-

Posts

1,837 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glen McGuire

-

-

Back to the display to finish this whole thing up. First up was adding a layer of sand around the chest to make it look like it had been recently unearthed. Going into this project, I had no idea what I was going to do for the sand. A few weeks ago, a friend of mine bought some Mod Podge for a small project. She barely used any of the bottle and asked me if I might need it for my SIB work. I had never even heard of the stuff, so I told her that I’d look around the MSW website to see if any other modelers used it.

Sure enough, it looks like a fairly popular product. Then I found one build log where the light bulb went on and bells started dinging. @turangi, For his Emma C Berry – Model Shipways build, used Mod Podge to make a gravel base for the display. He had really cool concept where he showed the ship in drydock having repairs made to the hull (see 1st pic below from his build log). His gravel base looked like what I had in mind for the sand around my treasure chest.

So I decided to follow Turangi’s lead and see if the Mod Podge would work for my display. I mixed up a glop of sand and Podge, dabbed it around the treasure chest, worked it to the edges, and then mashed it around a bit to create an uneven surface. Then I sprinkled a layer of dry sand over the whole thing to give it a realistic texture. I let the whole thing dry overnight and then dusted off the loose sand.

It came out pretty much like I had originally envisioned. So a big THANK YOU to Turangi for an excellent build log and showing me a great use for Mod Podge!

-

Welcome to MSW, BG! Lots of amazing folks out here. I learn something from them almost daily!

- mtaylor and Keith Black

-

2

2

-

Welcome, Ray! Glad to have you aboard!

- Dave_E, mtaylor and Keith Black

-

3

3

-

3 hours ago, Landlubber Mike said:

Almost like you needed to spray some WD-40 or other lubricant (not going there!) to get it in.

LOL!!!

3 hours ago, Landlubber Mike said:having such an angled bowsprit could have made things much more difficult if the bottle had a longer neck.

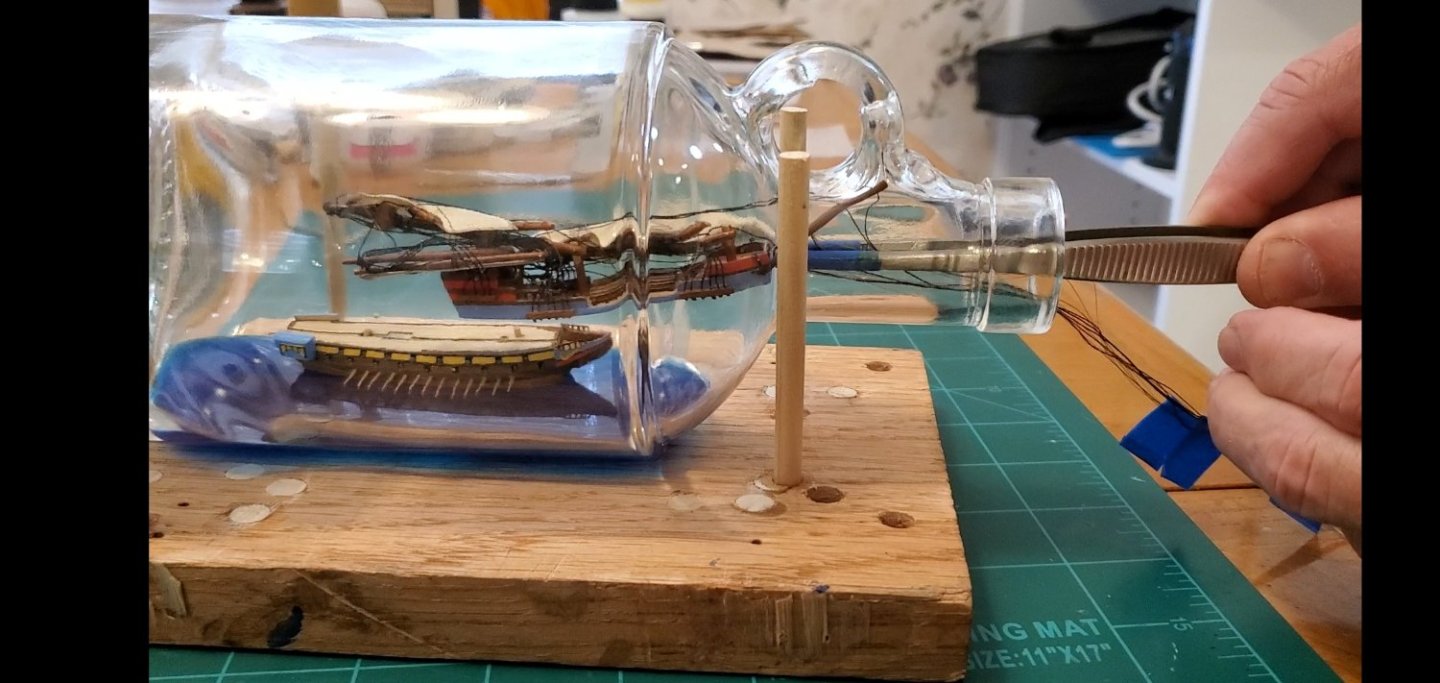

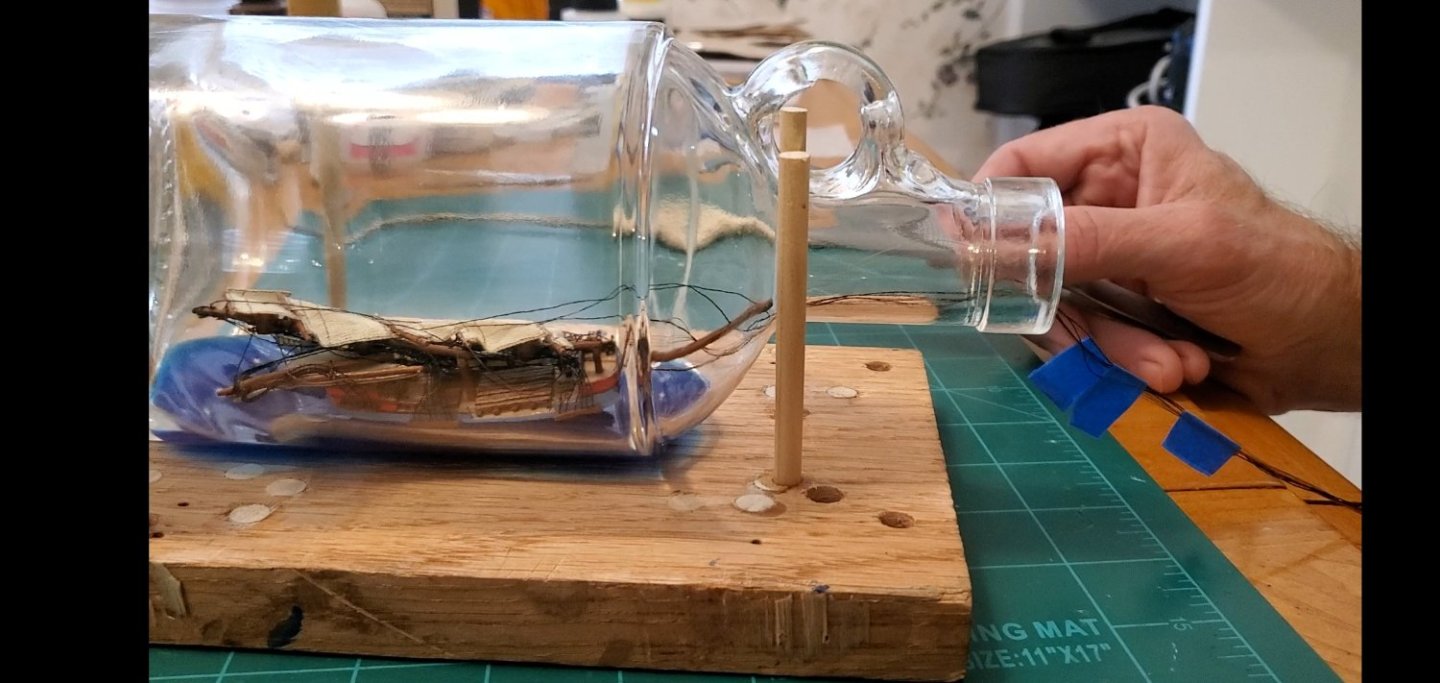

You are absolutely correct, Mike. The bowsprit on this ship had a much higher angle than my previous builds. I noticed that right away and had the same concern as you. I did some early test fitting to see what impact the sharp angle might have on the insertion process and was prepared to lower it if necessary. Fortunately, I was able to keep the same angle as I had originally planned. But to your point, had the bottle's neck been any longer I would have been forced to take some artistic license.

4 hours ago, Landlubber Mike said:Did you let the resin water dry and then glue the bottom half of the hull on top?

You are correct again. And all the concerns you mention are the reason I've done it that way for the last four builds (along with haunting memories of my Amati Hannah disaster when my ship sank in the soft acrylic paint water). As I know you are aware, it's difficult trying to place the hull in it's exact position with tweezers or whatever you are using for grasping. I've found it so much easier (and less stressful) to just drop the ship anywhere inside the bottle, add epoxy to the dry resin, and then move the ship onto the epoxy.

As for pouring the resin once the ship is inside the bottle, I know there are some very skilled people out there that do it that way. For me, there's just too many things that can go wrong. And I believe most of those things would be almost impossible to recover from.

Thanks for your all thoughtful comments, Mike. I always appreciate your insight.

-

2 hours ago, gjdale said:

“in a rare moment of brilliance, I decided to add the boats separately”. 😉

OMG! I'm dying laughing!!

- Knocklouder, mtaylor, gjdale and 2 others

-

5

5

-

4 hours ago, Keith Black said:

You know, had the ships' boats been attached before going through the neck things may not have folded up enough to get everything through. It all worked out for the best and it all looks great.

That is an excellent point, Keith. One that I had not considered. I went back to the video and did a screenshot (see below). It looks like I had plenty of room for 1 boat on the starboard side but maybe not on the port. Perhaps it was a blessing in disguise!

4 hours ago, BANYAN said:This has been another fascinating build to follow, and you have set your 'benchmark' very high for the follow-on build

Thank you, Pat! And thanks especially for adding extra pressure to the next project!!

- BANYAN, Keith Black, mtaylor and 2 others

-

5

5

-

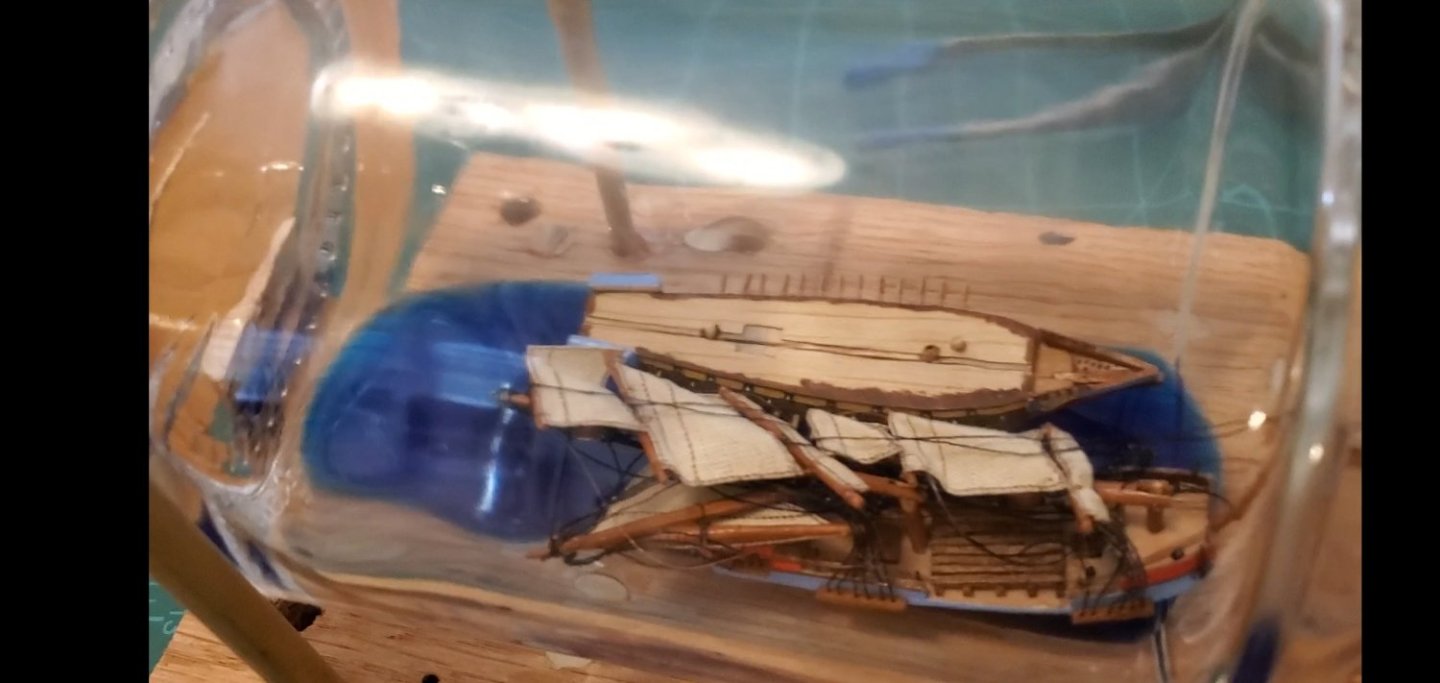

Well, heck. I thought the drama was over. But noooooooo, the palm-to-forehead slaps keep piling up on this project! I got up this morning feeling smug about my work, took an admiring look at the ship resting snug and secure inside the bottle, and began snipping the pull threads below the bowsprit. And then I realized I had forgotten to attach the ship's boats before putting the whole thing in the bottle. Yet another dodo moment. Ugh. Ugh. Ugh.

Fortunately, it was not too difficult to put the little devils in place on top of the crutch. Then I added some texture and whitecaps to the water.

With that, the work inside the bottle is officially complete! Now it's back to the display to finish things up. On the homestretch now!!

-

10 hours ago, Keith Black said:

Glen, fantastic job! The video wore me out. I kept saying to myself, square peg, round hole, square peg, round hole till she finally popped through.

That is a great analogy, Keith!

6 hours ago, gjdale said:I’m glad it was only 4 minutes long though - I don’t think I could have held my breath much longer!

I could not believe the video was only 4 minutes long when I looked at it afterwards. It seriously felt like it took a half hour to get that dang thing inside the bottle!

5 hours ago, Dave_E said:I just watched your video with 3 grandchildren who wanted to watch how you get a ship in the bottle. 👍😀

That is so cool, Dave!! Now I'm really glad I edited out all the swearing and cursing like Grant said! 😃

- Ian_Grant, Dave_E, Keith Black and 2 others

-

5

5

-

The real moment of truth was the next step – smashing down all the masts, yards, and sails and pushing the top half of the mast into the bottle. I made all 3 the mast hinges with slightly different angles so they would lie down next to each other rather than on top of each other. This proved crucial as there was zero room to spare. Part of the challenge was the crow’s nests taking up more space than simple mast tops.

After quite a bit of starting/stopping/adjusting/nudging/and gentle persuasion, it finally passed thru the neck and into the bottle. And the best part was that I heard no pops nor did I feel any snaps! So I was pretty confident I had not broken anything.

After a huge sigh of relief, I added epoxy to the top of the bottom half of the hull and laid the top half in place. I let that sit overnight and then raised the masts the next morning.

Everything was intact and the top of the main mast cleared the inside top of the bottle by about 1mm!! Another huge sigh of relief. The 3-piece ship idea actually worked!!!If anyone would like to see the full insertion process for the top half of the ship, I made about a 4-minute video and posted it here: https://www.youtube.com/watch?v=WO8o8WckMl4

-

The boat is afloat! In preparation for trying to put the ship in the bottle, I practiced breathing thru my eyelids as @Keith Black recommended. I think it helped.

I got the epoxy resin water poured into the bottle. But it also highlighted another mistake on my part. My earlier measurement of the inside bottle height was off by 1/8”. This meant I was not able to put as much “water” inside the bottle as planned. So the sea is a little shallow, but at least I figured that out before I poured the epoxy and inserted the ship!

The next step was inserting the 2 halves of the lower hull and gluing them together. Both fit inside rather easily and I had no problem joining them inside the bottle.

-

-

6 hours ago, gjdale said:

Had you considered using SilkSpan for your sails?

Hey Grant, I looked into silkspan after the success you had with your Amati Hannah sails. I was going to order some from Sig but they were out of stock on the light and medium. I tried a couple of local hobby stores here in Austin and they didn't even know what I was talking about. I just checked the Sig site again and they are still out. So if I could find some I would definitely give it a try.

-

7 minutes ago, Keith Black said:

Glen, the ship is a little beauty. I love the sails, they turned out great and hang well from the yards.

Thank you, Keith! I went just a shade darker this time and I like it better than my previous efforts.

- Keith Black, mtaylor and Dave_E

-

3

3

-

45 minutes ago, Ian_Grant said:

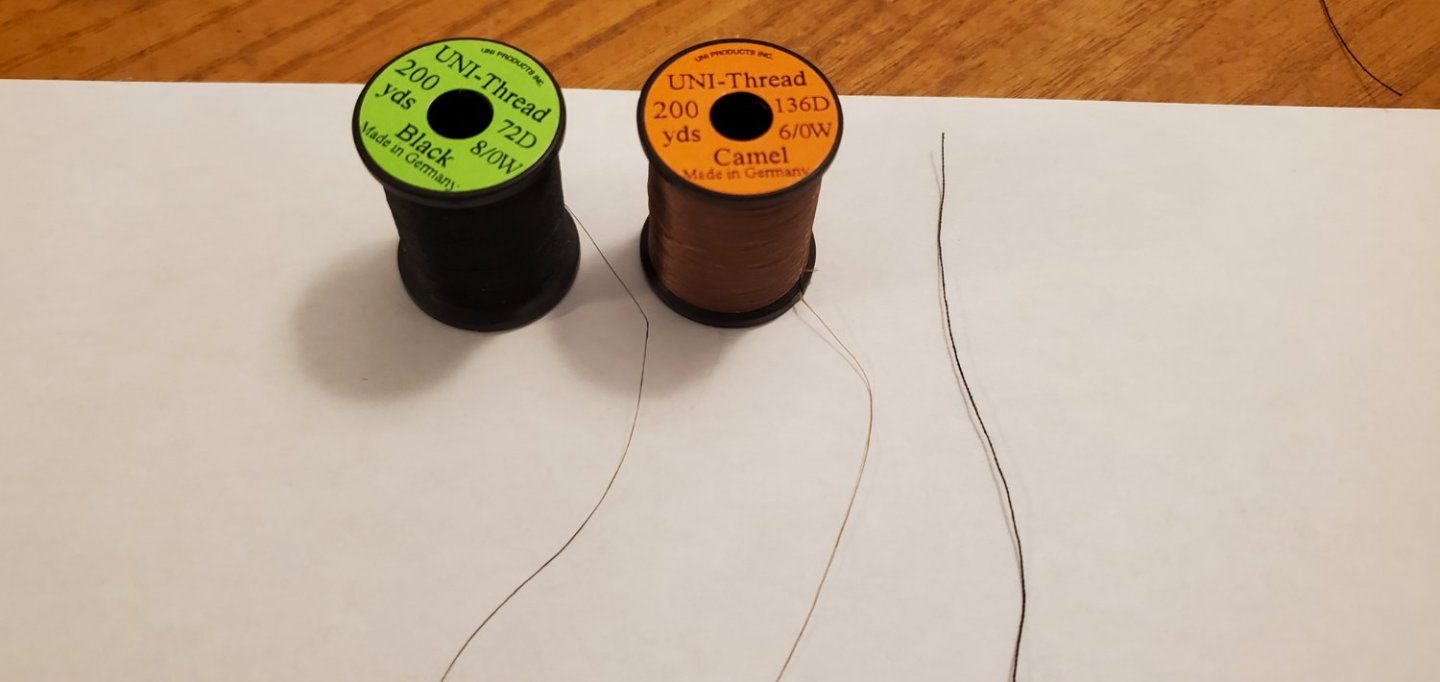

Would fly-tying thread work for ratlines on a 1/150 ship or is it too thin? Asking for a friend. He knows nothing about fly fishing - is it easily tied into compact knots? What kind of glue to lock them?

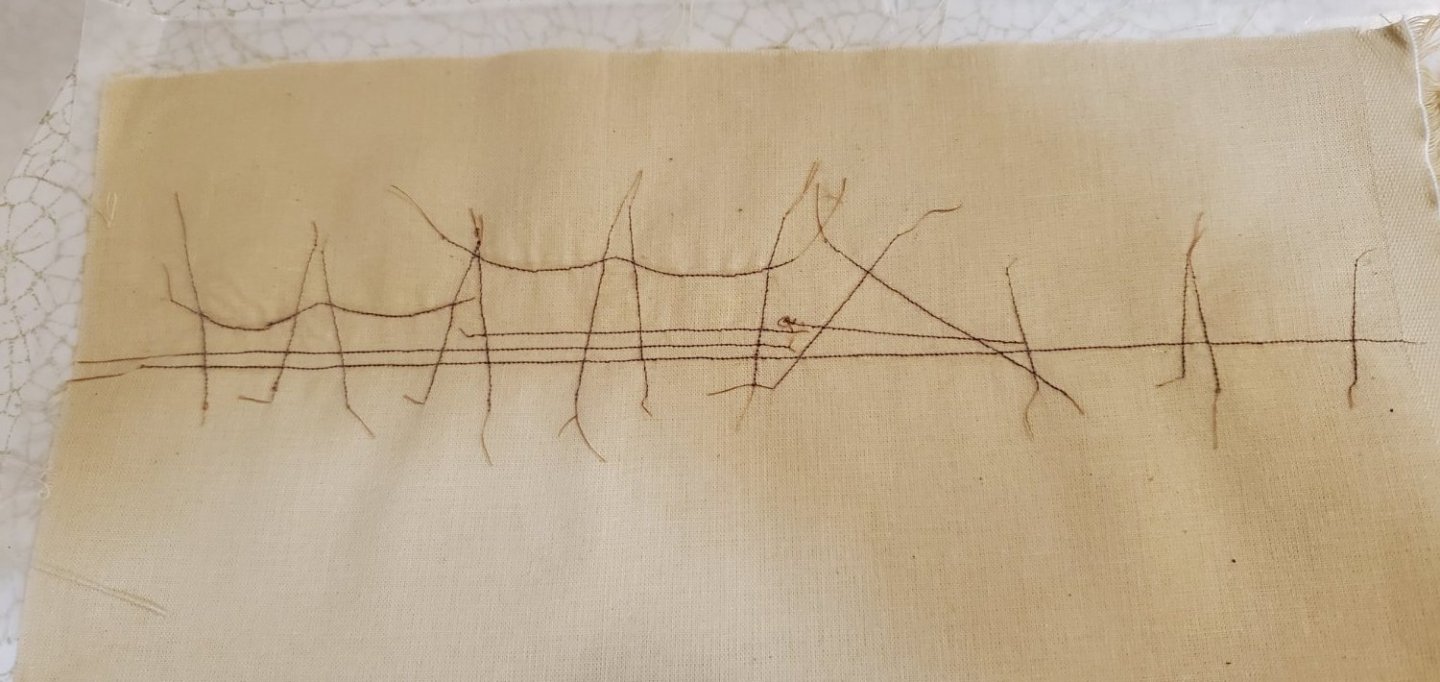

I think it would work well. I used regular thread for my 1/120 CSS Alabama ratlines and in hindsight, it looks a little thick. With the fly-tying thread for these bottle projects, I use 2 thicknesses. The pic below shows the 2 thicknesses I use next to a piece of regular all-purpose thread. The black fly-tying thread (72 denier) is the thinnest and I use it for the ratlines. The camel colored (136 denier) is almost twice as thick (believe it or not) and I use it for the the braces. I believe the 136D would be good for raltines at 1/150 scale.

I get them from Amazon for about $7 per spool. As far as knot tying, it is definitely tedious. It helps to have some very fine point tweezers and super magnifying reading glasses. But they do tie into very nice knots and once I get going, it actually goes pretty smoothly. Afterwards, I put a small drop of CA glue on the knot to lock it in then clip the excess strands with cuticle trimmers (highly recommended tool for thread this small). Very secure knot.

-

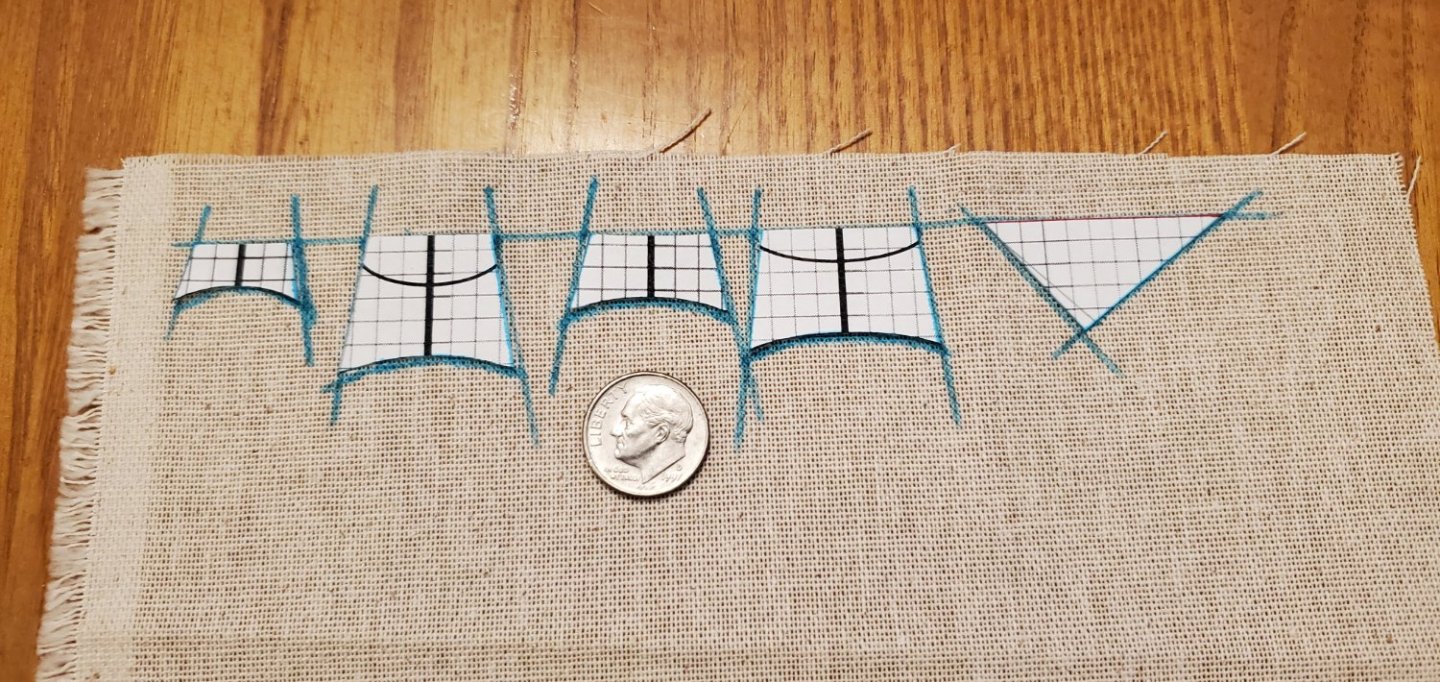

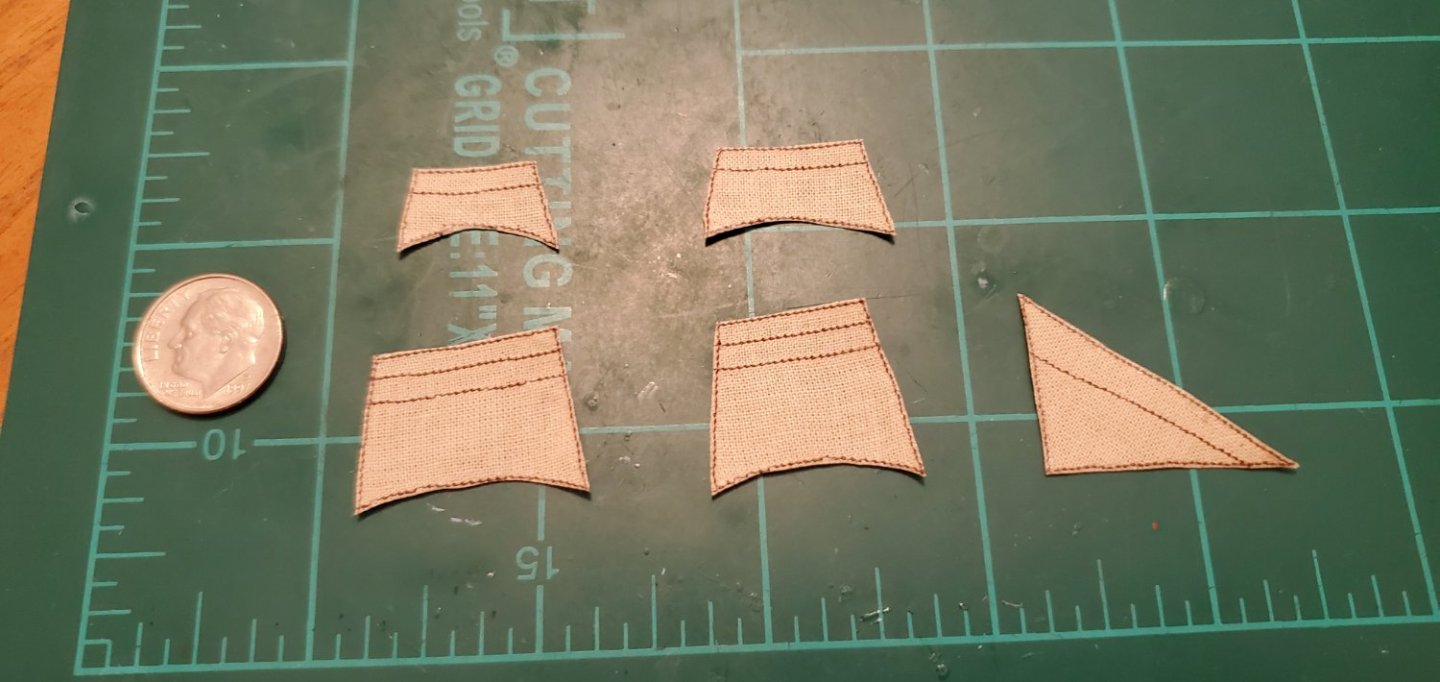

Today I worked on the sails. The pics show the basic process steps. They are made from muslin and the thread for the bolt ropes and reef bands is fly-tying thread again.

I've still got to make some anchors, add the ship's boats and maybe some misc deck fittings. Getting very close! I know the bottom halves of the hull will fit inside the bottle easily. Not sure about the top with all the sails, yards, and crow's nests. I have a feeling it's going to be another tight squeeze!

- Landlubber Mike, Prowler901, BANYAN and 6 others

-

4

4

-

5

5

-

On 12/6/2022 at 6:34 PM, Keith Black said:

you always get stage fright at about this point in you SIB builds

So true, Keith! I'm hoping to avoid another horse pucky moment!

Got the braces strung and threaded yesterday. They are tied to the yard ends then strung thru tiny eye bolts along the sides of the deck, over the bow, and thru the bowsprit. The brace threads are long and extend thru the neck of the bottle so I can adjust the yards angles after insertion.

- gjdale, Dave_E, Landlubber Mike and 6 others

-

9

9

-

-

-

4 hours ago, gjdale said:

Applying shingles is a little bit like tying ratlines – it seems to take forever, but eventually we’ll get there….

Also reminds me of putting copper plates on a hull. Row after row after row after row...

The flashing looks so realistic.

-

- Keith Black, Knocklouder, Dave_E and 6 others

-

2

2

-

7

7

-

-

2 hours ago, BANYAN said:

When you trailblaze you have to expect such dilemmas Glen; it is how you overcome that matters and you have done a great job.

Thanks, Pat. I really appreciate that!

- Keith Black, BANYAN, Dave_E and 1 other

-

4

4

-

38 minutes ago, Keith Black said:

You recovered better than TCU.

LOL! Maybe that's part of the problem. I'm usually working on the ship with one eye and watching a football game with the other!

10 minutes ago, Dave_E said:Sweet! 👍😀

Thank you, Dave!

- Knocklouder, Dave_E, mtaylor and 1 other

-

4

4

-

I was hoping I was done wearing the dunce cap, but no, it stayed firmly on my head as I attached the backstays. While attaching one of the starboard backstays on the foremast, I pulled it snug and promptly pulled off the channel on the port side. Note to self - glue the channels to the hull BEFORE painting the hull. Duh.

I recovered from that blunder and moved to the main mast where I pulled the dunce cap on even tighter. I grabbed a backstay with tweezers and secured it to the mast. I leaned back to admire my magnificent work and realized that I had attached a shroud instead of a backstay. With the channel ends of the shrouds already tied and glued firmly in the channels, this was yet another dodo move.

After much cursing and gnashing of teeth, I actually got lucky. After clipping the shroud away from the mast, there was just enough length left to tie it off to its eye bolt. Whew!

After that, things settled down and I got all the backstays and shrouds in place as well as the pull threads. Everything tightened up nicely with the masts at a reasonable upright angle and no sagging lines.

.thumb.jpg.a4867d7aa37d83e4737f78cbcb1b54b9.jpg)

Robert E Lee by John Ruy - FINISHED - BlueJacket Shipcrafters - 3/32” to 1’ scale or 1:128 - Steamboat

in - Kit build logs for subjects built from 1851 - 1900

Posted

Let me add my congratulations to the group on such a fine build. It's been a real pleasure watching your work, John.