arrangement like this? My current disposition is for a simple iron rod with two eyes, one either side of the arm on the after end which is fitted to the trailing edge of the rudder above the waterline bu means of a slit cut into the end which can be bolted to the rudder as required. However, have bolt holes, even if filled with the bolts until the tiller is fitted, would allow seepage and possible rot in the wood? I have seen no drawings with device fitted permanently. Many thanks Pat

-

- hmcss victoria

- tiller

-

(and 1 more)

Tagged with:

-

Hi Greg, as long it is only us that are slack and not the rigging Tidy, and very nice work mate and those blocks look supurb. Did you use the supplied heart blocks? I don't like the ones in the AL kit and looking for a source for better ones. Do the Polish guys supply these also? cheers Pat

- 319 replies

-

Hi Wayne, many thanks mate; you obviously use better search strings than me. I did find the magazine but could not find a drawing - much more to learn this end Many thanks again. cheers Pat

-

Hi folks, continuing to research for our club build of HMCSS Victoria (1855), we have unearthed the following in the Contract. She was not fitted with deadeyes, but rather Lanyard Plates as invented by Leut. James Rigmaiden. The patent was (I think) in 1849, and a model of the arrangement was displayed at the Paris Show in 1850/51. Some wording we have found states that the invention allowed ships to fire their canon closer to the shrouds with this design. I have found several online (pdf) books that chronicle or summarise the Paris Show stating that the model was on display (item 291) but have been unable to unearth any useful information. I have also looked in Goodwin, Lees and Steel with no joy. I have also trawled through the NMM's collections with no joy. As the names suggests I believe these would have been metal plates that replaced the deadeyes but retained a lanyard, but probably in a much more compact design - alternatively, they may even have been an early form of rigging screw/turnbuckle? The Victoria was fitted with some very leading/cutting edge technology for that time as a one-off build and plenty of (Gold Rush) money lavished on her. Has anyone heard of these, or even better (please make my day) provider info and/or illustration of the arrangement? Any help, advice or pointers would be much appreciated.

-

Add me to the queue John, she looks a grand little lady of the sea. Now IO suggest you park those tweezers somewhere they will do not further damage cheers Pat

-

That is very neat work Weflack, especially when considering the scale you are working at. That will be one very 'nice' realistic looking model. regards pat

-

Greg she is looking great; the ratline process will end soon - I am just starting the rigging and have this chore to look forward to Your boats look good; what plan did you use for the Gig and skiff (or yawl)? I have finished the longboat and cutter but two (possibly three to go) cheers Pat

- 319 replies

-

Hi Greg, mate keep an eye out around Floriad time, the ACT Model Shipwrights Club put on one of the best shows in the country! This year's is supposed to be bigger as they are trying to tie it in with the RAN 100yr celebrations. I'll see if I can track down a contact/link for you. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi Greg, about half way down this post. http://modelshipworld.com/index.php?/topic/3509-melbourne-tall-ship-festival-2013/?p=98369 There are only a couple of close-ups. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi Mike, try this post by St George. http://modelshipworld.com/index.php?/topic/3102-oar-lengths/?p=85602 - is this what you needed? Follow the link he provides in his first post. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi Mike, thanks for looking in. I'll be posting an update soon WRT the longboat, there are two schools of thought postured by Marquardt and by Parkin - who is to say who is right? In the end I did a bit of a mix but did use the Chapman Longboat hull (as proposed by Parkin I think) for the basis, but I did use a clinker finish (for strength which I think may have been a consideration for Cook - BUT this is all conjecture as despite reading logs etc there is no actual hint as two the type of build that I could find). I'll look up the details on the boat proper tinight or tomorrow and try to post you an answer via PM. I haven't looked at oars yet but I recall a good discussion here on MSW and some posts on the size ratios. need to do a search for that, but if I find it before you I'll give a holler.

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Nice work on the catheads and the replacement beam Danny; and another thankyou for the Mini-tutorial. You'll have to lay off some of shipwrights soon and employ some additional riggers cheers Pat

-

Very nice work on your rigging - trim and taut - the "jimmy' would promote you to Bosun for that! cheers Pat

-

Some real nice work there Mark; she's looking very trim and ship-shape. With all that extra time in retirement this will be finished by the end of the year won't it? cheers Pat

-

Agree, I don't use it for it intended task myself, but it did prove useful for the task above - that is all I use it for (and then had to replace their cheap plastic bolts with metal bolts and nuts The photo actually show a plank in it rather than a keel, I have found it useful for planing (as a sort of 'shooting' board/clamp) and sanding planks but that is about the sum total of its usefulness! On second thoughts/reading I think my response may be 'way off' and Francis is looking at how to 'tie' planks together? cheers Pat

-

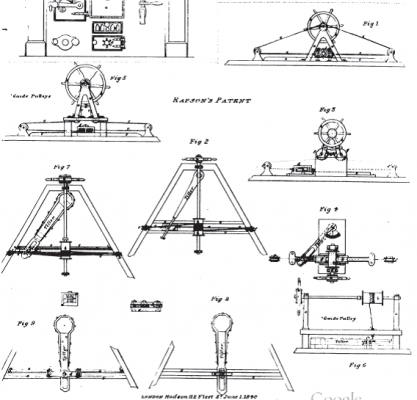

Hi Francis, I am not aware of any machine, but you can make up a jig if you have several planks/strakes that require exactly the same taper to be applied. Simply use a long clamp, or clamp several planks beween metal strips such that the amount to be sanded/taken off the plank is left exposed above the edges; then sand away. To determine the amount, use the spiling rules etc that can be found elsewhere on this site, mark the lines on a single plank then clamp as many planks together as is possible with the marked plank outboard and sand down to this line. If the marked line is aligned to the edge of the metal/clamp then it is much easier to simply sand down to the metal/harderwood/smaterial. It can be as elaborate as the AMATI Keel Clamp as shown here (I have no commercial connection) or simply by clamping the planks between to strips of old hacksaw blades or strips of hardwood and lining up the lines as explained above - then simply sand away I hope this is what you were asking about? cheers Pat

-

Hi John, good to see you back safe n' sound and having enjoyed your break. Now back to some real fun huh cheers Pat

-

I 'think' the updates/new work you decided to do really adds to the build Piet; the semi-working vanes look great! Never too much thinking, just a mater of filtereing the good ideas from the bad - in this case the filter woirked just fine cheers Pat

-

Nice work on those anchors Ilhan, yet another way to make them - I'll file this idea away I'm keeping well thanks - your progress would appear to suggest all is well on your side of the globe also. cheers Pat

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.